Production process of instant Chinese chestnut kernels and product

A production process and technology of chestnut kernels, applied in food preparation, food science, application and other directions, can solve the problems of low protein and fat content, unfavorable human health, product hardening, etc., achieve golden color, solve the problem of chestnut browning, The effect of slowing down aging problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

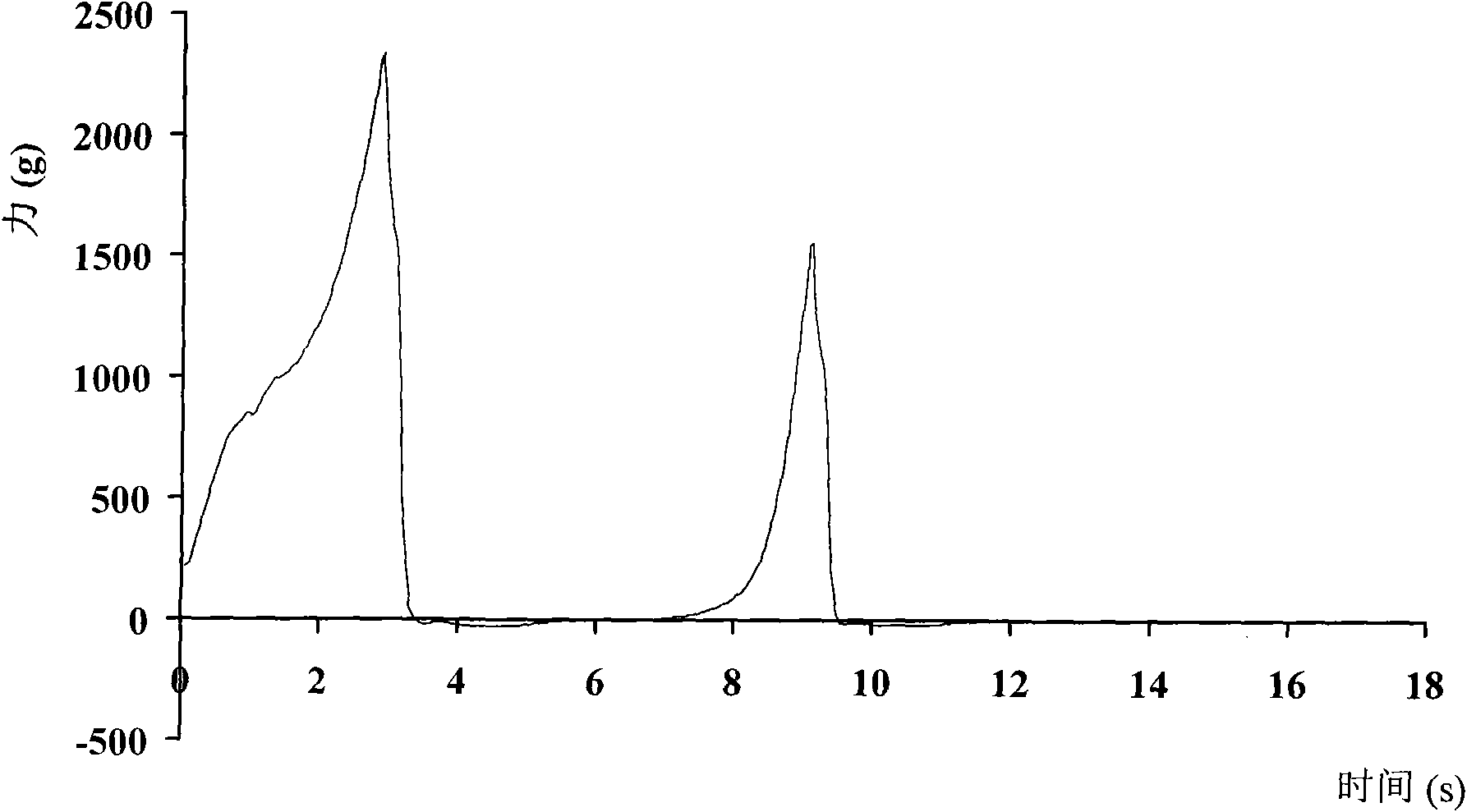

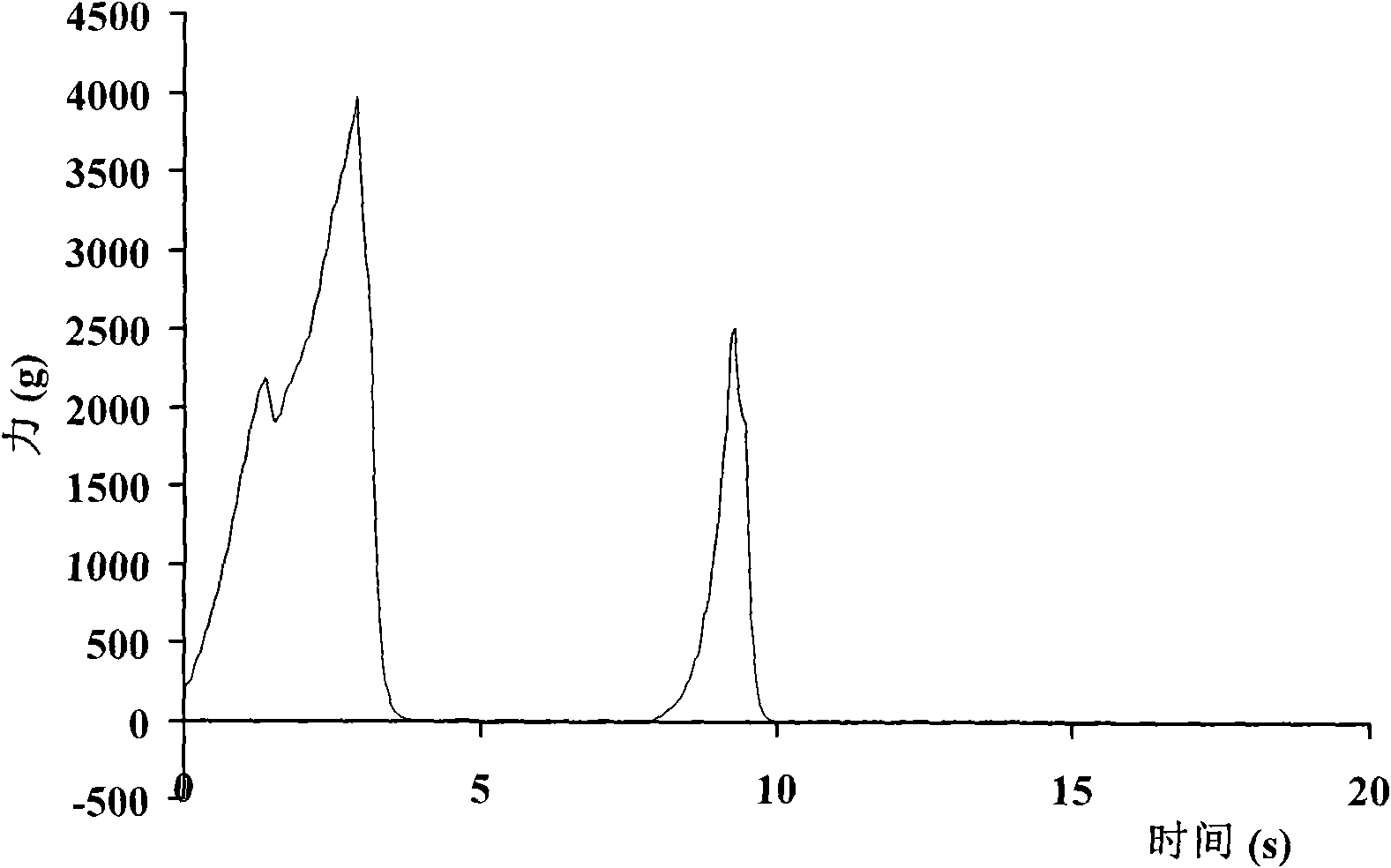

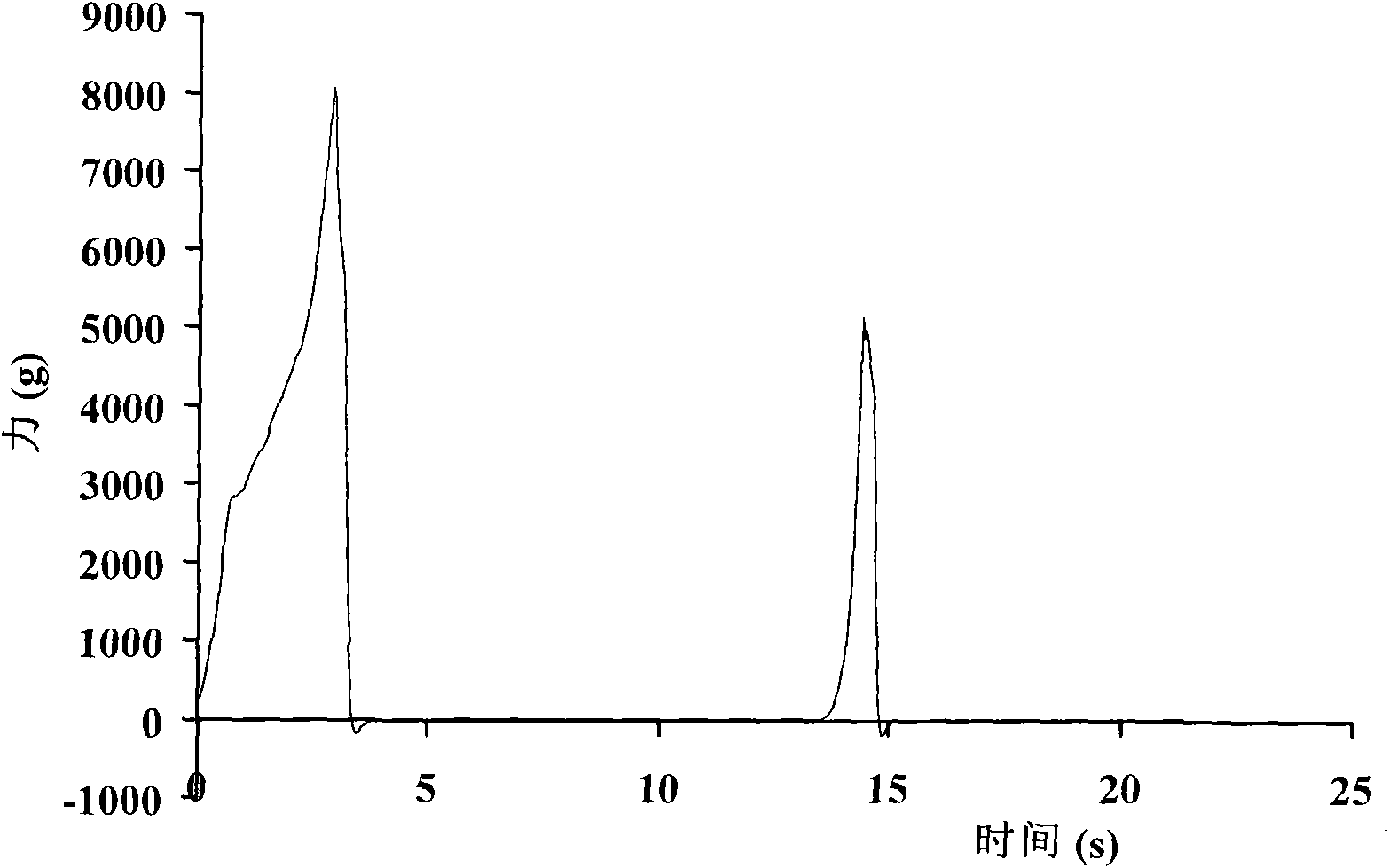

[0029] Three varieties of Liuhe late maturing (1), Liuhe middle maturing (2) and Pingqiao big hair chestnut (3) were selected from the chestnut production and storage base, and the water content (GB5497-1985) and reducing sugar (GB / T 5009.7- 2008) and starch content (GB5009.9-85), the effects of different varieties of reducing sugar content on the color of instant chestnut kernels are shown in Table 1, and the effects of different varieties of water content and starch content on texture are shown in Table 2 and figure 1 , 2 3. Integrating browning and texture indicators, choose Liuhe late-maturing chestnut kernels as raw materials for processing when they are just harvested. The water content is 58%, the reducing sugar is 1.25%, the total starch content is 29.5%, and the chestnut is steamed into paste. The broken fruit rate after melting is 10%. Chestnuts are graded and processed using mesh sieves with diameters of 16cm, 21cm, 23cm, 25cm, and 27cm. The outer skin is removed b...

Embodiment 2

[0043] During the chestnut harvesting period, four varieties of Liyang Qingzha, Jiaozha, Dadiqing and Chongyangpu were selected, and the moisture content, reducing sugar and starch content were measured according to the national standard. Dadiqing was selected as raw material for instant chestnut kernel processing. 55%, the reducing sugar is 1.45%, the total starch content is 30%, and the broken fruit rate after steaming and gelatinizing chestnut is 12%. Chestnuts are graded and processed using mesh sieves with diameters of 16cm, 21cm, 23cm, 25cm, and 27cm. The chestnut sheller is used to remove the outer skin, and the boiling water is blanched for 4 minutes. Freeze at -18°C until taken out and thawed at room temperature before processing. Soak in 40% sucrose solution for 30 minutes, take out, soak in tap water for 1.5 minutes, remove and wash off the surface sugar solution, steam at 100°C for 15 minutes, and then quickly cool with cold water. The chestnuts are individually p...

Embodiment 3

[0045] During the chestnut harvesting period, three varieties of Yanshankui, Yanshan Duanzhi and Yanshan Zaofeng were selected from different production bases and storage bases, and the water content, reducing sugar and starch content were measured according to the national standard, and Yanshan Zaofeng was selected as raw material for instant chestnut kernel Processing, its water content is 56%, the reducing sugar is 0.95%, the total starch content is 28%, and the broken fruit rate after steaming and gelatinizing chestnut is 12.5%. Chestnuts are graded and processed using mesh sieves with diameters of 16cm, 21cm, 23cm, 25cm, and 27cm. The chestnut sheller is used to remove the outer skin, and the boiling water is blanched for 5 minutes. Freeze at -18°C until taken out and thawed at room temperature before processing. Soak in 60% sucrose solution for 40 minutes, take it out, soak in tap water for 2 minutes, remove and wash off the surface sugar solution, steam at 100°C for 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com