Automatic inner wall spraying device for round cup-shaped injection molding products

A technology of injection molding products and spraying devices, which is applied in the direction of spraying devices, devices for coating liquid on the surface, coatings, etc., can solve the problems of poor quality consistency, high product cost, and low long-term efficiency, and achieve consistency and improve Efficiency, waste reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

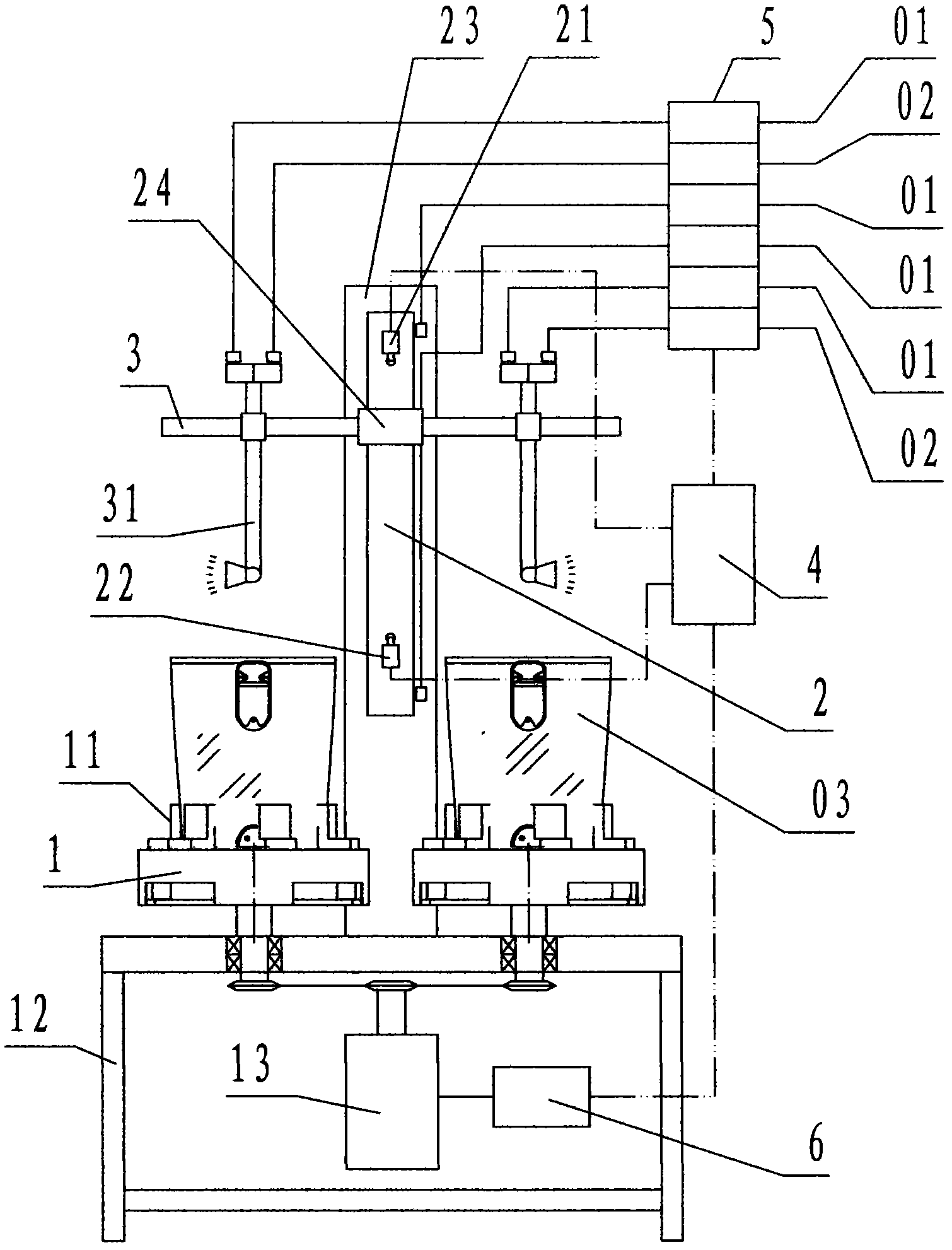

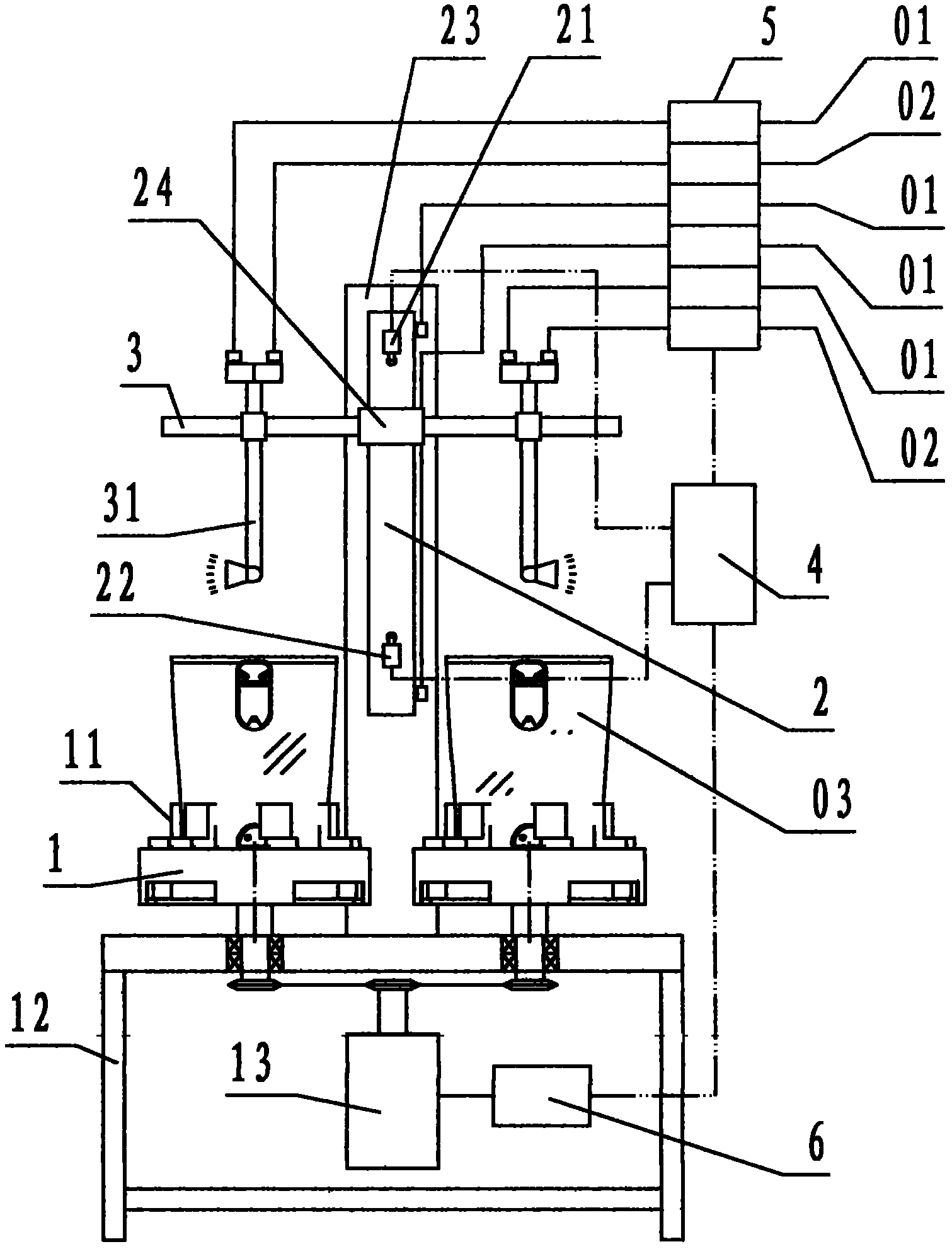

[0023] refer to figure 1 , an automatic inner wall spraying device for circular cup-shaped injection molding products of the present invention, comprising a rotary table 1, a base 12, a motor 13, a cylinder 2, a cantilever 3, a spray gun 31, a bracket 23, a PLC controller 4, and a solenoid valve 5. Frequency conversion speed regulator 6, wherein: the base 12 is a steel frame rectangular platform, and two rotating workbenches 1 are arranged side by side on the base 12, and the said rotating workbench 1 is set on the base 12 The rotatable disc-shaped turntable above;

[0024] The lower center of the rotary table 1 is provided with a rotating shaft that passes through the base 12 downwards. The rotating shaft is connected to the base 12 through a bearing. The output pulley of the motor 13 under the base 12 is connected; the upper center of the rotary table 1 is provided with a clamp 11 for inserting and clamping the circular cup-shaped product 03;

[0025] The support 23 is a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com