A kind of environment-friendly desizing agent for high-density polyester fabric and preparation method thereof

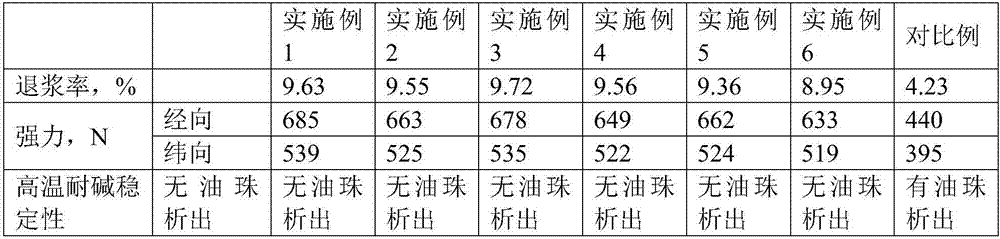

A polyester fabric, high-density technology, applied in textiles, papermaking, dry-cleaning fiber products, etc., can solve the problems of fabric damage, poor high temperature stability, etc., reduce surface tension, improve high temperature resistance and strong alkali resistance, and good desizing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

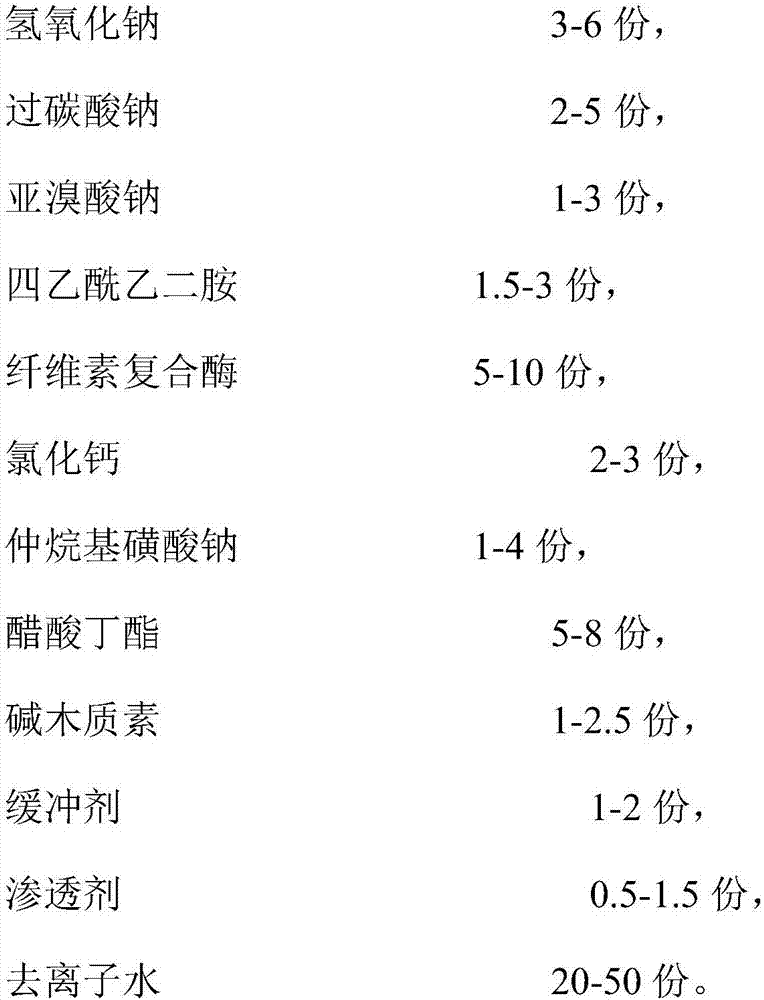

[0025] An environment-friendly desizing agent for high-density polyester fabrics, in parts by weight, comprising the following components:

[0026] 3 parts of sodium hydroxide, 2 parts of sodium percarbonate,

[0027] 1 part of sodium bromite, 1.5 parts of tetraacetylethylenediamine,

[0028] 5 parts of cellulose compound enzyme, 2 parts of calcium chloride,

[0029] 1 part of sodium secondary alkyl sulfonate, 5 parts of butyl acetate,

[0030] 1 part of alkali lignin, 1 part of buffer,

[0031] Penetrant 0.5 parts, deionized water 20 parts.

[0032] Its preparation method comprises the following steps:

[0033] (1) Mix and stir sodium hydroxide, sodium bromite, calcium chloride and deionized water evenly to obtain a mixed solution, transfer the mixed solution to a reaction kettle, add tetraacetylethylenediamine, sodium secondary alkylsulfonate , butyl acetate, alkali lignin and penetrant, heated up to 40-50°C, treated at a constant temperature for 1 hour, cooled down to ...

Embodiment 2

[0036] An environment-friendly desizing agent for high-density polyester fabrics, in parts by weight, comprising the following components:

[0037] 6 parts of sodium hydroxide, 5 parts of sodium percarbonate,

[0038] 3 parts of sodium bromite, 3 parts of tetraacetylethylenediamine,

[0039] 10 parts of cellulose compound enzyme, 3 parts of calcium chloride,

[0040] 4 parts of sodium secondary alkyl sulfonate, 8 parts of butyl acetate,

[0041] 2.5 parts of alkali lignin, 2 parts of buffer,

[0042] 1.5 parts of penetrant, 50 parts of deionized water.

[0043] Its preparation method comprises the following steps:

[0044] (1) Mix and stir sodium hydroxide, sodium bromite, calcium chloride and deionized water evenly to obtain a mixed solution, transfer the mixed solution to a reaction kettle, add tetraacetylethylenediamine, sodium secondary alkylsulfonate , butyl acetate, alkali lignin and penetrant, heated up to 40-50°C, treated at a constant temperature for 3 hours, and...

Embodiment 3

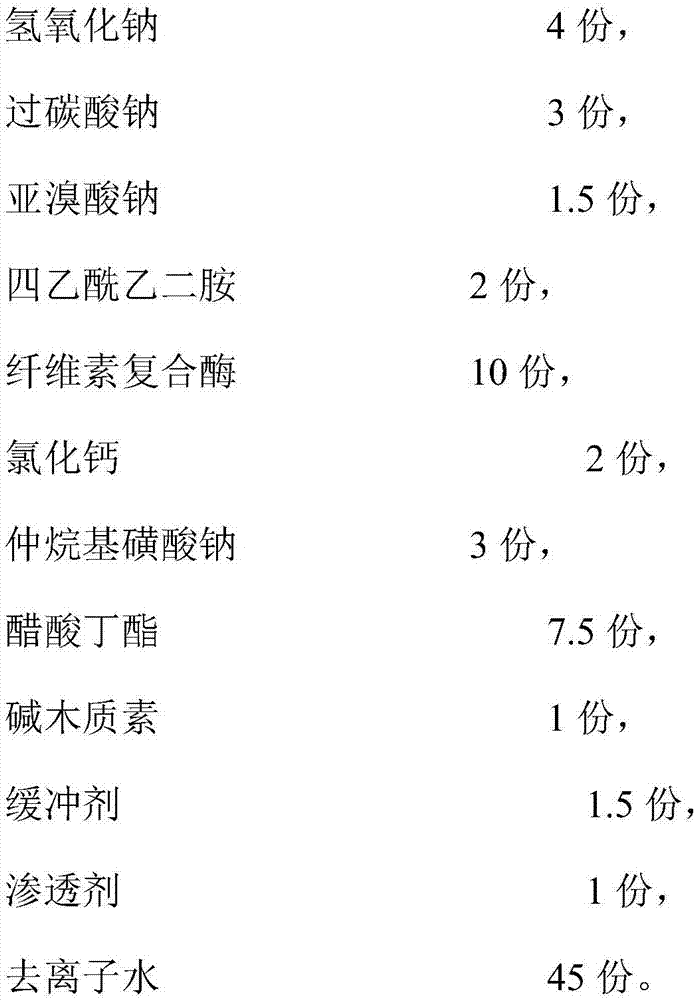

[0047] An environment-friendly desizing agent for high-density polyester fabrics, in parts by weight, comprising the following components:

[0048] 4 parts of sodium hydroxide, 3 parts of sodium percarbonate,

[0049] 1.5 parts of sodium bromite, 2 parts of tetraacetylethylenediamine,

[0050] 10 parts of cellulose compound enzyme, 2 parts of calcium chloride,

[0051] 3 parts of sodium secondary alkyl sulfonate, 7.5 parts of butyl acetate,

[0052] 1 part of alkali lignin, 1.5 parts of buffer,

[0053] 1 part of penetrant, 45 parts of deionized water.

[0054] Its preparation method comprises the following steps:

[0055] (1) Mix and stir sodium hydroxide, sodium bromite, calcium chloride and deionized water evenly to obtain a mixed solution, transfer the mixed solution to a reaction kettle, add tetraacetylethylenediamine, sodium secondary alkylsulfonate , butyl acetate, alkali lignin and penetrant, heated up to 40-50°C, treated at a constant temperature for 1.5h, cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com