Control system of machine for automatically injecting stator slot cover paper in storage cup

An automatic insertion and control system technology, applied in the field of control systems, can solve problems such as increased material costs, cumbersome operating procedures for workers, and reduced factory production output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

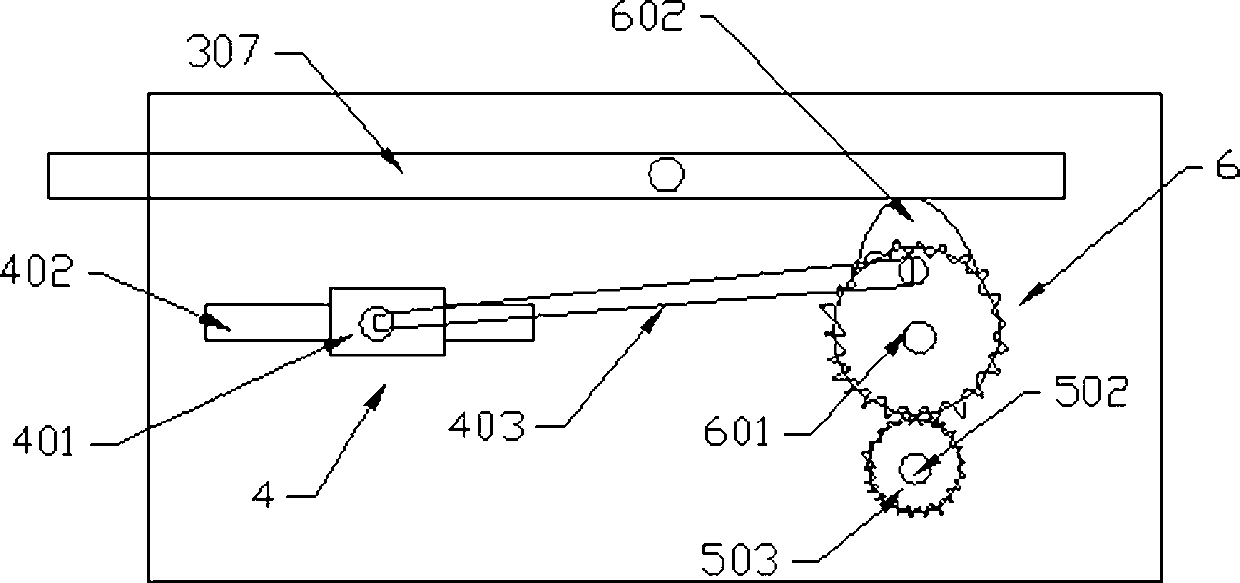

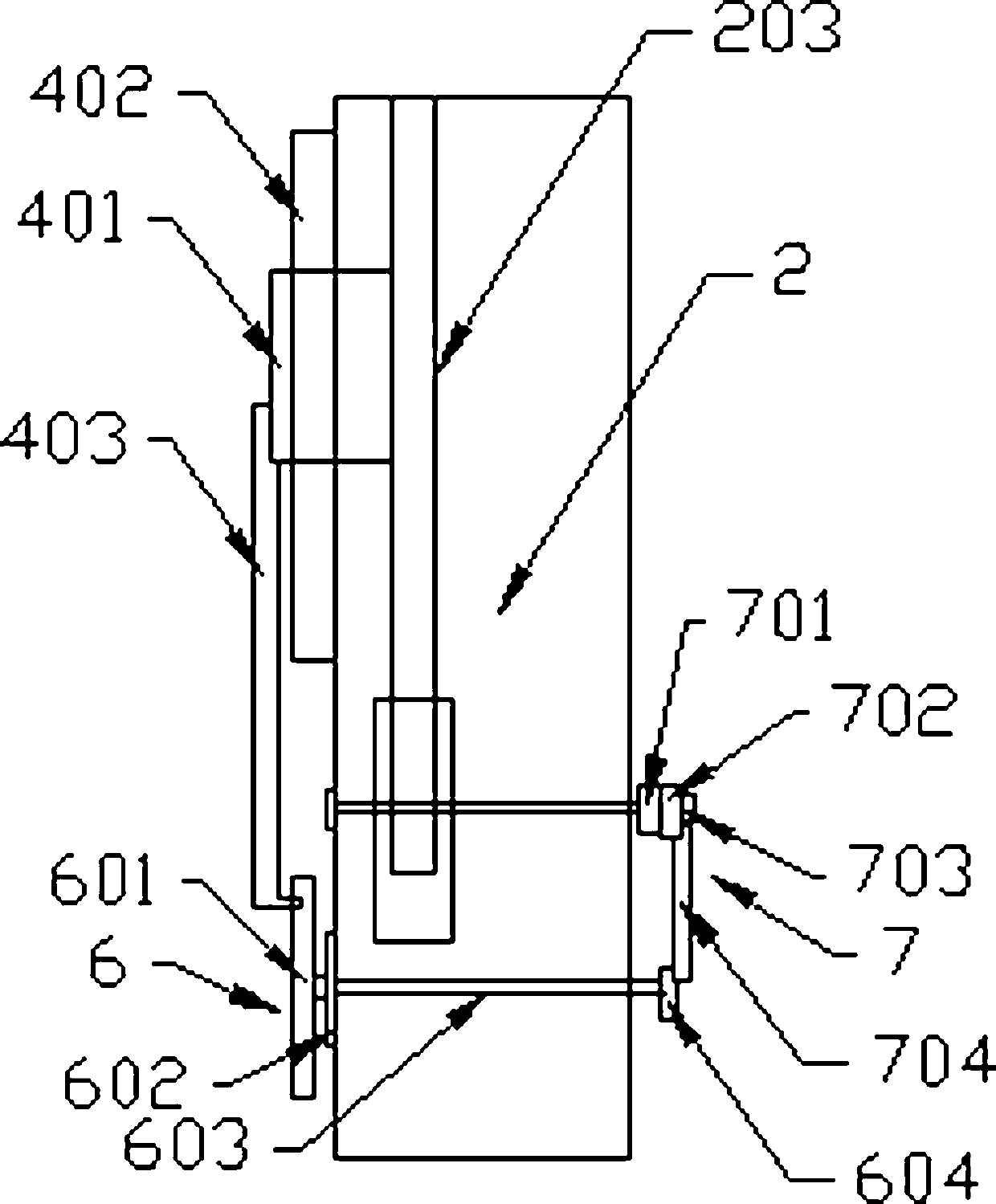

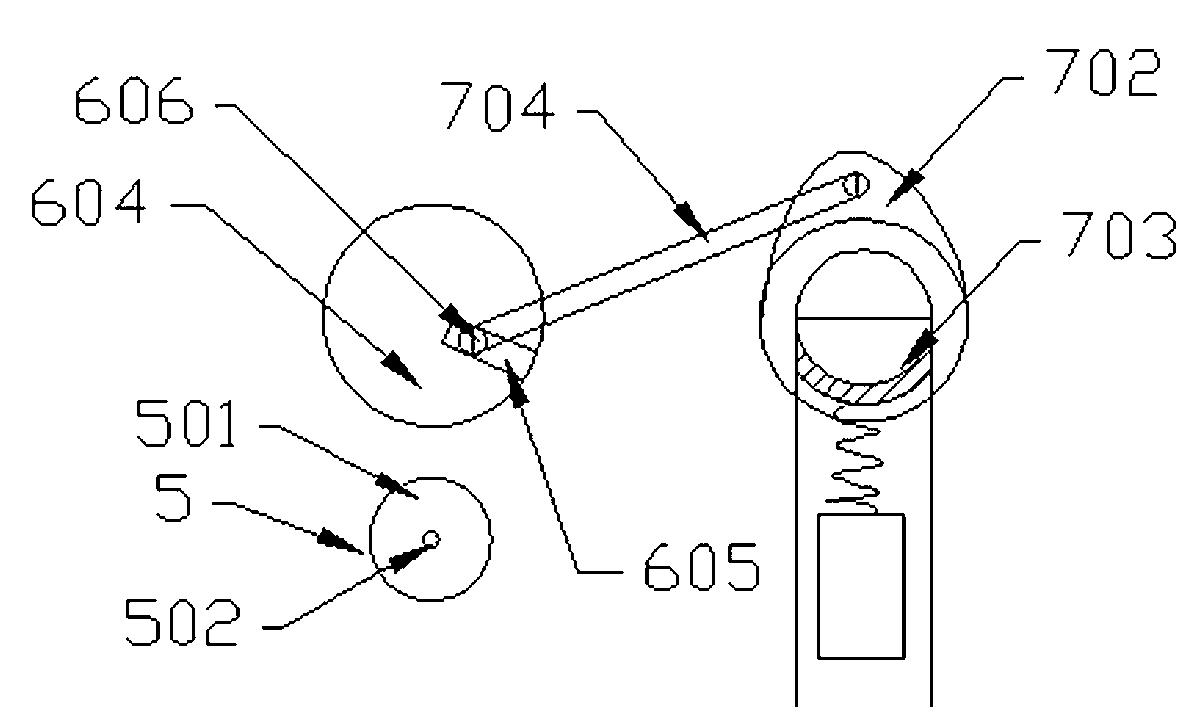

[0050] Such as Figure 1 to Figure 5 As shown, the present invention relates to a control system of a stator slot cover paper storage cup automatic insertion machine, including a start-up control device, a transmission mechanism, a transmission setting device 2 and an insertion device 3, and the transmission mechanism includes a first transmission structure 5, a second Two transmission structures 6 and a third transmission structure 7, the first transmission structure 5 is connected to the start control device, the second transmission structure 6 is connected to the insertion device 3, and the third transmission structure 7 is connected to the transmission and setting device 2 connection settings.

[0051]Such a device, when the controller 1 in the start-up control device is pressed and starts to run, the first transmission structure 5 is driven, and the second transmission structure 6 connected thereto begins to operate, and the second transmission structure 6 connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com