High-precision and full-automatic sealing equipment of metal tube shells

A metal tube, fully automatic technology, applied in the direction of metal processing equipment, welding equipment, resistance welding equipment, etc., can solve the problems of low production efficiency, backward control system, low efficiency, etc., achieve fast speed, improve yield and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

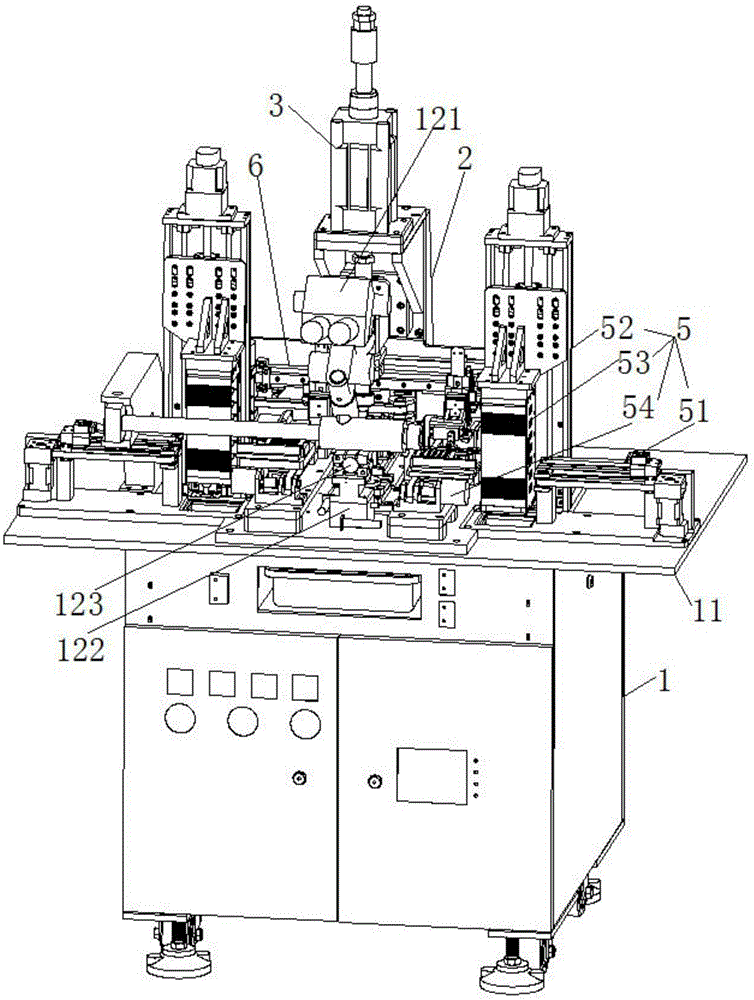

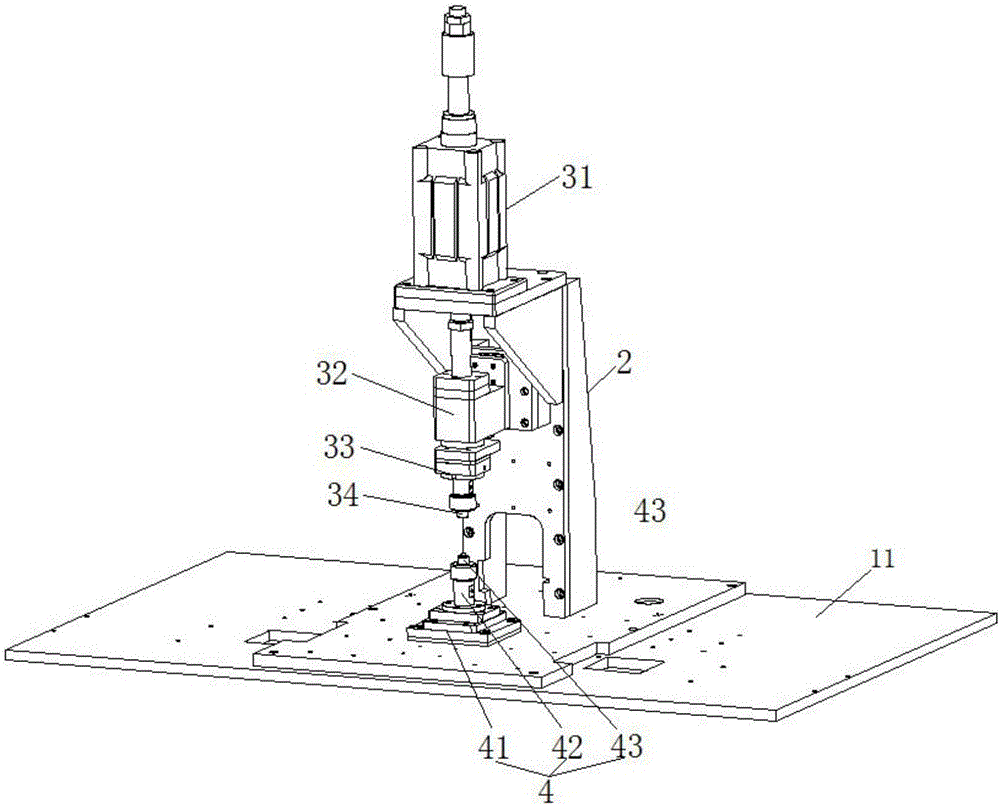

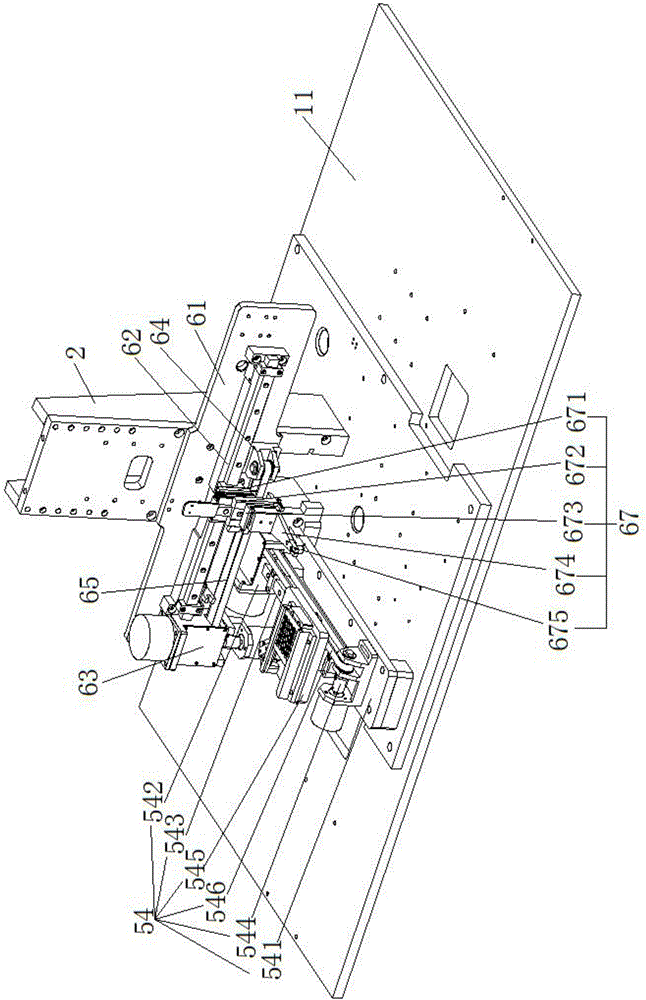

[0045] Example: such as Figures 1 to 6 As shown, the high-precision metal tube shell automatic sealing and welding equipment in this embodiment includes a chassis 1, a support base 2, a stamping welding mechanism 3, a welding seat mechanism 4, two feeding and conveying modules 5, and a linear movement mechanism 6;

[0046] The top of the cabinet 1 has a horizontally arranged workbench 11, the above-mentioned support base 2 is installed on the above-mentioned workbench 11, the above-mentioned stamping and welding mechanism 3 is installed on the upper end of the front side of the above-mentioned support base 2, and its stamping and welding end faces Arranged at the bottom, the above-mentioned welding seat mechanism 4 is installed on the above-mentioned workbench 11, and is located directly below the stamping welding end, and the two above-mentioned feeding and conveying modules 5 are symmetrically installed on the workbench 11 on both sides of the above-mentioned welding seat me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com