Application of plant green juice powder in maintaining stability of viable count of yoghourt in shelf life

A technology of green juice powder and viable count, which is applied in the field of fermented dairy product processing, can solve the problems of affecting the functionality of the starter, the rapid decline of the viable count of Lactobacillus bulgaricus, and the absence of technical reports on the application of plant green juice powder, etc. To achieve the effect of being beneficial to human health, good flavor and taste, and good flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

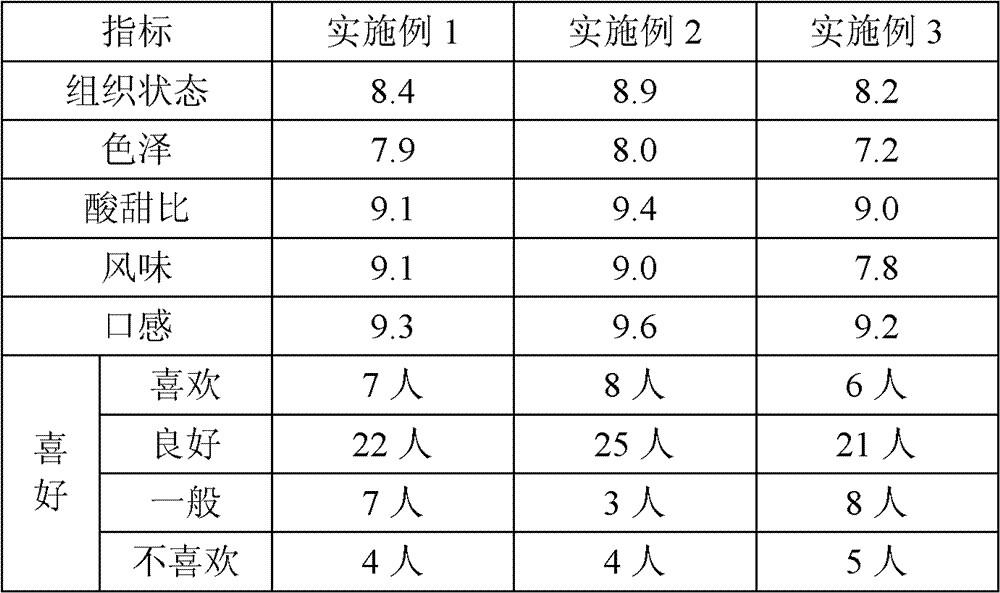

Embodiment 1

[0057] Embodiment 1, a kind of stirring type yoghurt and its production method that add plant green juice powder

[0058] 1. Raw material formula (according to 1 ton)

[0059] Barley Green Juice Powder 0.5kg

[0060] Green Onion Juice Powder 0.5kg

[0061] White sugar 65.0kg

[0062] Low Ester Pectin 1.0kg

[0063] Modified starch 4.0kg

[0064] BMY (basic bacteria + milk bifido) (CHR HANSEN cryogenic bacteria) 200U

[0065] Lactobacillus longum (CHR HANSEN cryogenic strain) 200g

[0066] Lactobacillus acidophilus (CHR HANSEN cryogenic strain) 10g

[0067] Milk (total dry 13%) balance

[0068] Plant green juice powder is commercially available. It is mainly squeezed fresh plants to make plant green juice. Add phosphate to adjust its pH to 6.5, then heat and spray it dry to form powder. Heating conditions: 180°C, 200s.

[0069] Two, the production of the stirred type yoghurt containing plant green juice powder original flavor probiotics of the present embodiment is main...

Embodiment 2

[0074] Embodiment 2, a kind of solidified yoghurt and its production method adding edible yeast polypeptide

[0075] 1. Raw material formula (based on 1000kg):

[0076] Wheat Green Juice Powder 0.6kg

[0077] Chive Green Juice Powder 0.4kg

[0078] White sugar 68.0kg

[0079] Low Ester Pectin 0.8kg

[0080] Modified starch 5.0kg

[0081] BMY (Basic Strain + Milk Bifido) (CHR HANSEN Cryogenic Strain) 200U

[0082] Lactobacillus longum (CHR HANSEN cryogenic strain) 200g

[0083] Lactobacillus acidophilus (CHR HANSEN cryogenic strain) 10g

[0084] Milk (total dry 13%) balance

[0085] Production of plant green juice powder: Squeeze fresh plants to make plant green juice, add phosphate to adjust its pH to 6.8, then heat it instantly and spray dry to form powder. Heating conditions: 185°C, 220s.

[0086] Two, produce the yogurt of the present embodiment according to following solidified yogurt process method:

[0087]1. Selection of raw milk: select fresh milk that has pas...

Embodiment 3

[0092] Embodiment 3: Probiotic Stirred Yogurt Containing Plant Green Juice Powder and Production Method thereof

[0093] 1. Raw material formula (based on 1000kg):

[0094] Oat Green Juice Powder 0.75kg

[0095] Green Onion Juice Powder 0.25kg

[0096] White sugar 65.0kg

[0097] Low Ester Pectin 0.6kg

[0098] Modified starch (hydroxypropyl starch) 7.0kg

[0099] BMY (Basic Strain + Milk Bifido) (CHR HANSEN Cryogenic Strain) 200U

[0100] Lactobacillus longum (CHR HANSEN cryogenic strain) 200g

[0101] Lactobacillus acidophilus (CHR HANSEN cryogenic strain) 10g

[0102] Milk balance.

[0103] Production of plant green juice powder: Squeeze fresh plants to make plant green juice, add phosphate to adjust its pH to 7.2, then heat and spray it dry to form powder. Heating conditions: 200°C, 180s.

[0104] Two, the production of the original flavor probiotic stirred yoghurt containing plant green juice powder of the present embodiment is mainly carried out according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com