Patents

Literature

49results about How to "Easy to clamp limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

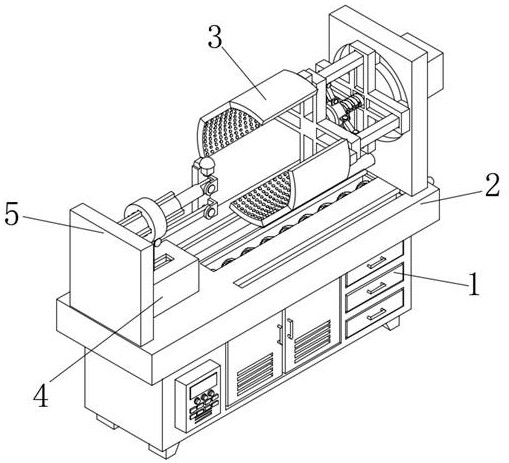

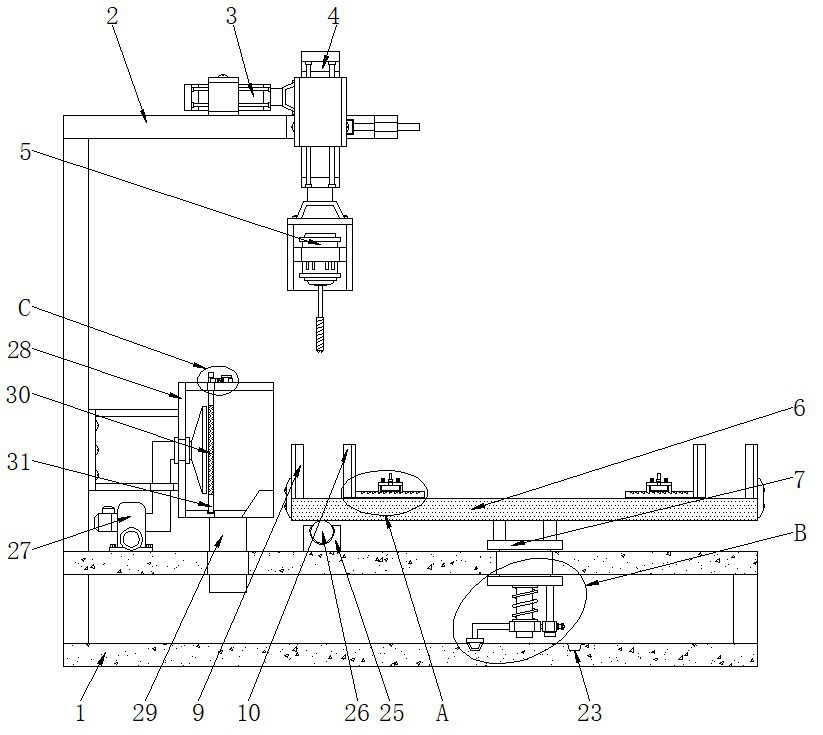

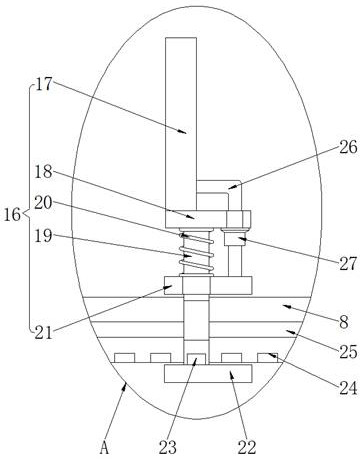

Medical test tube cleaning device

InactiveCN108526153AQuality improvementImprove accuracyHollow article cleaningChemicalsEngineeringTube cleaning

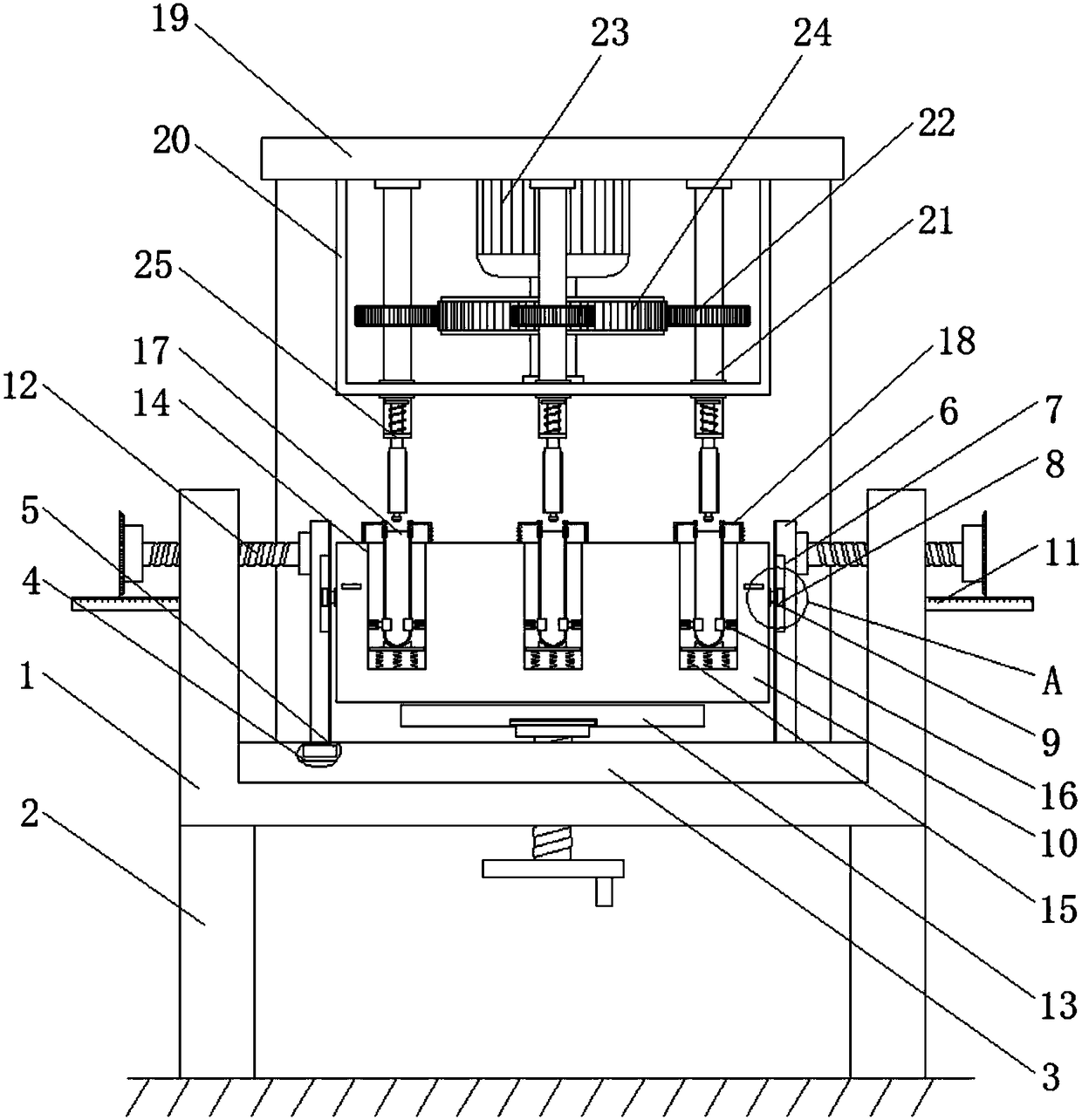

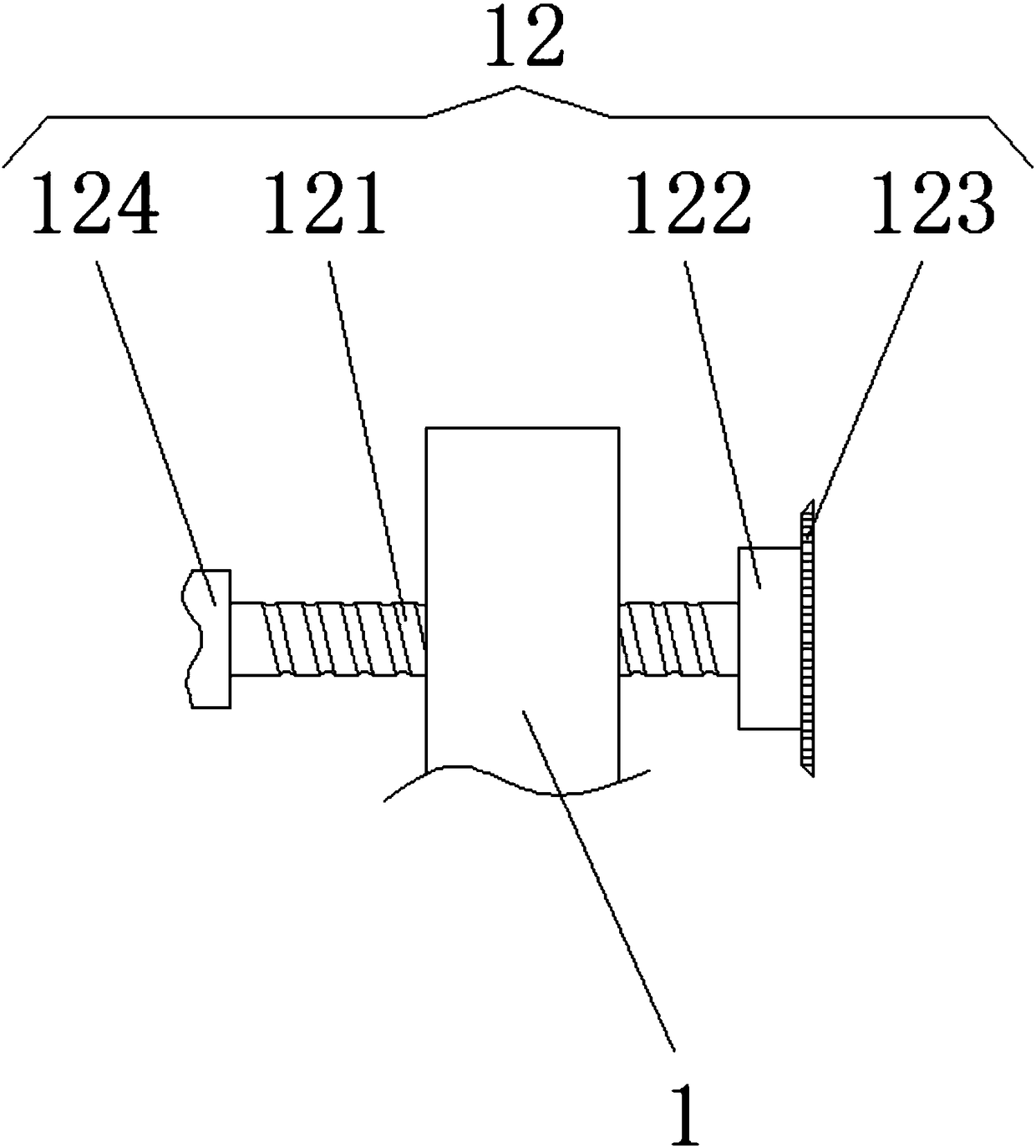

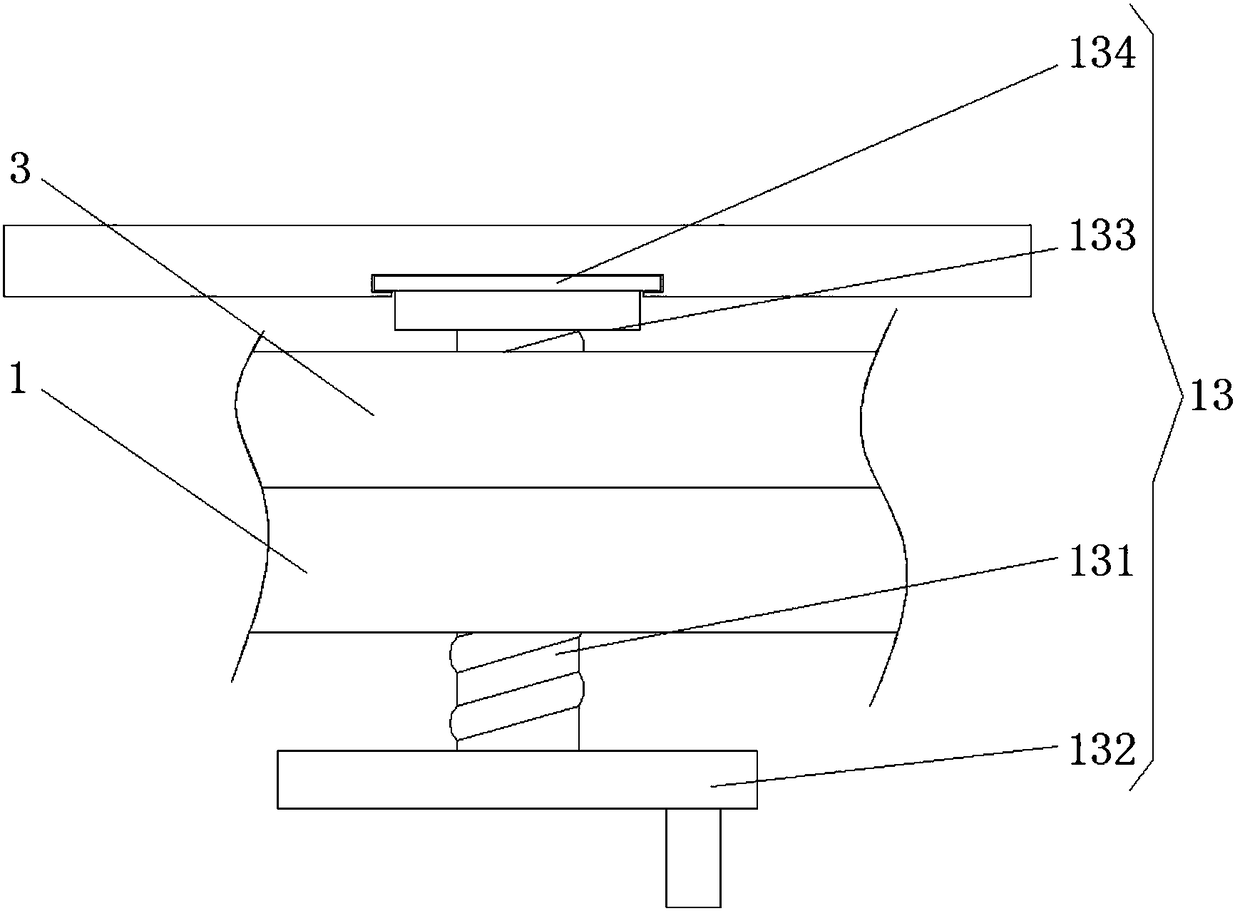

The invention relates to the technical field of medical instrument cleaning equipment, and discloses a medical test tube cleaning device. The medical test tube cleaning device comprises a supporting base, supporting legs are fixedly installed on the two sides of the bottom of the supporting base, and a limiting strip is fixedly installed at the bottom of an inner cavity of the supporting base. According to the medical test tube cleaning device, an adjusting device is arranged to cooperate with a measuring scale for calibration adjusting, accordingly, the situation that after medical test tubesare cleaned for a long time, the positions of the medical test tubes and the position of a cleaning device deviate is avoided, the positions of the medical test tubes are regularly adjusted, the effect that positions of the medical test tubes are relatively perpendicular to the positions of cleaning brushes, thus, the inner cleaning quality of the medical test tubes is improved, and the accuracyof the detection result is improved; and through the adjusting effect of a boosting device and the limiting effect of limiting blocks and limiting grooves, an object stage can be adjusted to integrally move upwards conveniently, the medical test tubes are conveniently pushed upwards to coincide with the cleaning brushes, and the cleaning brushes can conveniently conduct brushing.

Owner:严涛

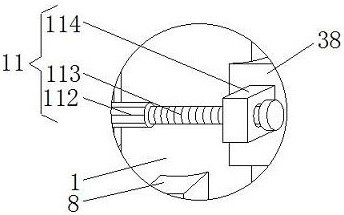

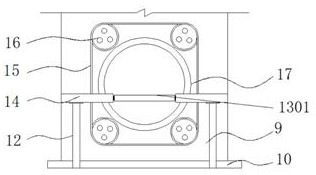

Tensioning type clamp capable of accurately positioning and clamping for piston machining

ActiveCN112059668AAdjustable distanceEasy to storePositioning apparatusMetal-working holdersClassical mechanicsMachining

The invention discloses a tensioning type clamp capable of accurately positioning and clamping for piston machining, and relates to the technical field of piston machining. The tensioning type clamp comprises a main body support frame and a bracket, wherein connecting blocks are arranged at the two ends of the interior of the main body support frame, and rotating shafts are mounted in the connecting blocks. Through the arrangement of a tensioning device, a second hydraulic air rod, a transverse plate, an inner cavity, a third hydraulic air rod and clamping plates, the distance between the twoclamping plates can be adjusted leftwards and rightwards under the action of the third hydraulic air rod in the inner cavity in the using process, an object placed between the two clamping plates canbe fixed, and then the clamped object can be tensioned again through the interaction of the tensioning device, the second hydraulic air rod and the transverse plate, the structure is clear, a user canconveniently overhaul and maintain the object in the later period, meanwhile, the tensioning device can move in the vertical direction of a side-arranged sliding groove, so that shaking of the position when the object is tensioned is effectively avoided.

Owner:扬州市凯峰达物资有限公司

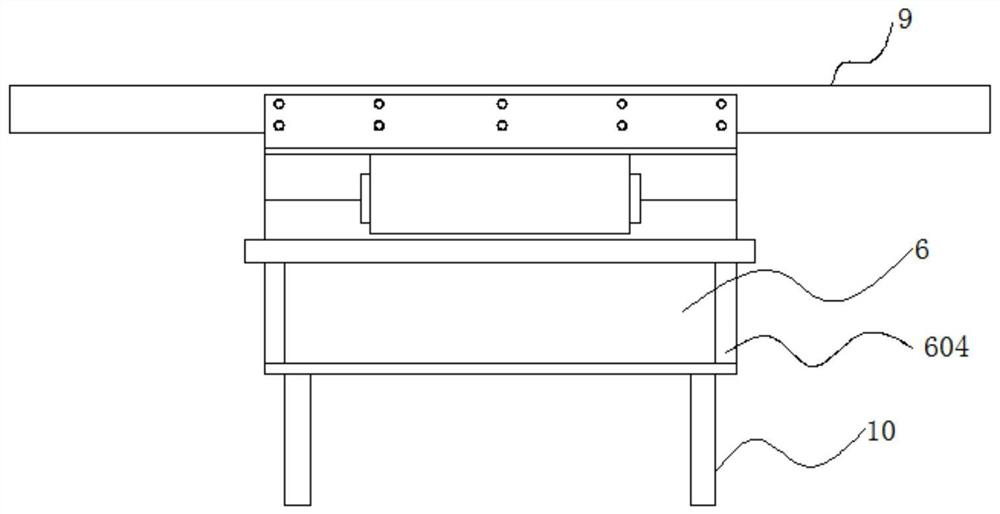

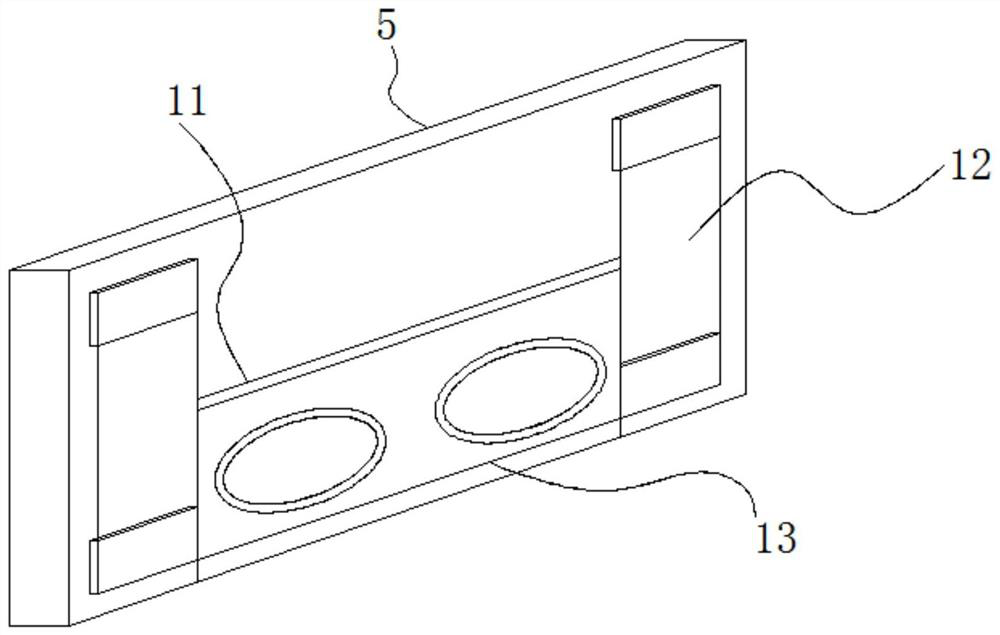

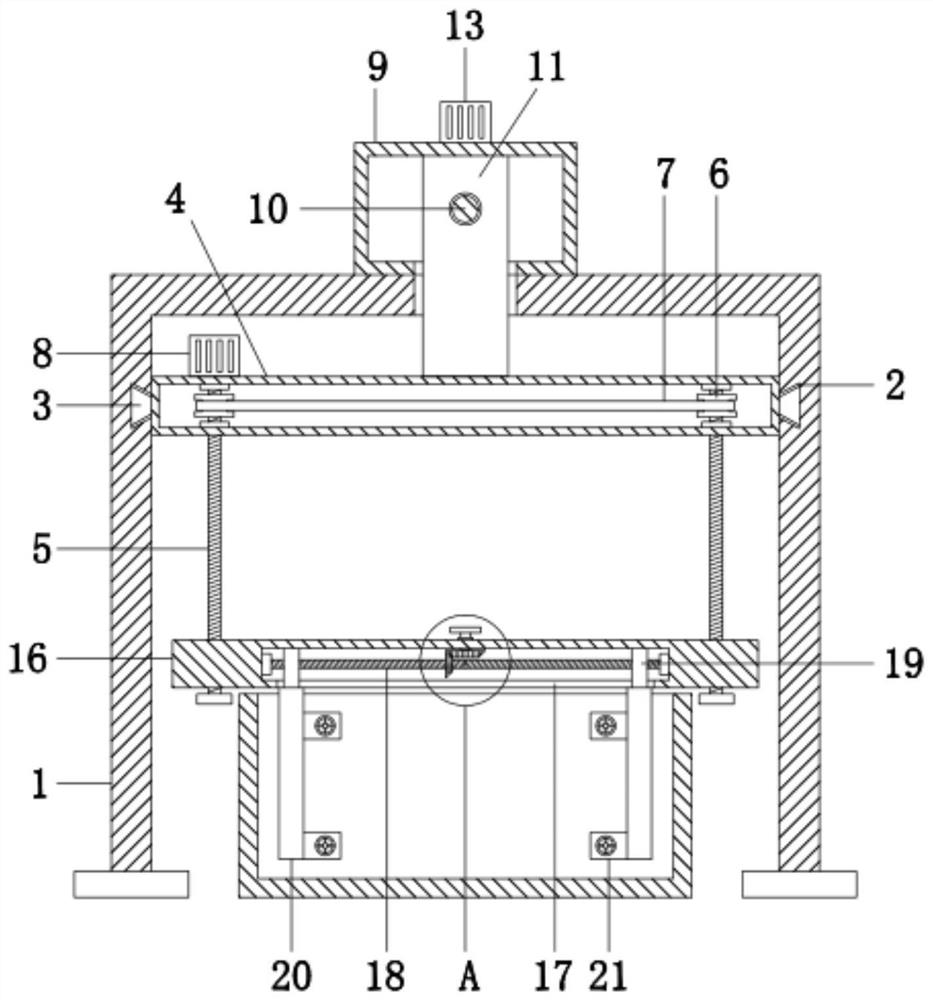

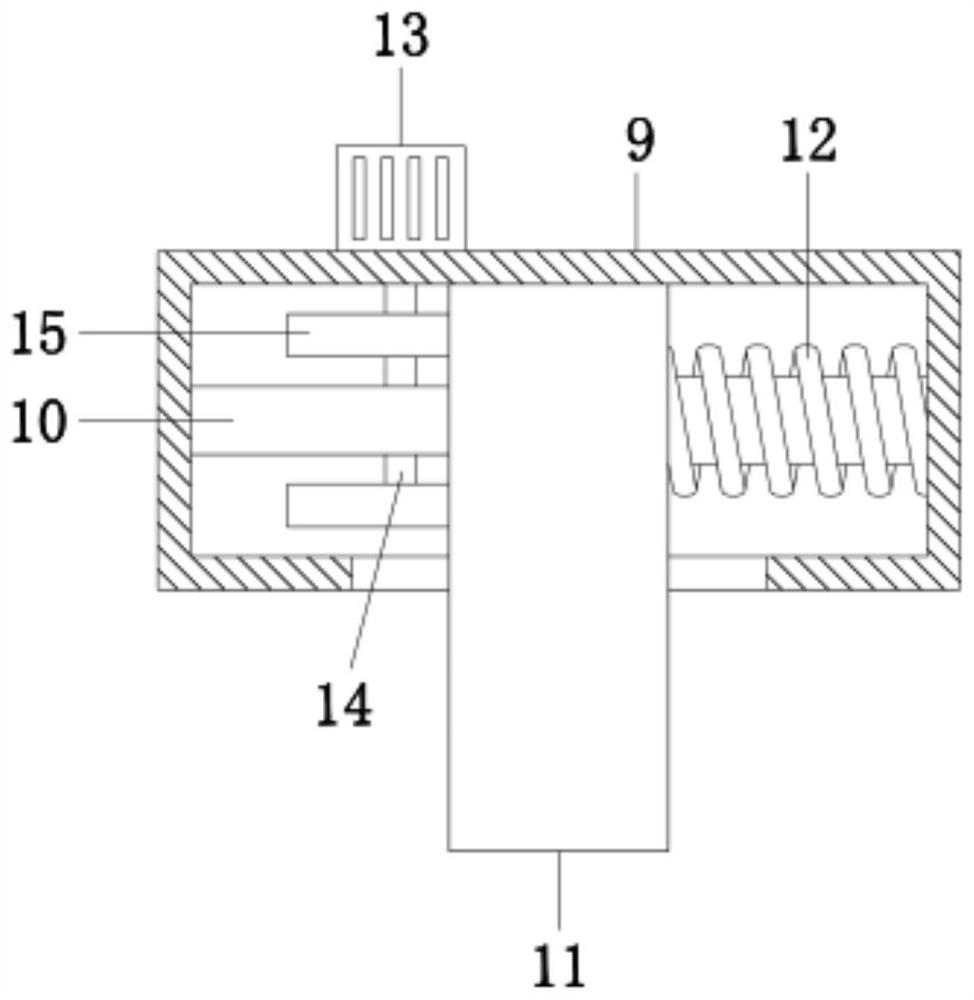

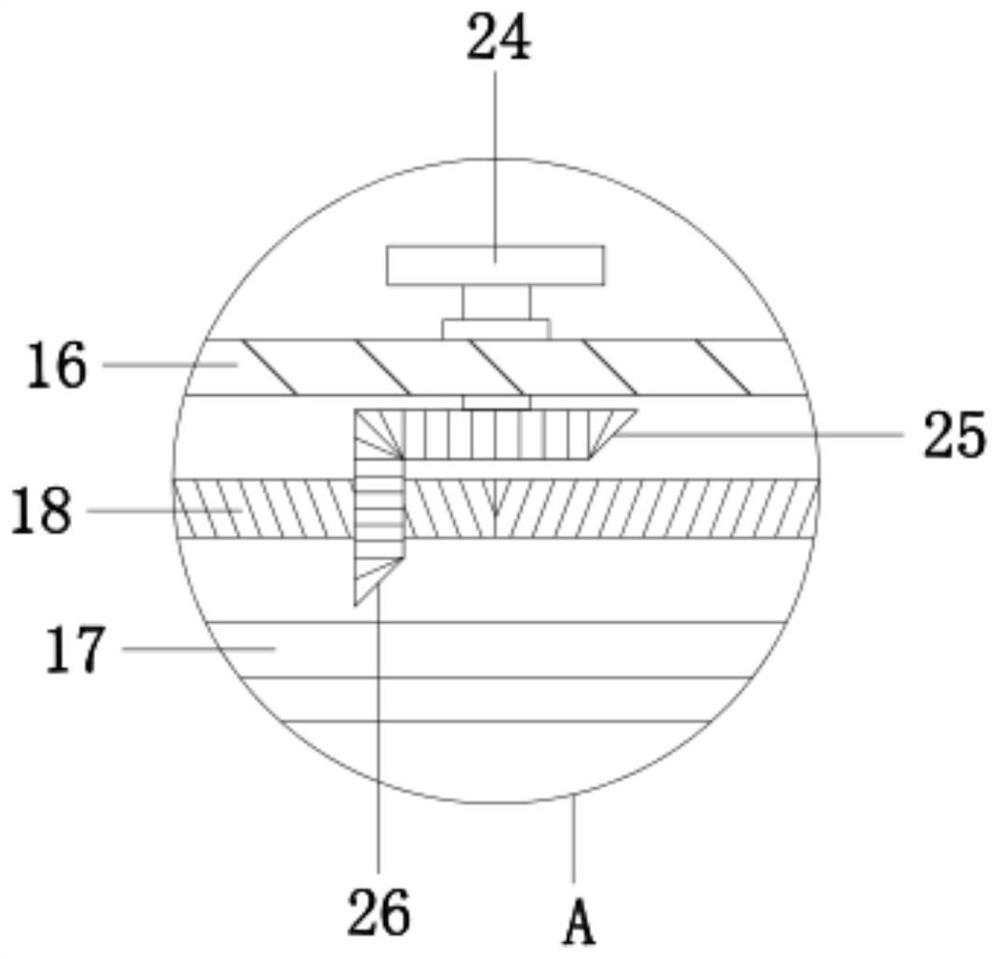

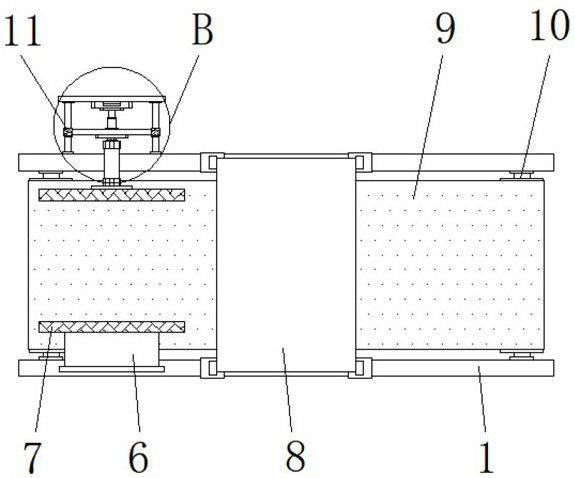

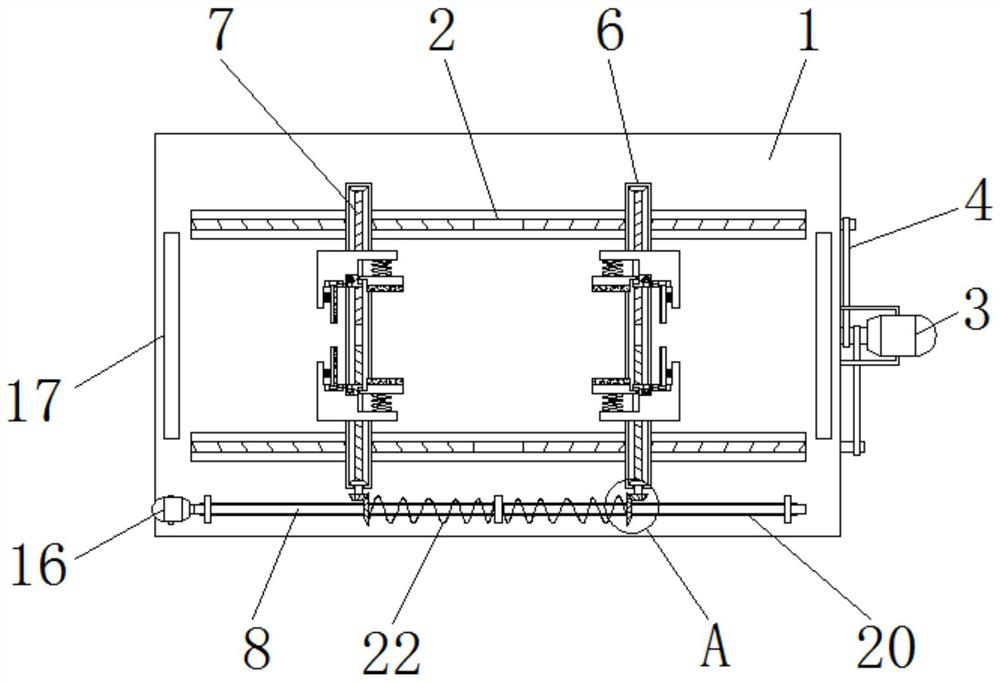

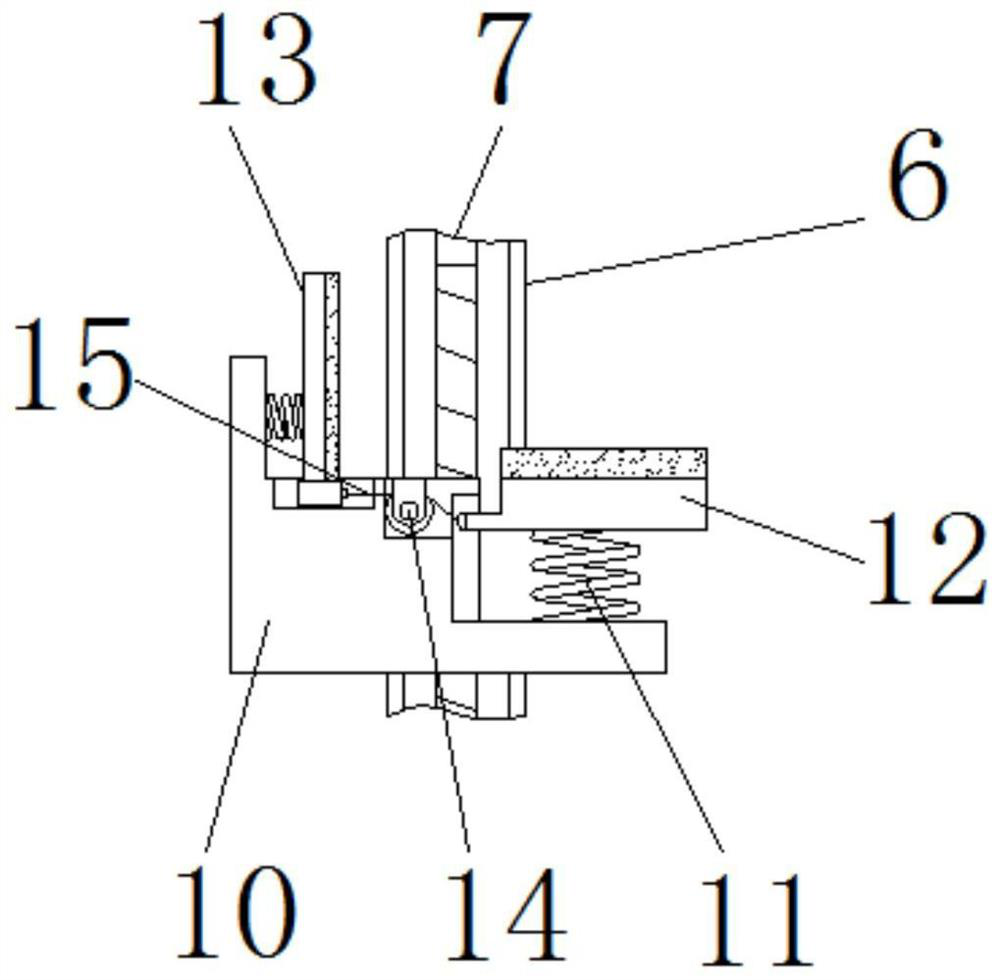

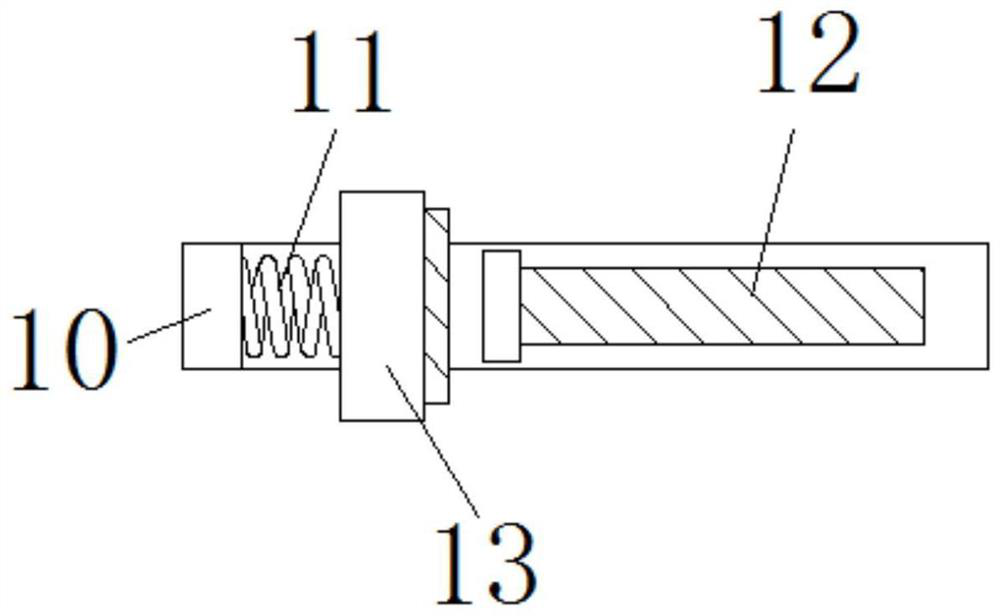

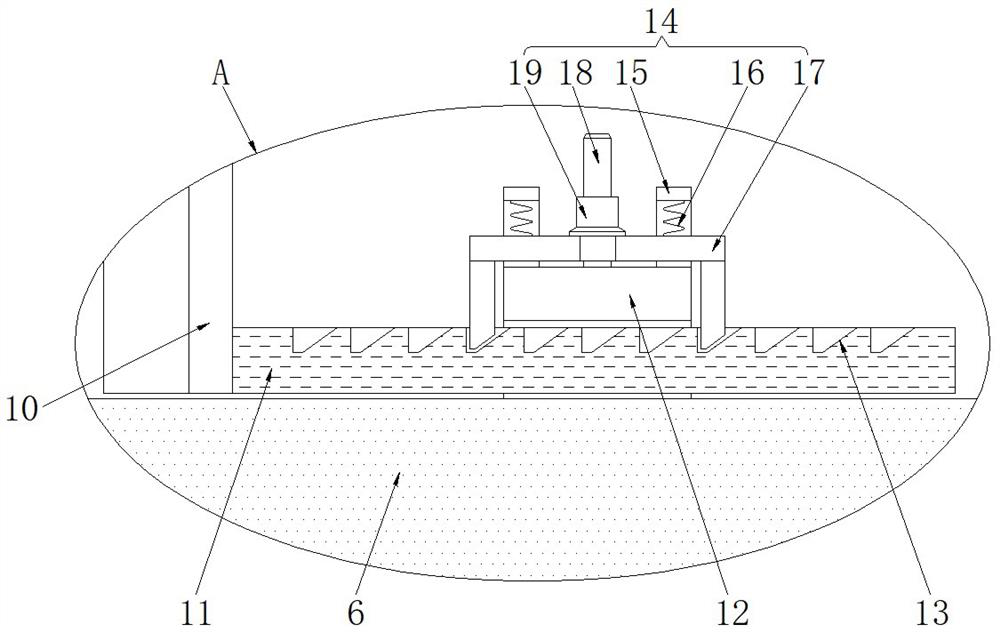

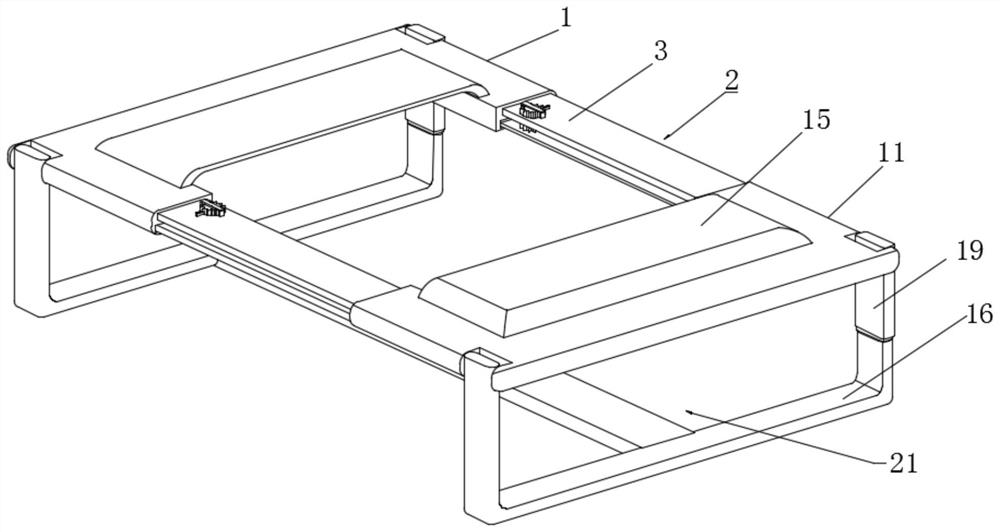

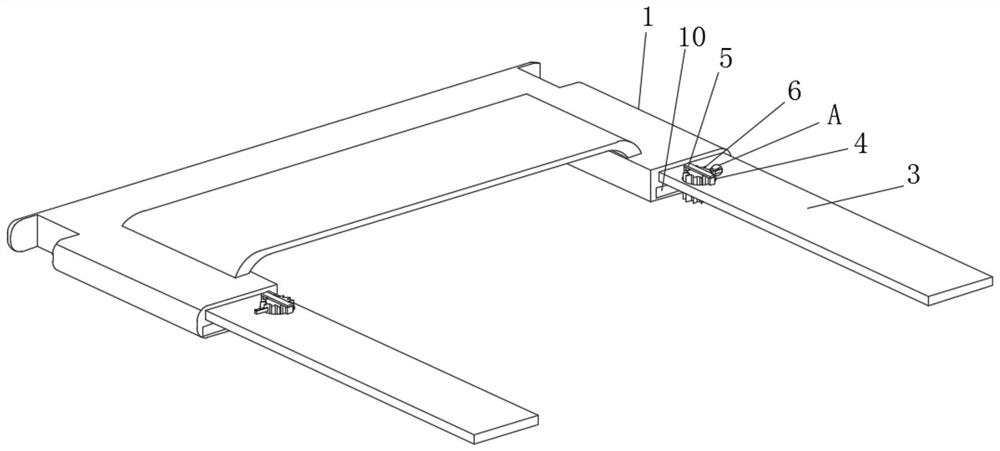

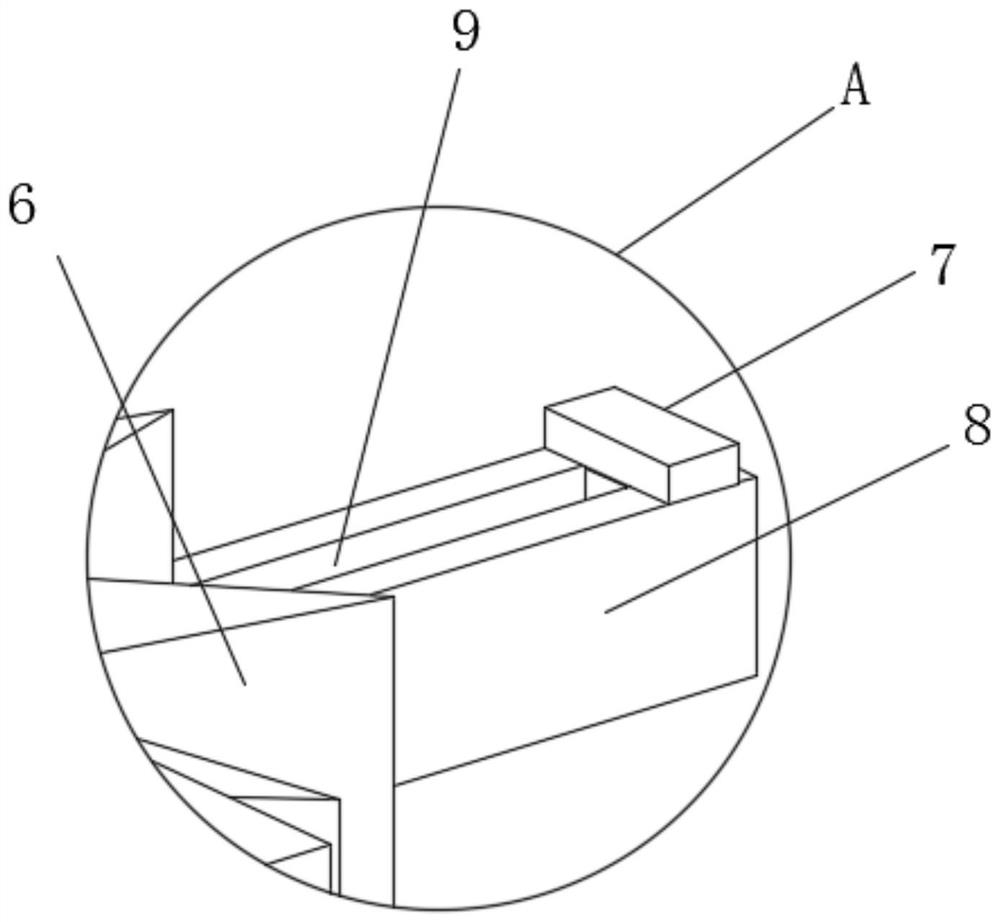

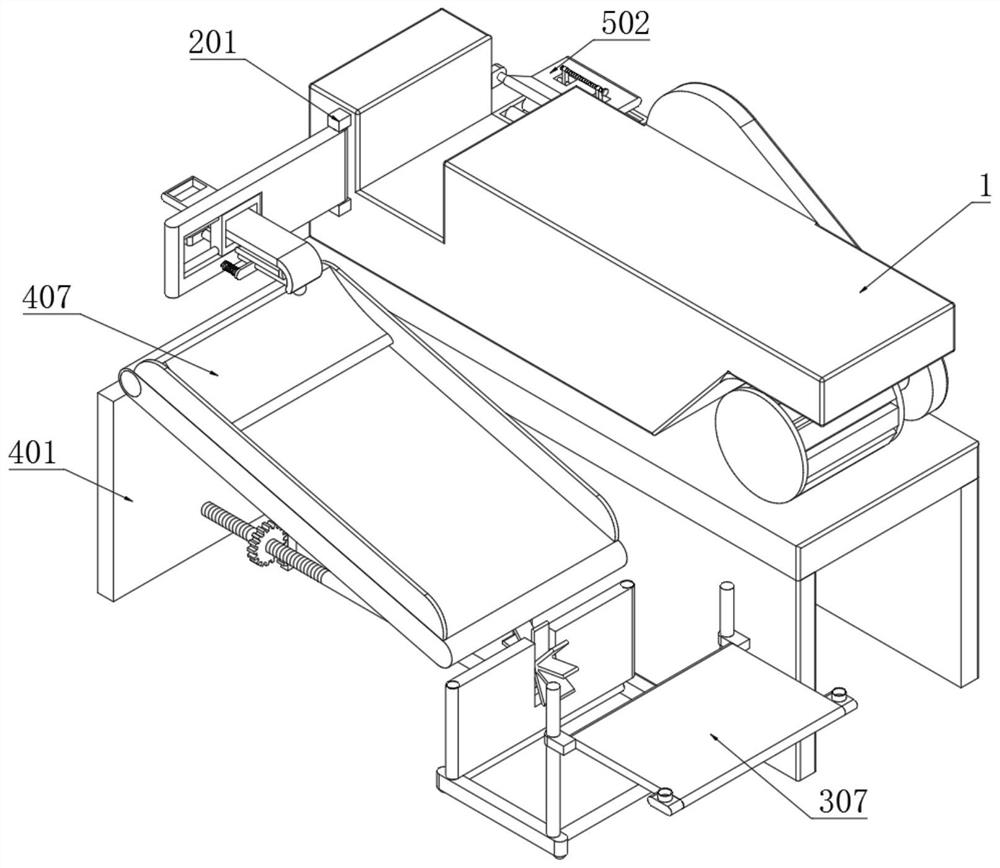

Textile fabric desizing equipment for textile use

InactiveCN111648074AEasy to clamp limitMeet the needs of useTextile treatment machine arrangementsTextile treatment carriersStructural engineeringDesizing

The invention discloses textile fabric desizing equipment for textile use. The textile fabric desizing equipment for textile use comprises a concave rack, two chutes, slide blocks, a hollow plate, first screws, a belt wheel, a belt, a first motor, a reciprocating mechanism and a clamping mechanism, wherein a port is formed in the top end of the concave rack; the two chutes are separately formed inthe top ends of the left and right sides of an inner cavity of the concave rack in a front-back direction; the slide blocks are embedded into the inner cavities of the chutes and the inner sides of the slide blocks extend outside the chutes; a hollow plate is fixedly mounted inside the slide blocks and connects the two slide blocks; and the two first screws are separately mounted on the left andright sides of the top end of the inner cavity of the hollow plate through a bearing, and the bottom ends of the first screws extend outside the hollow plate. According to the textile fabric desizingequipment for textile use, a textile fabric impregnated in a desizing liquid moves in a reciprocating manner, so that the desizing effect is improved and the desizing time is shortened. The textile fabric desizing equipment for textile use can be convenient to clamp and limit textile fabrics of different widths, so that the using demand of an enterprise is met, and the textile fabric desizing equipment for textile use is widely popularized favorably.

Owner:新昌县才珏纺织机械有限公司

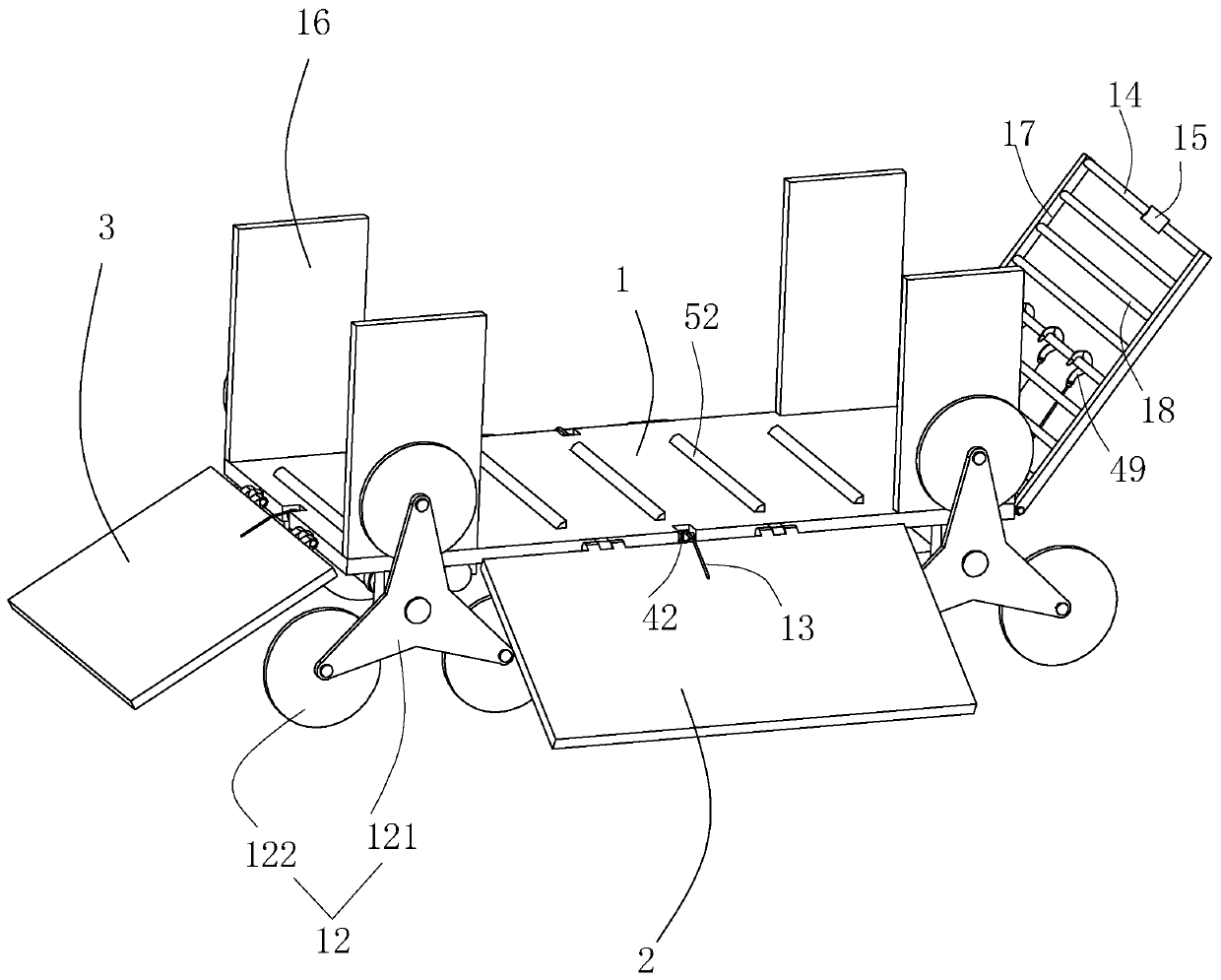

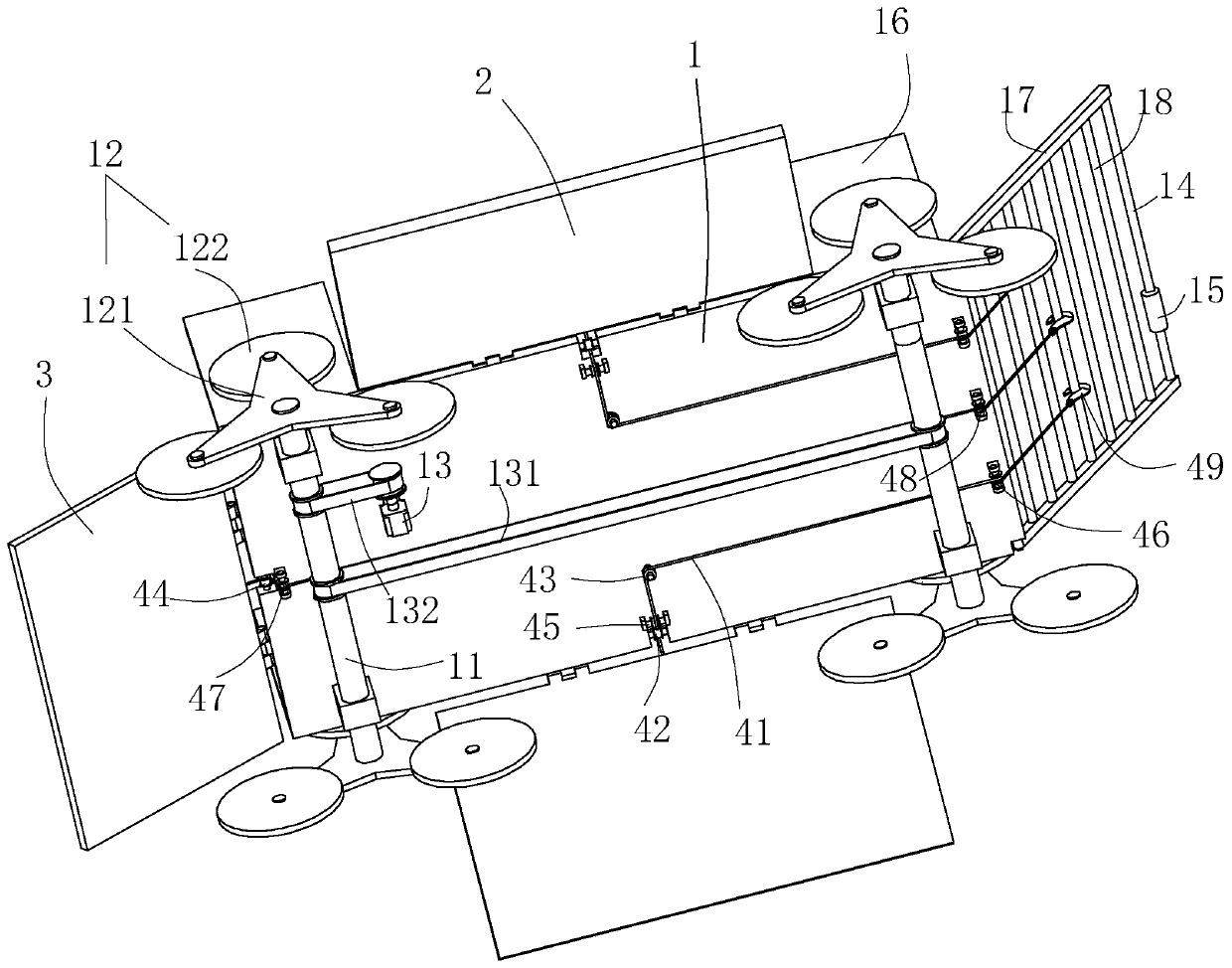

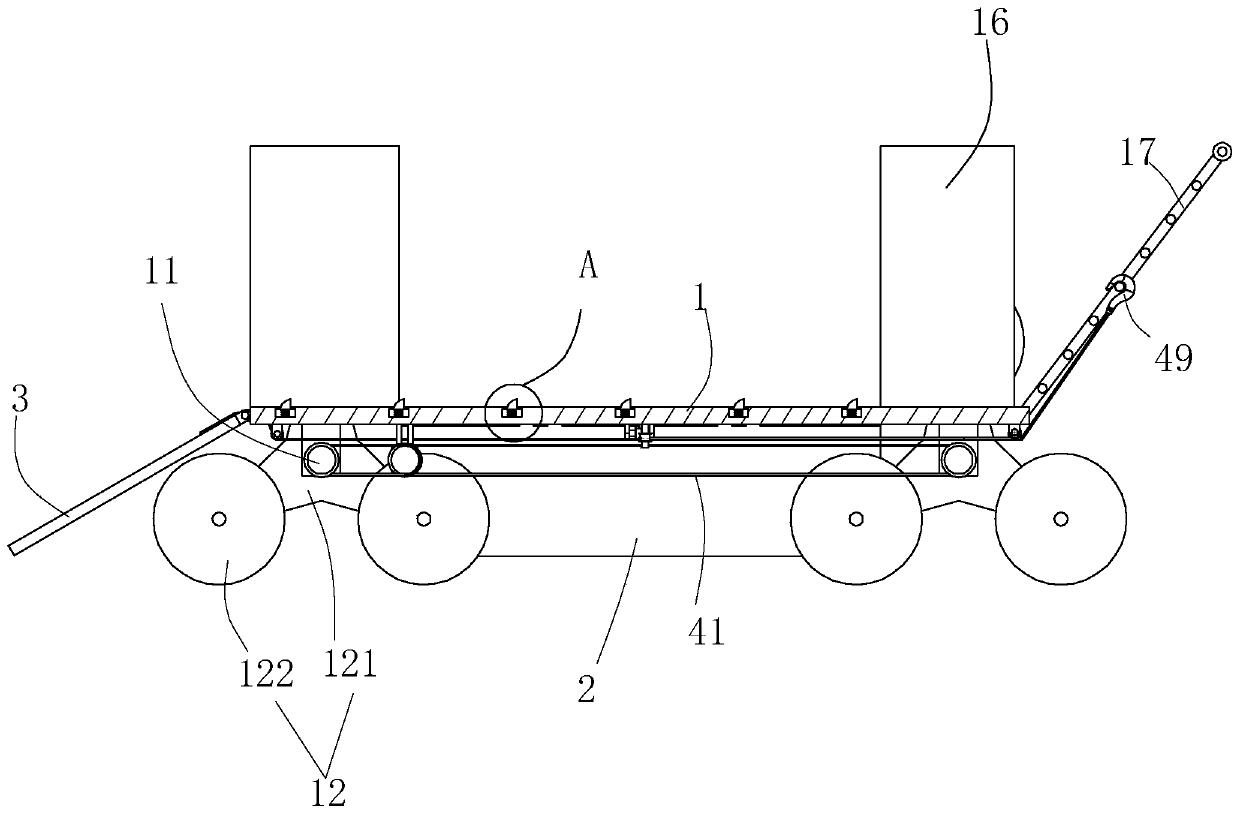

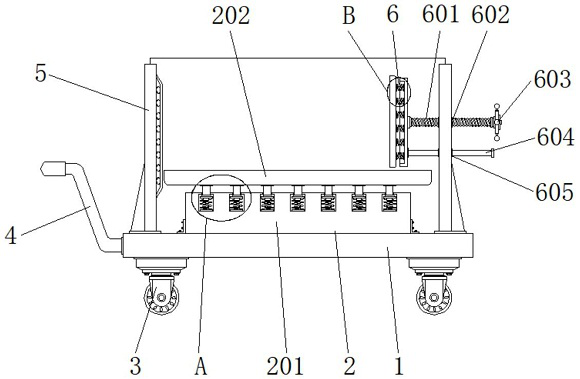

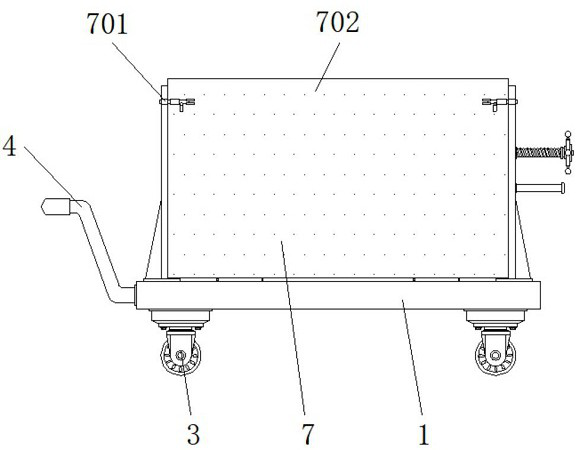

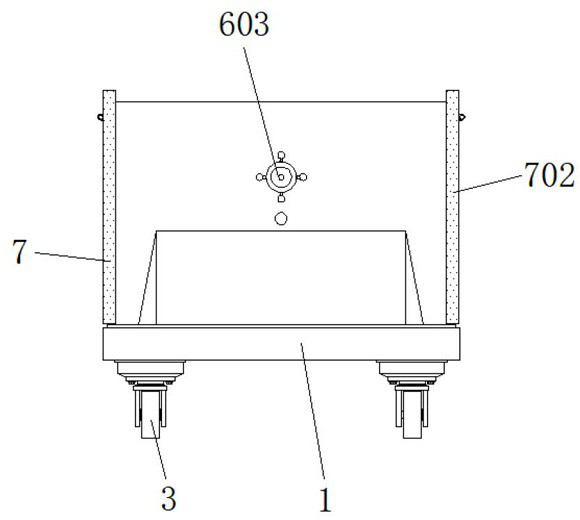

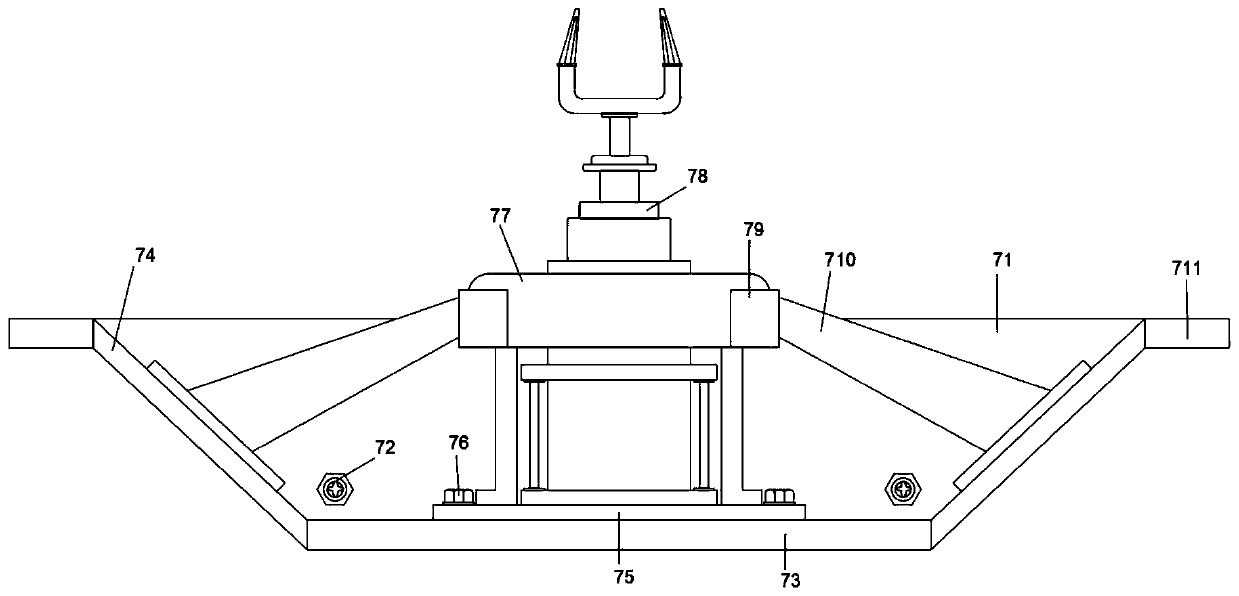

Electric power assisted carrying device for stair

InactiveCN110155136AReduce manual laborEasy to load and unload goodsHand carts with multiple axesHand cart accessoriesEngineeringHeavy load

The invention relates to an electric power assisted carrying device for a stair. The electric power assisted carrying device comprises a rack, wherein the two ends of the lower end surface of the rackare rotatably connected with axles; the two ends of each axle are coaxially rotatably provided with triangular wheel assemblies; a drive device for driving the axles to rotate is mounted on the rack;the front end of the rack is fixed with a holding handle; a controller for controlling rotation speed of the drive device is mounted on the holding handle; the two sides and the rear end of the rackare rotatably hinged with side baffle plates and a rear baffle plate separately; and a traction device for controlling rotation angles of the side baffle plates and a rotation angle of the rear baffleplate is mounted on the rack. In this way, the traction device, the side baffle plates and the rear baffle plate are matched, so that a user conveniently loads and unloads goods from multiple directions of the rack; when the side baffle plates and the rear baffle plate abut against ground, goods can be loaded and unloaded from an inclined surface formed by the side baffle plates and the rear baffle plate, so that a function of conveniently loading and unloading heavy things is realized; and the drive device drives the triangular wheel assemblies to rotate, so that the function of reducing manual labor while heavy things are carried on the stair is realized.

Owner:广东汉威城建有限公司

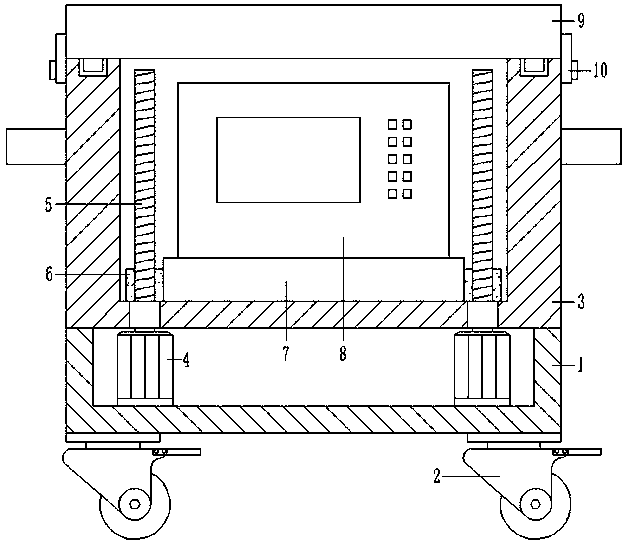

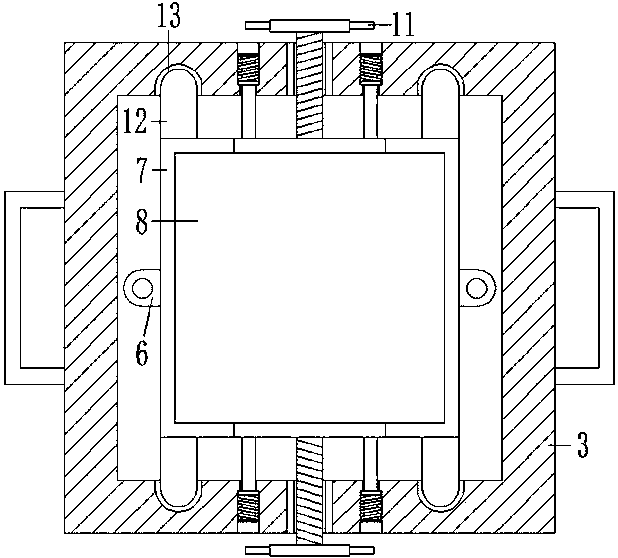

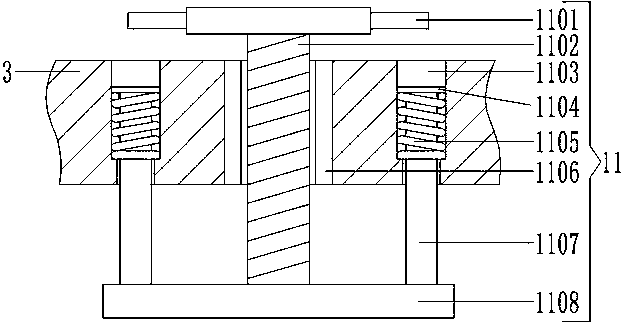

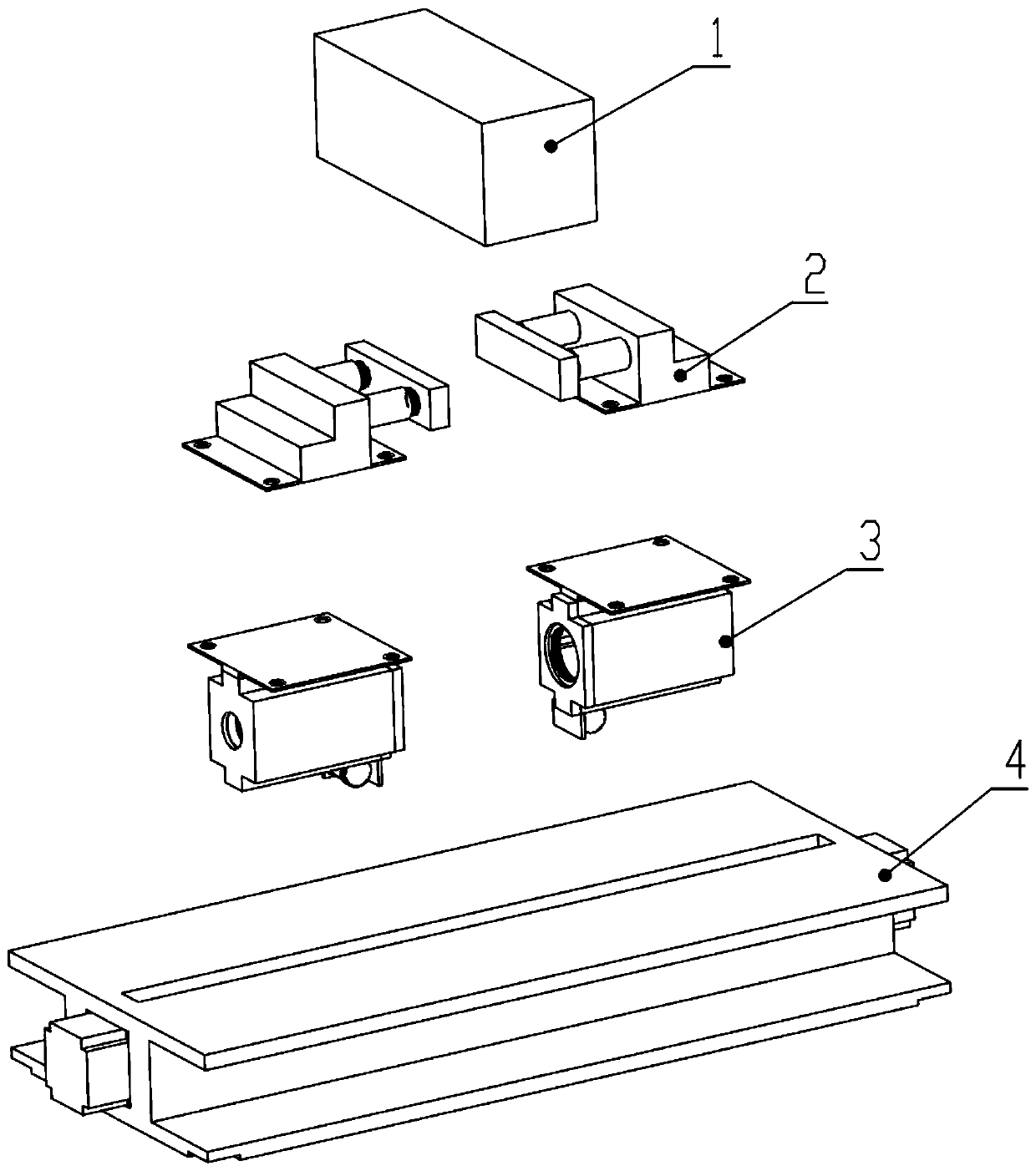

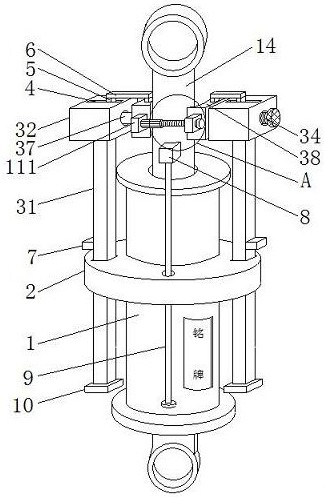

Portable oil liquid detection device

The invention discloses a portable oil liquid detection device comprising a movable cabinet body; universal wheels are arranged at the bottom of the movable cabinet body, a box body is arranged at thetop of the movable cabinet body, forward and reverse motors are arranged on the left side and the right side of the bottom of the inner cavity of the movable cabinet body, the tops of the forward andreverse motors are connected with a screw rod, the top of the screw rod extends into the inner cavity of the box body, the two sets of screw rods are in threaded connection with an inner thread seat,a bearing plate is fixedly connected between the two sets of inner threaded seats, an oil liquid quality detector body is arranged at the top of the bearing plate, a box cover is covered on the top of the box body, buckle locks are symmetrically arranged on the left side and the right side of the box cover, clamping limiting mechanisms are symmetrically arranged on the upper side and the lower side of the box body, guide columns are fixedly connected to the left side and the right side of the top of the bearing plate and the left side and the right side of the bottom of the bearing plate respectively, and guide grooves are formed in the left side and the right side of the upper end of the inner cavity of the box body and left side and right side of the lower end of the inner cavity of thebox body respectively. The portable oil liquid detection device in the invention is reasonable in structural design, thereby facilitating movable carrying of operators, so that the oil liquid can beeffectively detected in time, and the working efficiency of the operators is improved.

Owner:JIANGSU MARITIME INST

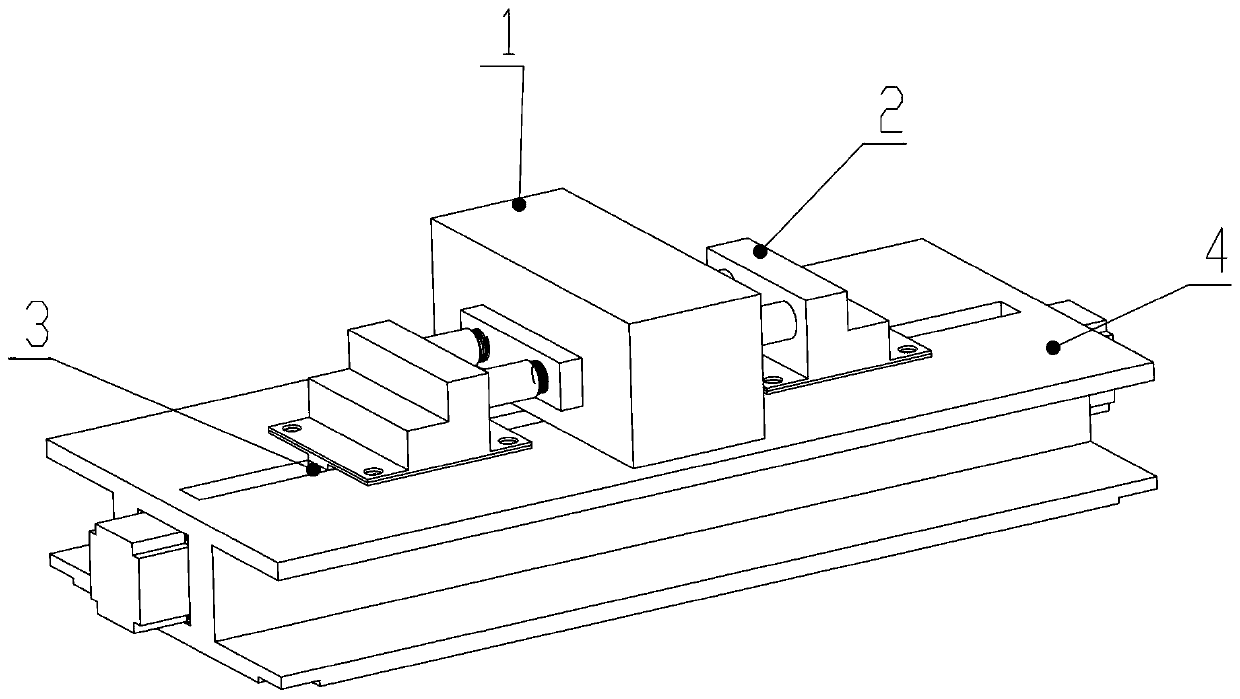

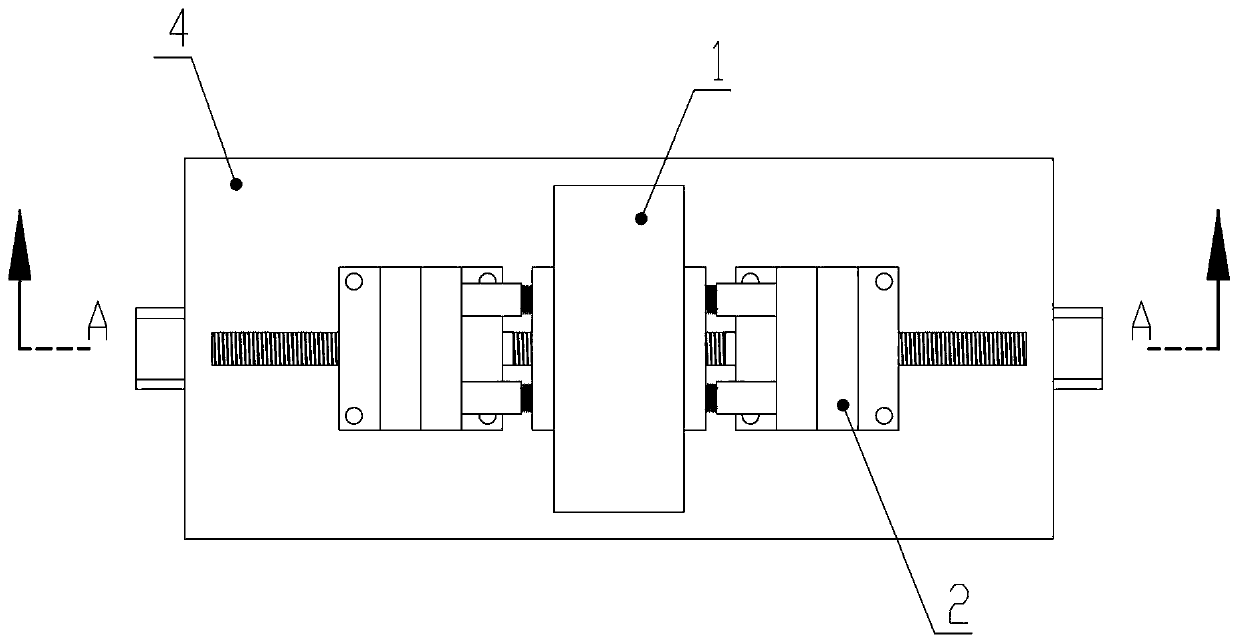

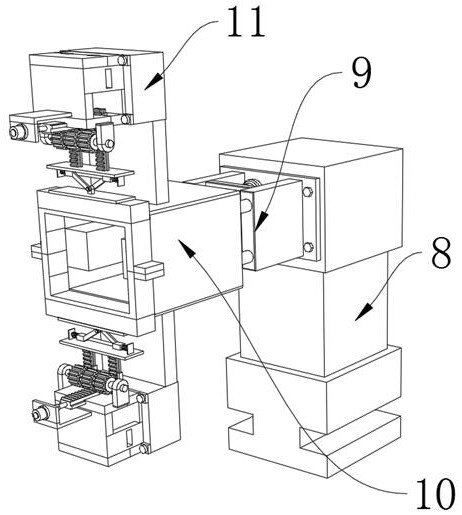

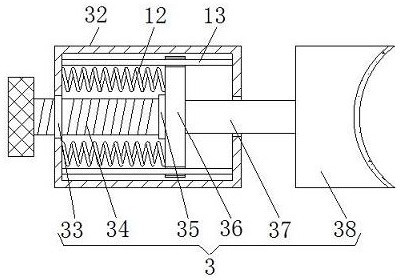

Machining fixing and limiting mechanism capable of adjusting limiting strength conveniently

ActiveCN111531382ASufficient powerFast clamping limitPositioning apparatusMetal-working holdersElectric machineGear wheel

The invention discloses a machining fixing and limiting mechanism capable of adjusting limiting strength conveniently. The machining fixing and limiting mechanism comprises a fixed workpiece, clampingmechanisms, adjusting and control mechanisms and a transmission mechanism. The adjusting and control mechanisms are in symmetric threaded rotary sliding connection to the inner end face of the transmission mechanism. If users need to adjust the strength of clamping the fixed workpiece, the users can start fixed motors through the outer adjusting and control mechanisms, the fixed motors can drivegear grooves to shift towards the front portion, then connecting baffles and elastic switches are driven to shift towards the front portion, the shift stroke of limiting clamp blocks is indirectly prolonged at this moment, then shifting generated when the limiting clamp blocks pull spring clamp rings is longer, and the strength that the clamping mechanisms clamp and locate the fixed workpiece is improved; and the users can adjust the distance between the connecting baffles and limiting sliding plates, then the clamping strength to the fixed workpiece is adjusted, the users can adjust the strength of clamping the fixed workpiece rapidly and conveniently, and safety performance of clamping the fixed workpiece is improved.

Owner:贵阳一舟航科机械设备制造有限公司

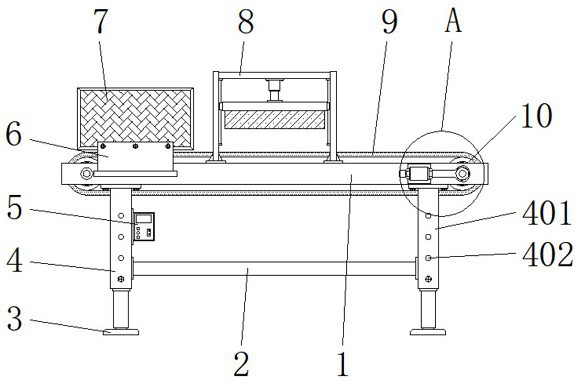

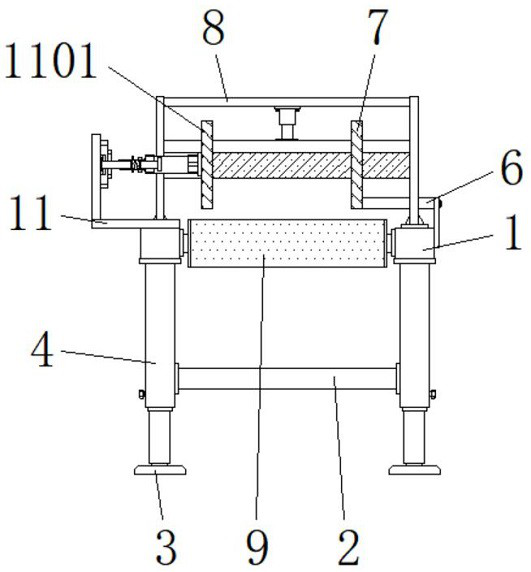

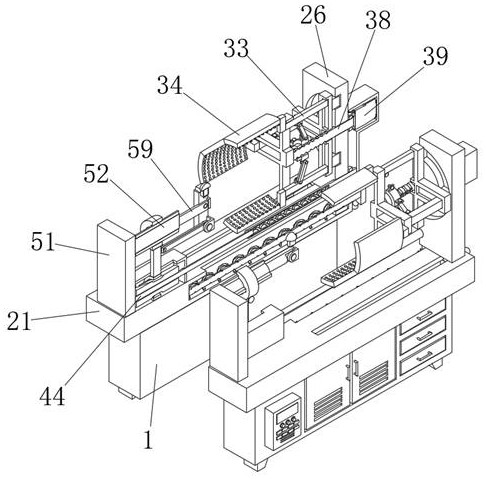

Conveying equipment with clamping structure for automobile part automatic machining

InactiveCN112722779AEasy to clamp limitAvoid displacementConveyorsCleaning using toolsMotor vehicle partStructural engineering

The invention discloses conveying equipment with a clamping structure for automobile part automatic machining. The conveying equipment comprises a conveying frame, a transverse rod, a baffle, a conveying belt and conveying rollers, lifting structures are installed on the two sides of the bottom end of the conveying frame correspondingly, and a telescopic air cylinder is fixed to the bottom end of a connecting rod. According to the conveying equipment with the clamping structure for automobile part automatic machining, automobile parts can be conveniently clamped and limited by arranging a limiting structure, by starting the telescopic air cylinder, the telescopic air cylinder can drive the connecting rod to move, at the moment, the connecting rod can drive a telescopic rod to stretch out and draw back, and meanwhile, the connecting rod can drive sliding sleeves on the two sides to slide outside a sliding rod; the guiding performance of the telescopic rod during stretching and retracting can be enhanced through the sliding rod, when the telescopic rod stretches and retracts to a proper position, the telescopic air cylinder is closed, and a certain distance is reserved between a movable plate and the baffle and just facilitates passing of the automobile parts; and meanwhile, the inclined automobile parts can be adjusted through the movable plate and the baffle, and the phenomenon of displacement of some automobile parts during conveying is prevented.

Owner:东莞市劲华五金机械有限公司

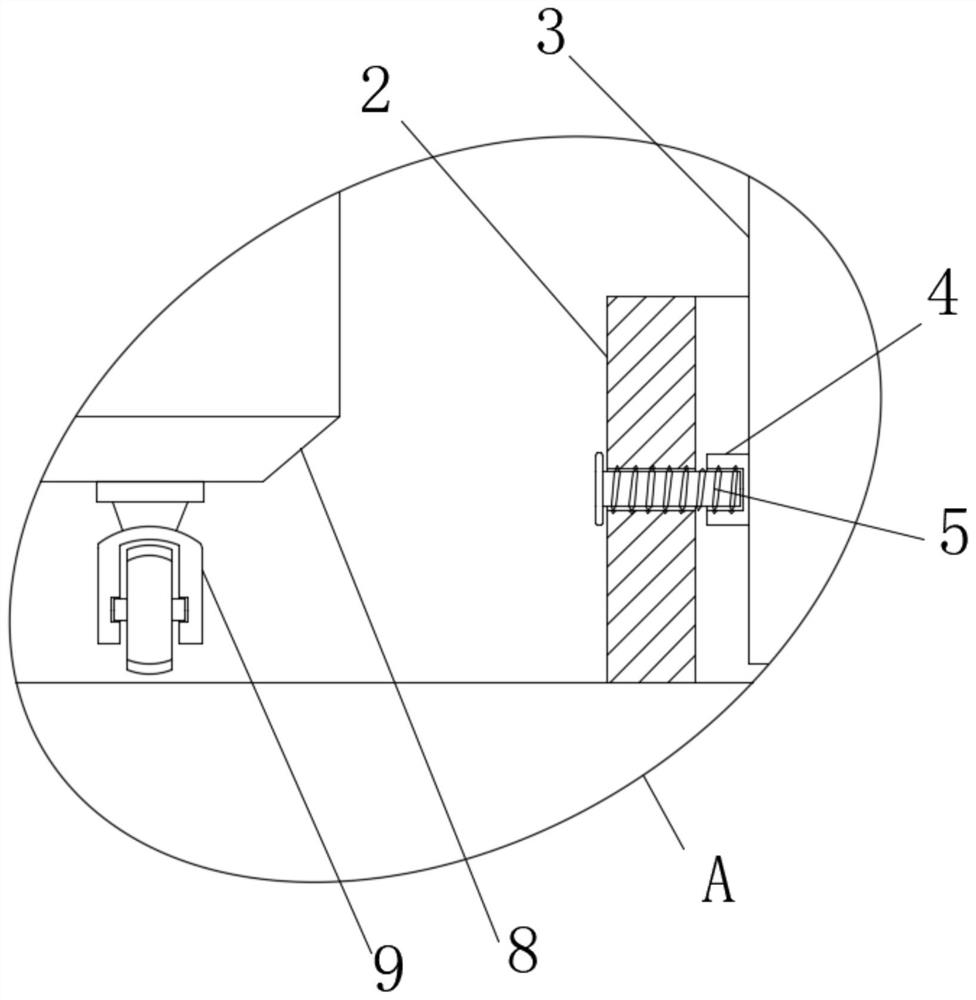

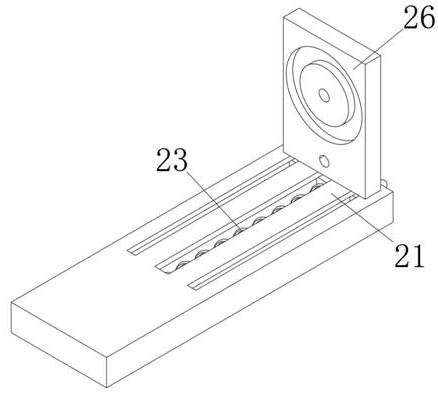

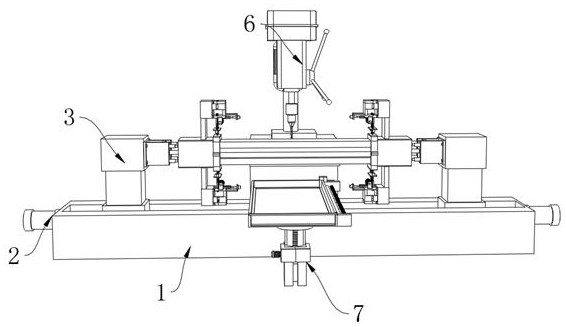

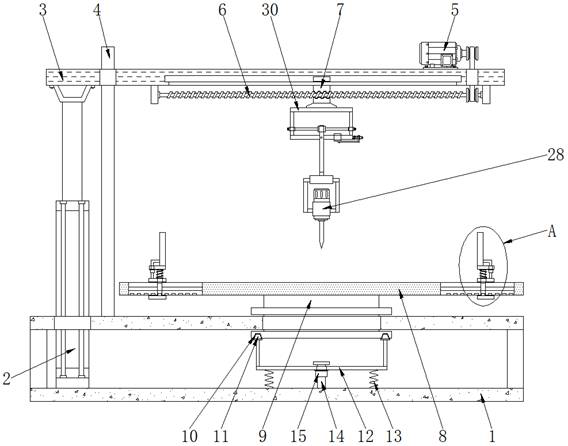

Drilling device for stainless steel precision casting

InactiveCN113369925AEasy to clamp limitCases to prevent driftPositioning apparatusMetal-working holdersGear wheelElectric machinery

The invention discloses a drilling device for a stainless steel precision casting. The drilling device comprises a device body, a guide rotating rod, a clamping block, a supporting column and a limiting spring, main guide threaded rods are arranged on the front side and the rear side of the interior of the device body in a penetrating mode correspondingly, and a main motor is fixedly arranged in the middle of the outer wall of the right side of the device body; and the left end of a guide rotating rod on the top face of the device body is fixedly connected to the end of an output shaft of an auxiliary motor, supporting columns are fixedly arranged on the left side and the right side of the top face of the device body, protruding blocks are fixedly arranged on the left side and the right side of the outer wall of the guide rotating rod on the top face of the device body, and grooves are formed in the left side and the right side in a bevel gear on the outer wall of the guide rotating rod. According to the drilling device for the stainless steel precision casting, while the main guide threaded rods drive the clamping block to transversely move, auxiliary guide threaded rods drive the clamping block to longitudinally move, the clamping blocks of different specifications and sizes can be conveniently clamped and limited by the clamping block, and the situation that a drilling machine deviates when working is prevented.

Owner:陈海军

Stone machining transportation device with guide structure

PendingCN113954940AEasy to clamp limitPrevent shaking from side to sideSupporting partsHand carts with multiple axesEngineeringScrew thread

The invention discloses a stone machining transportation device with the guide structure; the device comprises a transportation base body, moving wheels, a pushing rod and side plates, a protection structure is installed at the top end of the transportation base body, and discharging structures are movably hinged to the two ends of the transportation base body; by arranging a limiting structure, stones can be conveniently clamped and limited, a rotating handle is held to rotate, the rotating handle can drive a threaded rod to rotate, at the moment, the threaded rod can rotate in a threaded hole, and the threaded rod can drive a limiting plate groove to move towards one side during rotation; a limiting plate groove can drive a guide rod to slide in a sliding hole, the guide rod can improve the guiding performance of the limiting plate groove during moving, the limiting plate groove can abut against one side of the stone when moving to a certain distance, a limiting rubber pad can be attached to one side of the stone, so that the stone can be clamped and limited conveniently; and the phenomenon that the stones shake left and right during transportation is prevented, and potential safety hazards are reduced.

Owner:深圳市盈顺机电设计有限公司

Conveying device for machine tool production

The invention discloses a conveying device for machine tool production. The device comprises a top plate. The four corners of the bottom of the top plate are connected with the four corners at the topof a lifting mechanism. The conveying device has the beneficial effects that two pneumatic clamping jaws in a limiting mechanism are clamped, heavy parts are conveniently clamped and limited, the heavy parts can be clamped and limited, due to cooperation of a fixing disc, a linkage cylinder and a bearing located inside a groove in a supporting plate in a rotating mechanism, and rotation can be conveniently performed when rotation is needed during installation. A first plate, a torsion spring, a second plate, a clamping block and a tooth socket in an adjusting mechanism are used in cooperationof convex teeth at the outer side wall of the fixing disc in the rotating mechanism, the fixing disc with the well-adjusted position can be conveniently limited, and therefore installation with the well-adjusted angle can be performed conveniently. Due to cooperative use of the top plate and the lifting mechanism, the rotating mechanism can be cooperatively and conveniently made to ascend, a clamping limiting mechanism limited by the adjusting mechanism can be made to ascend and is conveyed to the angle where installation can be performed conveniently, and operation is easy.

Owner:盐城市钊扬工业设计有限公司

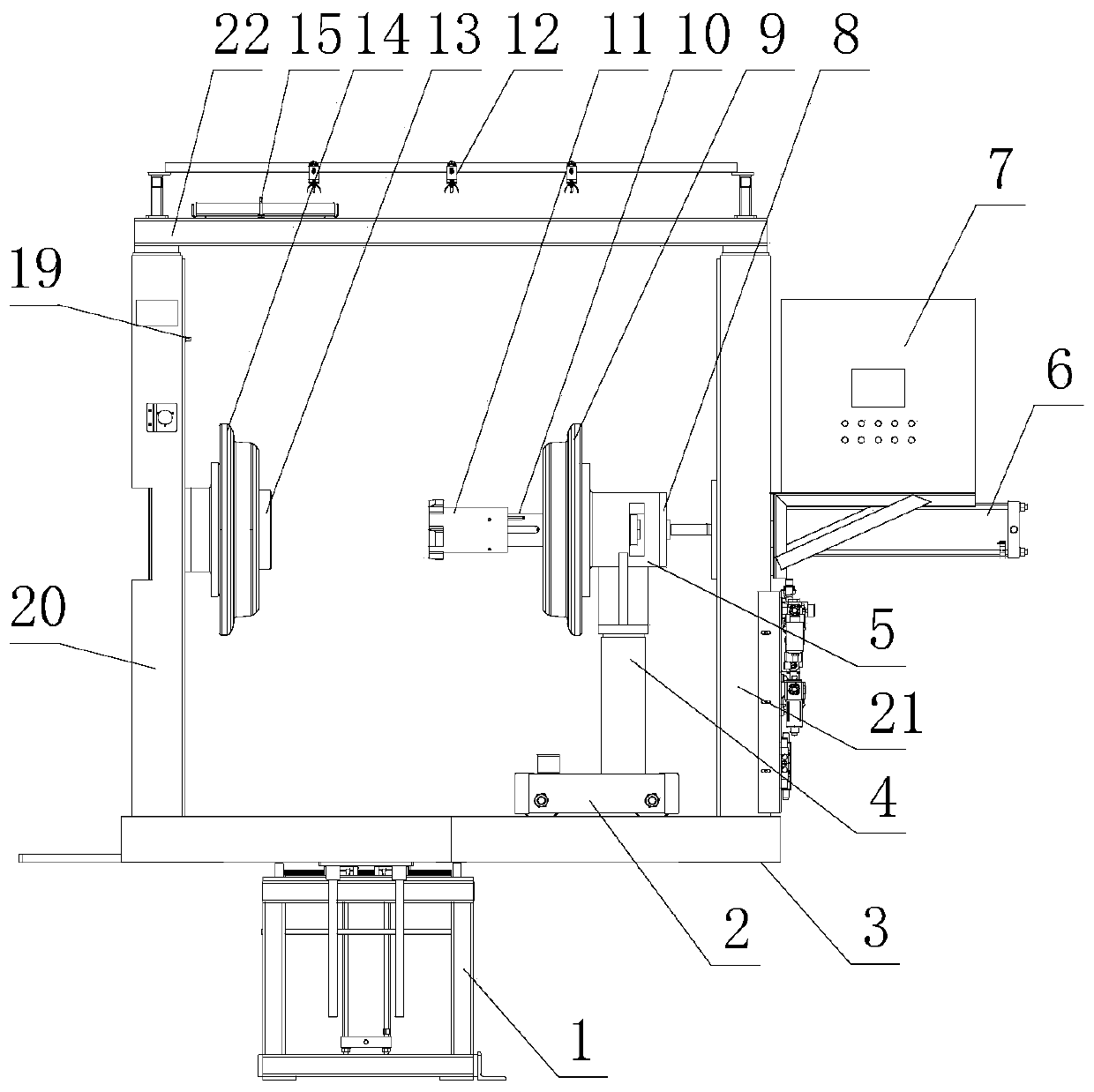

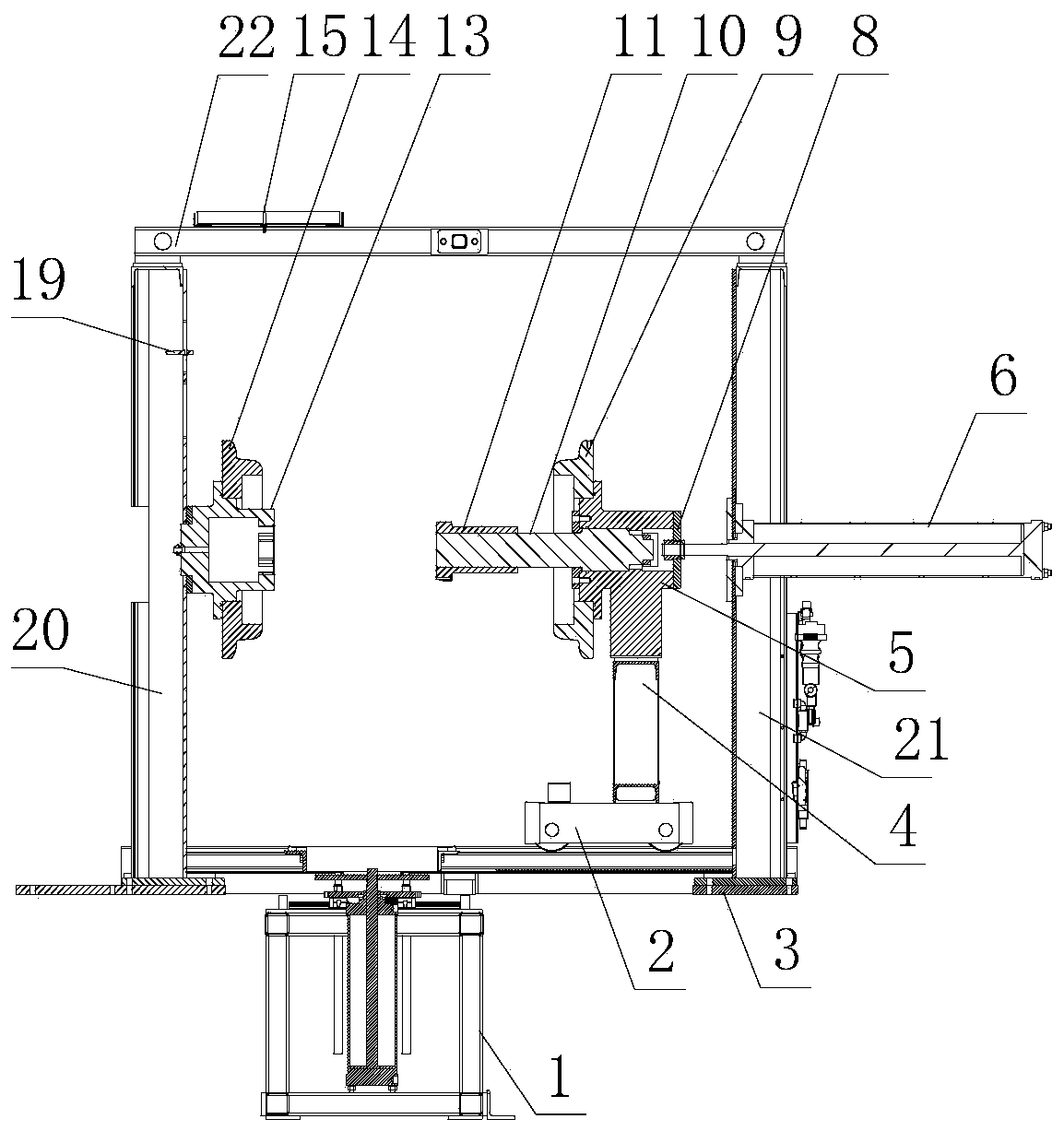

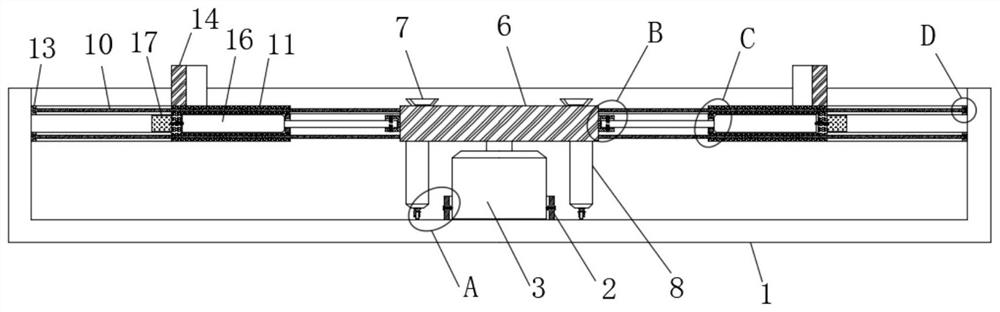

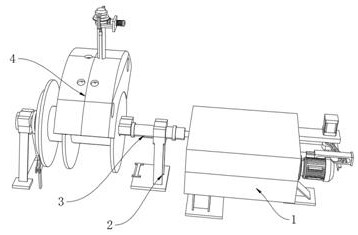

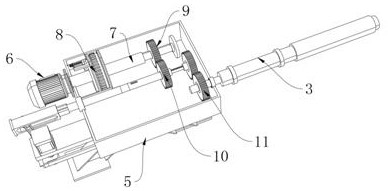

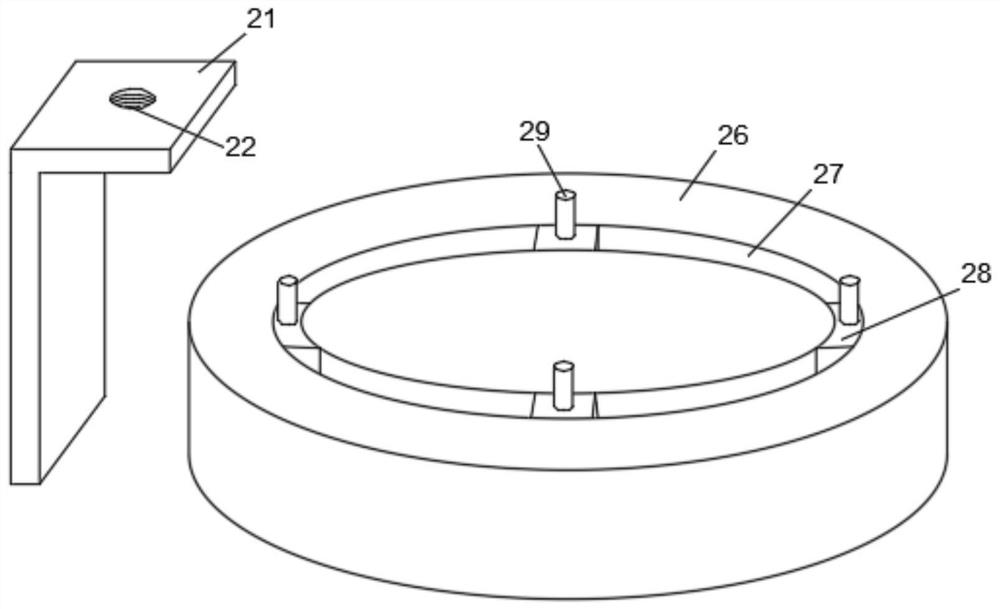

Upright type single station engineering tire rear pumping device

PendingCN111546678AConvenient detachable installationThe inflation process is safe and reliableTyresEngineeringSingle station

The invention relates to an upright type single station engineering tire rear pumping device and belongs to the technical field of tire rear pumping equipment. The device comprises a rack, a lifting device, a left limiting mechanism and a right limiting mechanism, a control cabinet and a rotary fastening mechanism. The left limiting mechanism comprises a left chuck seat and a left chuck and the left chuck is installed on the rack via the left chuck seat. The right limiting mechanism comprises an extensible air cylinder, a right chuck seat and a right chuck; the extensible air cylinder is installed on the rack; an air cylinder rod of the extensible air cylinder penetrates through the rack and is fixedly installed at the right end of the right chuck seat; the right chuck is installed on theright chuck seat; an interlocking rod is rotatably installed at the left end of the right chuck seat; a locking rod head is rotatably installed at the left end of the interlocking rod; the locking rodhead makes reciprocating movement in a rotary way along the interlocking rod; and a plurality of jacking screw holes are formed in the locking rod head in the radial direction and are used for installing jacking screws. The left chuck and the right chuck are arranged in a coaxial mode. The device is used for solving the technical problem that according to the prior art, a rear pumping device occupies a large area and is low in working efficiency.

Owner:SHANDONG LINGLONG ELECTROMECHANICAL

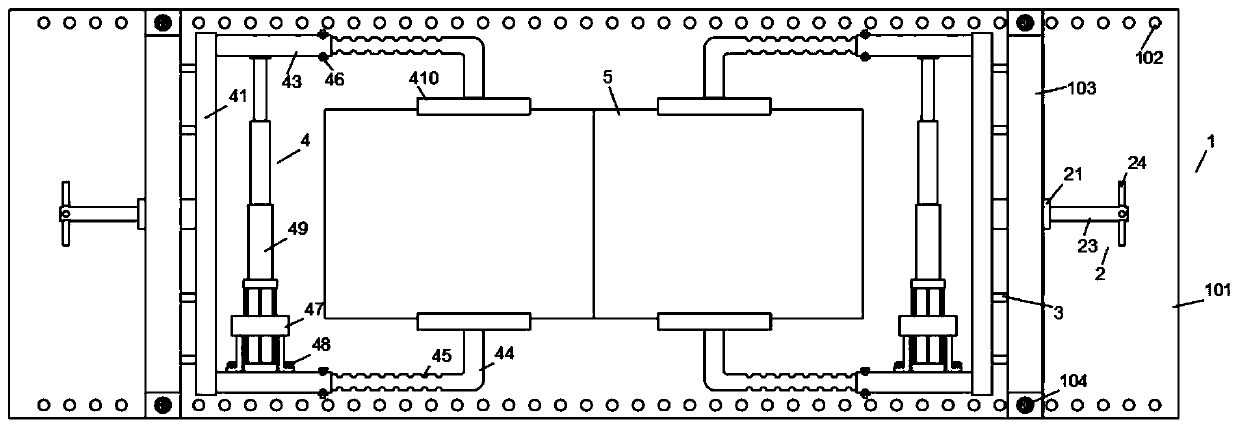

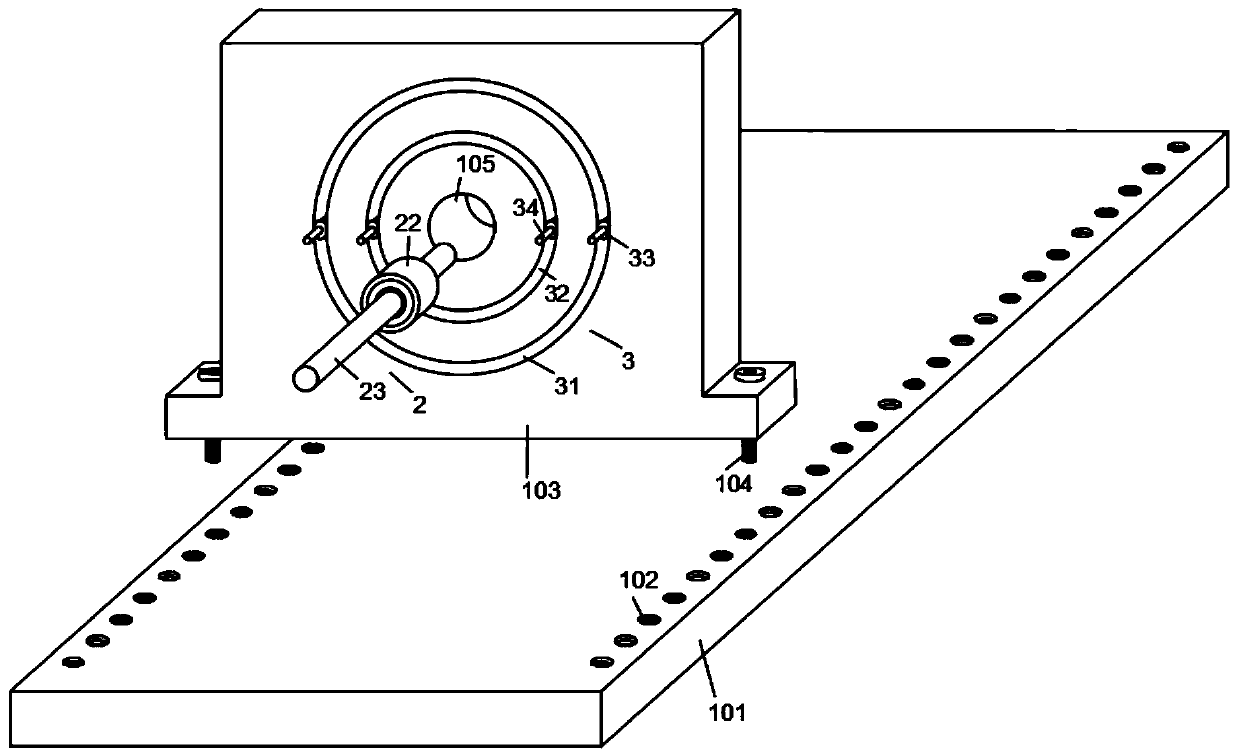

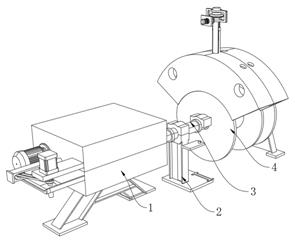

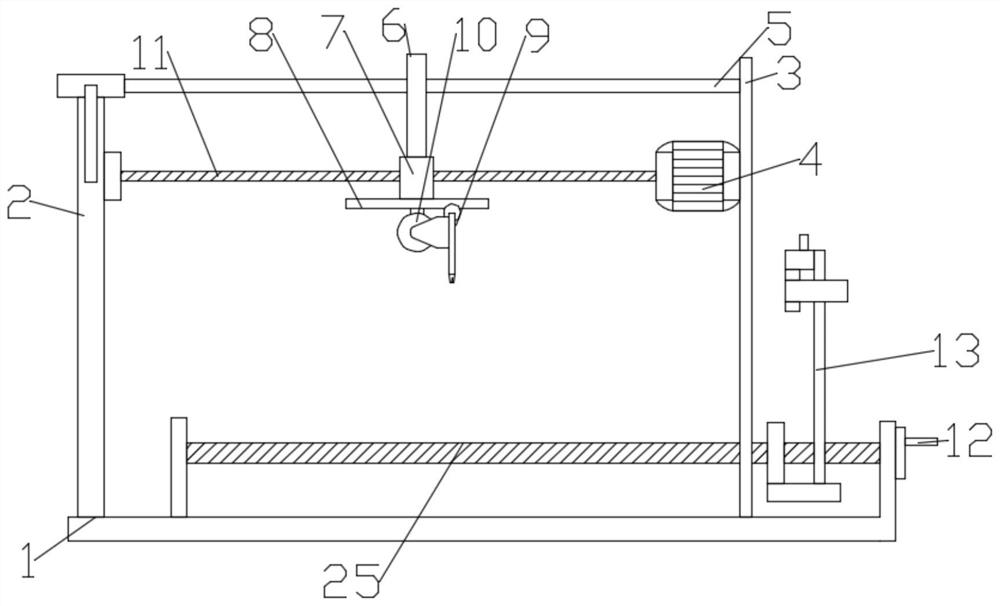

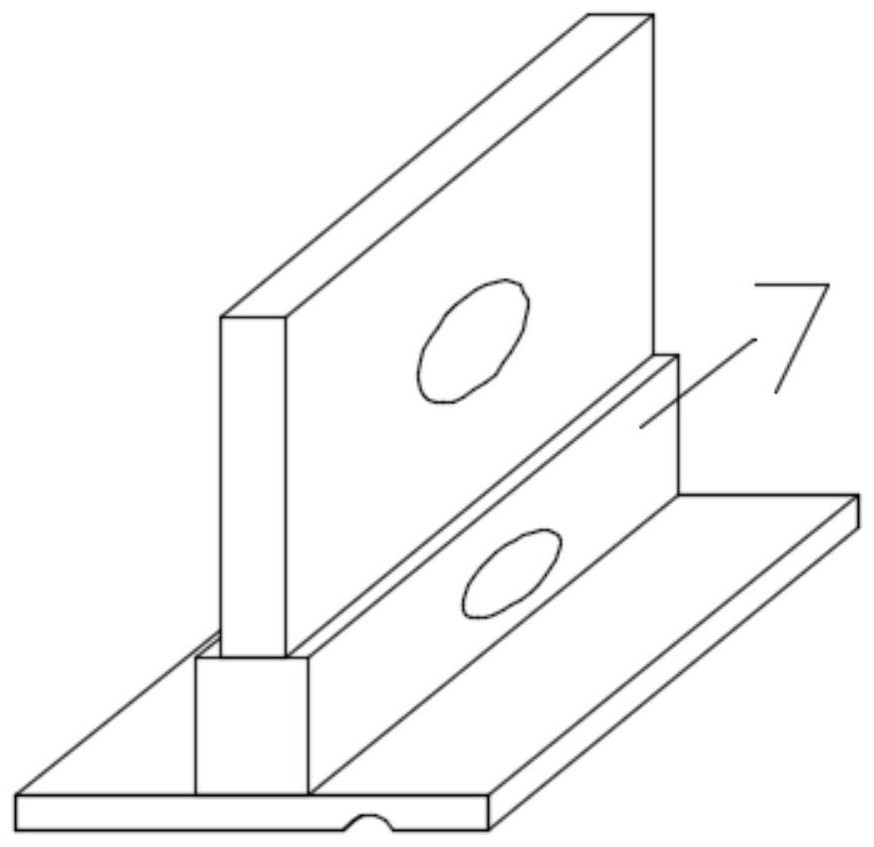

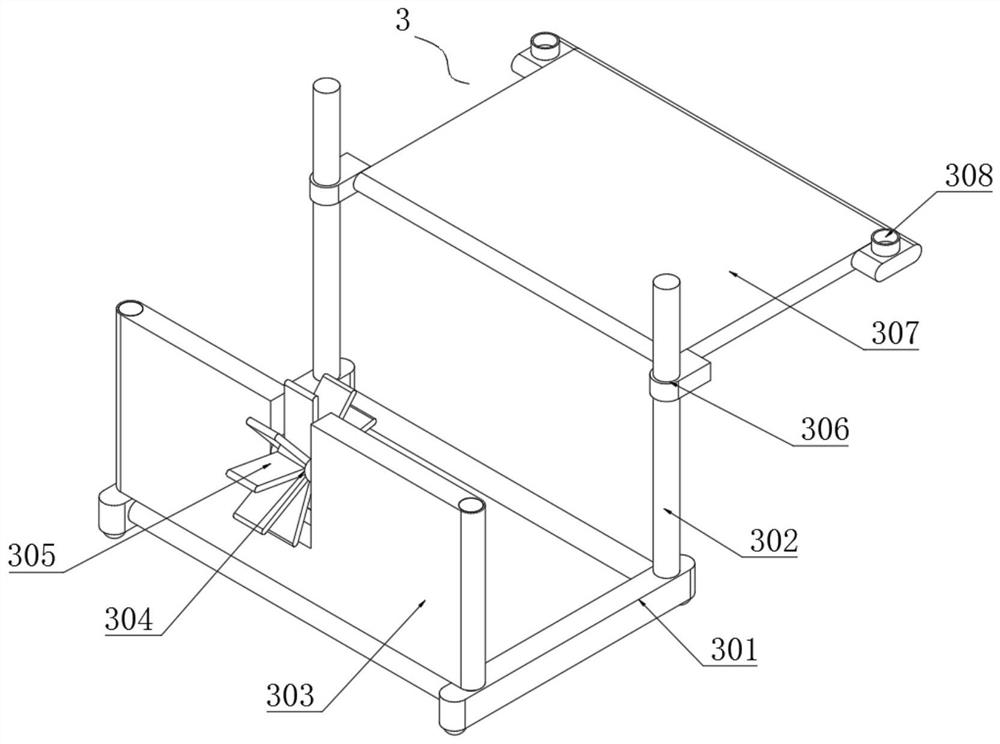

Frame-type turnover frame for assisting in welding

InactiveCN111331306AThe distance is easy to adjustEasy to clamp limitWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWelding

The invention discloses a frame-type turnover frame for assisting in welding. The frame-type turnover frame comprises a fixing mechanism, wherein the fixing mechanism comprises a base, a plurality ofscrew grooves, T-shaped supporting bases, limiting screws and connecting grooves, wherein the screw grooves are dug in the front and rear ends of the top of the base, and the T-shaped supporting basesare arranged at the two sides above the base. The frame-type turnover frame has the advantages that through the arrangement of the fixing mechanism, the distance between two oil tanks which need to be welded is conveniently adjusted, through the cooperative use of rotation mechanisms, auxiliary mechanisms and clamping mechanisms, the two oil tanks are conveniently clamped and limited for welding,and the using limitation is small; and meanwhile, through the arrangement of the clamping mechanisms, the oil tanks with different sizes are convenient to clamp and limit, the situation that the oiltanks are too large or too small in size and cannot be clamped for welding is avoided, and thus the frame-type turnover frame has high practicability.

Owner:苏州晨霞美合智能科技有限公司

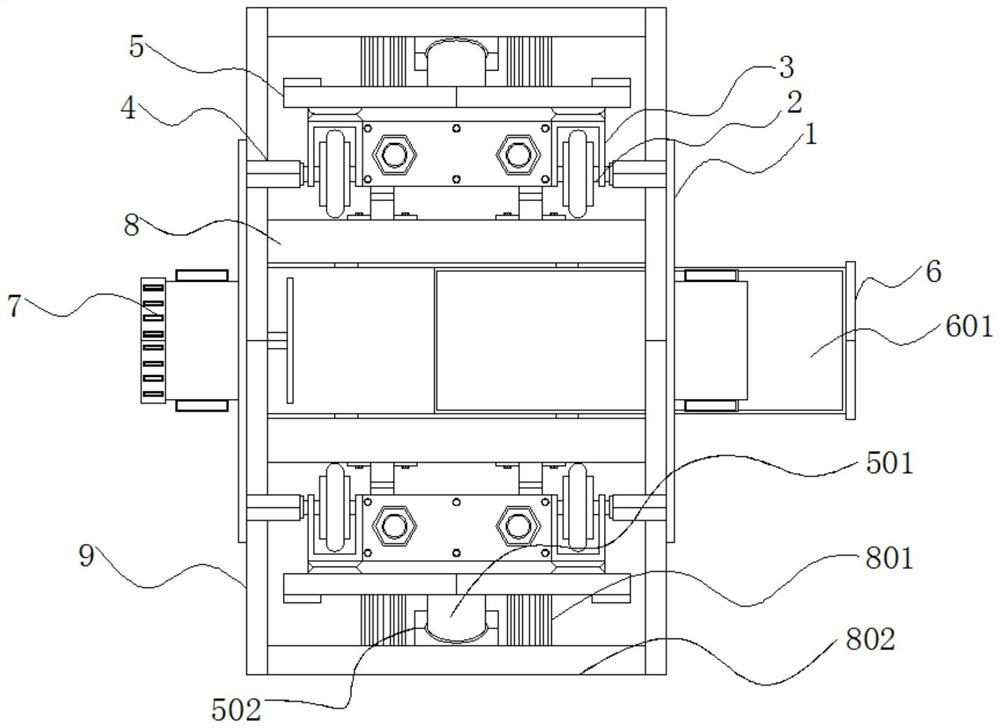

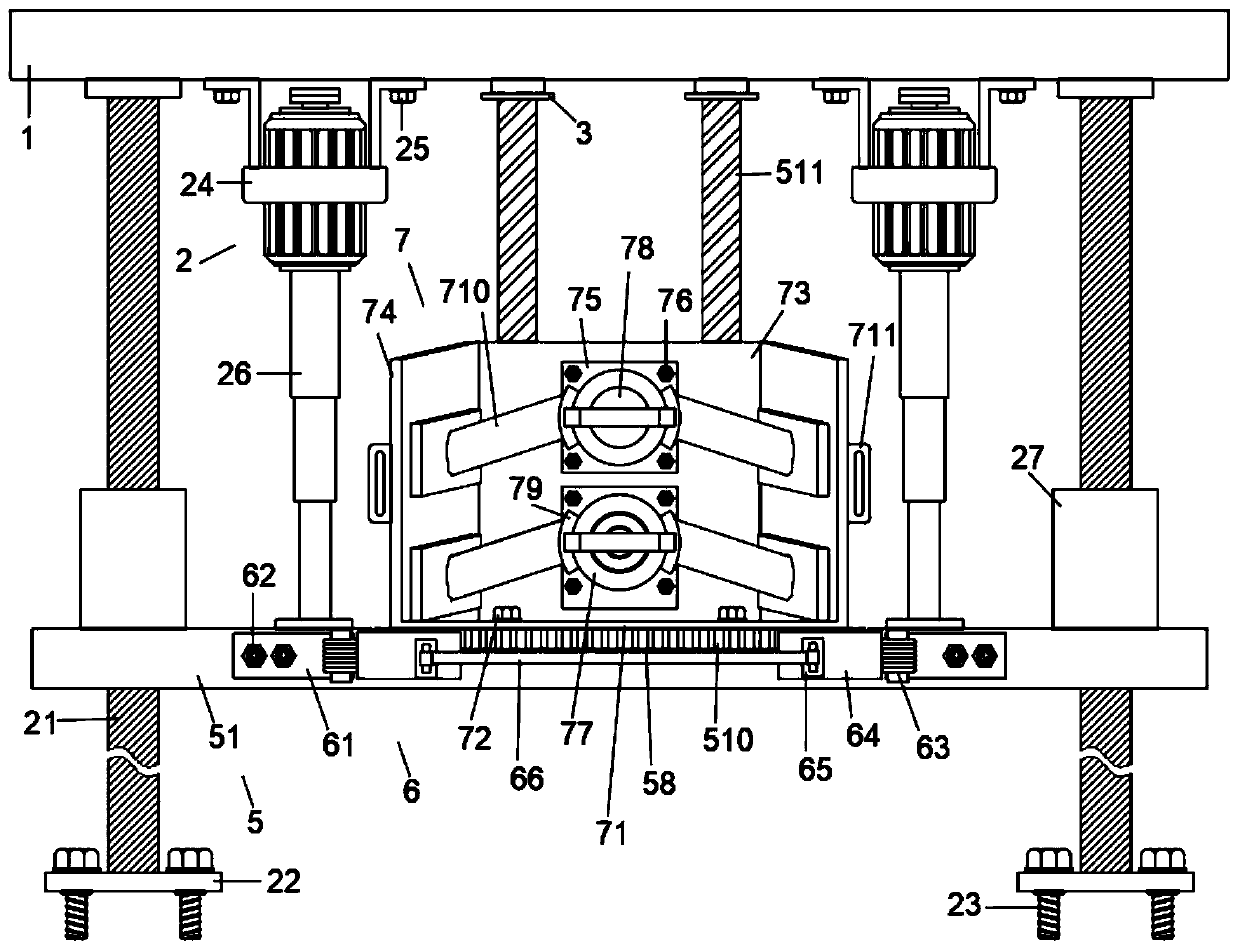

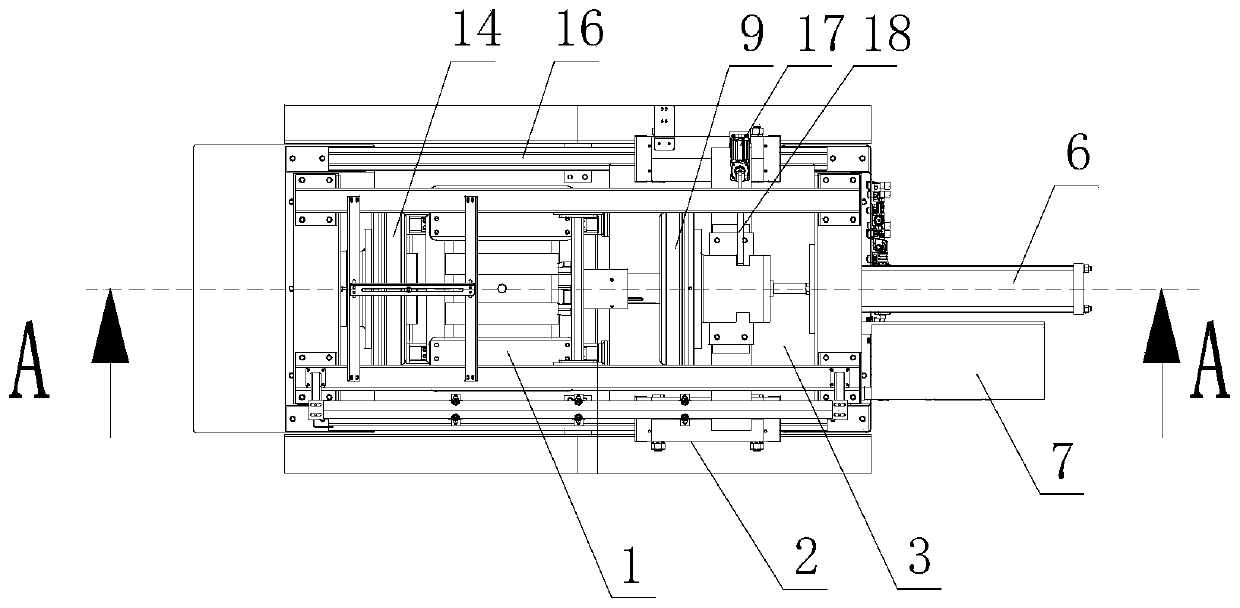

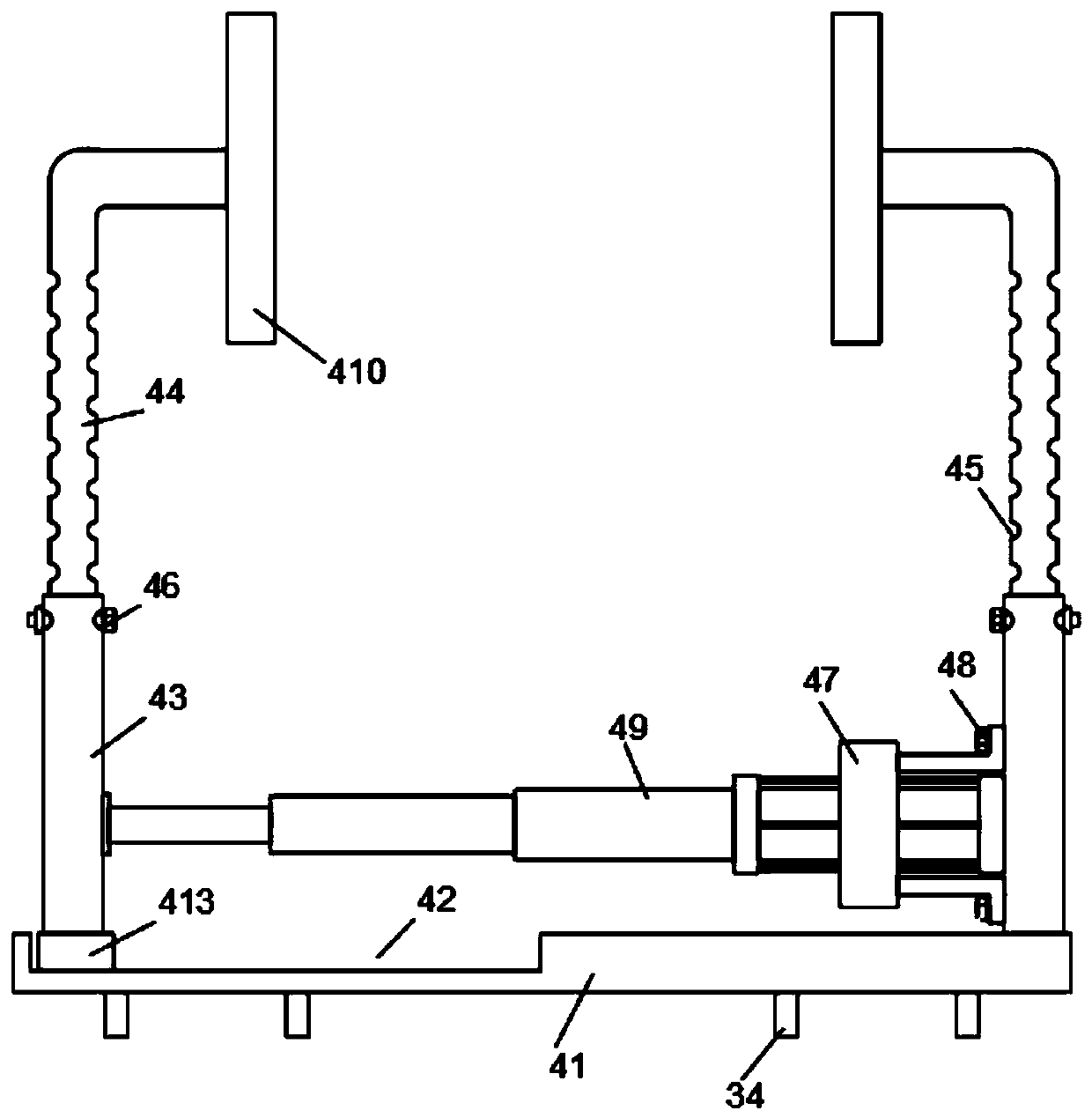

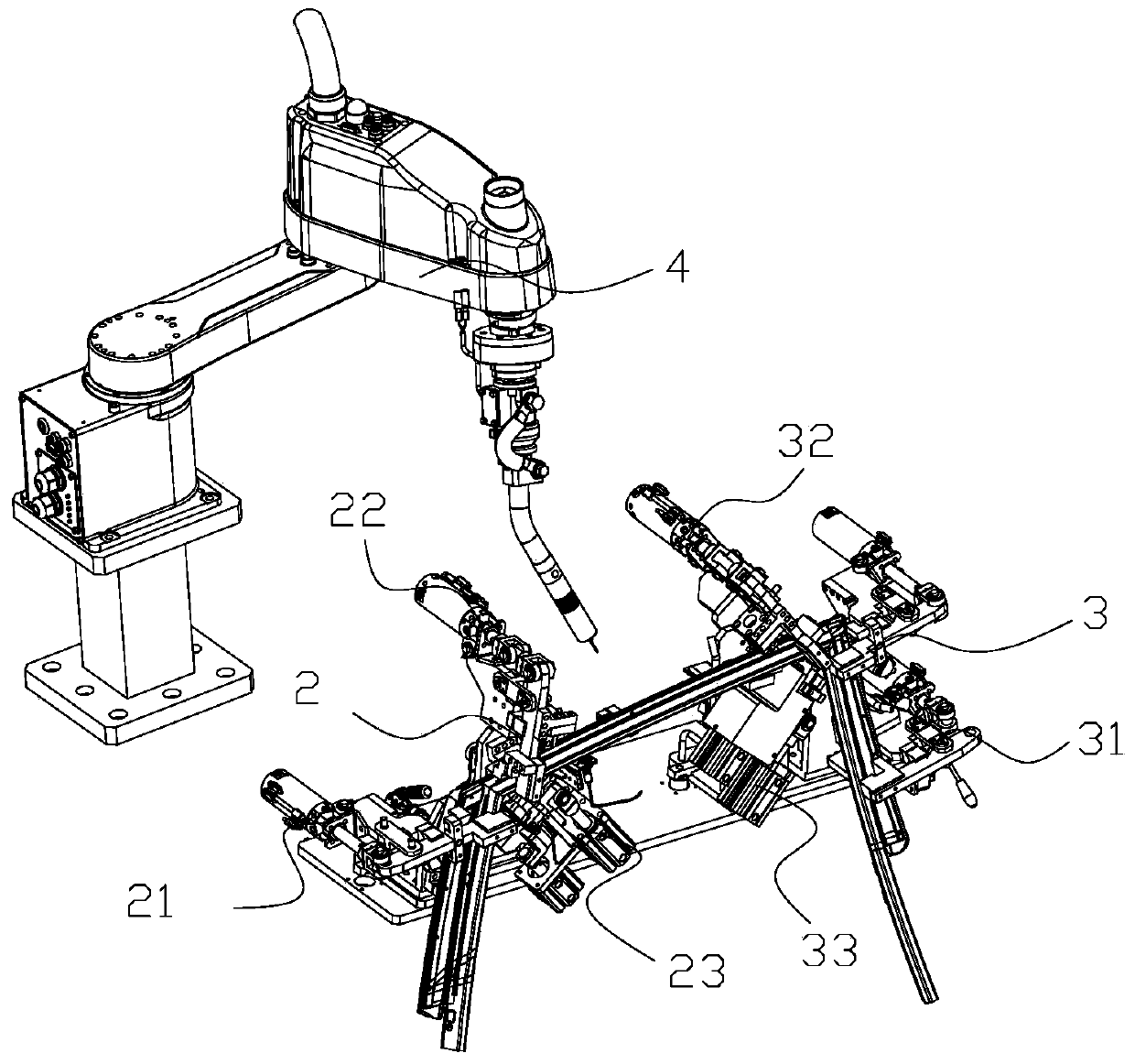

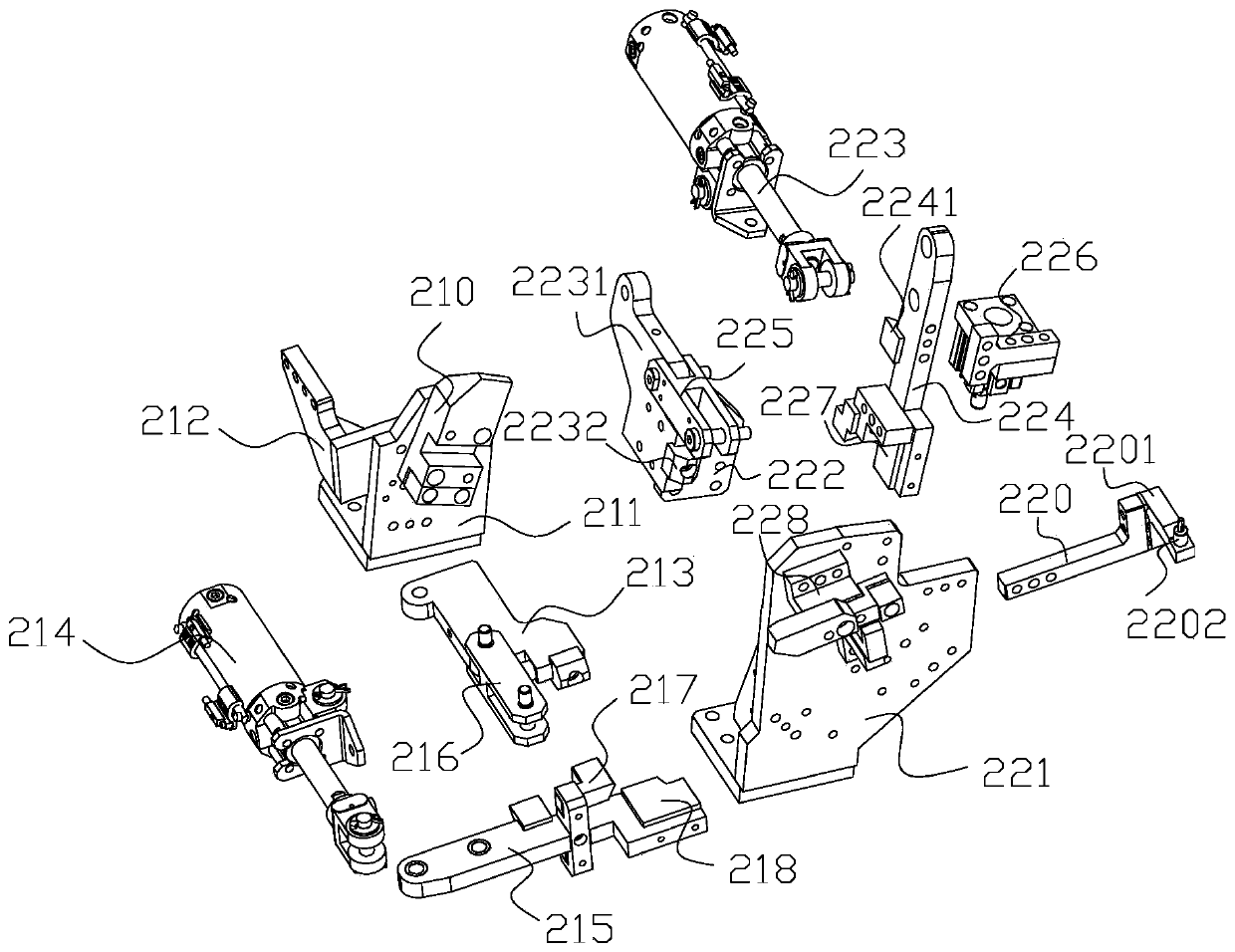

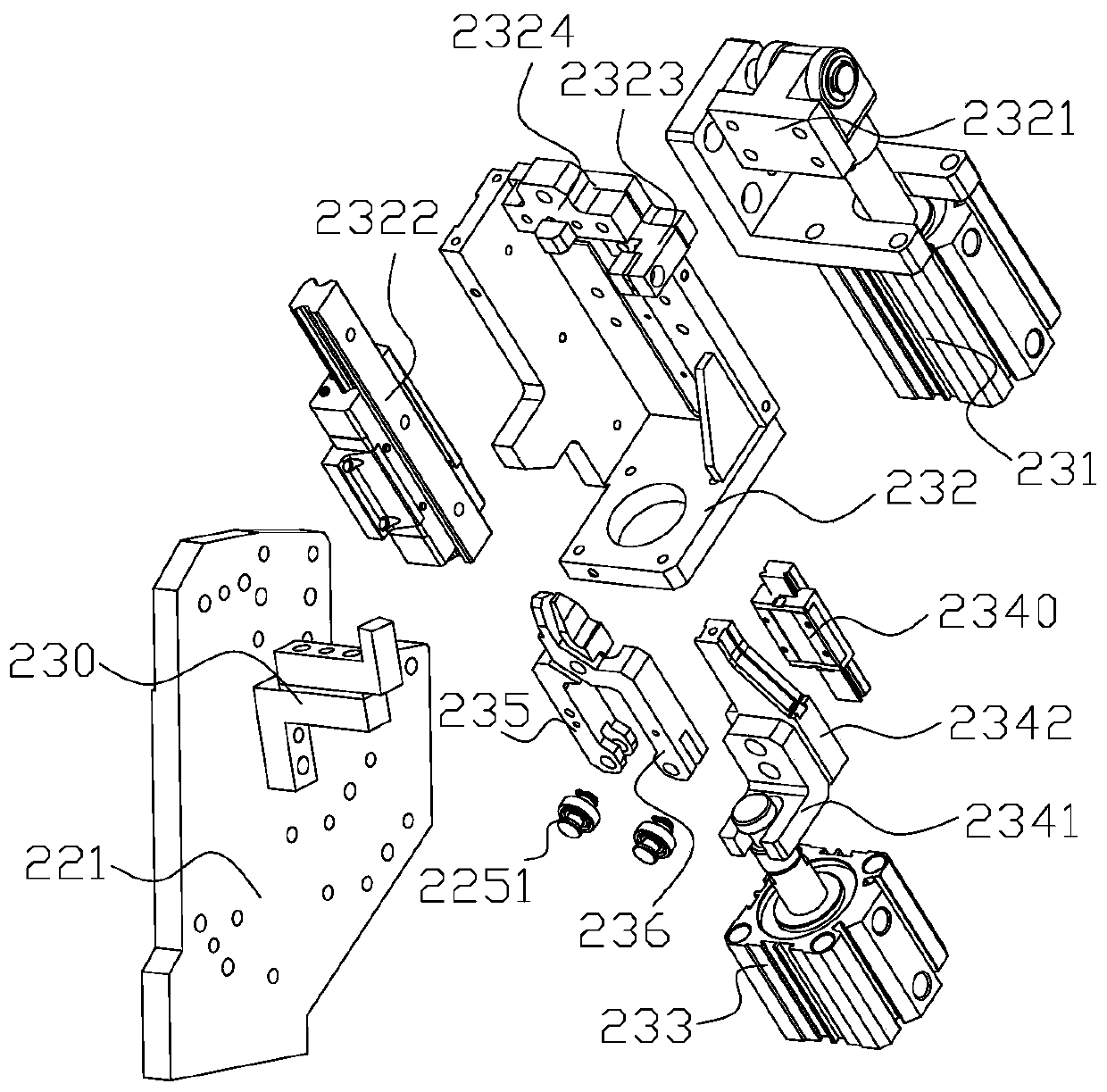

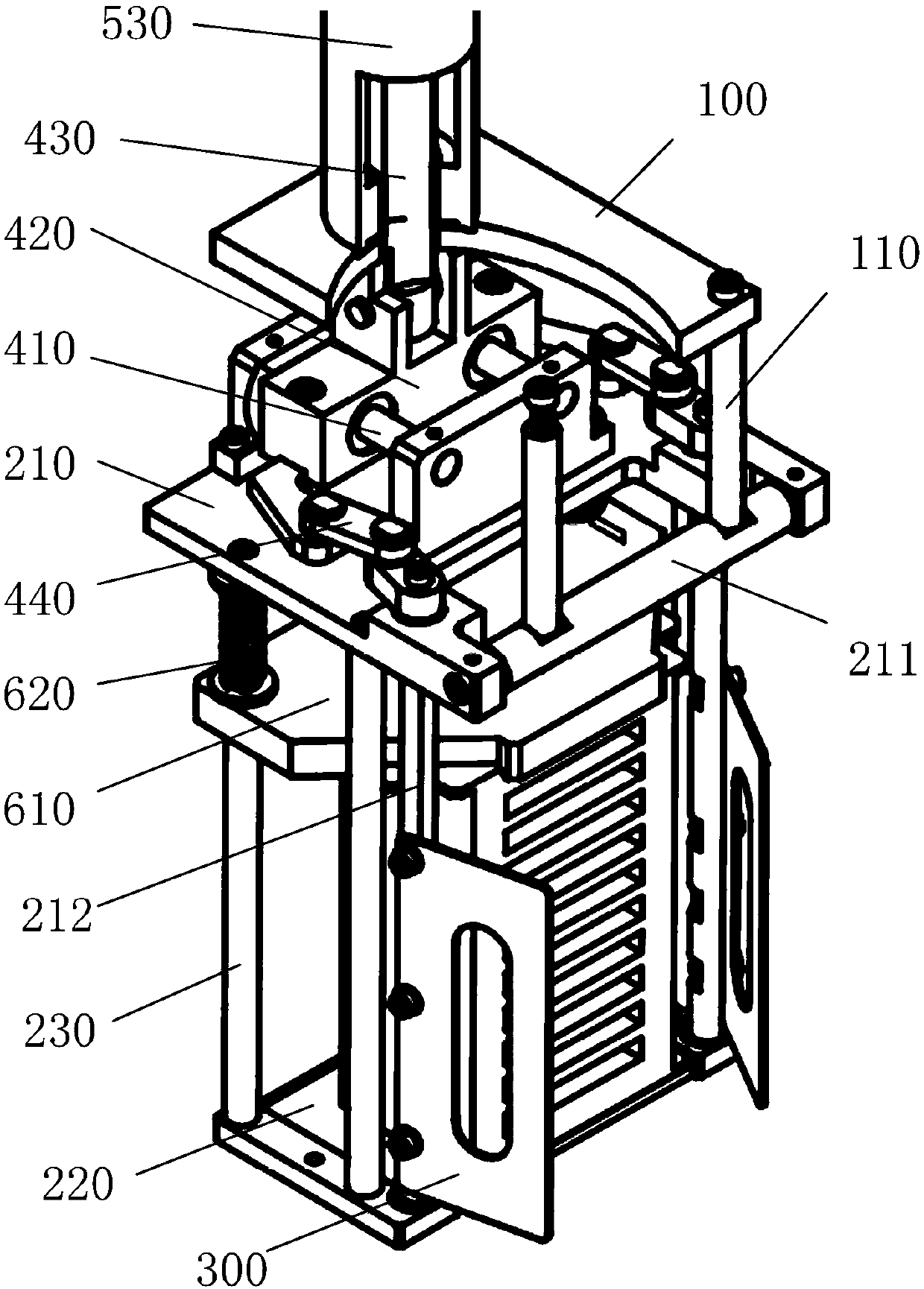

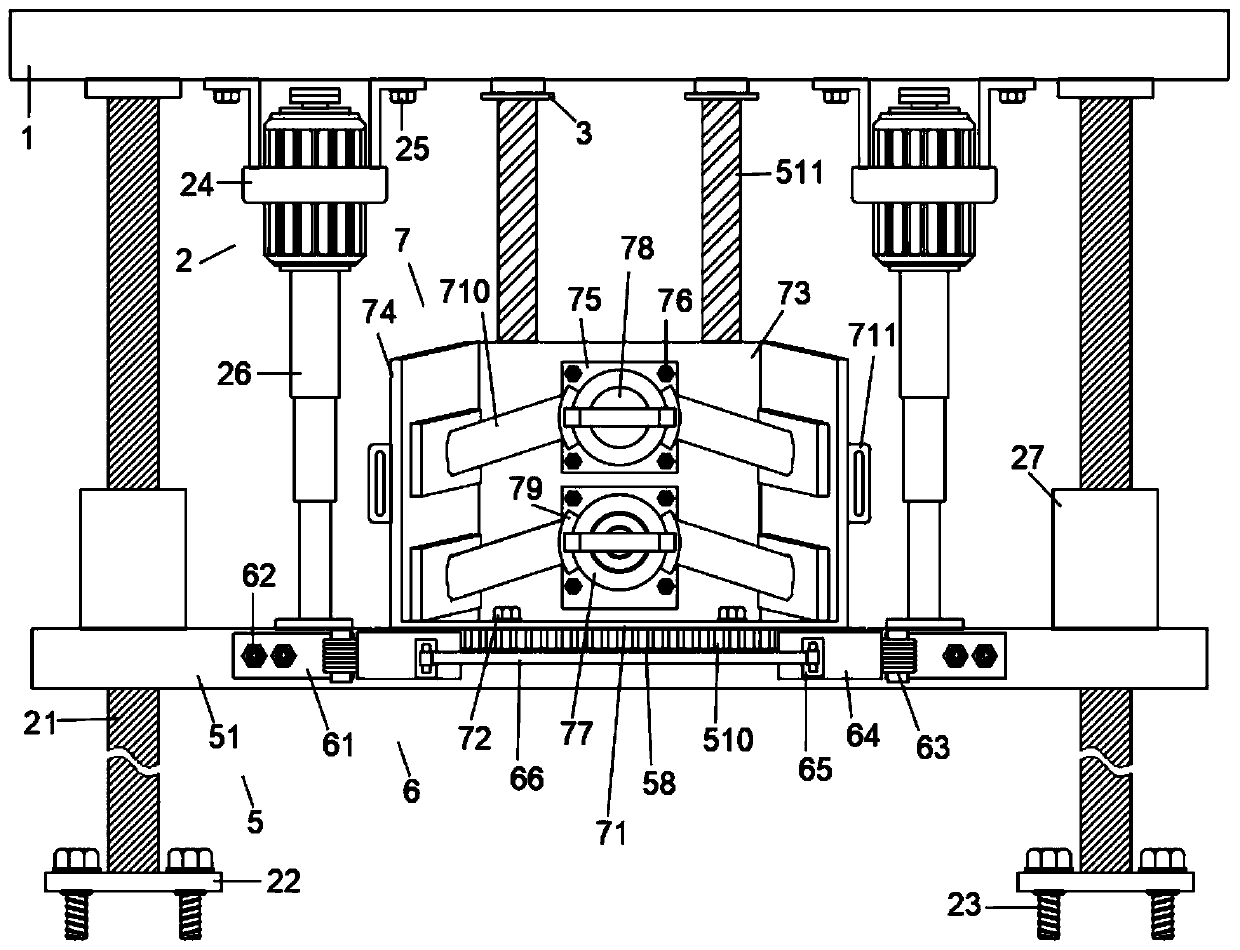

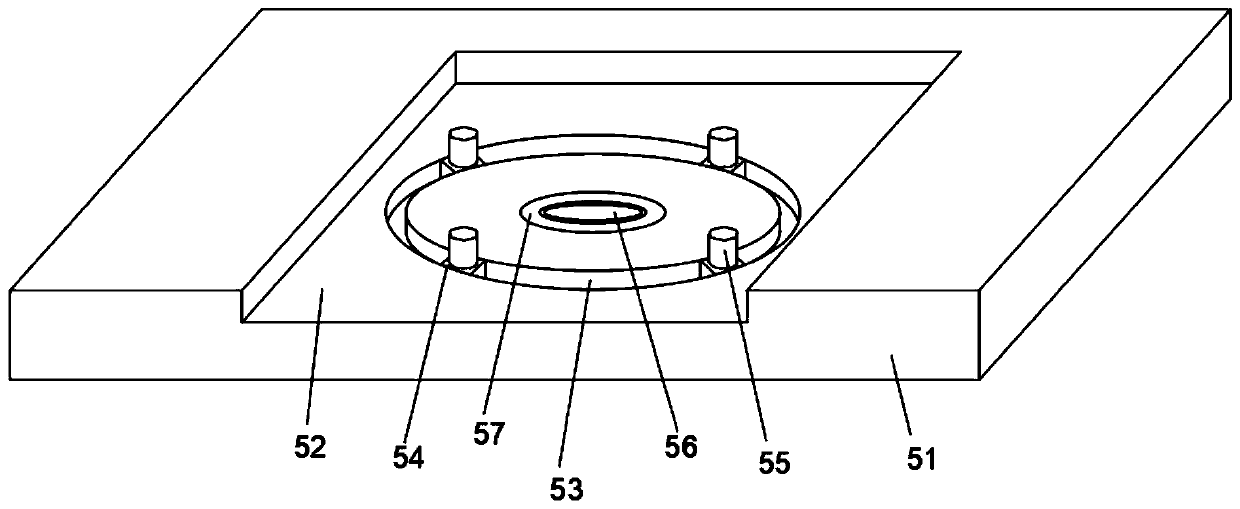

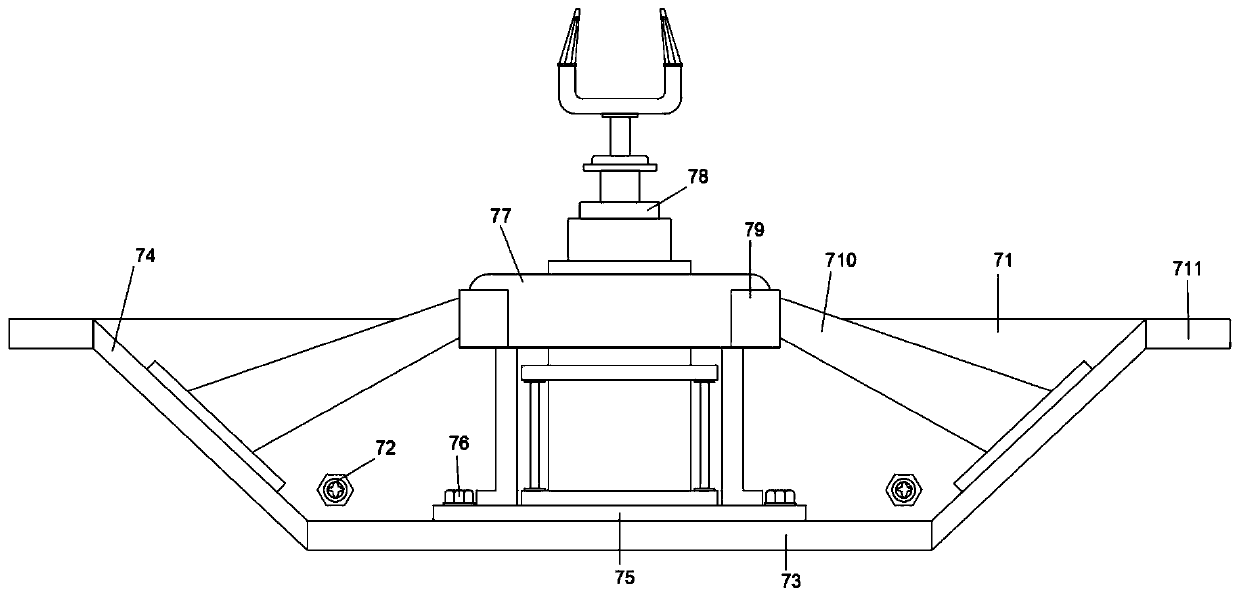

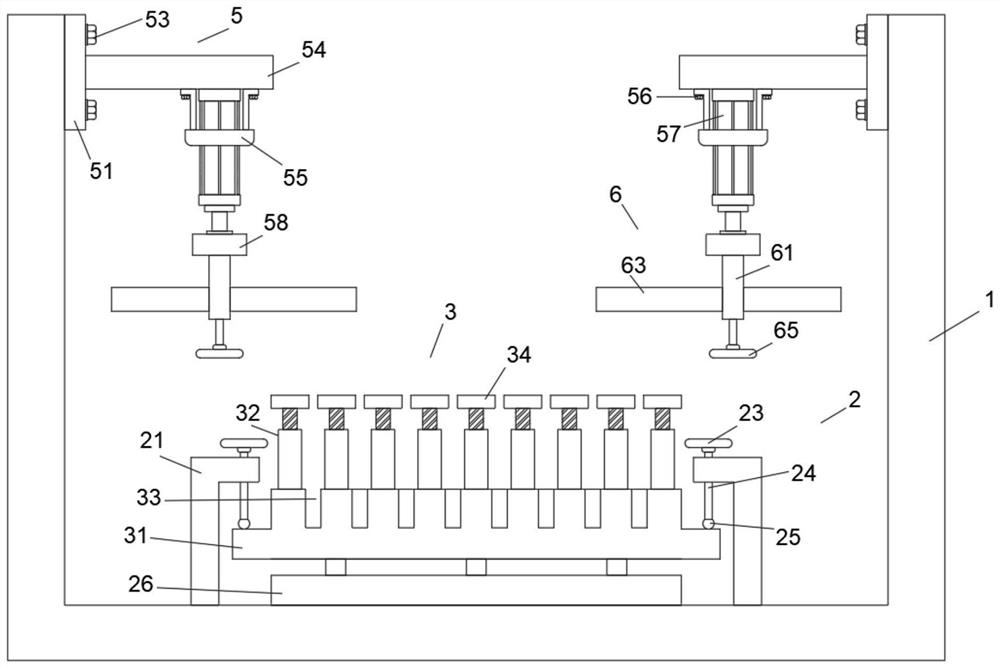

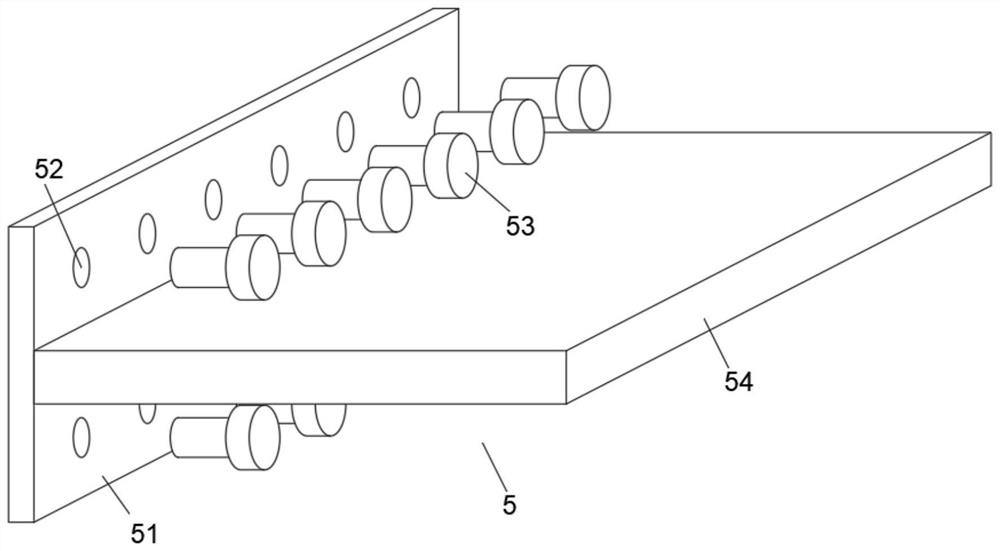

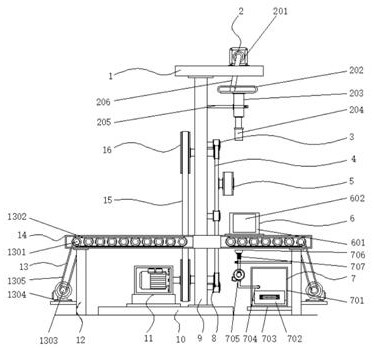

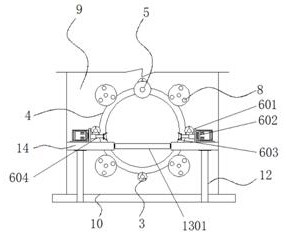

Vehicle frame welding device and welding method thereof

ActiveCN110625304AImprove clamping stabilityImprove clamping comprehensivenessWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameControl system

The invention relates to the technical field of vehicle frame welding. A vehicle frame welding device comprises a rack, a first fixing device, a second fixing device, a welding robot and a control system; the first fixing device is arranged at the left part of the rack; the first fixing device is used for clamping a left rod and the left part of a cross rod; the second fixing device is arranged onthe right part of the rack; the second fixing device is used for clamping a right rod and the right part of the cross rod; the left rod, the cross rod and the right rod are fixed through matching ofthe first fixing device and the second fixing device; the welding robot is positioned at the rear side of the rack; the welding robot is used for welding the left rod, the cross rod and the right rodtogether; and the control system is respectively used for controlling actions of the first fixing device, the second fixing device and the welding robot. The vehicle frame welding device has the technical effect of further improving the clamping firmness and the clamping comprehensiveness, further improving the supporting strength, facilitating stable welding and further improving the welding efficiency and the welding quality.

Owner:CHONGQING HUANSONG INDS GROUP

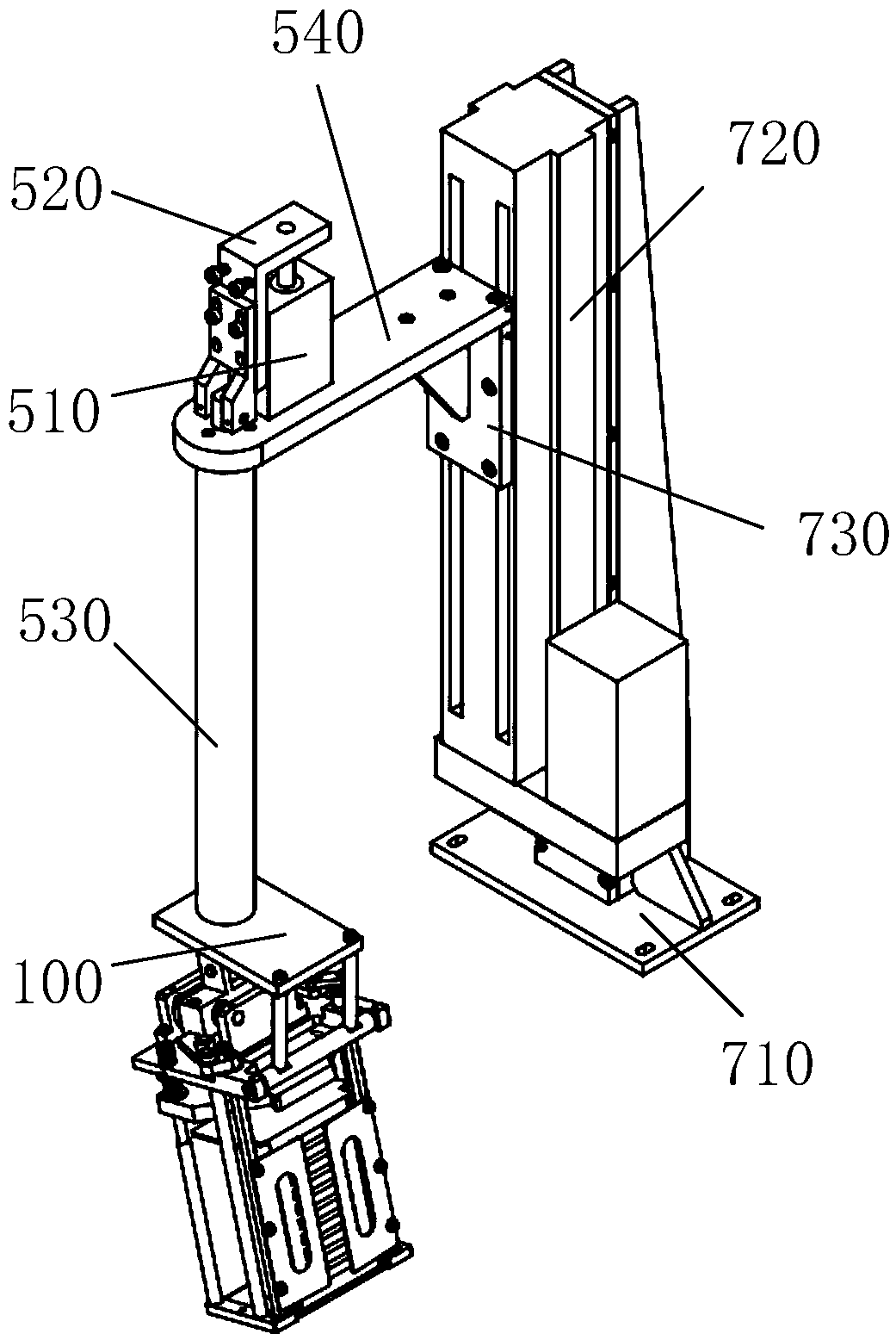

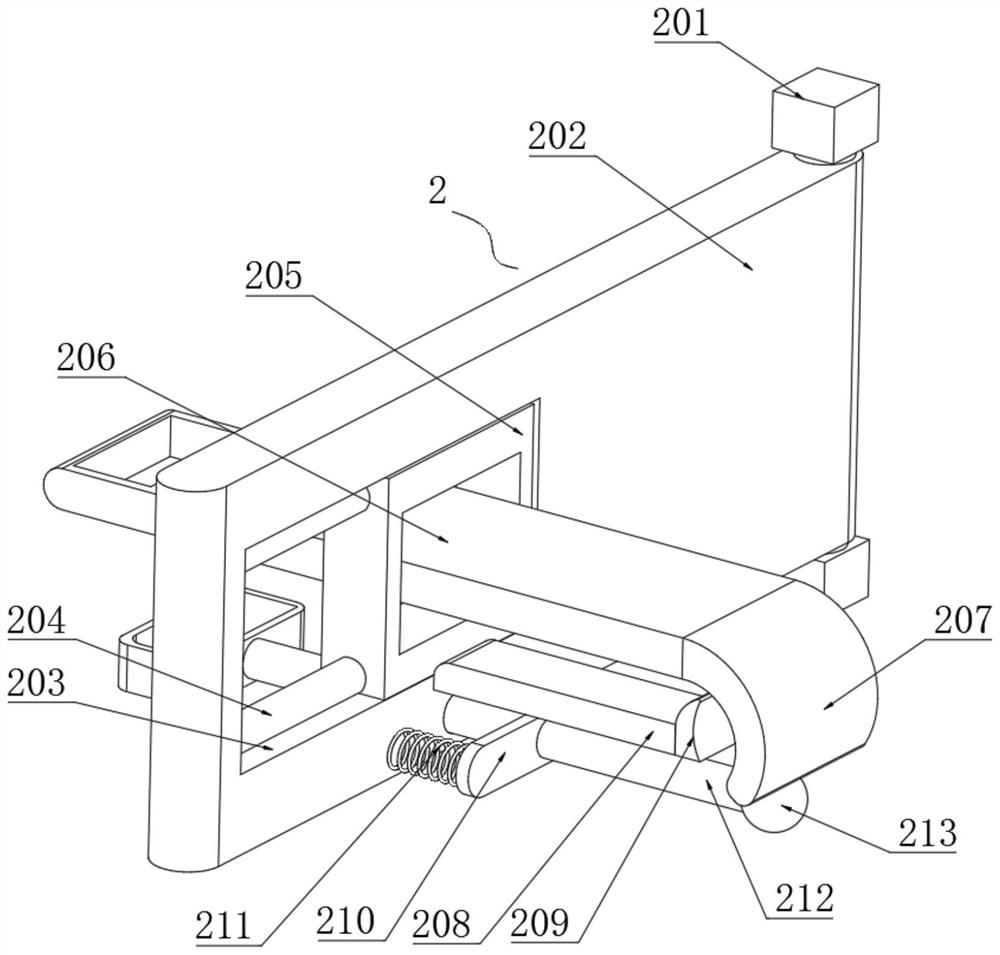

Chip box taking and placing mechanism and shaking device of semiconductor wet process soaking tank

ActiveCN109659259AEasy to clamp limitConvenient clamping limitSemiconductor/solid-state device manufacturingConveyor partsEngineeringSemiconductor

The invention relates to a chip box taking and placing mechanism and a shaking device of a semiconductor wet process soaking tank. The mechanism comprises a connecting plate, a frame, a baffle and a driving transmission device, wherein the connecting plate is used for connecting the frame and the driving transmission device, the frame is used for containing a film magazine, and the baffle is arranged on the frame through a vertical rotating shaft and can change the clamping and pressing state of a chip box in the frame under the driving of the driving transmission device. The device comprisesthe mechanism. The chip box taking and placing mechanism and the shaking device have the advantages of being high in chip box taking and placing efficiency, easy and convenient to operate and simple in structure.

Owner:BEIJING SEMICON EQUIP INST THE 45TH RES INST OF CETC

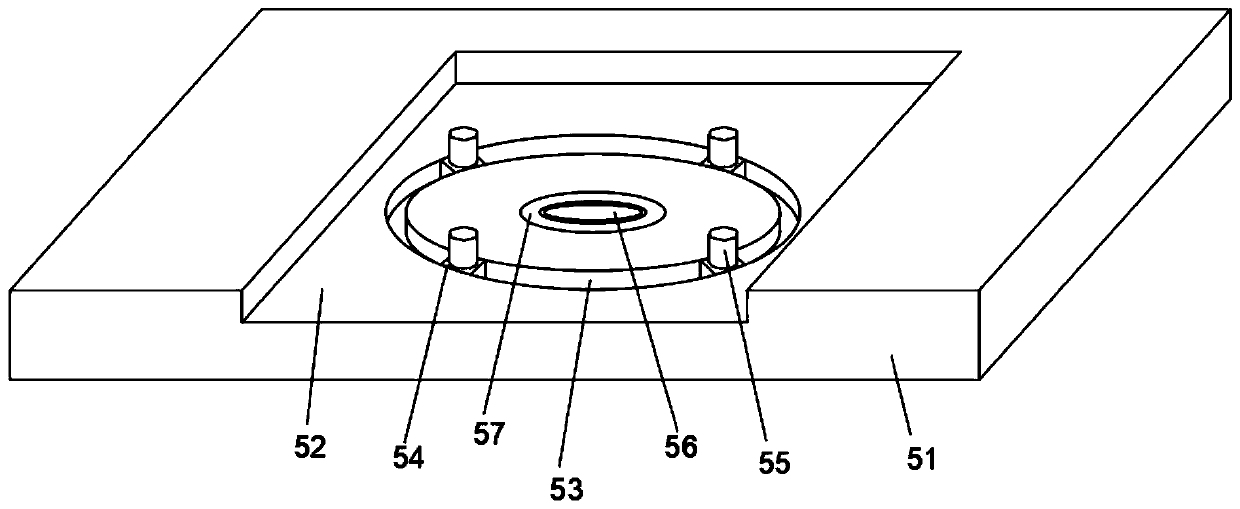

Product position adjusting mechanism for packaging for irregular objects

The invention relates to the technical field of packaging adjusting mechanisms, and specifically relates to a product position adjusting mechanism for packaging for irregular objects. The product position adjusting mechanism for packaging for the irregular objects comprises an installation frame, wherein a limiting ring is arranged on a bottom plate of the installation frame; the limiting ring surrounds the outer side of a driving motor; a connector is arranged on the surface of the driving motor; a connecting screw rod is connected into the connector in an inserting mode; the connecting screwrod is screwed to the surface of the limiting ring; a rotating shaft of the driving motor is fixed to the bottom surface of a rotating disc; a suction disc is arranged on the top surface of the rotating disc; and supporting columns are arranged on the bottom surface of the rotating disc. The product position adjusting mechanism for packaging for the irregular objects has the following beneficialeffects: the rotating disc is additionally arranged on the upper part of a shaft body of the driving motor, the suction disc is additionally arranged on the surface of the rotating disc and temporarily fixed to an acrylic plate, the supporting columns are additionally arranged on the bottom surface of the rotating disc, universal wheels are installed at the bottoms of the supporting columns, and at this moment, the supporting columns play the role of supporting, and drive the universal wheels to slide, so that no swinging of the rotating disc during rotating is guaranteed.

Owner:胡美芳

Composition of conveying device for machine tool production

The invention discloses a composition of a conveying device for machine tool production. The conveying device comprises a top plate, wherein the four corners of the bottom of the top plate are connected with the four corners of the top of a lifting mechanism respectively. The conveying device has the beneficial effects that two pneumatic clamping jaws in a clamping limiting mechanism are used forconveniently clamping and limiting heavy parts, heavy parts can be clamped and limited, through cooperation of a bearing, a connecting cylinder and a fixed disc, located in a groove, of a supporting plate in a rotating mechanism, rotation is facilitated when rotation is needed during installation, and then through cooperation of a first plate, a torsional spring, a second plate, a clamping block and a tooth groove in an adjusting mechanism and use of convex teeth on the outer side wall of the fixed disc in the rotating mechanism, the fixed disc with the adjusted position can be conveniently limited, so that the installation with the adjusted angle is convenient; through matched use of the top plate and the lifting mechanism, the rotating mechanism can be conveniently matched to ascend, sothat the clamping limiting mechanism limited by the adjusting mechanism can ascend and be conveyed to an angle convenient to install, and the operation is easy.

Owner:青岛张氏力拓精密机械有限公司

Inner wall machining equipment with positioning and supporting structure for equipment part production

InactiveCN112676984AEasy to processEasy to clamp limitGrinding drivesGrinding machinesMechanical engineeringMachining

The invention relates to the technical field of part production, in particular to inner wall machining equipment with a positioning and supporting structure for equipment part production. The equipment comprises a machining device main body, a moving mechanism is arranged on the surface of the machining device main body, a fixed mechanism is arranged in the moving mechanism, and the fixed mechanism comprises a third connecting block; and the third connecting block is inserted into the moving mechanism. By arranging a fixed rotating rod and a limiting rotating ring, fixed clamping plates can drive a part to move on the surface of the machining device main body by rotating the fixed rotating rod, machining of the part is facilitated, meanwhile, the fixed clamping plates can get close to each other by rotating the limiting rotating ring, and the part can be clamped and limited conveniently; and an operator does not need to perform holding and limiting for a long time, the physical exhaustion of the operator is reduced, and meanwhile, the operator does not need to watch over for a long time, so that the production efficiency of the part is greatly improved, and the production cost of the part is reduced.

Owner:叶有弟

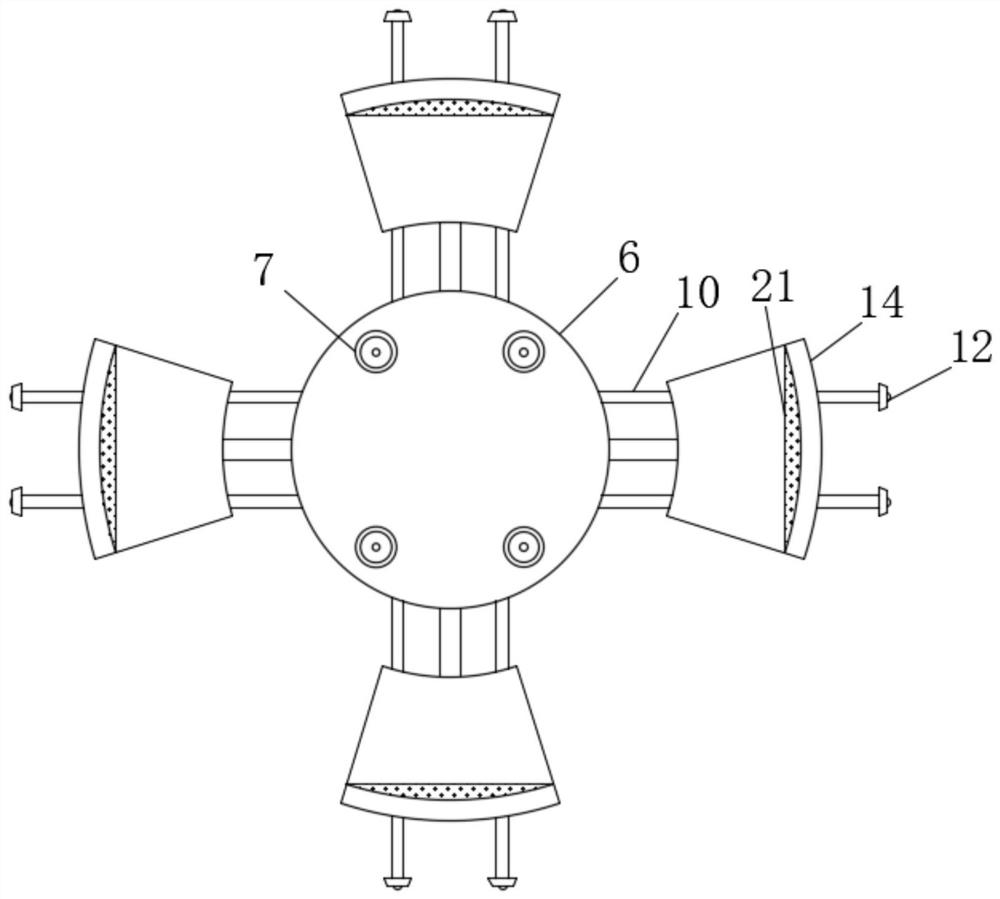

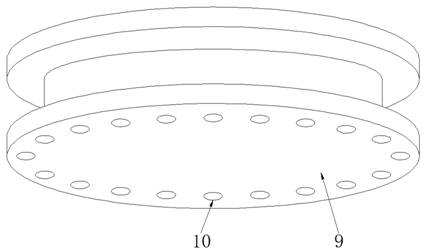

Stable type valve machining tapping device capable of preventing chippings from splashing

PendingCN114535724APrevent looseningAvoid breakingThread cutting machinesPositioning apparatusStructural engineeringVALVE PORT

The stable type valve machining tapping device capable of preventing the chippings from splashing comprises a base with a supporting function, a tapping table, a dust suction device, a clamping mechanism, a limiting mechanism, an adjusting mechanism and a dust suction box, the tapping table is arranged above the base, and the dust suction device is installed on the left side of the base; the clamping mechanisms are arranged at the upper end of the tapping table at equal angles, the limiting mechanism is arranged above the connecting plate, the adjusting mechanism is arranged below the bearing block, and the lower end of the dust suction box is fixedly connected with a chip removal cylinder. According to the stable type valve machining tapping device capable of preventing the chippings from splashing, valves of different sizes can be clamped and limited conveniently, the valves are prevented from loosening in the tapping process, the fastening effect is good, the valves can be tapped in batches conveniently, the valve tapping efficiency is greatly improved, and the practicability is high. And in addition, chippings generated in the tapping process can be conveniently collected and cleaned, and the chippings are prevented from splashing and collapsing.

Owner:王双丽

Auxiliary supporting and mounting mechanism for tempered glass

ActiveCN113389778AGuaranteed stabilityLow costWallsSecuring devicesStructural engineeringToughened glass

Owner:RIZHAO HUAYE GLASS

A fixed limit mechanism for mechanical processing that is convenient for adjusting the limit force

ActiveCN111531382BSufficient powerFast clamping limitPositioning apparatusMetal-working holdersElectric machineGear wheel

The invention discloses a fixed limit mechanism for mechanical processing which is convenient for adjusting the limit force, which includes a fixed workpiece, a clamping mechanism, a control mechanism and a transmission mechanism. If the present invention needs the user to adjust the strength of clamping and fixing the workpiece, the user can start the fixed motor through the external control mechanism, and the fixed motor can drive the gear groove to move forward, and then drive the connecting baffle and the elastic switch to move forward. The time directly lengthens the displacement stroke of the limit block, which in turn makes the displacement of the limit block pull the spring snap ring longer, and improves the strength of the clamping mechanism for clamping and positioning the fixed workpiece. The user can connect the baffle according to the adjustment The distance from the limit slide plate further adjusts the clamping strength of the fixed workpiece, which is convenient for the user to quickly and conveniently adjust the clamping strength of the fixed workpiece, and improves the safety performance of clamping the fixed workpiece.

Owner:贵阳一舟航科机械设备制造有限公司

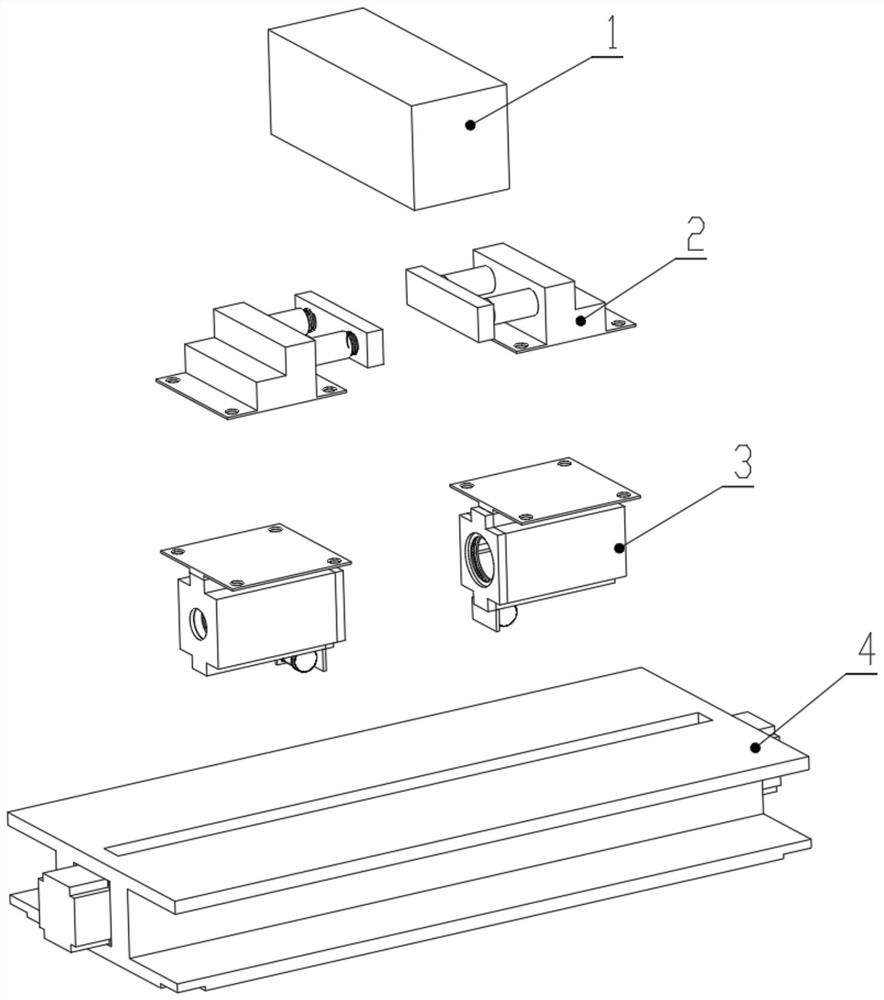

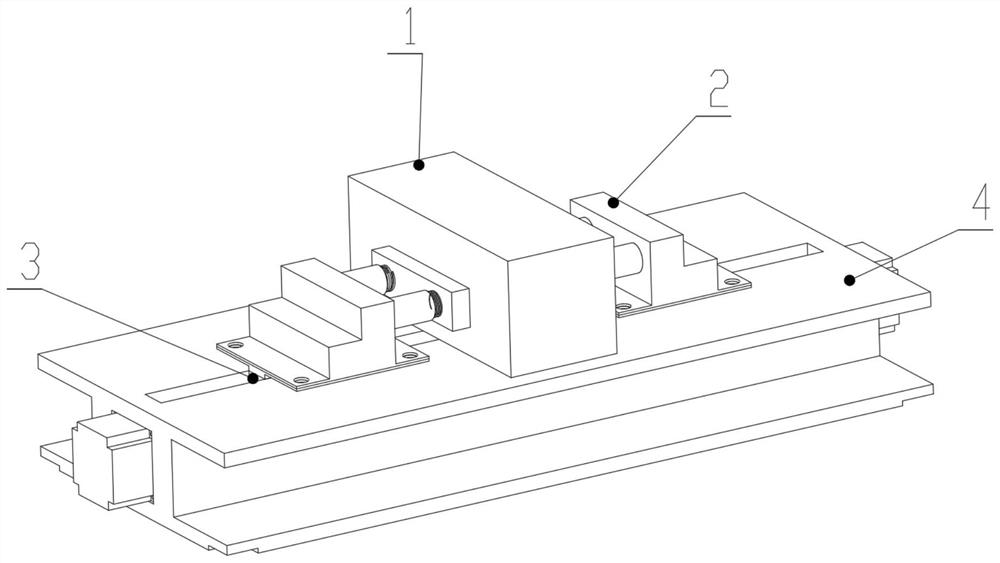

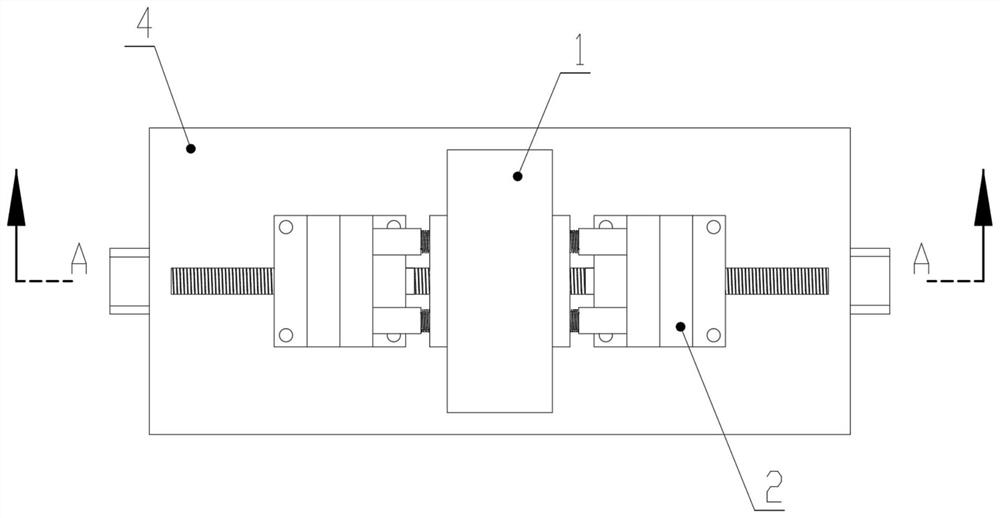

Punching device for production and processing of modular building connecting part and using method of punching device

InactiveCN114012478AEasy to clamp limitStable processing made limitPositioning apparatusMaintainance and safety accessoriesPunchingConstruction engineering

The invention discloses a punching device for production and processing of a modular building connecting part and a using method of the punching device, and relates to the technical field of novel building punching devices. The device comprises a carrying base, the two sides of the carrying base are fixedly connected with first hydraulic piston cylinders through screws, and the output ends of the first hydraulic piston cylinders are fixedly connected with opposite automatic building part positioning structures. Through design of the automatic building part positioning structure, the device can conveniently complete automatic clamping and limiting of the building connecting part, so that automatic machining and manufacturing of the building connecting part are completed; through design of a transverse buffering force unloading structure and an elastic supporting anti-deviation structure, the device can conveniently and stably machine and limit a machined and clamped workpiece, and the influence of machining jumping on the punching position is avoided; and through design of an automatic scrap recycling and guiding-out structure, the device can conveniently and automatically collect and guide out machining scraps.

Owner:丁雪松

A kind of intelligent anchoring equipment for windproof transverse stay cable of large mechanical ship

ActiveCN113602423BImprove stabilityEasy to clamp limitAnchor handling/lashingMarine engineeringChain link

The invention discloses an intelligent anchoring device for large-scale mechanical ship windproof transverse stay cable. The present invention includes an anti-runaway rope anchoring structure, an auxiliary positioning base, a conduction rod and a limit anchoring wheel hub structure. The output end of the anti-runaway rope anchoring structure is fixedly connected with a conduction rod, and the outer side of the conduction rod is rotatably connected to the auxiliary positioning base. One end of the conduction rod away from the runaway prevention rope anchoring structure is fixedly connected with the limit anchoring hub structure. The present invention, through the design of the limited and anchored wheel hub structure, makes the device easy to complete the automatic clamping and limiting of the rest of the chain after the anchor is completed, avoiding the chain sliding on the roller under the blowing of the wind and pulling the anchor. The displacement greatly improves the stability of the anchor, and through the design of the anti-out-of-control rope anchor structure, the device is convenient to form an output emergency stop during the anchor anchoring process and the anchor retraction process, improving the safety of use in emergencies.

Owner:南通麒麟重工机械有限公司

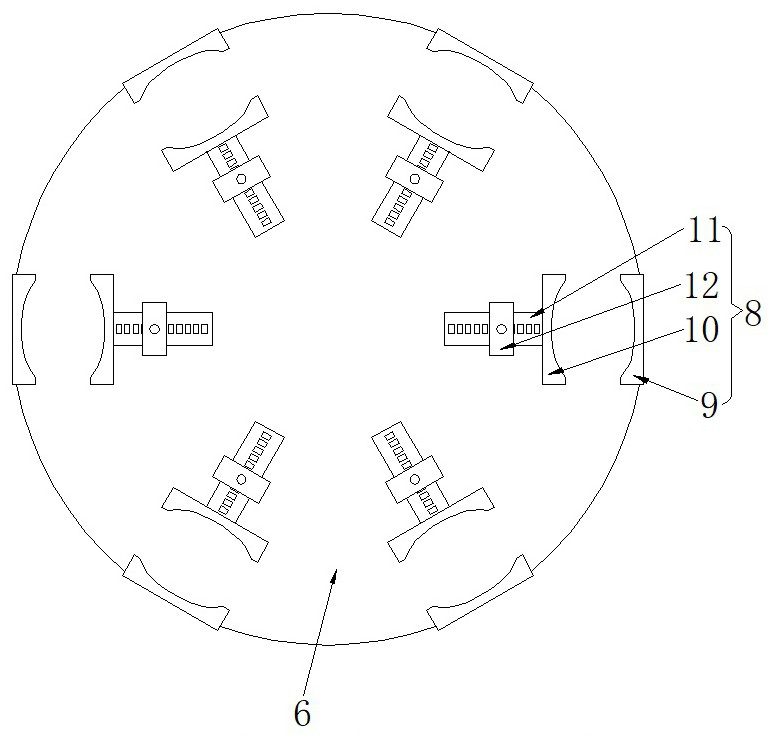

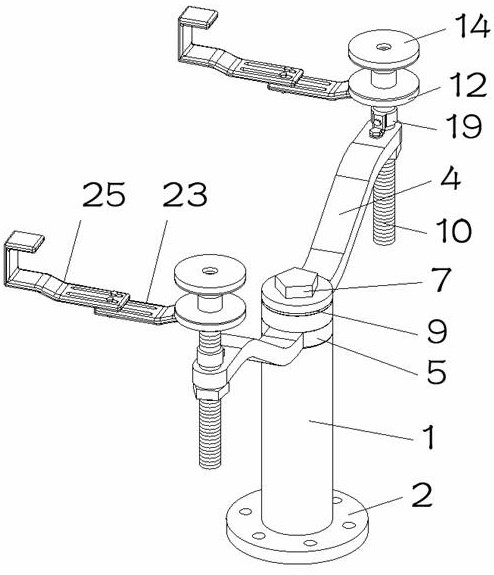

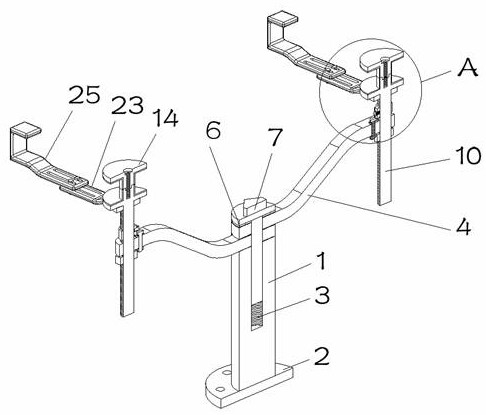

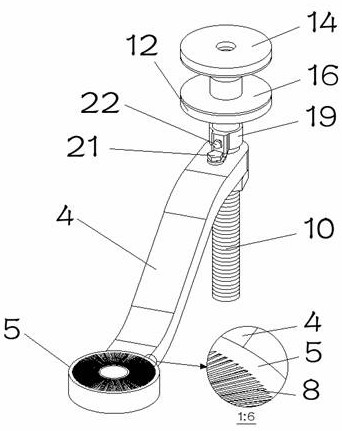

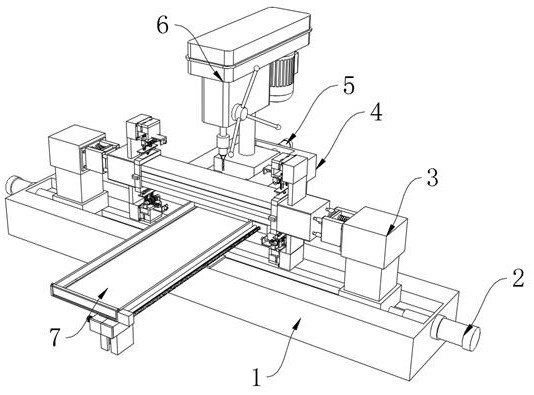

Non-slip multi-angle adjustable drilling device for hardware machining

InactiveCN114472952AImprove slippagePrevent slippageAutomatic control devicesFeeding apparatusStructural engineeringMachining process

The multi-angle adjustable drilling device comprises a base directly arranged on the ground or a workbench, a drilling table, a drilling machine, a bearing column, a clamping mechanism, a mounting sleeve and a fixing mechanism, the drilling table is arranged above the base, the drilling machine is arranged above the drilling table, the bearing column is arranged above the drilling machine, and the clamping mechanism is arranged above the mounting sleeve. The bearing column and the base are connected in a rotating mode, the clamping mechanisms are arranged on the edge of the drilling table at equal angles, the mounting sleeve is used for limiting the position between the mounting support and the fixing frame, and the fixing mechanism is arranged on the right side of the fixing frame. According to the multi-angle adjustable drilling device not prone to slipping and used for hardware machining, machined hardware is clamped and limited, slipping is prevented in the machining process, the angle of the drilling machine is conveniently adjusted, and when different positions of the same hardware are drilled, the hardware does not need to be repeatedly disassembled and clamped.

Owner:姜汇溪

Hydraulic oil cylinder barrel structure capable of preventing axial rotation

PendingCN113883118AEasy to fasten the limitEasy to clamp limitFluid-pressure actuatorsHydraulic ramEngineering

The invention provides a hydraulic oil cylinder barrel structure capable of preventing axial rotation. The hydraulic oil cylinder barrel structure comprises a cylinder barrel body, a fixing disc is welded to the surface of the cylinder barrel body, a piston rod is movably connected to the center of the top of the cylinder barrel body, and a first fixing block is welded to the center of the top of the piston rod; and a first connecting hole is formed in the center of the front face of the first fixing block, and clamping mechanisms are arranged on the two sides of the piston rod correspondingly. Through cooperation of moving columns, fixing boxes, first threaded sleeves, first threaded rods, bearings, moving plates, limiting columns and clamping seats, a user can conveniently clamp and limit the piston rod through the clamping seats, the piston rod is prevented from axially rotating during jacking, and through cooperation of mounting blocks, second threaded sleeves, second threaded rods and convex blocks, the user can conveniently clamp and fasten the two clamping seats; and through cooperation of positioning blocks and positioning rods, the user can conveniently assist the clamping mechanisms in limiting the piston rod.

Owner:CHANGDE LIANJIA MACHINERY

Pacemaker sandbag fixer

The pacemaker sandbag fixator comprises a first fixing frame and a second fixing frame, an adjusting mechanism is arranged between the first fixing frame and the second fixing frame, limiting nets are arranged at the positions, close to the edges of the inner side walls, of the upper ends of the first fixing frame and the second fixing frame, and movable grooves are formed in the corner positions of the first fixing frame and the second fixing frame. First bandages and second bandages are arranged in the movable grooves correspondingly, a protection mechanism is arranged between the two first bandages, the adjusting mechanism comprises a first adjusting plate, and a groove is formed in the position, close to the first fixing frame, of the upper end of the first adjusting plate; according to the fixing device, sandbags of different sizes can be conveniently clamped and limited, so that the fixing device is suitable for the sandbags of different sizes, the practicability of the fixing device is effectively improved, the sandbags can be well fixed to the body of a patient, meanwhile, sweat generated at the contact position of the back of the patient and the base plate can be absorbed, the sandbags are kept dry, and the comfort is improved.

Owner:颍上县人民医院

A clamping device for valve body end surface processing

ActiveCN111300094BEasy to clamp limitSmooth rotationPositioning apparatusMetal-working holdersRegulatorEngineering

The invention discloses a clamping device for machining the end face of a valve body, comprising a support frame, a rotation limit mechanism is connected to the bottom of the support frame, a fixing mechanism is connected to the top of the rotation limit mechanism, and the top ends of the inner walls on both sides of the support frame are drilled through. There are two rows of connecting grooves, the support frame is respectively connected with supporting mechanisms through the two rows of connecting grooves on both sides, and the bottoms of the two supporting mechanisms are connected with adjusting machines. The valve body is clamped with the end face of one side of the flange plate, and it is convenient to clamp the flange plate on the valve body of different sizes; through the use of the rotating limit mechanism and the fixing mechanism, it is convenient to have the method. The flanged valve body rotates during the machining process, which is convenient to operate; through the combination of the support mechanism and the adjustment mechanism, it is convenient to insert the internal push-in limit on the two end faces of the valve body, which has good practicability and promotion. .

Owner:广州市科阳机电阀门有限公司

Knitted fabric processing device facilitating cutting

InactiveCN111851051AEasy to clamp limitImprove cutting efficiencySevering textilesStructural engineeringMechanical engineering

The invention discloses a knitted fabric processing device facilitating cutting, and belongs to the technical field of fabric processing. The problem that an existing device cannot clamp and fix a fabric, and consequently the fabric is prone to falling off is solved. The knitted fabric processing device is characterized in that a base, a left vertical plate and a right vertical plate are included;the left vertical plate and the right vertical plate are arranged on the base, and the bottom of the left vertical plate and the bottom of the right vertical plate are fixed to the base; the left vertical plate and the right vertical plate are fixedly connected through a supporting cross rod, and a cutting mechanism is arranged below the supporting cross rod; and a fabric clamping assembly used for clamping the fabric is further arranged on the base and connected with a displacement mechanism. According to the knitted fabric processing device of the embodiment, a position mechanism is arranged, the position of the fabric clamping assembly is conveniently adjusted, thus the cutting efficiency of the fabric is improved, meanwhile through arrangement of the fabric clamping assembly, fabricswith different thicknesses are conveniently clamped and limited, falling off of the fabrics is avoided, the position of the cutting mechanism is flexible and adjustable, and the cutting efficiency isfurther improved.

Owner:SUZHOU AILIFANG CLOTHES CO LTD

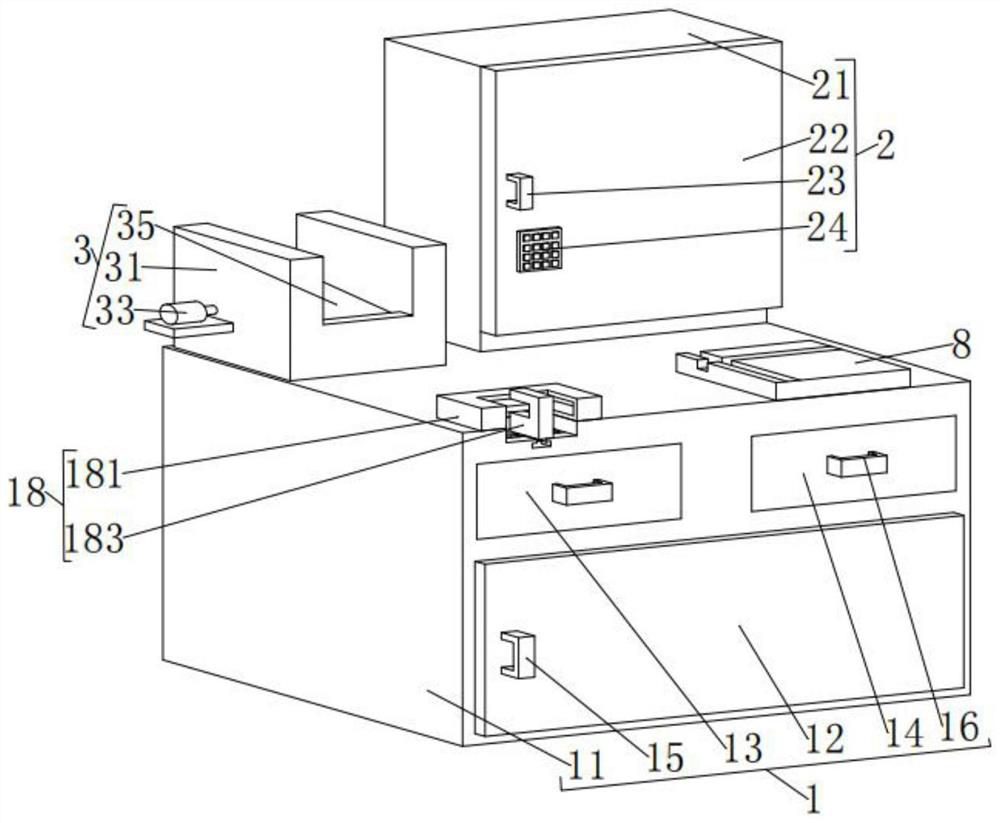

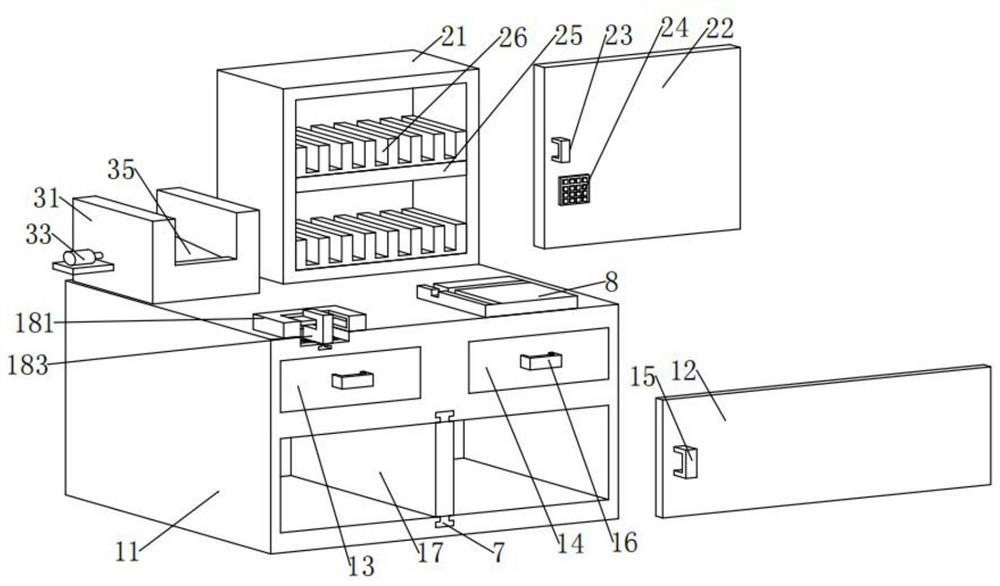

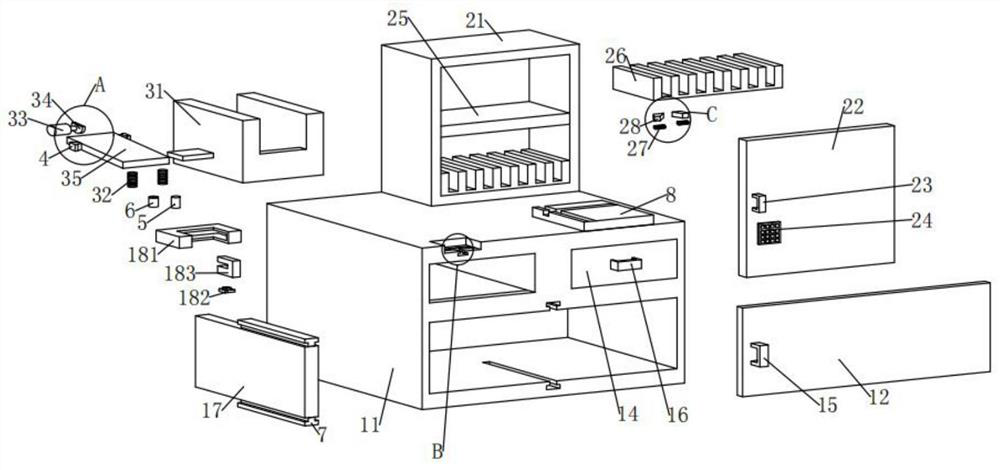

Medical record information data integration tool

InactiveCN113384096AEasy to storePlay a protective effectBook cabinetsChestsMedical recordSoftware engineering

The invention discloses a medical record information data integration tool. The integration tool comprises an auxiliary structure, a storage structure and an arrangement structure, wherein the storage structure is fixedly arranged on the auxiliary structure, and the arrangement structure is fixedly arranged on the auxiliary structure; the invention relates to the technical field of data integration tools, some articles possibly used during binding or storage and cutting tools can be conveniently stored through the first structure, file bags can be stored through the second structure, files can be conveniently clamped and limited, the coded lock can protect internal files and prevent file bags from inclining or turning over, information data are sorted and aligned through overall cooperation, the data can be vibrated through the sorting structure to be aligned, then the data are put into the clamping frame to be bound through a stapler, taking during use is facilitated, and the file cover can be clamped and limited, so uniformity is ensured, and the situation that the file cover is inconvenient to find due to inclination is prevented.

Owner:陈海霞

Steel bar cutting and packaging device for construction site

The invention discloses a steel bar cutting and packaging device for a construction site. An auxiliary mechanism is mounted at the bottom position of one end of a cutting machine body, the auxiliary mechanism comprises fixing blocks, a rotating plate, a sliding hole, a guide rod, a sliding frame, a connecting plate, a limiting plate, a supporting rod, a limiting plate, a mounting plate, a contraction spring, a sliding rod and a rubber ball, the fixing blocks are symmetrically welded to the bottom position of one end of the cutting machine body, the rotating plate is rotationally embedded into the bottom ends of the fixing blocks, and the sliding hole is formed in the side position of one end of the rotating plate. According to the steel bar cutting and packaging device, one side of a steel bar is conveniently limited, so that through the rotating plate, when the steel bar is cut, the steel bar is conveniently extruded and fixed by matching with the limiting plate, the steel bar is conveniently cut, and then the cutting efficiency is improved.

Owner:中建三局科创产业发展有限公司

A metallized film capacitor winding machine

ActiveCN112700979BEasy to cutEasy to cleanWinding capacitor machinesWinding machineHydraulic cylinder

The invention discloses a metallized film capacitor winding machine, specifically relates to the technical field of winding machines, comprising a bottom plate, one side of the top of the bottom plate is fixedly connected with a vertical plate, and the top of the vertical plate is fixedly connected with a top plate, so The top of the top plate is provided with a cutting mechanism, the two sides of the vertical plate are fixedly connected with a workbench, the inside of the workbench is provided with a conveying mechanism, the two sides of the bottom end of the workbench are fixedly connected with legs, and the workbench One side of the bottom end is provided with a dust removal mechanism, and one side of the top end of the workbench is provided with a clamping and limiting mechanism. The present invention is provided with a support seat, a hydraulic cylinder, a clamping block and a telescopic sleeve rod. When in use, after the item is transported to the designated position, the staff places the item between the clamping blocks, starts the hydraulic cylinder, and the hydraulic cylinder drives the expansion and contraction. The sleeve rods are stamped opposite to each other, so as to clamp and limit the items, which is convenient for the rolling of the items, and is suitable for clamping and limiting the items of different sizes, which improves the applicability of the equipment.

Owner:新昌县杨辉网络科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com