Method for producing granule-containing liquid drink

A production method and particle technology, applied in the field of liquid beverage and dairy product processing, can solve the problems of uneven mixing, different dispersion effects, and restricting the production and research and development of particle-containing liquid beverages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

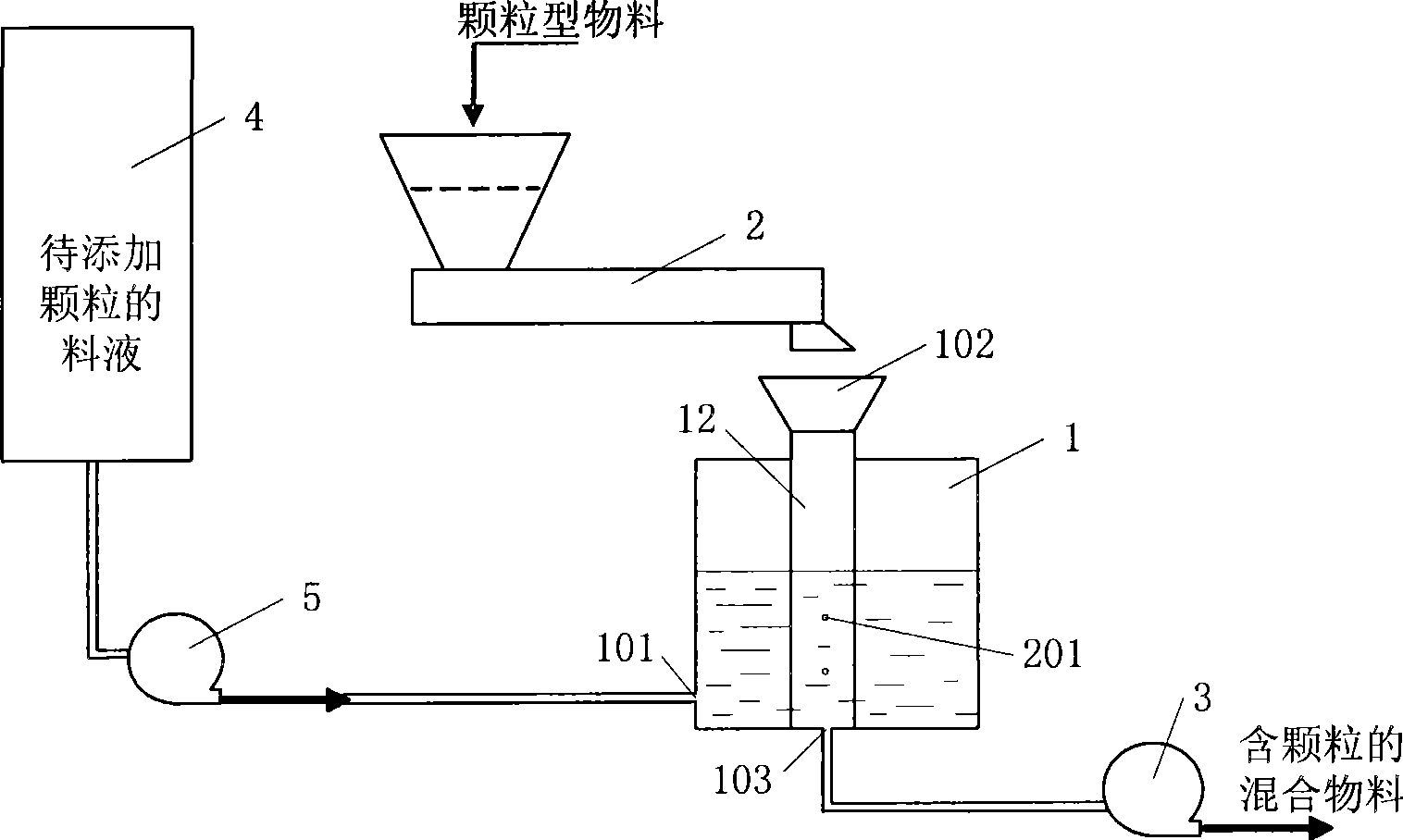

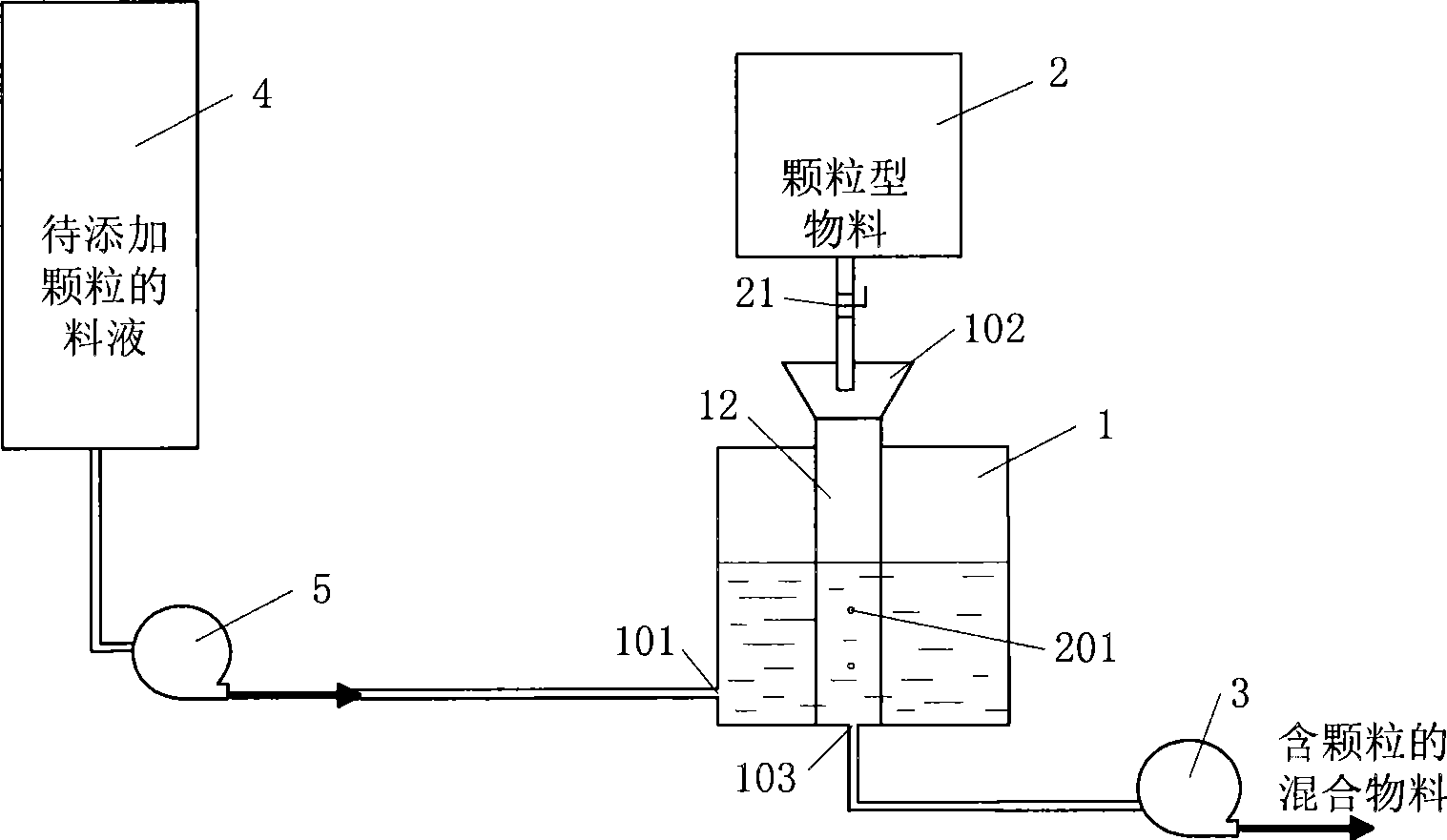

Method used

Image

Examples

Embodiment 1

[0075] Produce a kind of flavored milk that contains cereal grains, the raw material formula of this flavored milk is as follows (in 1000kg):

[0076] Ingredients name Basic dosage (kg) fresh milk 800 White sugar 28

[0077] stabilizer 3.2 malt essence 7 complex nutrients 0.15 essence 1.1 Cereal grains (ripened japonica rice grains) 100 ingredient water margin

[0078] Raw material quality standard: Grain granules are granules of natural japonica rice after proper ripening (with a particle size within 1-10 mm), most of which are complete granules, basically no starch precipitation, uniformly dispersed, and no cohesion occurs. The dry weight of 100 kg of cured japonica rice grains before ripening is about 56 kg. All raw and auxiliary materials meet the relevant national standards.

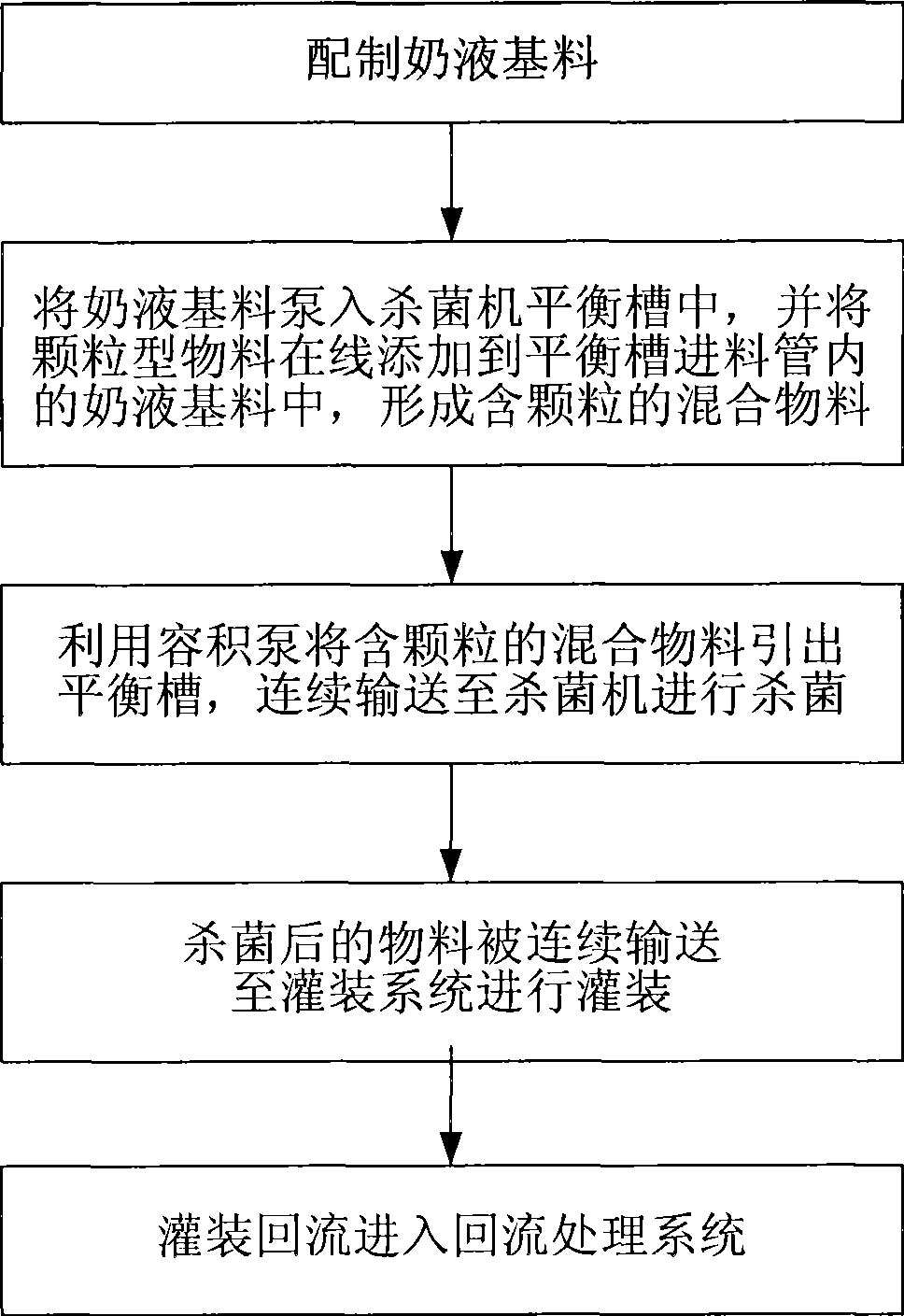

[0079] The production process of the flavored milk containing cereal grains in this embodiment can be found in figure 1 A...

Embodiment 2

[0108] Utilize the method of the present invention to produce a kind of milk drink containing coconut fruit particles, the raw material formula of the milk drink of this embodiment is as follows (in 1000kg):

[0109] Ingredients name Basic dosage (kg) fresh milk 350 white sugar 60 stabilizer 4.0 acidity regulator 5 complex nutrients 0.15 essence 1.1 Raw coconut granules 50 ingredient water margin

[0110] Raw material standard:

[0111] Raw material of coconut fruit granule: the size of coconut fruit granule is 3×3×3mm, pH 4.5, sugar content 15Brix, fruit granule content 70%, and all raw and auxiliary materials meet the relevant national standards.

[0112] The production process of the milk drink containing coconut fruit particles of the present embodiment specifically includes the following steps:

[0113] (1) The batching process of the milk base material

[0114] (1) Put a certain amount of pasteurized milk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com