Porous supported electrospun nano photocatalytic fiber membrane and preparation method thereof

A nano-light and fiber film technology, applied in the field of nano-materials, can solve the problems of small specific surface area of fiber film materials, limited photocatalyst, limited catalytic degradation efficiency, etc., and achieve the effects of low cost, environmental safety and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

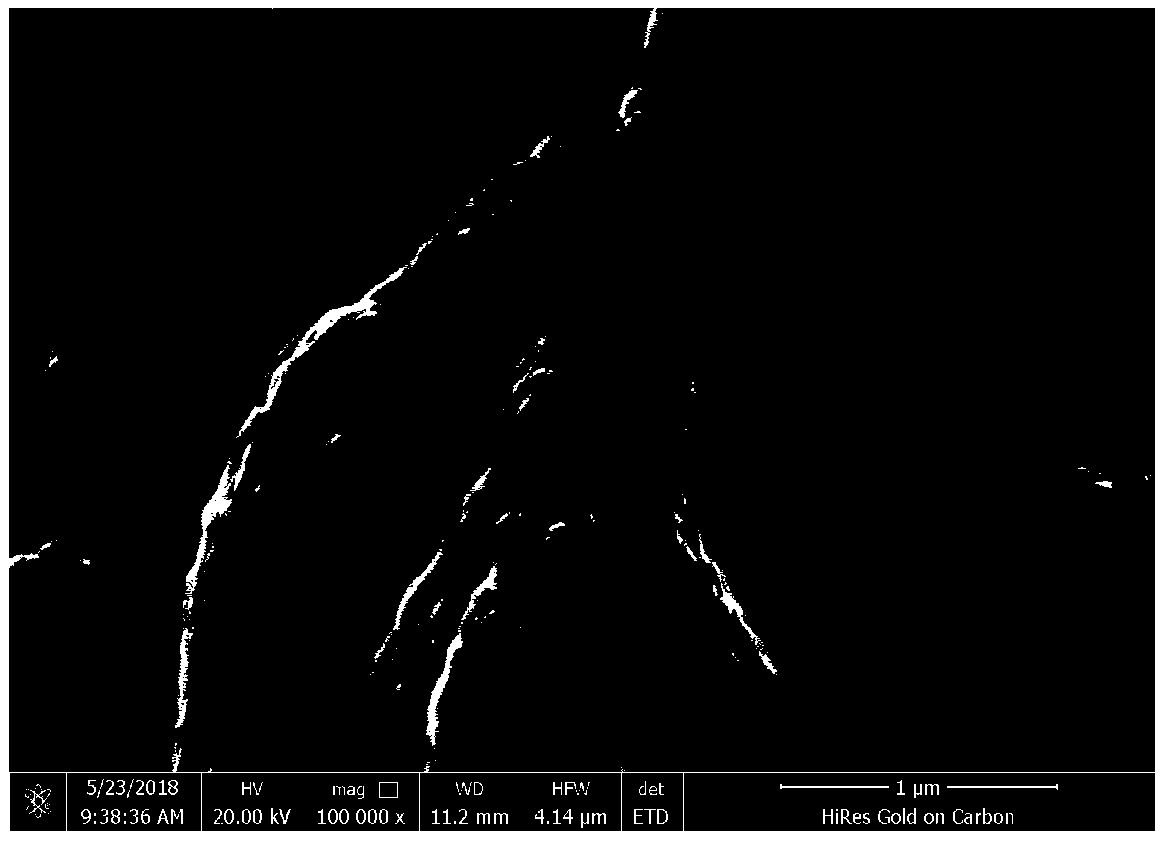

Image

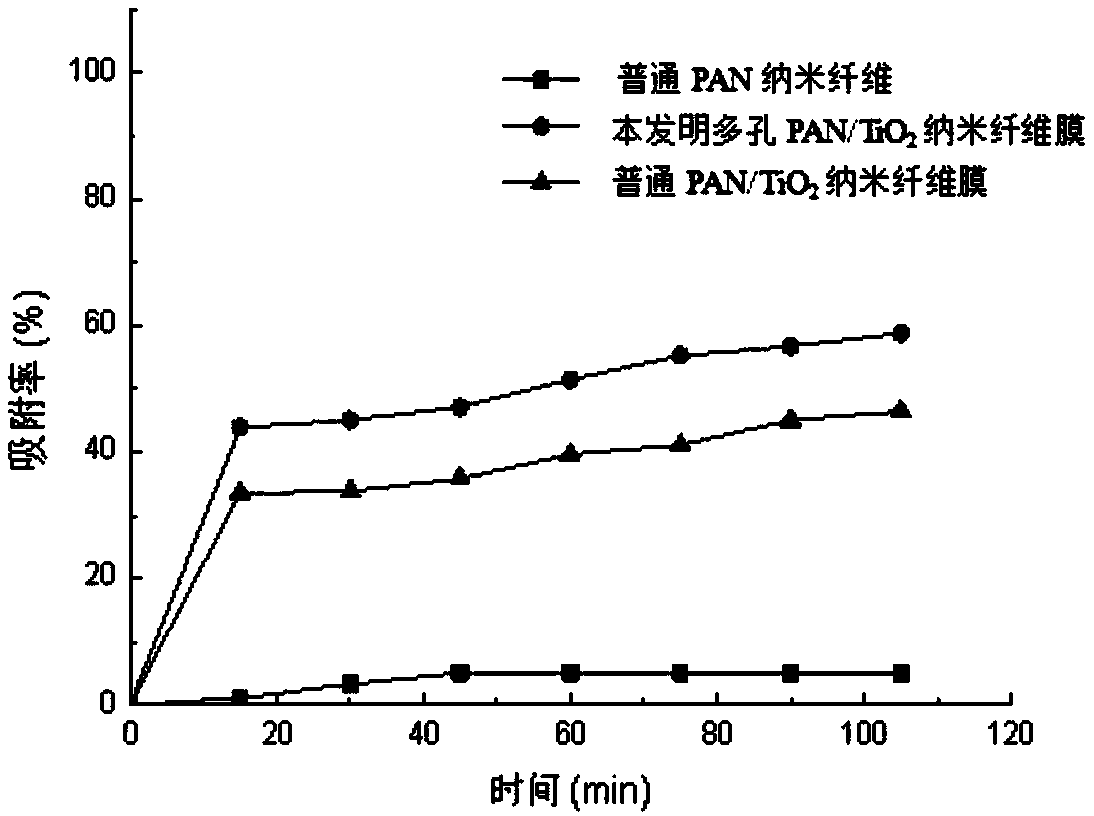

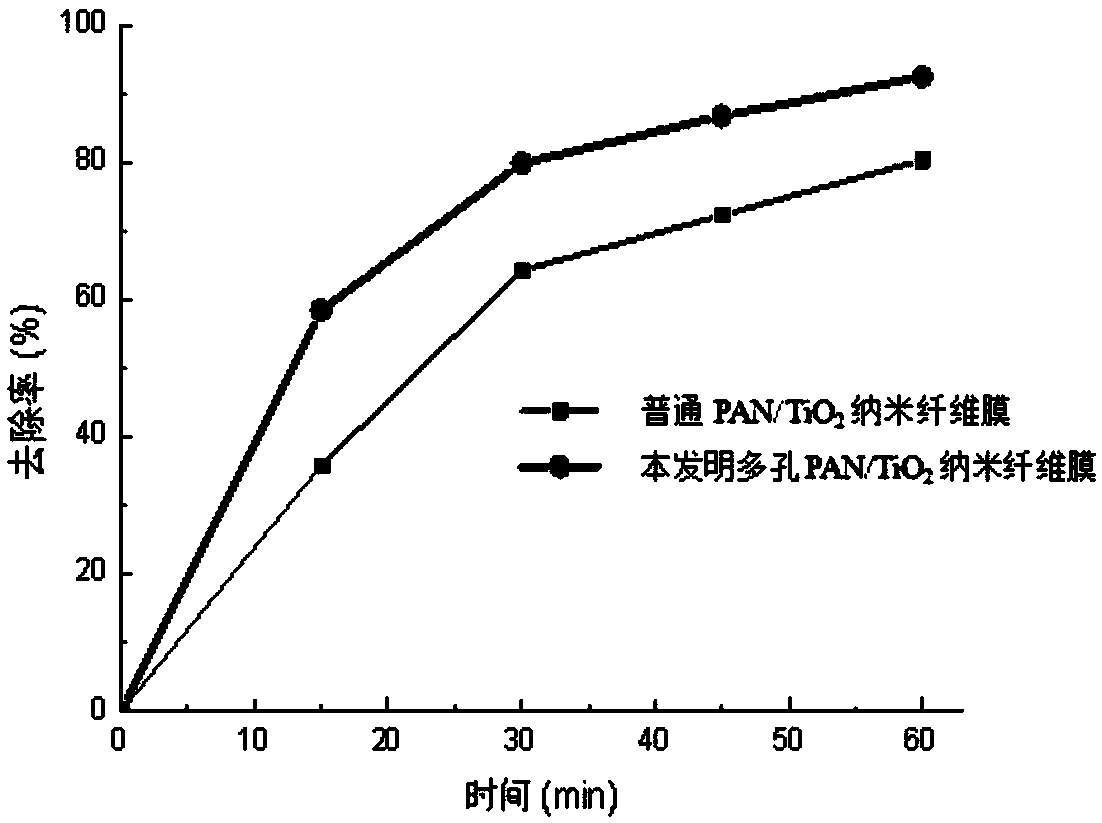

Examples

Embodiment 1

[0040] A method for preparing a porous loaded electrospun nanometer photocatalytic fiber membrane, specifically comprising the following steps:

[0041] (1) Polyacrylonitrile (PAN), polyvinylpyrrolidone (PVP) and nano titanium dioxide (TiO 2 ) are directly dissolved in the solvent together to carry out the configuration of the electrospinning solution, wherein, the relative solvent of PAN is 18wt.%, the relative solvent of PVP is 1wt.%, and nanometer TiO 2 The relative solvent is 6wt.%, and nano-TiO 2 It is anatase type, the particle size is 5nm, and the solvent is dimethylformamide (DMF);

[0042] (2) Vigorously stir the solution in step (1) at a temperature of 40°C for 20 hours, then cool the stirred solution to obtain an electrospinning solution. The electrospinning solution needs to be naturally cooled to room temperature reuse;

[0043] (3) Put the electrospinning solution prepared in the above step (2) into a 5mL syringe, and control the extrusion speed to 0.1mL / h thr...

Embodiment 2

[0049] A method for preparing a porous loaded electrospun nanometer photocatalytic fiber membrane, specifically comprising the following steps:

[0050] (1) Polyacrylonitrile (PAN), polyvinylpyrrolidone (PVP) and nano titanium dioxide (TiO 2 ) are directly dissolved in the solvent together to carry out the configuration of the electrospinning solution, wherein, the relative solvent of PAN is 12wt.%, the relative solvent of PVP is 8wt.%, and nano TiO 2 The relative solvent is 3.5wt.%, and nano-TiO 2 It is anatase type, the particle diameter is 8nm, and the solvent is dimethylacetamide (DMAc);

[0051] (2) Stir the solution in step (1) vigorously at a temperature of 55°C for 15 hours, then cool the stirred solution to obtain an electrospinning solution. The electrospinning solution needs to be naturally cooled to room temperature reuse;

[0052] (3) Put the electrospinning solution prepared in the above step (2) into a 10mL syringe, under the power supply high voltage of 14kV...

Embodiment 3

[0058] A method for preparing a porous loaded electrospun nanometer photocatalytic fiber membrane, specifically comprising the following steps:

[0059] (1) Polyacrylonitrile (PAN), polyvinylpyrrolidone (PVP) and nano titanium dioxide (TiO 2 ) are directly dissolved in the solvent together to carry out the configuration of the electrospinning solution, wherein, the relative solvent of PAN is 6wt.%, the relative solvent of PVP is 14wt.%, and nano TiO 2 The relative solvent is 1wt.%, and nano-TiO 2 It is anatase type, the particle size is 10nm, and the solvent is dimethyl sulfoxide (DMSO);

[0060] (2) Vigorously stir the solution in step (1) at a temperature of 70°C for 10 hours, and then cool the stirred solution to obtain an electrospinning solution. The electrospinning solution needs to be naturally cooled to room temperature reuse;

[0061] (3) Put the electrospinning solution prepared in the above step (2) into a 10mL syringe, under the power supply high voltage 10kV, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com