Water saving temperature control backwater valve

A valve and water inlet technology, applied in valve details, valve devices, valve operation/release devices, etc., to achieve the effect of not consuming energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

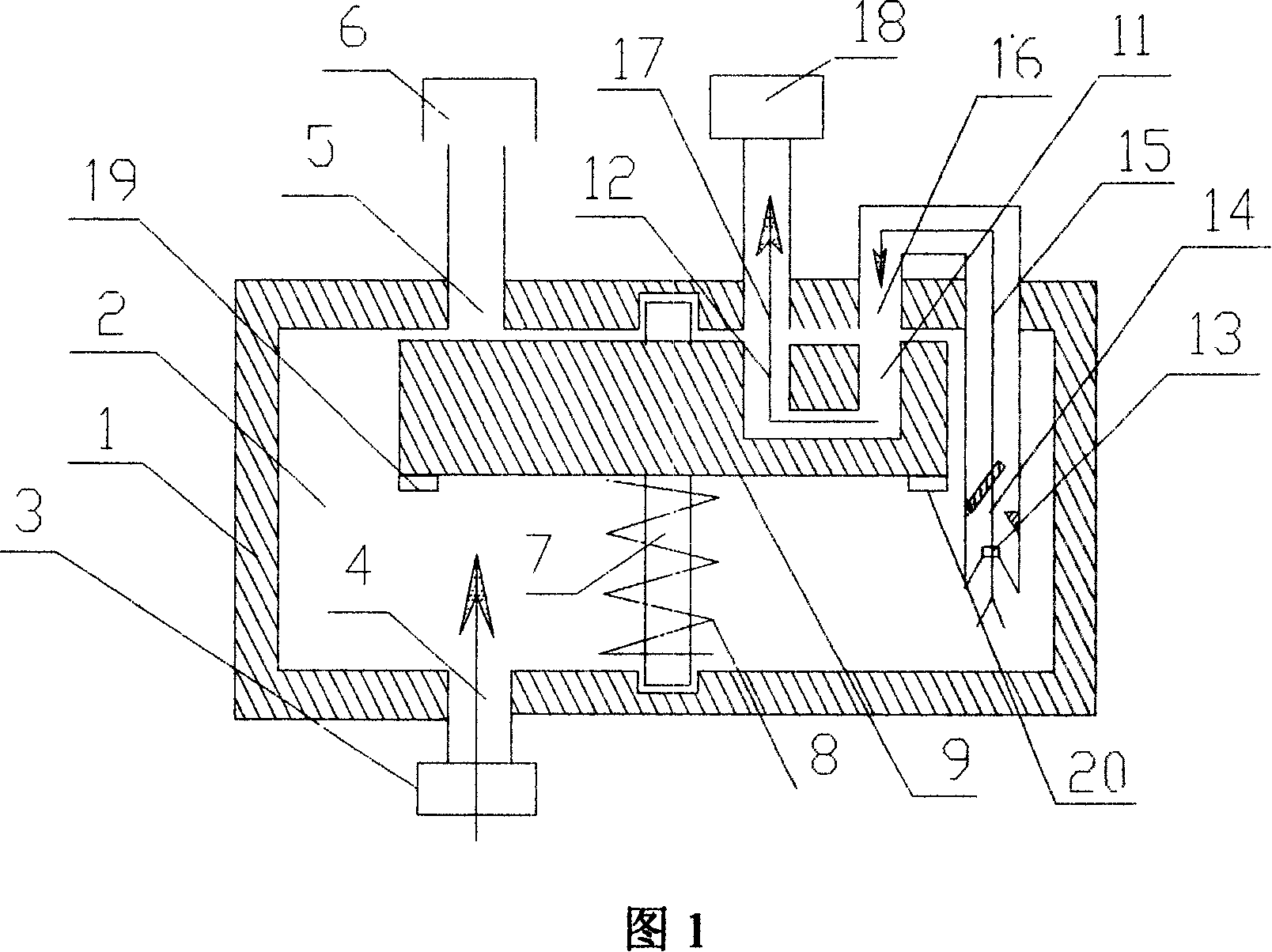

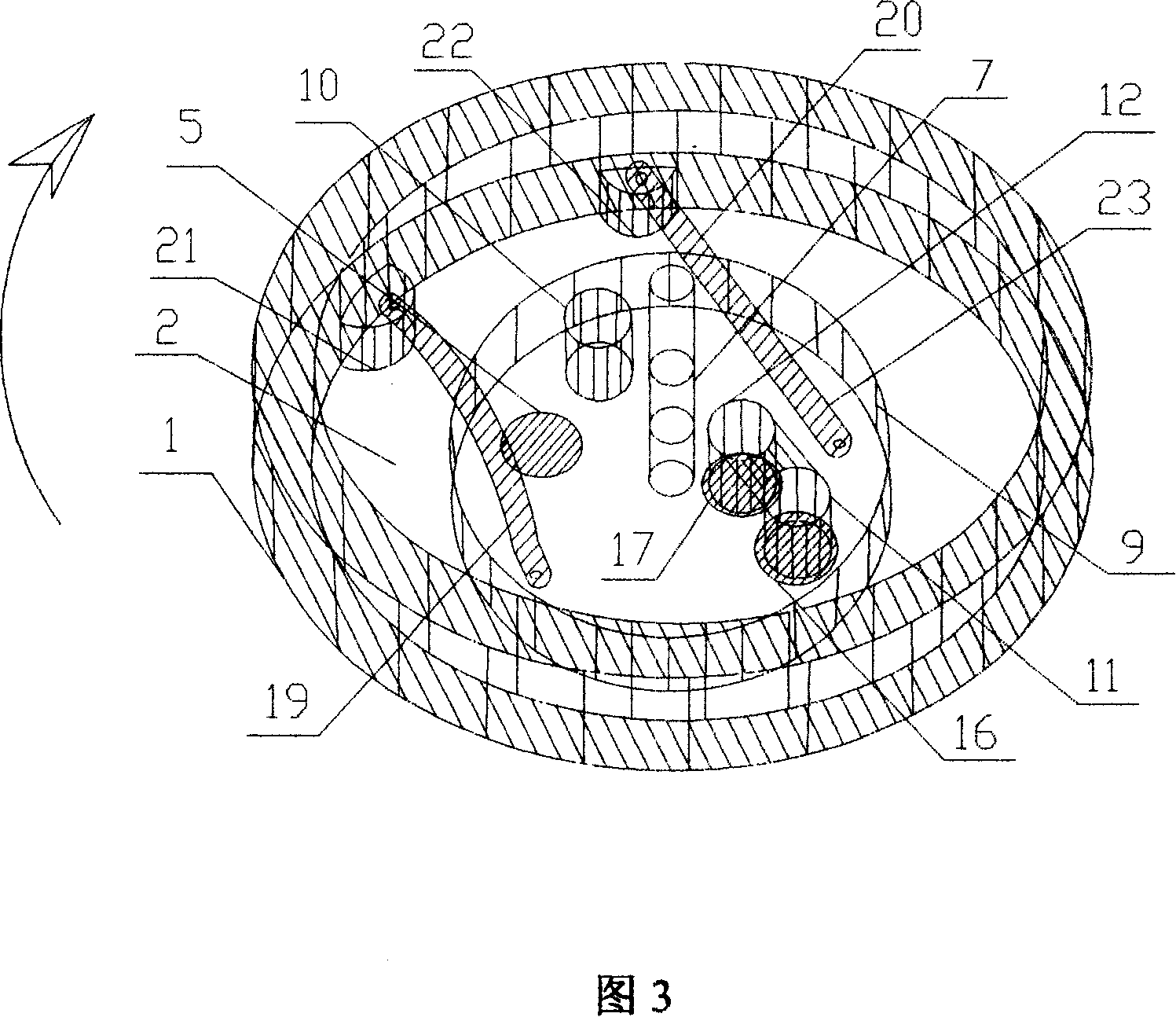

Embodiment 1

[0014] In the initial state, the position of the core body 9 is such that the inlet 11 of the U-shaped channel is aligned with the opening 16 of the return water inlet cavity, the outlet 12 of the U-shaped channel is aligned with the return water outlet opening 17, and the return water channel is in an open state. The water that enters the cavity from the water pipe makes the pressure in the cavity equal to the pressure in the hot water pipe. When the water in the cavity is cold water, the temperature-sensitive controls 19 and 20 will maintain the original shape, and the cold water in the cavity will Under the action of the pressure in the hot water pipe and the pressure converter 13, push it with a pressure higher than the hot water pipe and pass through the check valve 13 to enter the U-shaped passage on the core 9 and enter the return pipe outlet 18 to finally return into the water supply pipe; when the cold water in the cavity 2 gradually turns into hot water and reaches a ...

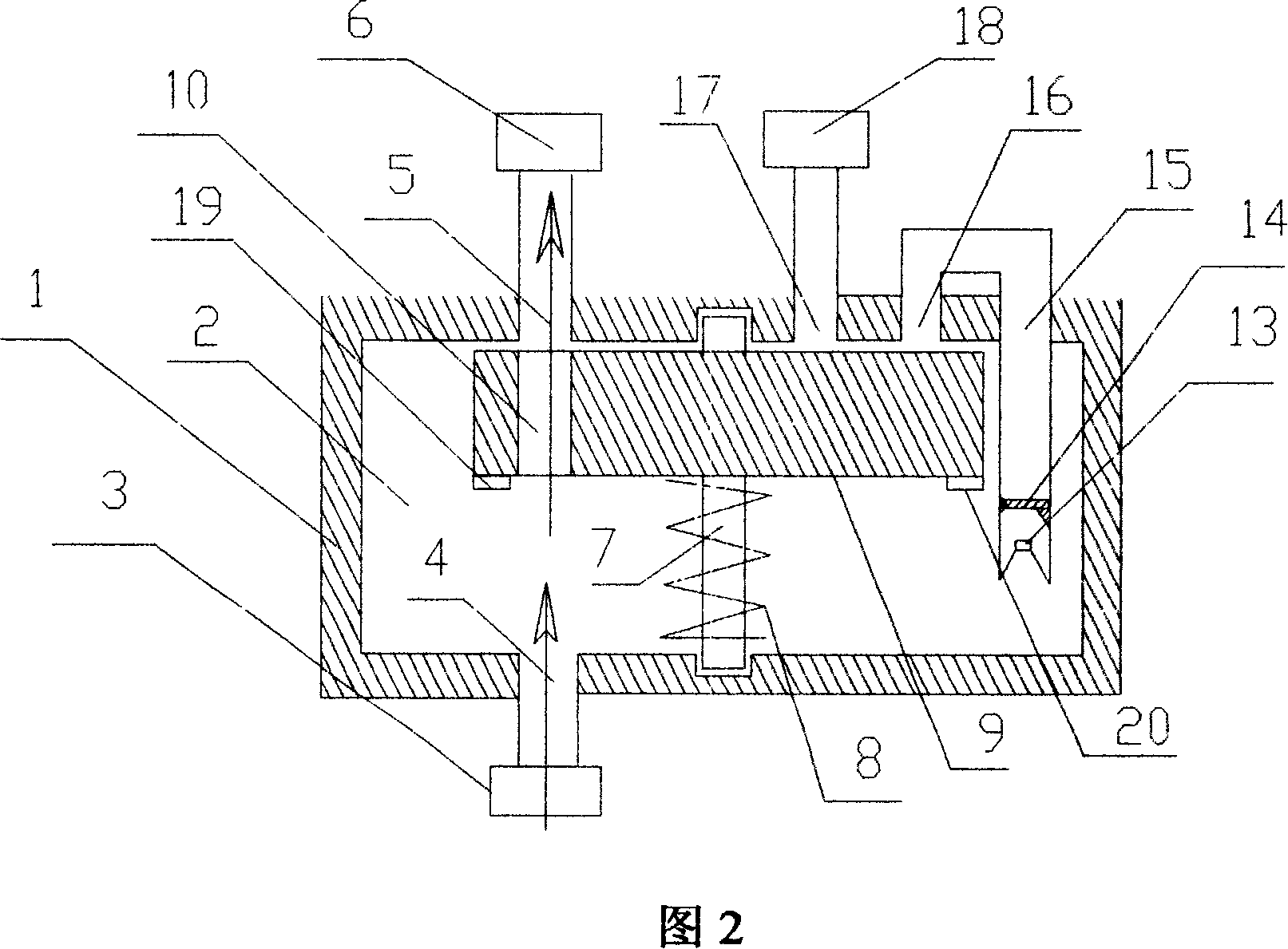

Embodiment 2

[0016] In the initial state, the position of the core body 9 is such that the inlet 11 of the U-shaped channel is aligned with the opening 16 of the return water inlet cavity, the outlet 12 of the U-shaped channel is aligned with the return water outlet opening 17, and the return water channel is in an open state. The water that enters the cavity from the water pipe makes the pressure in the cavity equal to the pressure in the hot water pipe. When the water in the cavity is cold water, the temperature-sensitive controls 19 and 20 will maintain the original shape, and the cold water in the cavity will Under the action of the pressure in the hot water pipe and the pressure converter 13, push it with a pressure higher than the hot water pipe and pass through the check valve 13 to enter the U-shaped passage on the core 9 and enter the return pipe outlet 18 to finally return into the water supply pipe; when the cold water in the cavity 2 gradually turns into hot water and reaches a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com