Self-traveling lifting type sprayer spraying rod device

A sprayer and lift-type technology, which is applied in the field of self-propelled lift sprayer spray rod device, can solve the problems of poor mechanical applicability, reduced mechanical utilization rate, and inability to work on high-position working faces, so as to improve efficiency, Energy saving and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

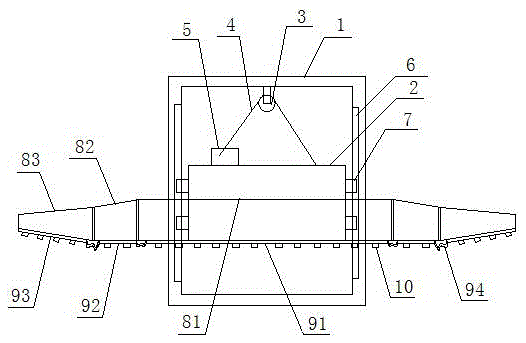

[0013] Such as figure 1 The spray boom device of a self-propelled lifting sprayer includes a frame 1, a lifting frame 2, a fixed pulley 3, a cable 4, a hoist 5, a nozzle pipe and a spray boom assembly, and a guide rail is provided inside the frame 1 6. The lifting frame 2 is provided with a pulley 7 matching the guide rail 6. The guide rail 6 and the pulley 7 form a vertical movement pair. The lifting frame 2 is fixedly connected with the spray rod assembly. A hoist 5 is fixedly installed on the upper end of the frame 2 , and the cable 4 is looped in the hoist 5 and one end passes through the fixed pulley 3 and is fixed on the lifting frame 2 .

[0014] The spray boom assembly includes a fixed frame 81, two middle suspensions 82 and two end suspensions 83. One end hinges up and down.

[0015] The nozzle includes a fixed nozzle 91 with a nozzle 10, an end nozzle 93 with a nozzle 10, a middle nozzle 92 with a nozzle 10, and a flexible flexible nozzle connected between the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com