Automatic bowl plate feeding mechanism on rice seeding production line

A technology of assembly line and bowl, which is applied in the directions of manipulator, planting method, transplanting machine, etc., can solve the problem of high labor intensity in raising seedlings, and achieve the effect of improving seeding efficiency and reducing manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

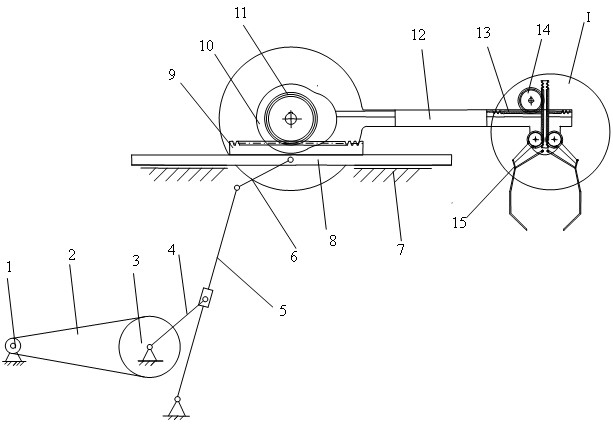

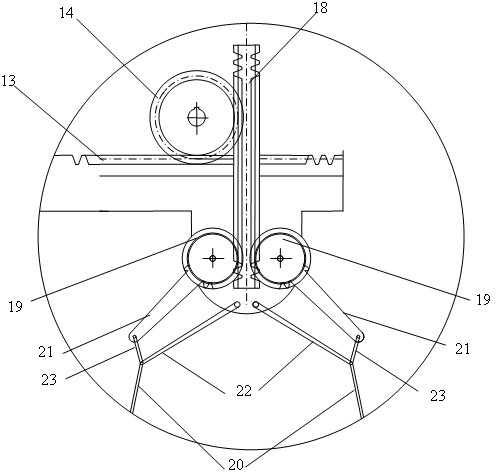

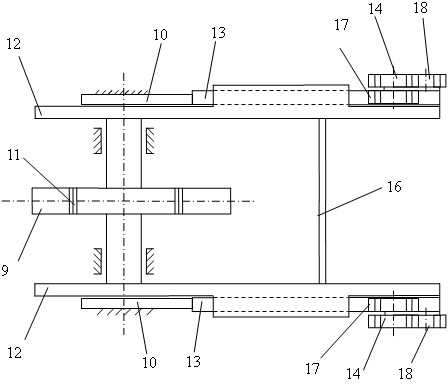

[0015] Such as figure 1 , figure 2 , image 3 As shown, it includes crank mechanism, rocker 5, connecting rod 6, frame 7, slider 8, rack 9, two cams 10, first gear 11, two mechanical arms 12, two rack ejector rods 13, a pair of second gears 14, two manipulators 15, reinforcing rods 16, a pair of third gears 17, two double-sided racks 18; the crank 4 in the crank mechanism is connected with the rocking bar 5 through a slide block, and the rocking bar 5 The connecting rod 6 drives the slider 8 to slide relative to the frame 7, the rack 9 mounted on the slider 8 meshes with the first gear 11, and the two ends of the shaft of the first gear 11 are respectively equipped with mechanical arms 12, A reinforcing rod 16 is arranged between the two mechanical arms 12, and the two cams 10 are respectively fixed on both sides of the frame 7, the axis of the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com