Medical image X-ray film developing device

A medical image and film technology, applied in optics, photography, photosensitive materials, etc., can solve problems such as increased work intensity, low efficiency, and shadow liquid splashing, and achieve the effects of ensuring photocopying efficiency, increasing film processing quality, and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

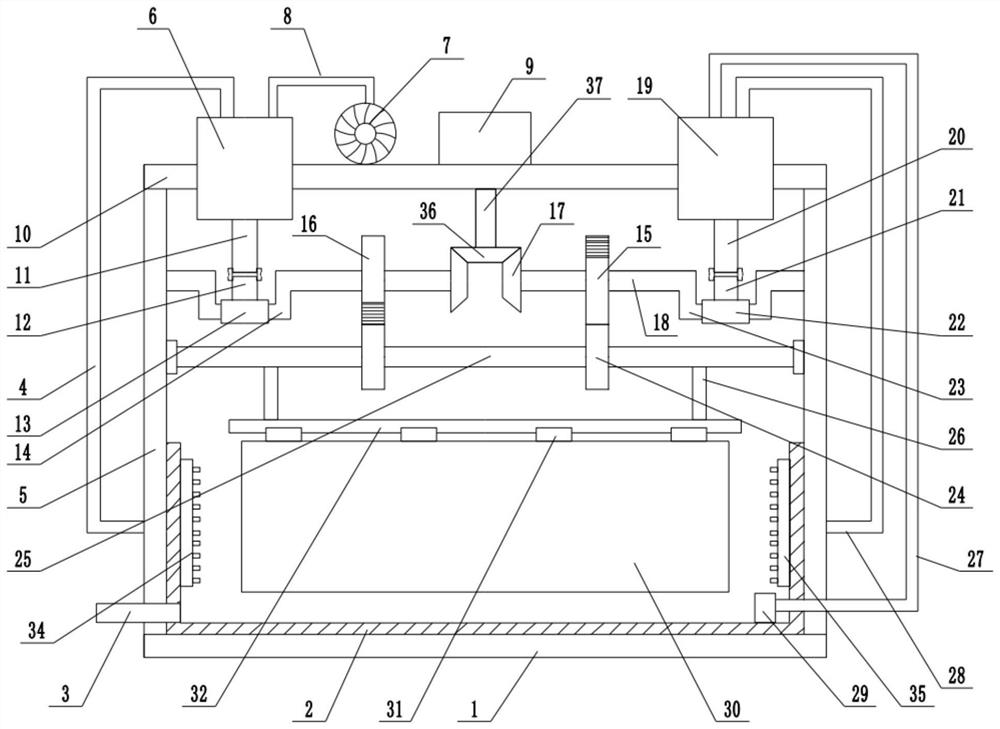

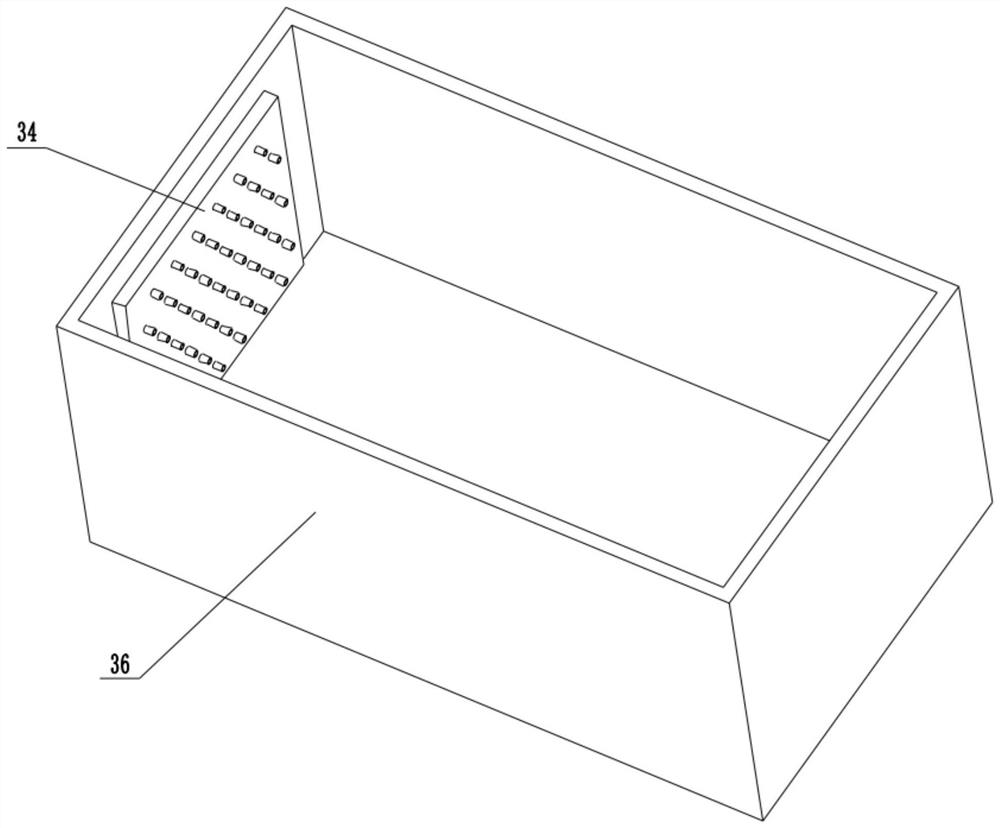

[0030] refer to Figure 1~3, in an embodiment of the present invention, a medical image X-ray film developing device, comprising a fixed base plate 1, a photoprint tank 2 in the middle of the upper end of the fixed base plate 1, a drying chamber 34 is installed on the left side of the inner wall of the photoprint tank 2, and the inner wall of the photoprint tank 2 The liquid spray chamber 35 is installed on the right side, and the bottom of the photocopy tank 2 is also equipped with a liquid discharge pipe 3, which is used to realize the discharge of the liquid after the photocopying is completed. A support frame 5 is installed on both sides of the upper end of the fixed bottom plate 1, and a top plate is installed on the top of the support frame 5. 10. A drying box 6 is installed on the left side of the upper end of the top plate 10. One end of the drying box 6 is connected to a drying chamber 34 through the drying pipe 4, and the other end is connected to the induced draft fa...

Embodiment 2

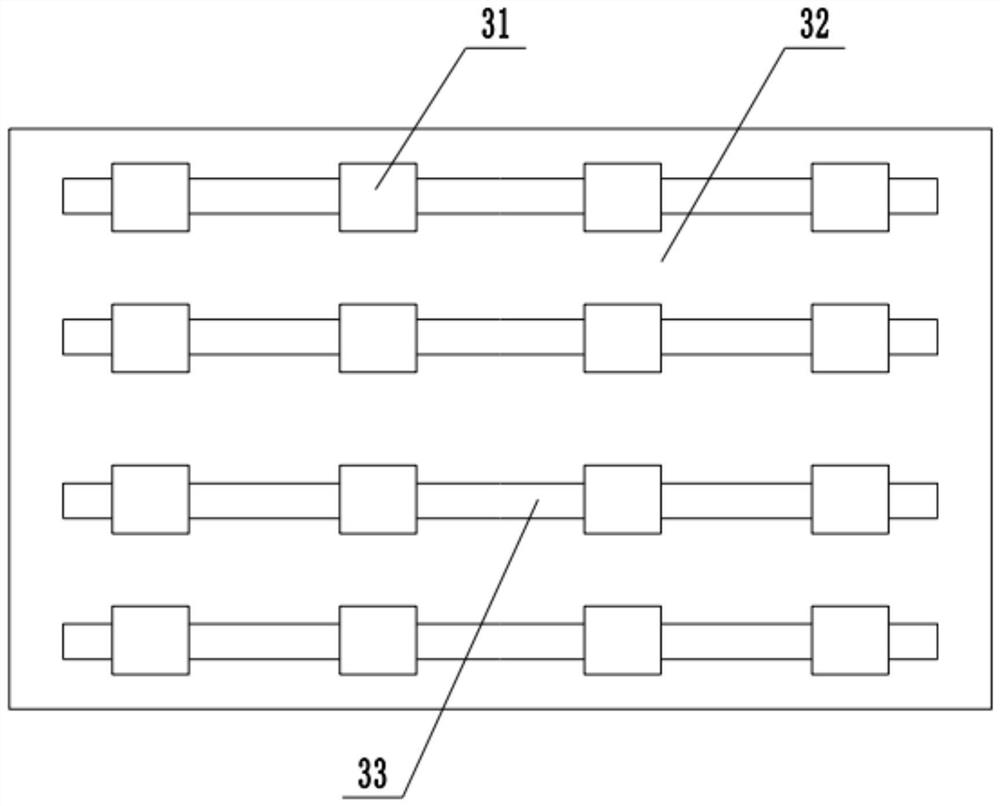

[0032] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that a plurality of sliding grooves 33 are arranged in the middle part of the lower end of the swing plate 32, and a plurality of sliding blocks 31 are installed inside the sliding grooves 33, and the sliding blocks The X-ray film 30 is installed detachably at the lower end of the 31, and some chute 33 and slide block 31 are set to realize the fixation of some X-ray films 30 before and after, which further increases the film processing efficiency.

[0033] In the present invention, when working, the X-ray film 30 is placed at the bottom of the slider 31 for fixing, and at the same time, photoprinting solution is placed inside the photoprinting tank 2, and then the driving motor 9 is started, under the action of the driving gear 36 and the driven gear 17 The rotating shaft 18 is rotated, and then the left gear 16 and the right gear 15 are intermitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com