Heating apparatus enabling convenience for winter concrete construction

A heating device and concrete technology, which is applied in water supply devices, building material processing, construction and other directions, can solve the problems of difficult to control the overall temperature of concrete, poor thermal conductivity of concrete, affecting the durability of components, etc., to avoid the risk of temperature stress, The effect of high thermal energy utilization efficiency and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

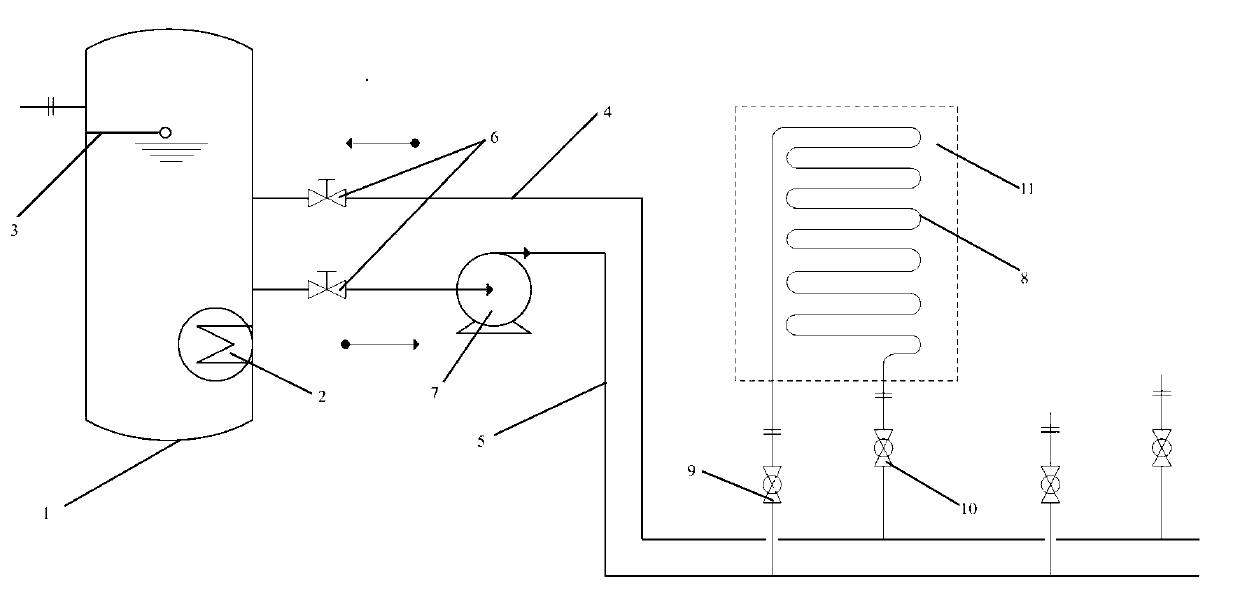

[0021] Such as figure 1 As shown, the present invention includes a water tank 1, a heater 2 and an automatic water replenishment valve 3 are arranged in the water tank 1, an outlet pipe 4 and a return pipe 5 are installed outside the water tank 1, and the connection between the outlet pipe 4 and the return pipe 5 and the water tank 1 A cut-off valve 6 is installed, and a water pump 7 is provided at the joint between the outlet pipe 4 and the water tank 1. At least one branch pipe 8 is installed between the outlet pipe 4 and the return pipe 5, and one end of the branch pipe is connected to the water outlet through the water inlet valve 9. The other end of the pipe 4 is connected to the return pipe 5 through the return valve 10, and the middle part of the branch pipe 8 is bent inside the position where the concrete is to be poured.

[0022] Further, the water inlet valve 9 and the water return valve 10 are both ball valves.

[0023] Further, the branch pipe 8 is a pipe made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com