Dyeing process and dyeing apparatus for collagen fiber regenerated leather

A technology of collagen fiber and dyeing device, which is applied in the direction of dyeing method, textile processing machine accessories, textile material treatment, etc., can solve problems that have not been seen before, and achieve the effect of improving dyeing effect and uniform dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

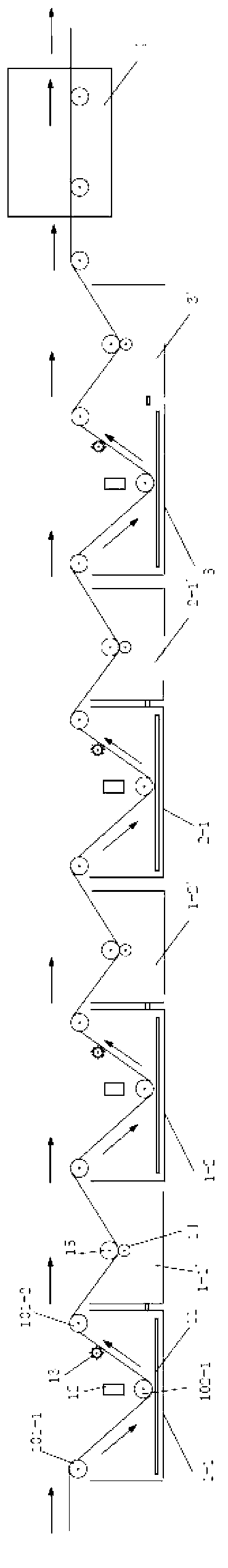

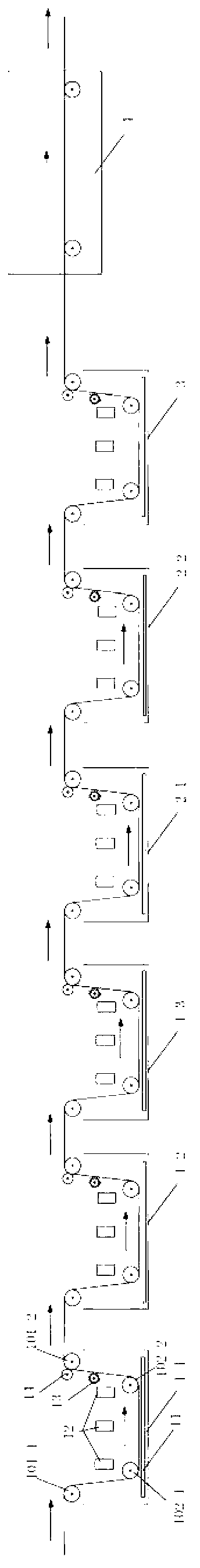

Image

Examples

Embodiment 1

[0033] The invention relates to a dyeing process of collagen fiber regenerated skin, comprising the following steps:

[0034] (1) Dyeing treatment:

[0035](1-1) One dyeing: Dye the collagen fiber regenerated leather blank in the first dyeing bath placed in the ultrasonic sound field for 0.5 to 5 minutes, wherein the first dyeing bath contains dyeing agent, coloring penetrating agent and tannin In the process, the concentration of the dyeing agent is 0.1~12%, the pH value is adjusted to 3~5 with ammonia water, the temperature of the bath liquid is 30~98°C, and the ultrasonic power is 1000~2000W; Floating color on the surface; finally extrude the skin until the liquid content in the skin is 30-55%, and return the extruded liquid to the first dyeing bath;

[0036] (1-2) Second dyeing: Dye the collagen fiber regenerated skin base after the first dyeing in the second dyeing bath placed in the ultrasonic sound field for 0.5 to 5 minutes, wherein the second dyeing bath contains dye...

Embodiment 2

[0045] The invention relates to a dyeing process of collagen fiber regenerated skin, comprising the following steps:

[0046] (1) Dyeing treatment:

[0047] (1-1) One dyeing: Dye the collagen fiber regenerated leather blank in the first dyeing bath placed in the ultrasonic sound field for 0.5 to 5 minutes, wherein the first dyeing bath contains dyeing agent, coloring penetrating agent and tannin , the concentration of the dyeing agent is 8%, the pH value of the bath liquid is adjusted to 3~5 with ammonia water, the temperature of the bath liquid is 40~45°C, and the ultrasonic power is 1800W; color; finally extrude the skin until the liquid content in the skin is 30-55%, wherein the extruded liquid is returned to the first dyeing bath;

[0048] (1-2) Second dyeing: Dye the collagen fiber regenerated leather blank in the second dyeing bath placed in the ultrasonic sound field for 0.5 to 5 minutes, wherein the second dyeing bath contains dyeing agent, coloring penetrating agent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com