Soy sauce flavor type Chinese spirit preparation method

A sauce-flavored wine and fermented grains technology, which is applied in the field of liquor production, can solve problems such as high koji-making temperature and accumulation temperature, decline in the quality and style of comprehensive liquor, and unprominent sauce flavor of liquor, so as to remove staleness and effectively control starch Dissolution rate, effect of clean body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

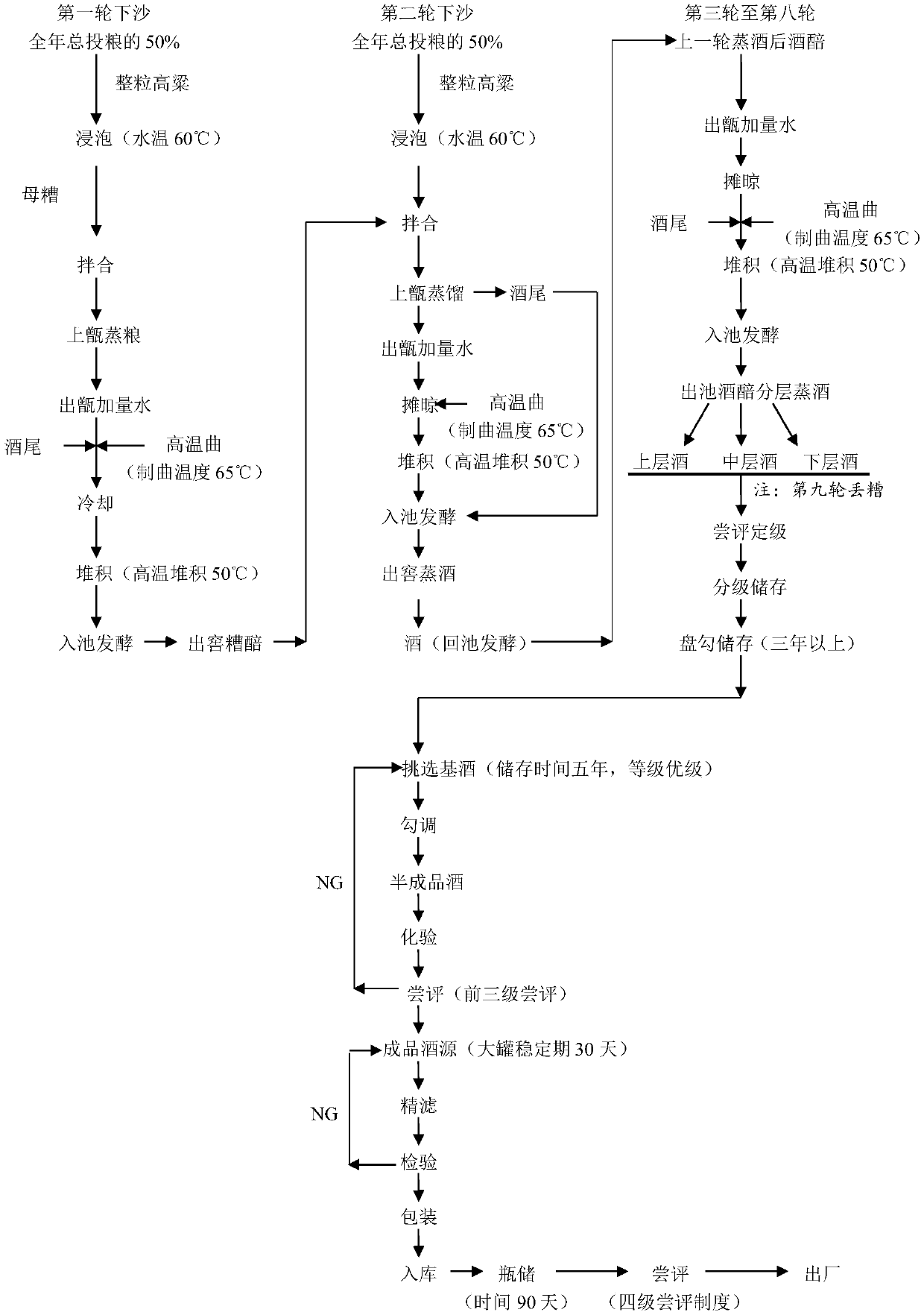

Method used

Image

Examples

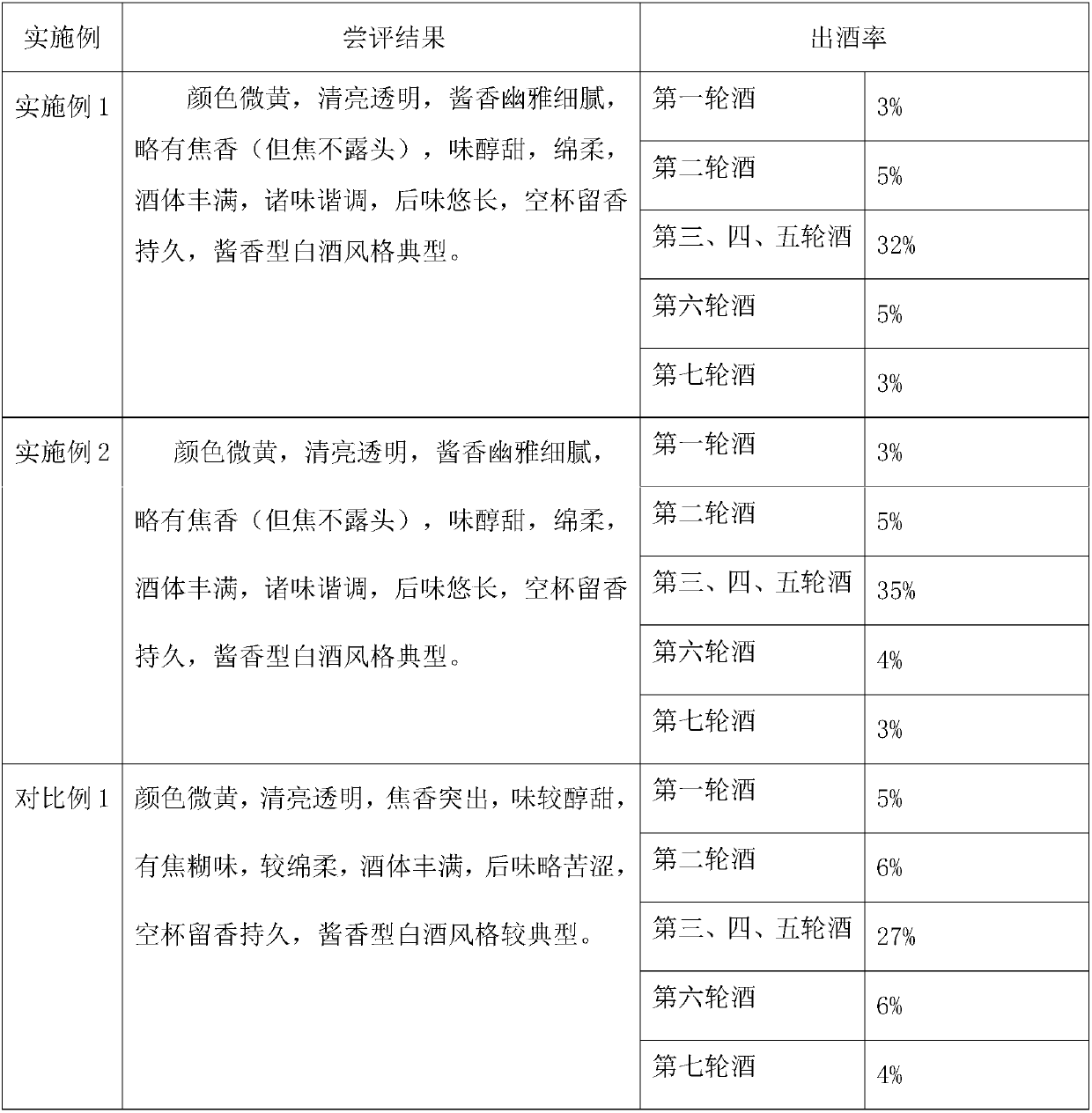

Embodiment 1

[0045] A. Food preparation process

[0046] Select 100Kg whole grain sorghum for use and divide it into two equal parts, one is divided into the sand material, and the other is the coarse sand material.

[0047] B. Sanding process

[0048] Add 50Kg of whole sorghum into hot water at 60°C to make the water level higher than the surface of sorghum. After soaking for 20 hours, drain all the water soaked in sorghum, then add 3Kg of mother grains to the soaked sorghum, stir evenly, Then steam the grains in a retort to make the gelatinization rate of sorghum reach 90%. After the retort is released, sprinkle water to replenish water until the water content of the grain grains reaches 41%. Then add wine tails and koji medicine accounting for 8% of the mixed raw materials. After cooling, it is piled up into a conical fermented grain pile, piled up and fermented for about 5 days, and the maximum stacking temperature is 50°C, adding wine tails accounting for 0.7% of the amount of mixed ...

Embodiment 2

[0056] A. Food preparation process

[0057] Select 100Kg whole grain sorghum for use and divide it into two equal parts, one is divided into the sand material, and the other is the coarse sand material.

[0058] B. Sanding process

[0059] Add 50Kg of whole sorghum into hot water at 60°C to make the water level higher than the surface of sorghum. After soaking for 24 hours, drain all the water soaked in sorghum, then add 4Kg of mother grains to the soaked sorghum, stir evenly, Then steam the grains in a retort to make the gelatinization rate of sorghum reach 85%. After the retort is released, sprinkle water to replenish water until the water content of the grain grains reaches 45%. Then add wine tails and koji medicine accounting for 12% of the mixed raw materials. , pile up into a conical fermented grain heap after cooling, accumulate and ferment for 4-5 days, up to the stacking temperature of 50°C, add wine tails accounting for 1% of the amount of mixed raw materials, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com