Electronic cigarette and control method thereof

An electronic cigarette and controller technology, applied in tobacco, smoker's products, ohmic resistance heating parts and other directions, can solve the problems of inconsistent taste and unstable heating wire temperature, achieve consistent taste, save power, and avoid burning taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

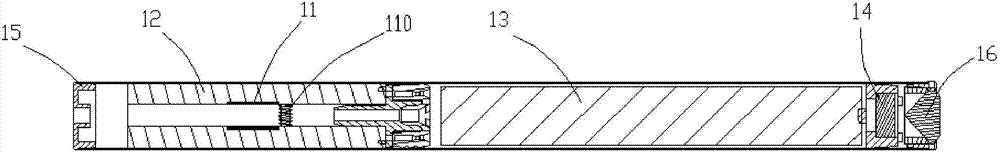

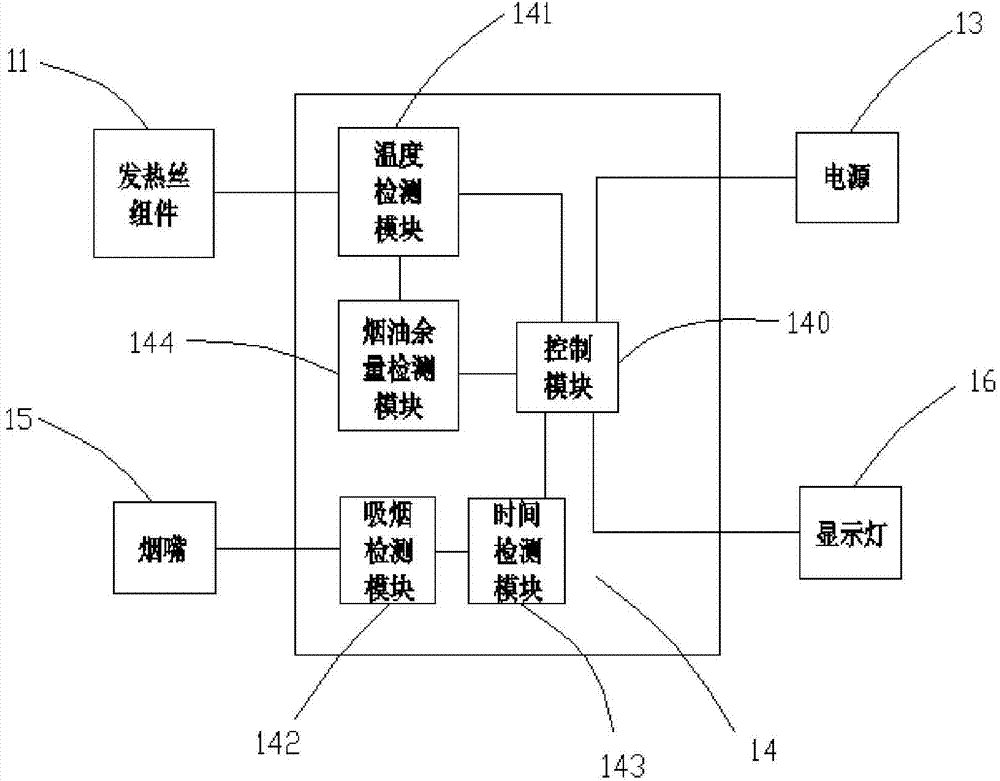

[0034] figure 1 It is a cross-sectional view of an electronic cigarette according to an embodiment, and the electronic cigarette includes a heating wire assembly 11 , an e-liquid storage member 12 , a power source 13 , and a controller 14 .

[0035] The heating wire assembly 11 is used to generate heat, and includes a heating wire 110 whose resistance value varies with temperature. In this embodiment, the material of the heating wire 110 includes metal cerium (Ce), and the resistance value of the heating wire 110 increases with the temperature. and increase.

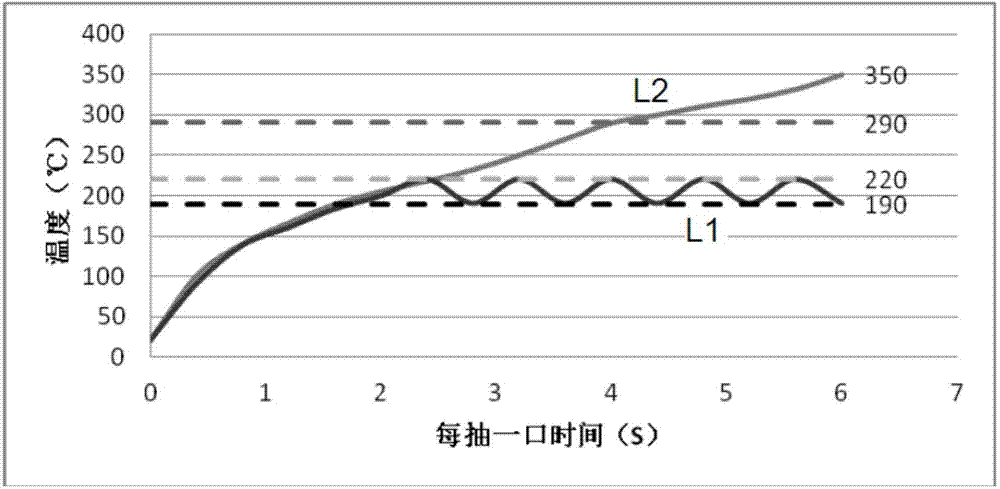

[0036] The e-liquid storage part 12 is connected to the heating wire assembly 11 and is used to store e-liquid. The e-liquid has a vaporization lower limit temperature t1 and a vaporization upper limit temperature t2. In this embodiment, the vaporization lower limit temperature t1 is 190°C, and the vaporization upper limit temperature t2 is 220°C. When the temperature of the heating wire assembly 11 is between the vapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com