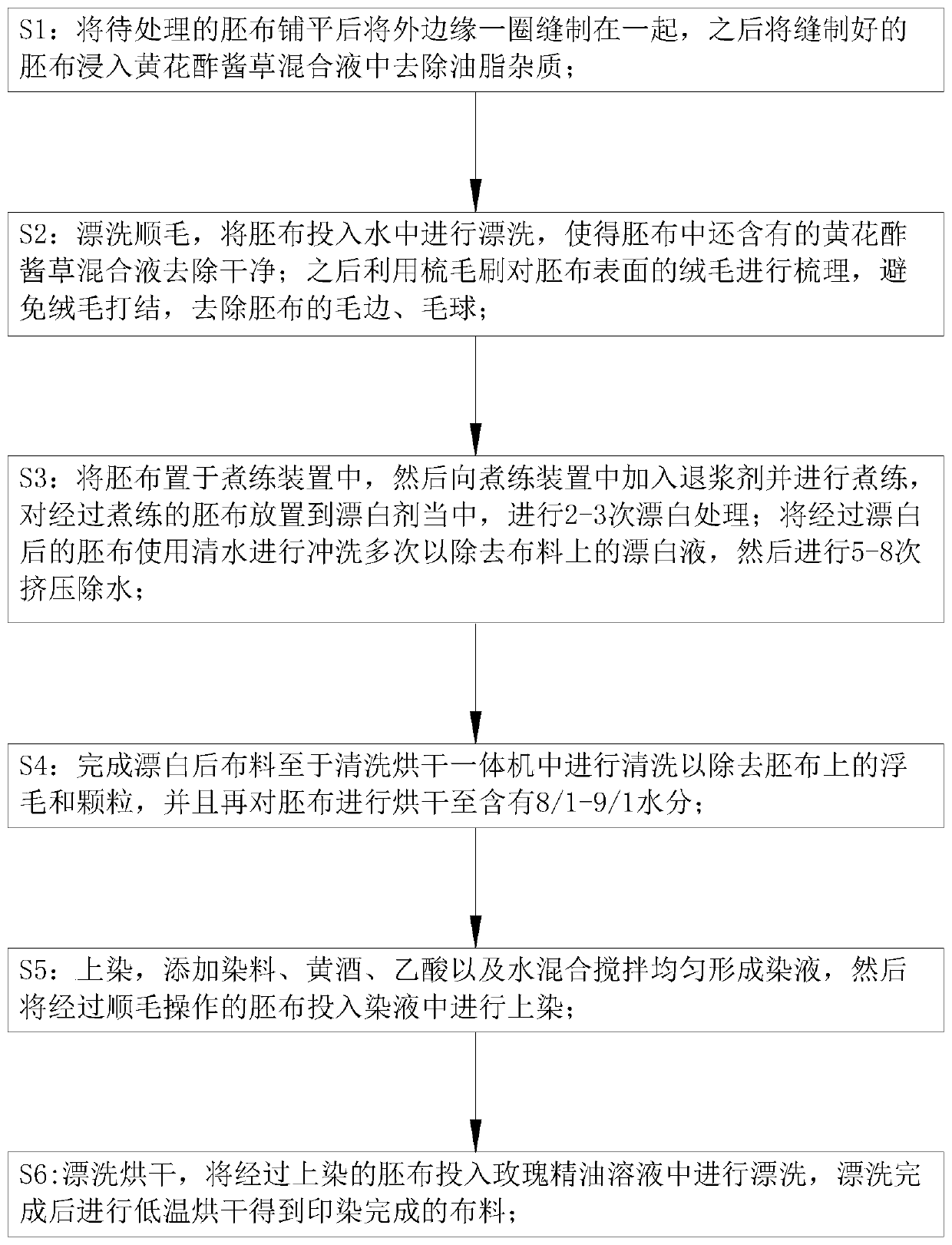

Environment-friendly energy-saving cloth printing and dyeing process

An environmental protection, energy saving, printing and dyeing process technology, applied in the field of textile printing and dyeing, can solve the problems of consuming large desizing agents, increasing the failure rate of desizing devices, increasing pollution, etc., and achieve the effect of increasing desizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

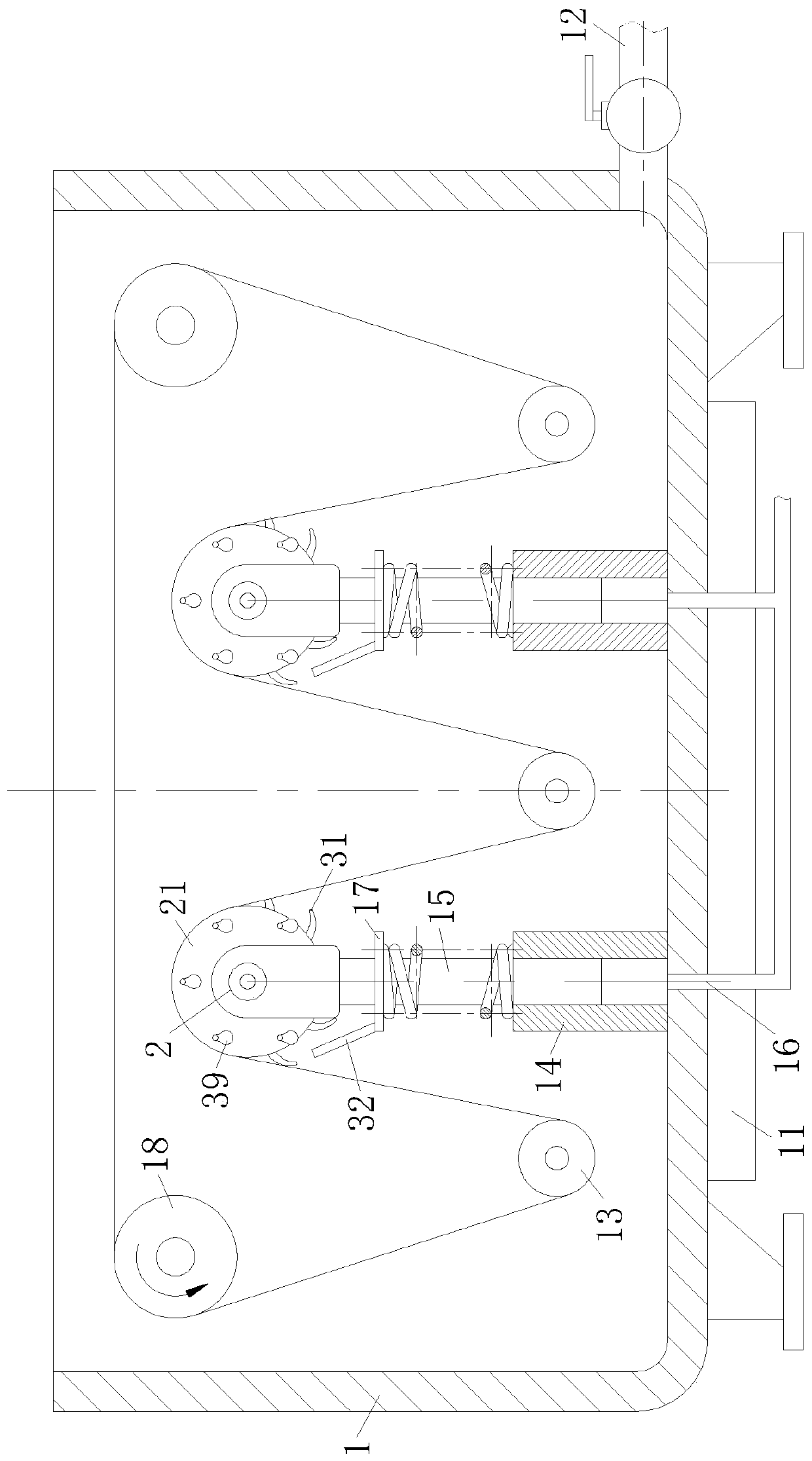

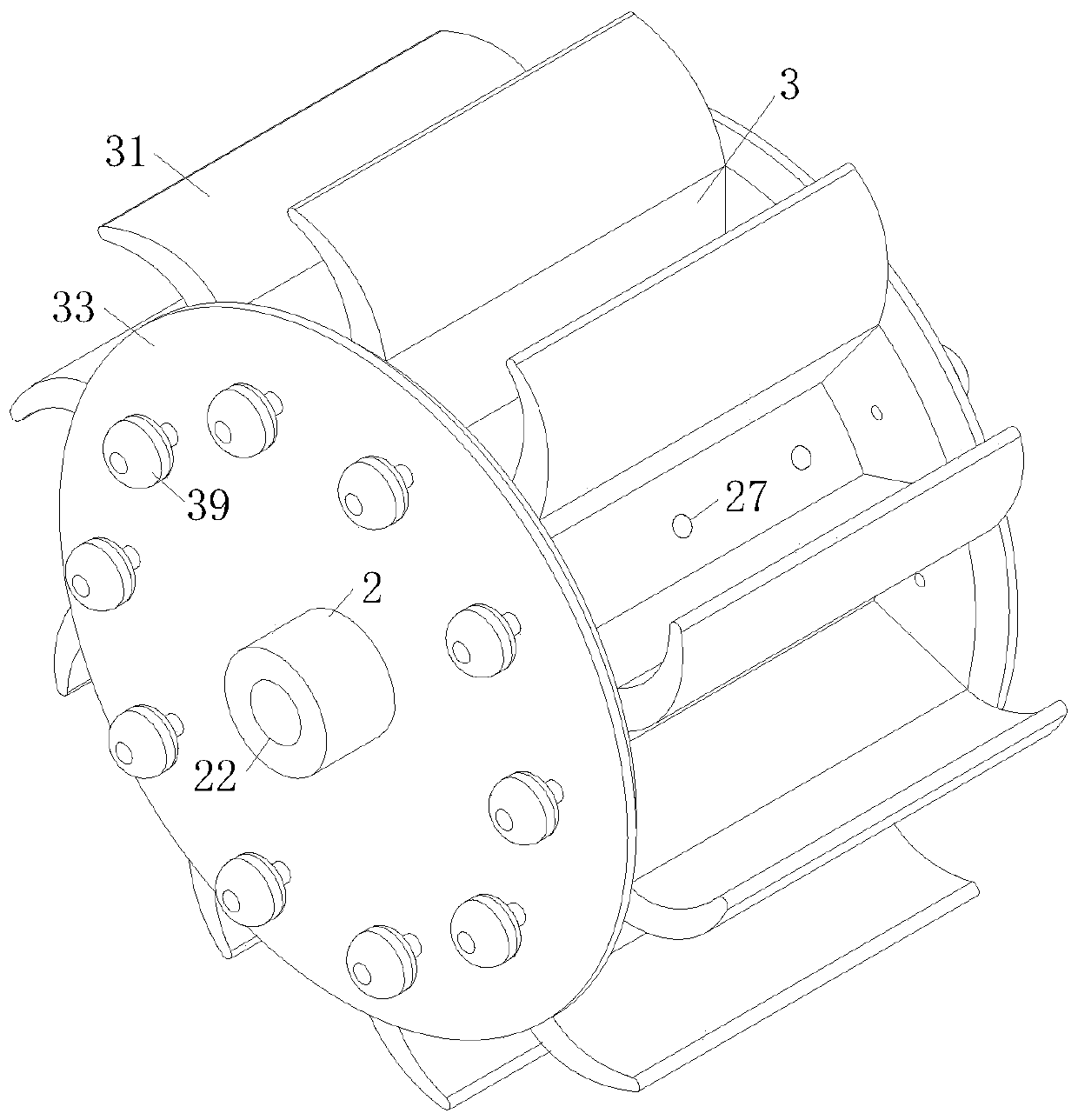

[0042] As an embodiment of the present invention, a group of blades 3 are evenly distributed on the periphery of the tension roller 21, and the blades 3 are used to increase the circulation speed of the desizing agent in the pool body 1, thereby further increasing the desizing efficiency of the gray cloth; When the tension roller 21 rotates continuously under the drive of the gray cloth, the tension roller 21 drives the blade 3 to rotate continuously, thereby causing the blade 3 to continuously stir the aqueous solution in the pool body 1 to ensure that the concentration of the aqueous solution in the pool body 1 is uniform, thereby preventing the gray cloth from The concentration of the nearby aqueous solution decreases, which affects the desizing efficiency of the gray cloth.

[0043] As an embodiment of the present invention, the end of the blade 3 away from the tension roller 21 is fixedly connected with a shrapnel 31; It is used to store energy for the rotating shrapnel 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com