Contact structure member and production method thereof, and probe contact assembly using said contact structure member

A technology for contacting components and contacting components, which is applied to contact components, measuring leads/probes, components of connecting devices, etc., can solve problems such as inconsistent quality, and achieve the effects of low cost, high reliability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

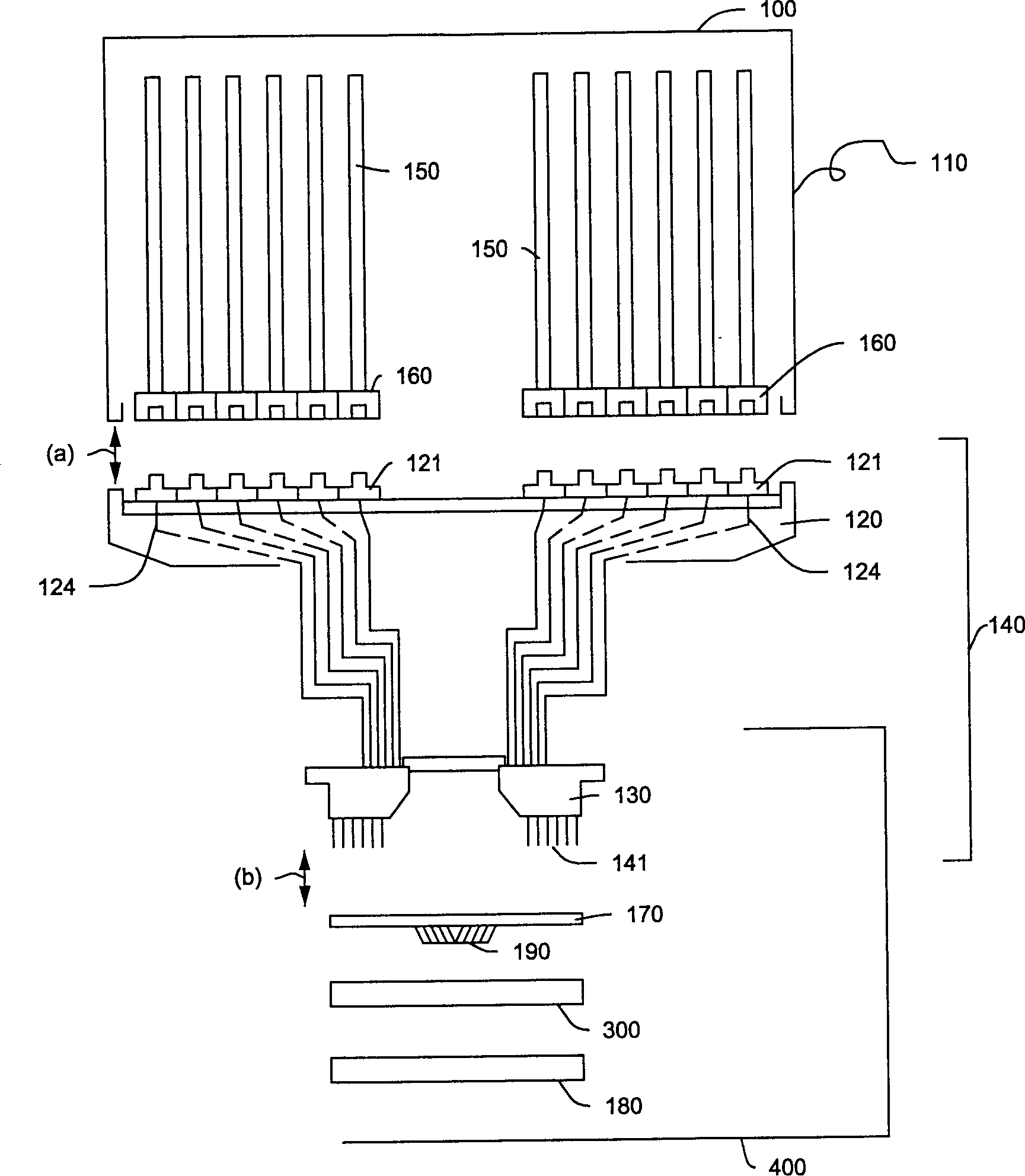

[0078] Detailed description of the preferred embodiment

[0079] Figure 5 -7 represents an example of the contact member of the present invention. Please note that the description of the present invention will be annotated with terms including "horizontal", "vertical" and the like. The inventors use these terms to describe the relative positional relationship of elements related to the invention. Therefore, terms like "horizontal" and "vertical" should not be read only narrowly as "ground-level" or "gravity-vertical".

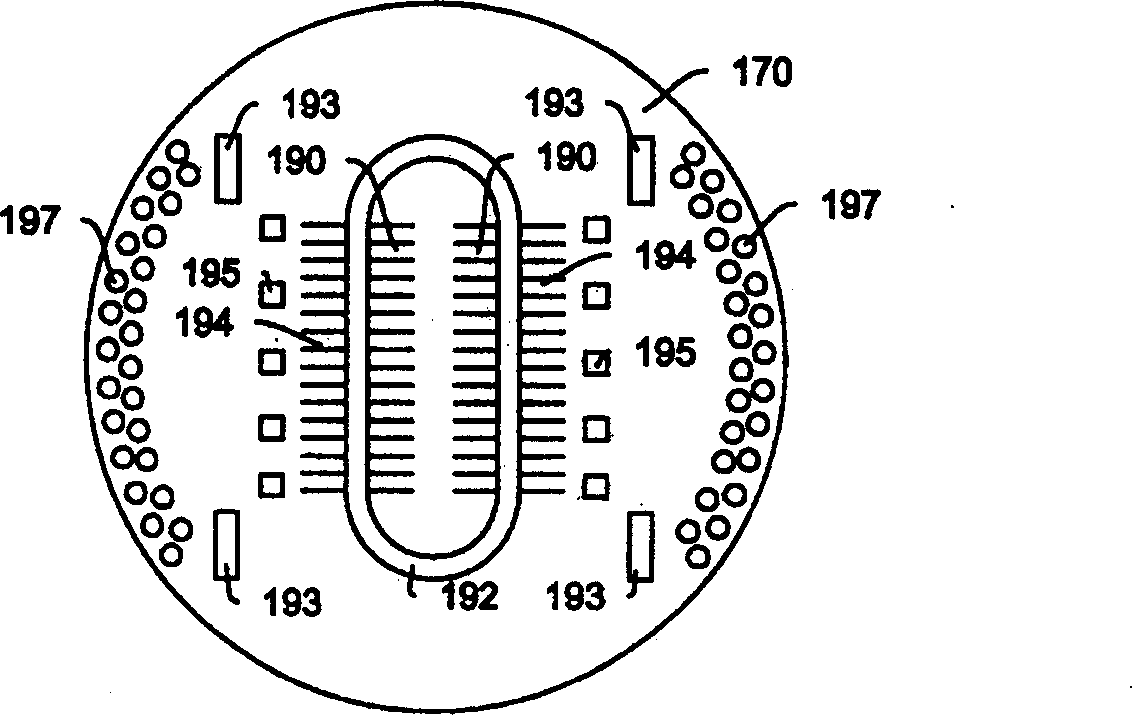

[0080] The contact member is constituted by a contact substrate 20 and contacts 30 . exist Figure 5 example, each contactor 30 1 Extending substantially in the vertical direction, and forming: a middle portion, the middle portion is connected to the contact substrate 20; a contact portion, at Figure 5 wherein the lower end thereof is preferably pointed; a first spring portion, located between the middle portion and the contact portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com