Temperature control differential pressure backwater tap

A faucet, temperature control technology, applied in the direction of temperature control, water supply device, non-electric variable control, etc., to achieve obvious benefits and save water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

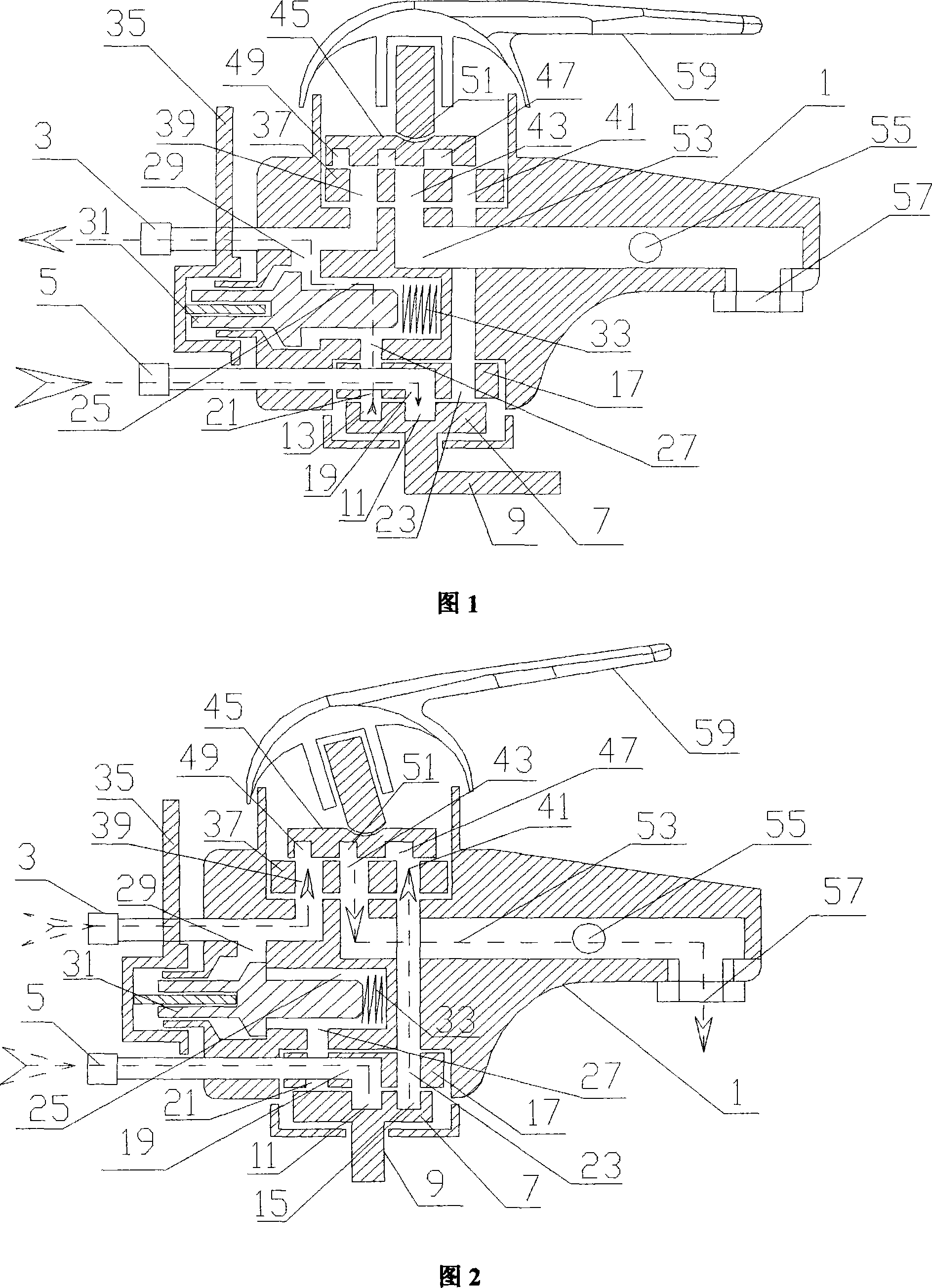

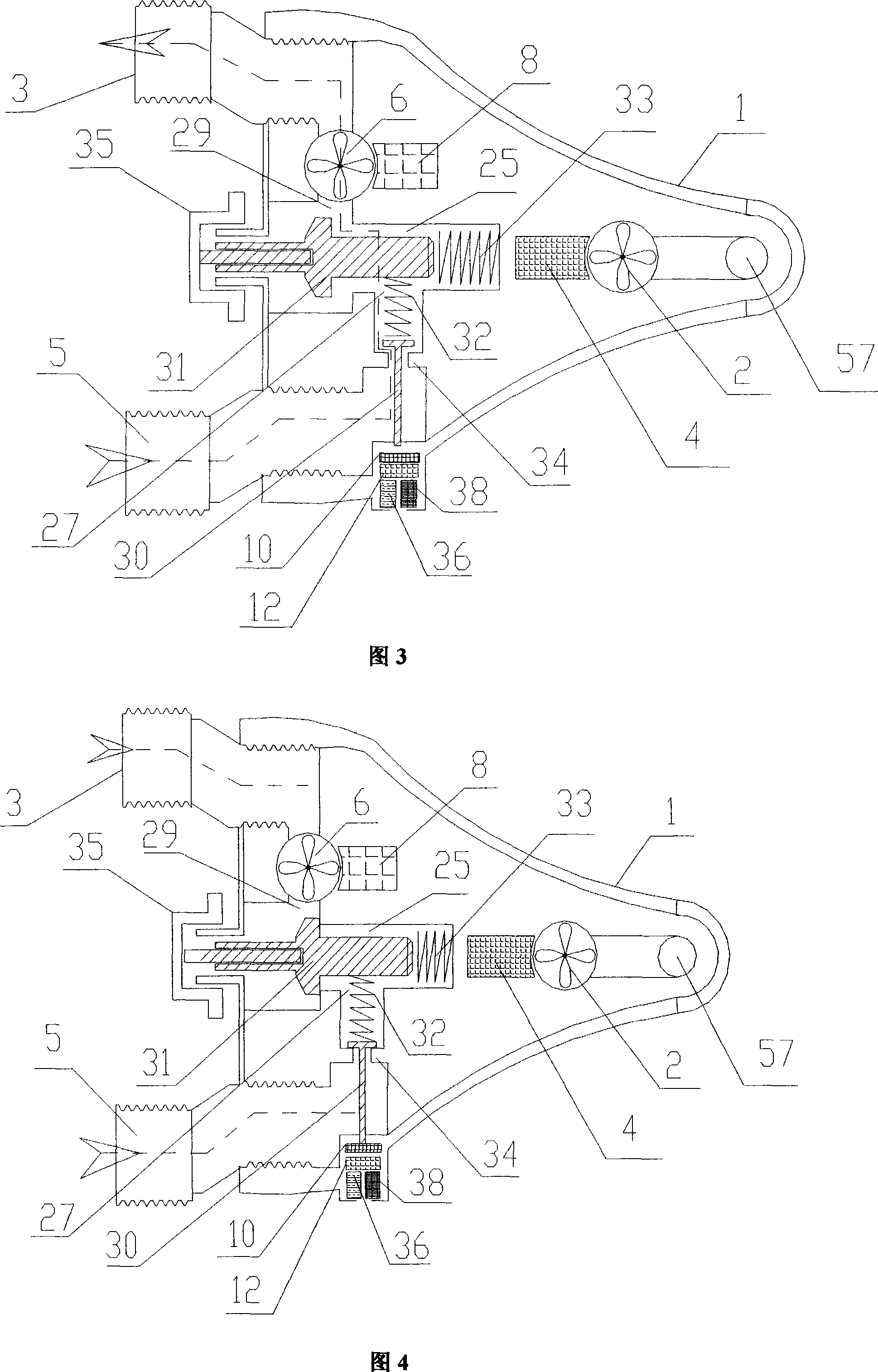

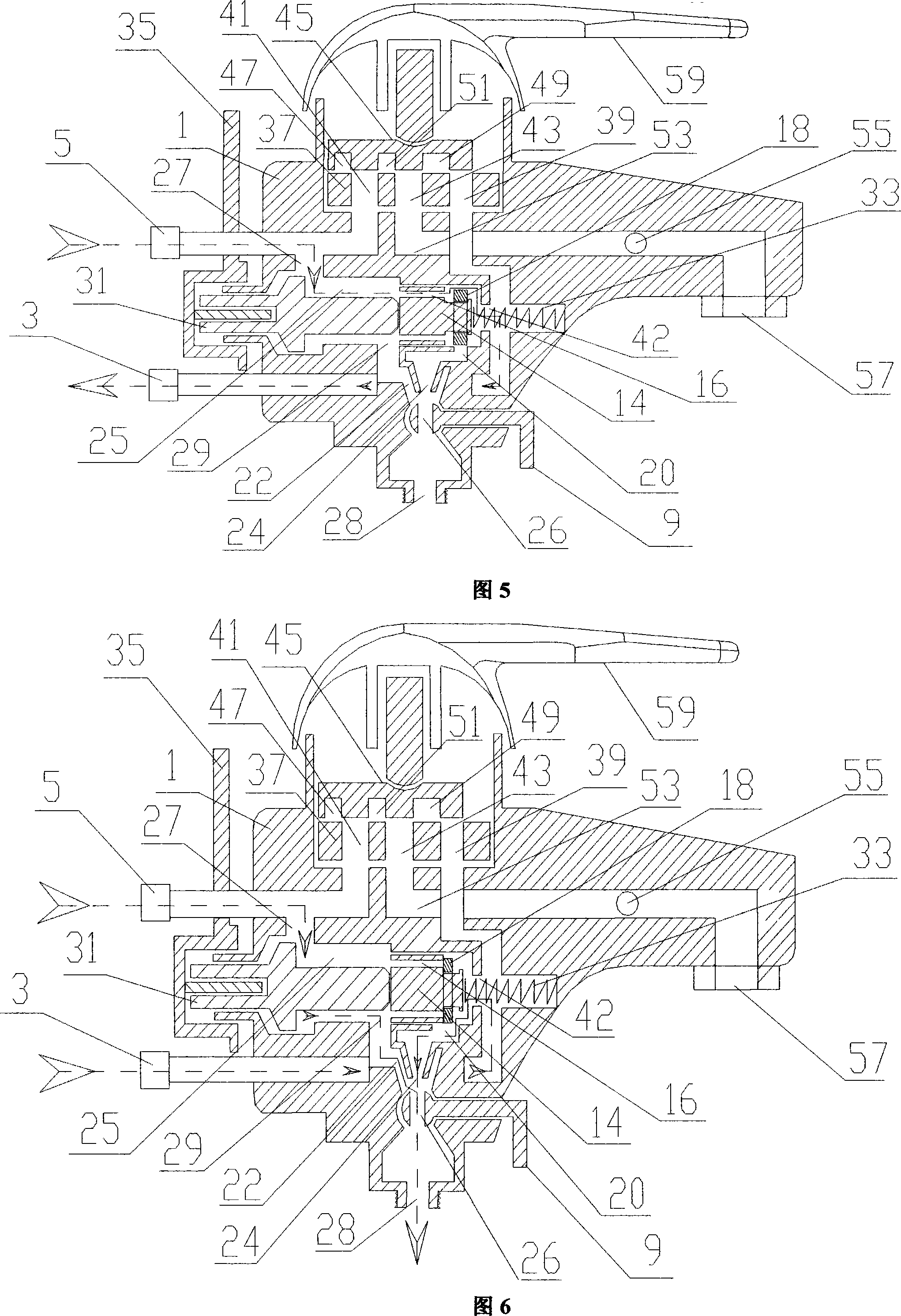

[0015] The following describes the basic structure of the temperature-controlled differential pressure return faucet of the present invention and its working mode and state in different use environments with reference to FIGS. 1-9.

[0016] As shown in FIGS. 1 and 2 , the faucet includes a housing 1 , a cold water pipe 3 , a hot water pipe 5 , an upper valve plate 7 of a water return valve and a water return handle 9 . Among them, the water inlet tank 11 of the upper valve plate of the backwater valve, the water return tank 13 of the upper valve plate of the backwater valve and the water outlet tank 15 of the upper valve plate of the backwater valve belong to the concave grooves on the upper valve plate of the backwater valve, and their positions correspond to those of the backwater valve respectively. The water inlet hole 19 of the lower valve plate of the backwater valve on the lower valve plate 17, the water return hole 21 of the lower valve plate of the backwater valve and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com