Living bacterium type room temperature yoghurt and making method thereof

A yogurt, normal temperature technology, applied to milk preparations, bacteria used in food preparation, dairy products, etc., can solve the problems of product status, taste deterioration, and products that cannot be stored at room temperature, so as to reduce equipment investment and the number of viable bacteria The effect of stabilizing and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

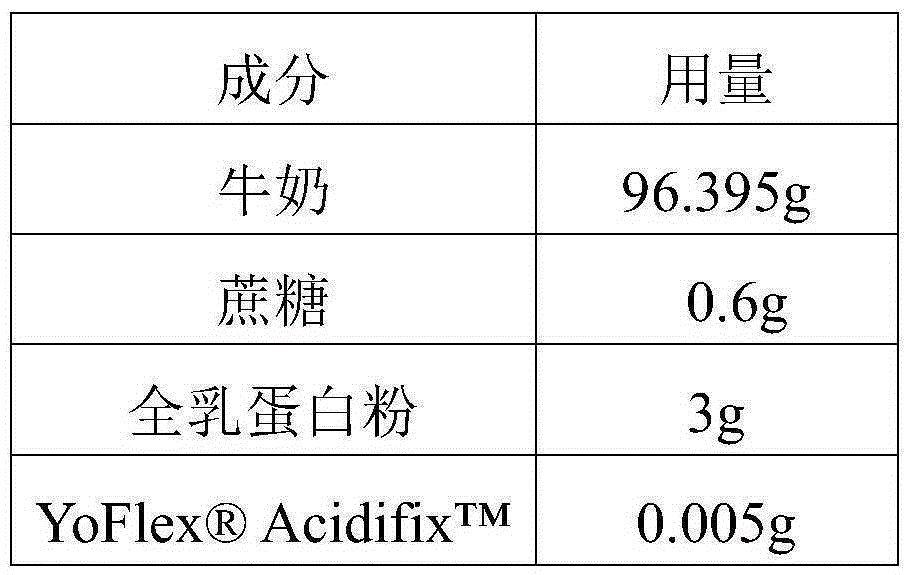

[0031] formula:

[0032]

[0033] The process steps are as follows:

[0034] 1. Heat the milk to 40°C, add sucrose and whole milk protein powder, and keep stirring for 30 minutes;

[0035] 2. Heat up the material obtained in step 1 to 60°C, homogenize at 60°C and 20Mpa, and then sterilize at 90°C for 600s to obtain a fermentation substrate;

[0036] 3. Cool the fermentation substrate obtained in step 2 to 39° C., add a starter, and insulate and ferment until the terminal acidity is 80° T;

[0037] 4. Add 7.4% (w / w) fructose syrup to the fermented milk in step 3, stir for 5-10 minutes, fill and store at room temperature.

[0038] The protein content in the raw material is 4.69%, pH: 4.78.

Embodiment 2

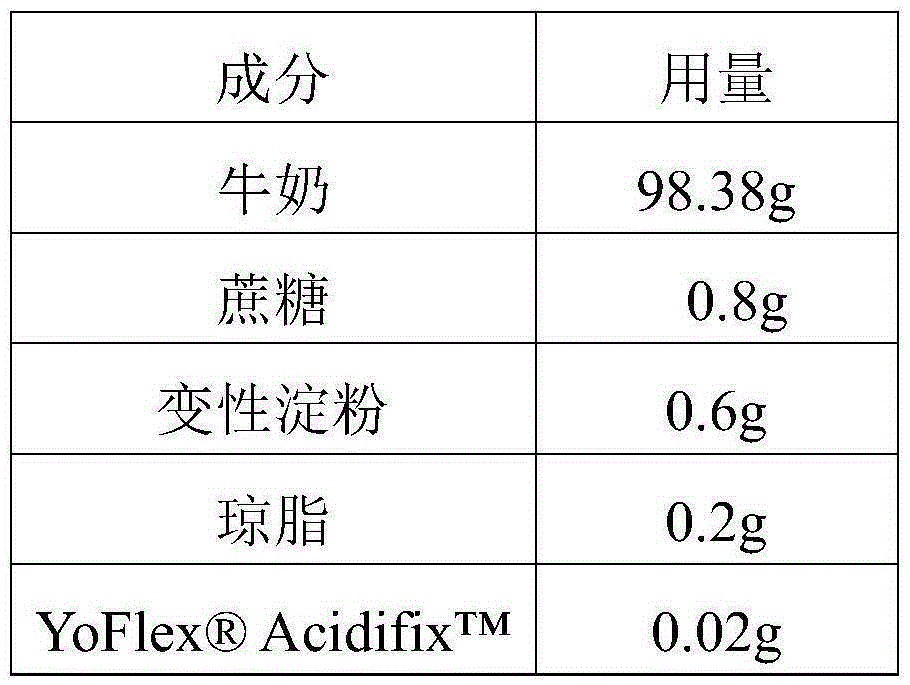

[0040] formula:

[0041]

[0042] The process steps are as follows:

[0043] 1. Heat the milk to 50°C, add sucrose, modified starch, and agar, and keep stirring for 15 minutes;

[0044]2. Raise the temperature of the material obtained in step 1 to 65°C, after homogenizing at 65°C and 18Mpa, sterilize at 135°C for 5s to obtain the fermentation substrate;

[0045] 3. Cool the fermentation substrate obtained in step 2 to 43°C, add a starter, and insulate and ferment until the terminal acidity is 70°T;

[0046] 4. Add 5.2% (w / w) fructose syrup to the fermented milk in step 3, stir for 5-10 minutes, fill and store at room temperature.

[0047] The protein content in the raw material is 2.95%, pH: 4.35.

Embodiment 3

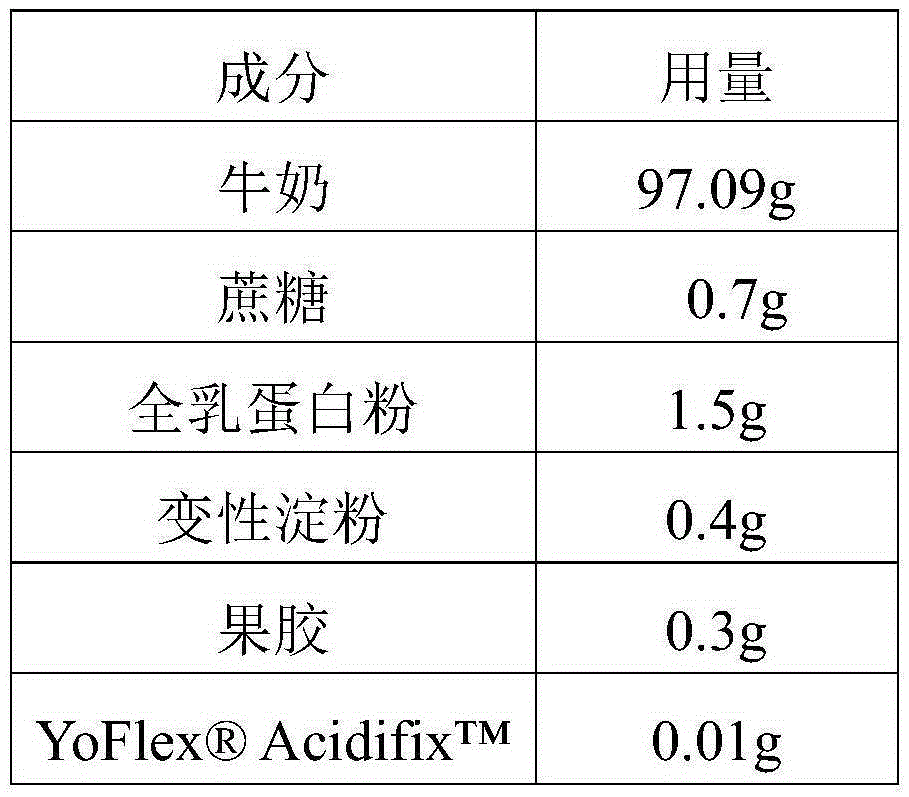

[0049] formula:

[0050]

[0051] The process steps are as follows:

[0052] 1. Heat the milk to 50°C, add sucrose, whole milk protein powder, modified starch, and pectin, and keep stirring for 15 minutes;

[0053] 2. Heat up the material obtained in step 1 to 60°C, homogenize at 60°C and 25Mpa, then sterilize at 90°C for 600s to obtain the fermentation substrate;

[0054] 3. Cool the fermentation substrate obtained in step 2 to 40°C, add a starter, and insulate and ferment until the terminal acidity is 75°T;

[0055] 4. Add 30% (w / w) jam (25% sugar content) to the fermented milk in step 3, stir for 5-10 minutes, fill and store at room temperature.

[0056] The protein content in the raw material is 3.81%, pH: 4.55.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com