Automatic lining vamp polishing device

A polishing device, a technology for shoe uppers, applied in footwear, shoe-making machinery, clothing, etc., can solve problems such as the need for manual assistance, and achieve the effects of reducing equipment costs, simple structure, and reducing manual labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

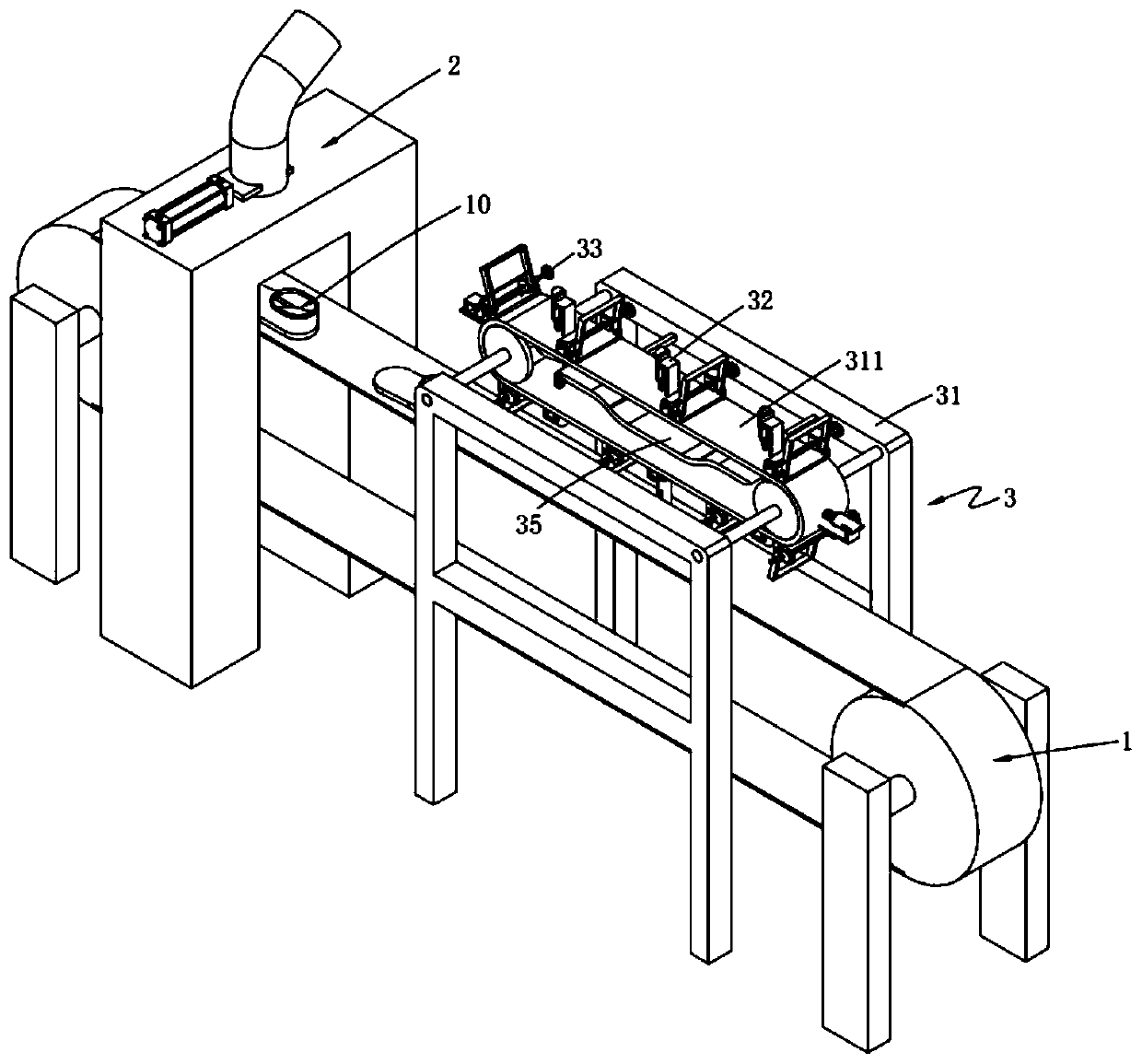

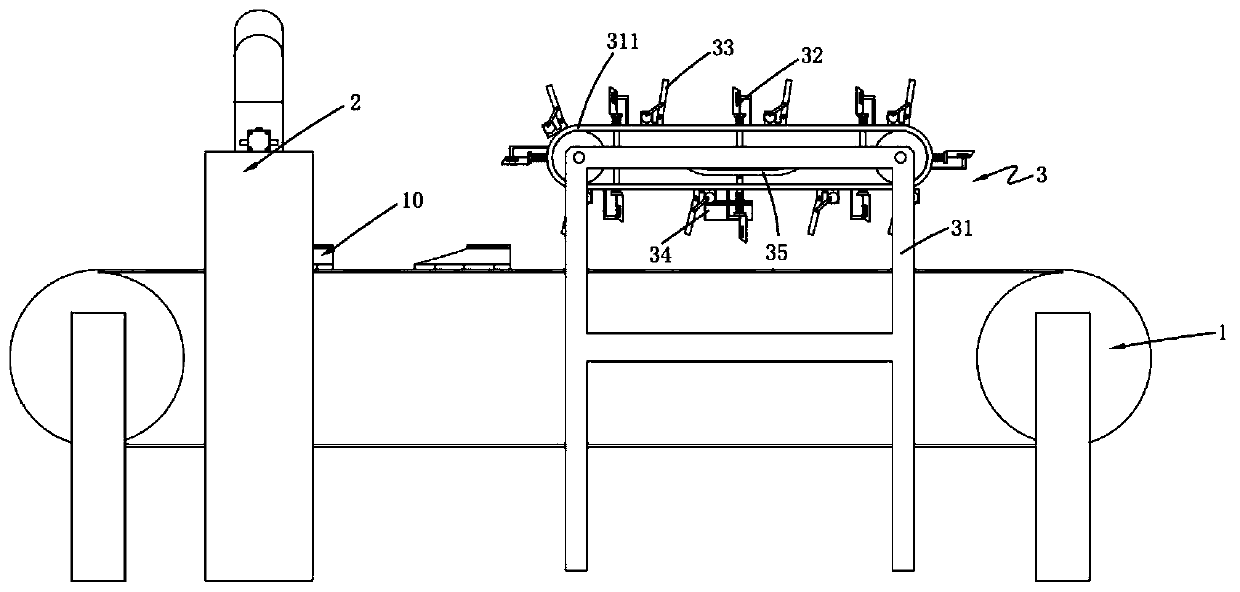

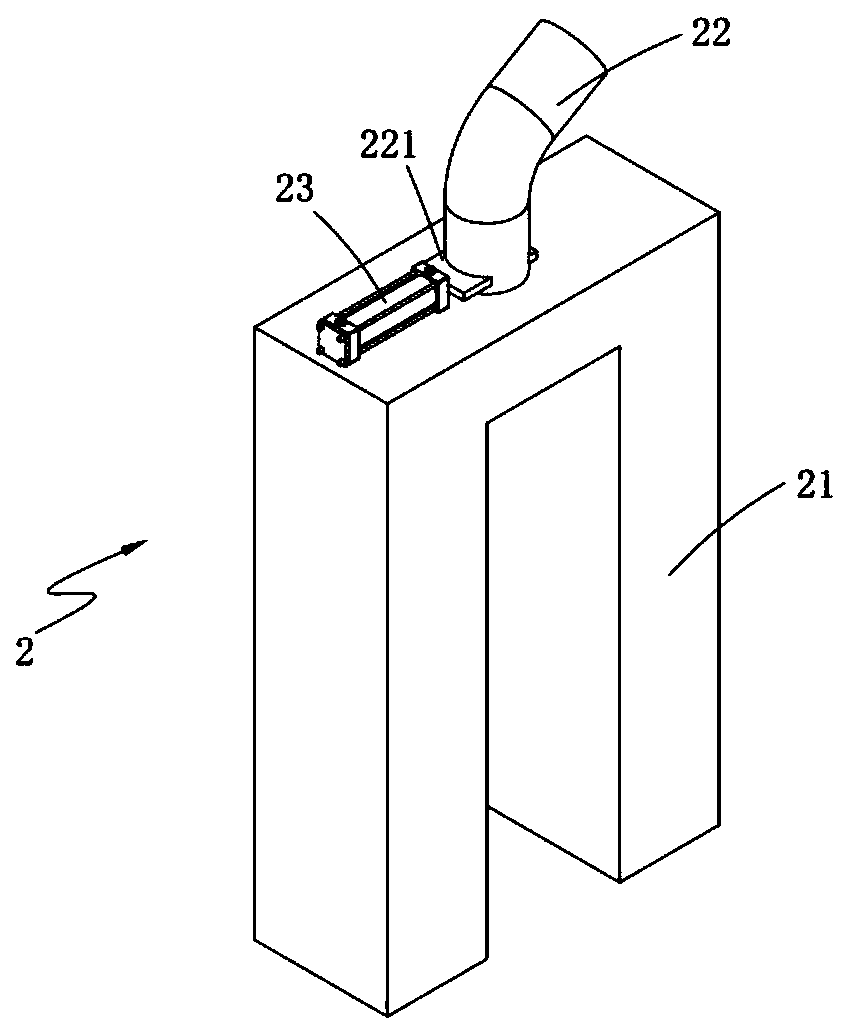

[0053] Such as figure 1 , 2 As shown in and 3, an automatic lining vamp polishing device includes a conveying mechanism 1, a pad feeding mechanism 2 and a polishing mechanism 3 are arranged in sequence along the conveying direction of the conveying mechanism 1, and the conveying mechanism 1 passes through the The polishing mechanism 3, the pad sending mechanism 2 includes a frame 21, a pad sending track 22 and a cylinder 23, the pad sending track 22 is arranged on the frame 21, and it delivers the foam pad 9 to the delivery mechanism 1, The bottom of the cushion feeding track 22 is provided with a baffle 221, the cylinder 23 drives the baffle 221 to move, and the polishing mechanism 3 includes:

[0054] Support 31, said support 31 is provided with conveyer belt 311 along its length direction, the conveying speed of this conveyer belt 311 is the same as the conveying speed of described conveying mechanism 1, and it is positioned at the top of described conveying mechanism 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com