Patents

Literature

105results about How to "Cases to prevent drift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

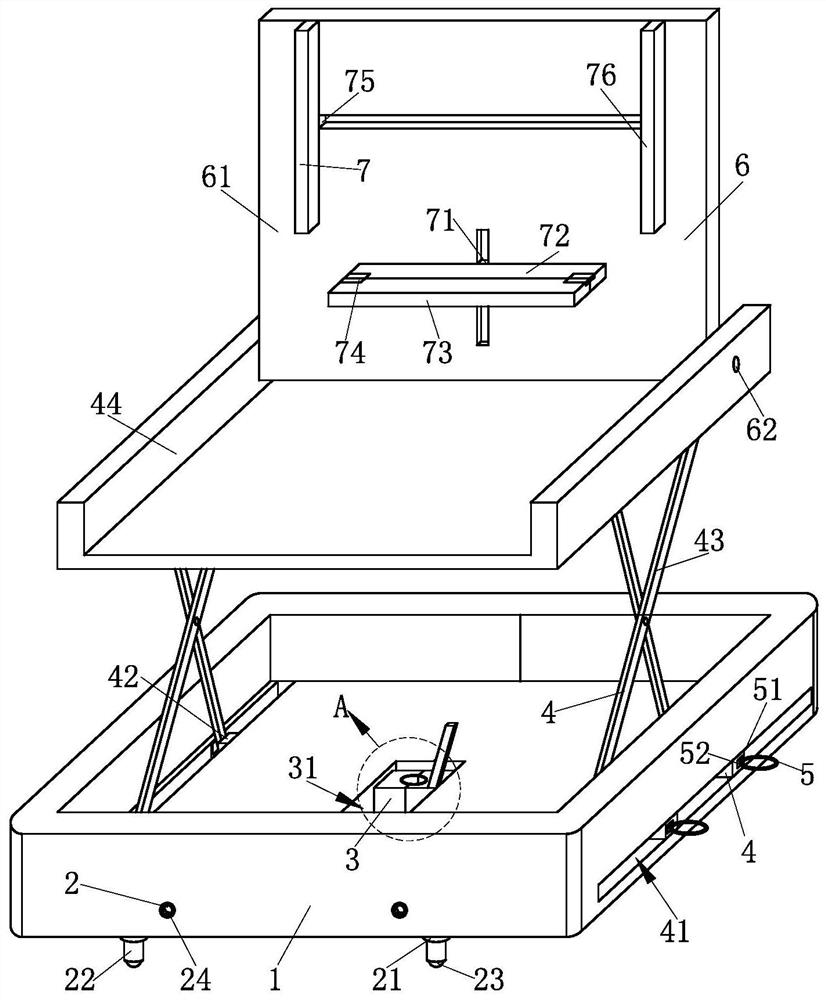

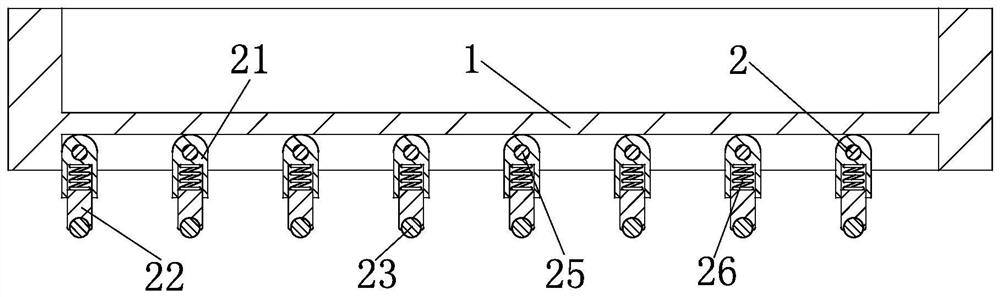

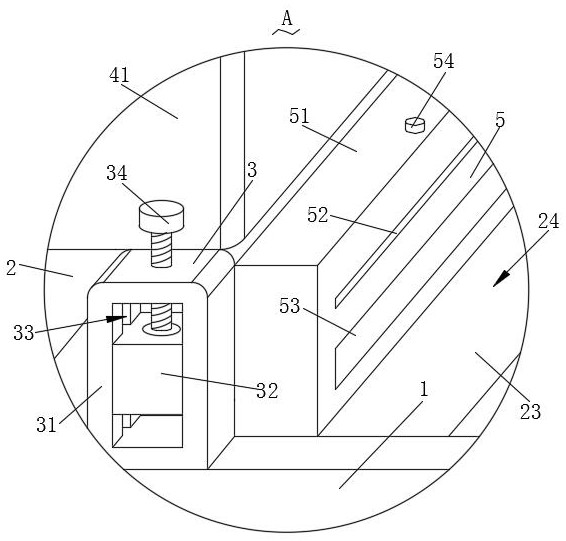

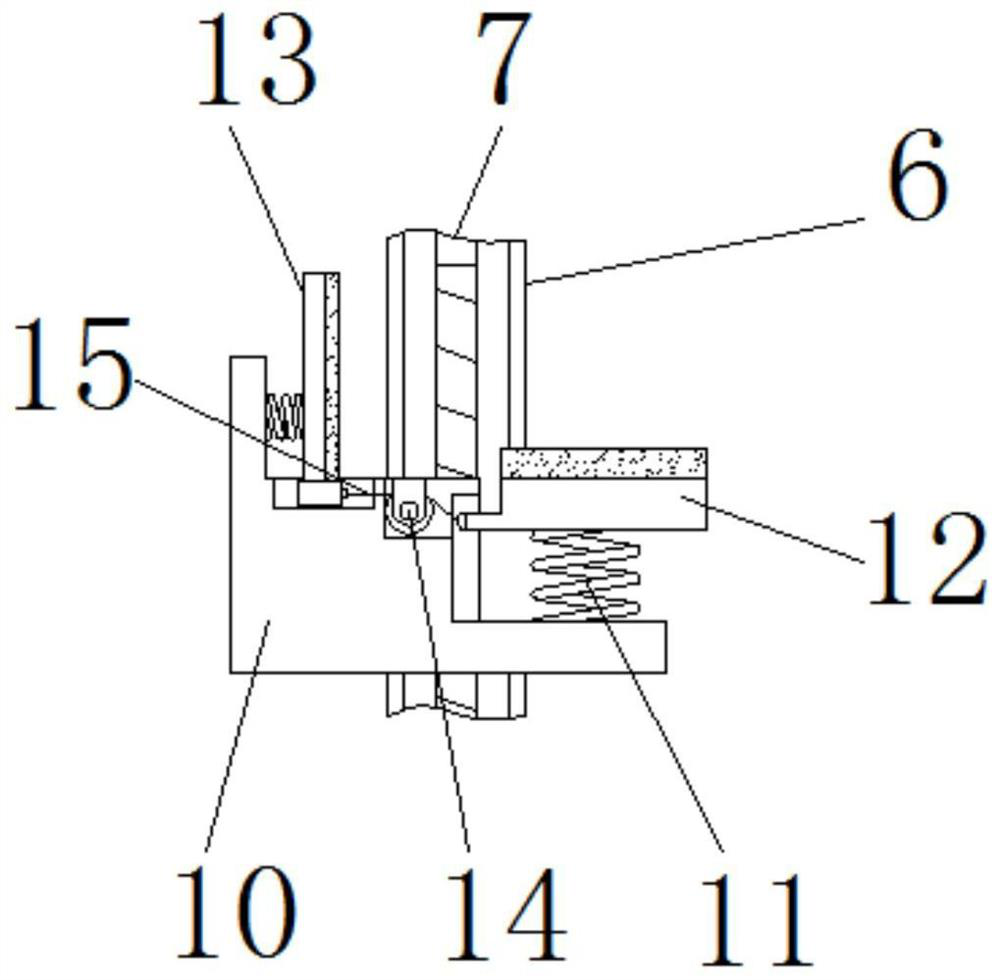

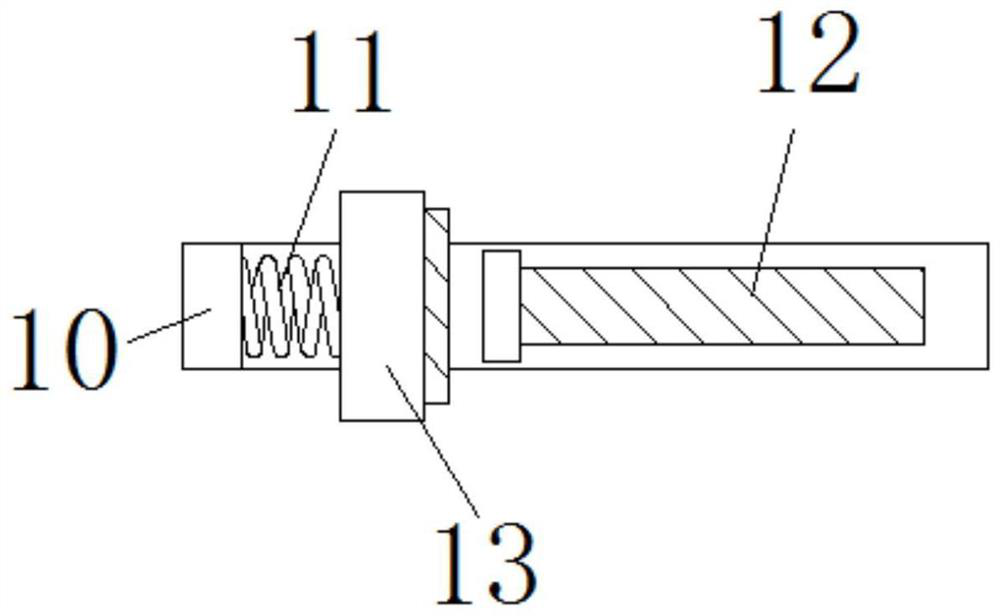

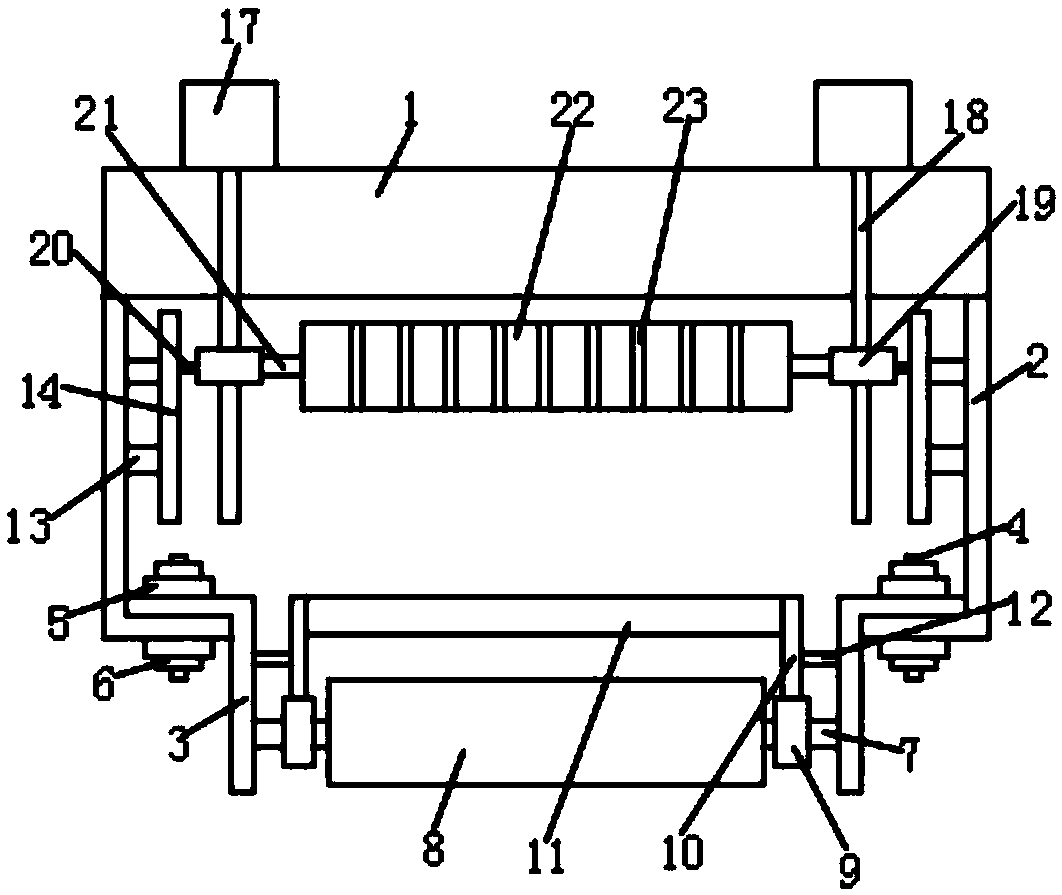

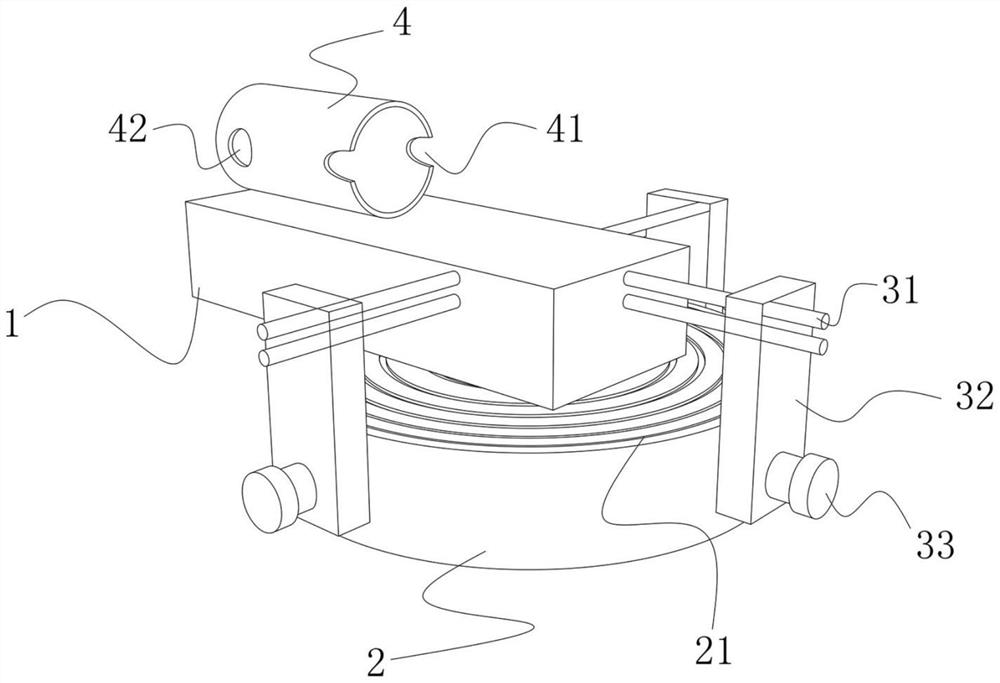

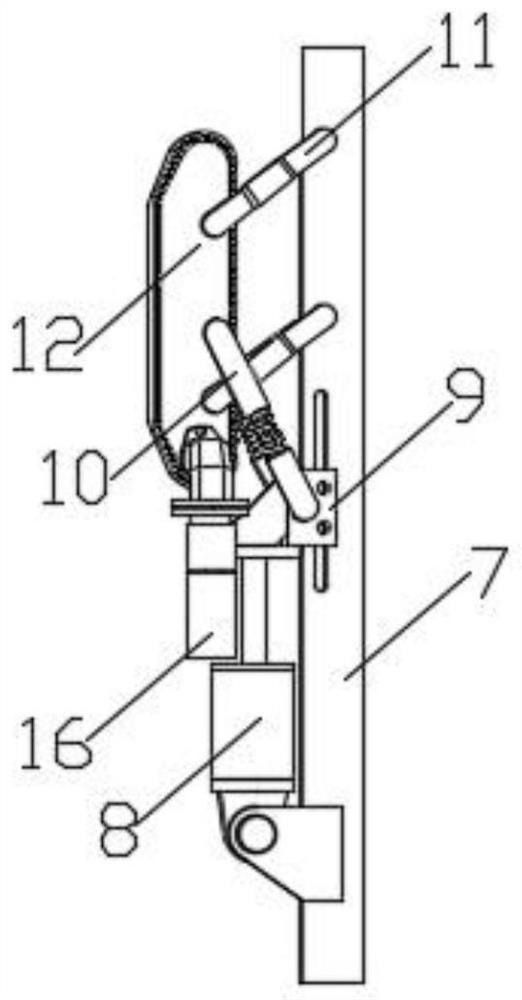

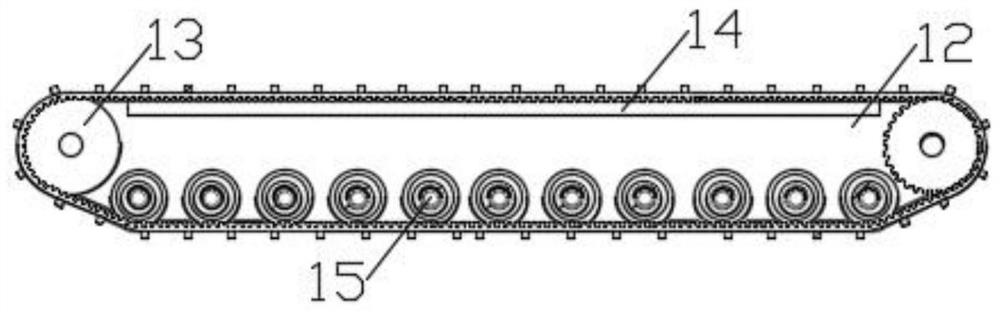

Steel pipe nondestructive testing fixing device

InactiveCN111624323AEasy to install and replaceEasy to storeWork benchesTesting metalsSteel tubeNondestructive testing

The invention relates to the field of steel pipe nondestructive testing devices, in particular to a steel pipe nondestructive testing fixing device, which comprises a box body, a supporting structure,a clamping structure, a folding structure, a positioning structure, a limiting structure and a fixing structure. The supporting structure is mounted at the bottom end of the box body to achieve the effect of supporting the box body when the box body is used for nondestructive testing; the box body can be better attached to the surface of the steel pipe, so that movement of the box body is facilitated, and the detection precision is improved; the clamping structure is mounted at the bottom end of the box body in a matched manner, so that the detection head can be conveniently mounted and replaced; by means of folding structure, the assembly for placing the detector can be folded and stored, so that the device is convenient to use; the folding structure is simple in structure and convenientto use, can play a supporting role in use, can be prevented from automatically falling back after being lifted by being matched with the arrangement of the positioning structure, thus ensuring the stability of placing the detector. By means of the limiting structure, the arrangement assembly for placing the detector can be conveniently supported, retracted and stored.

Owner:永旗农业科技发展(杭州)有限公司

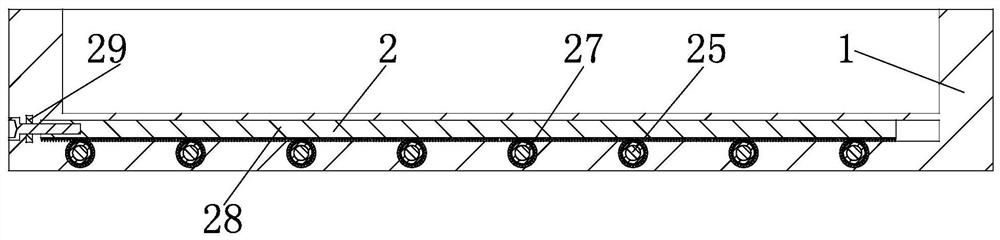

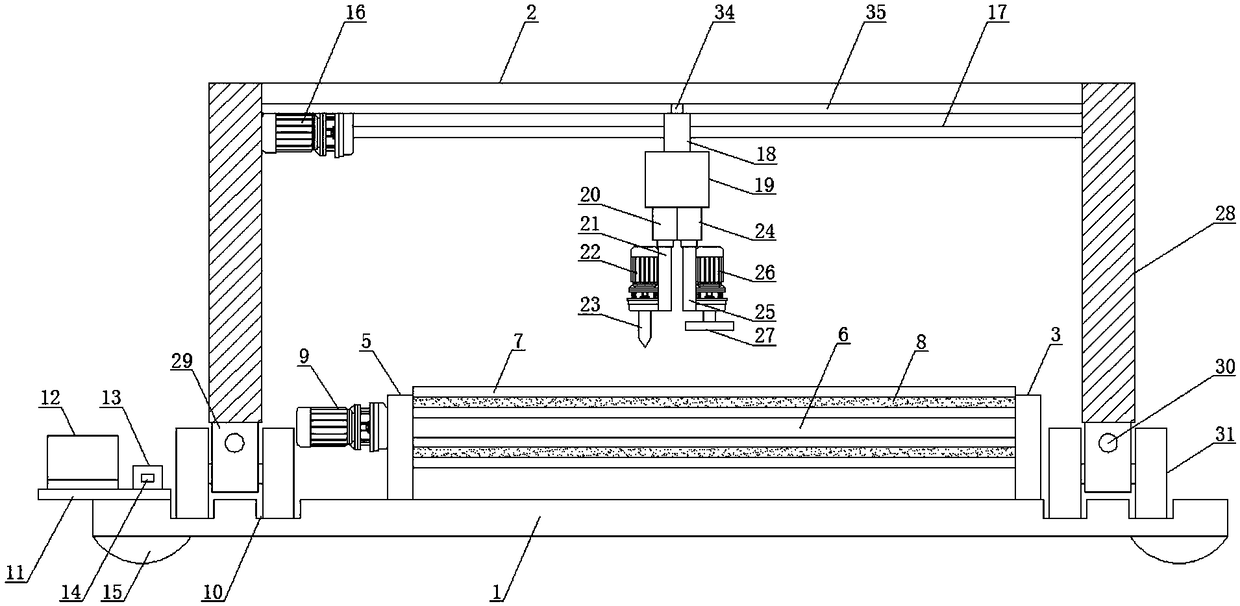

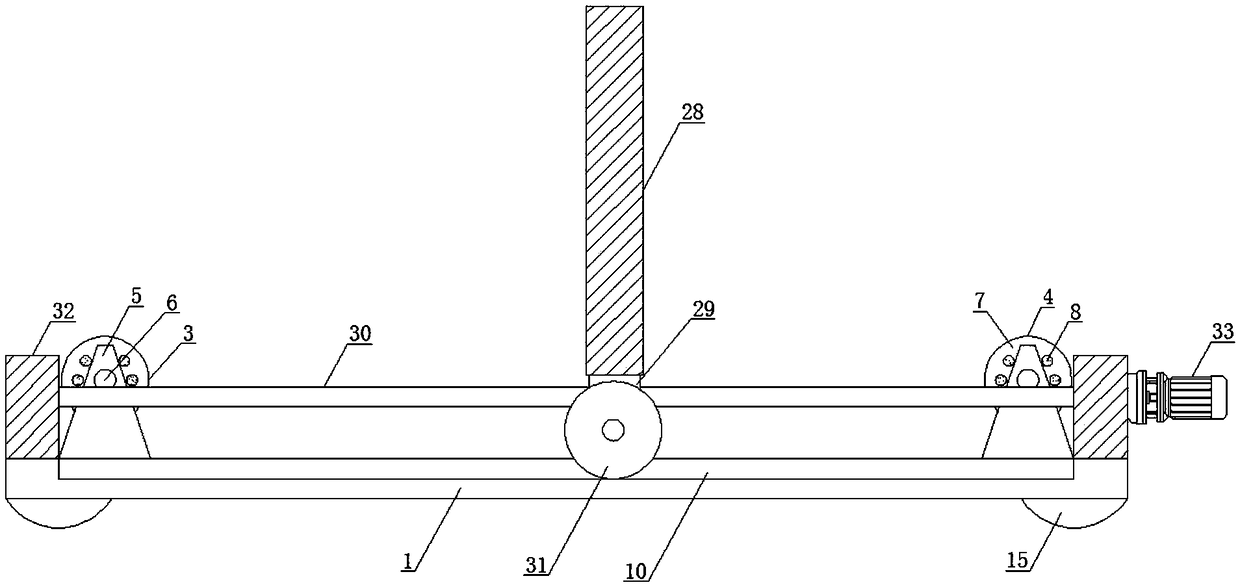

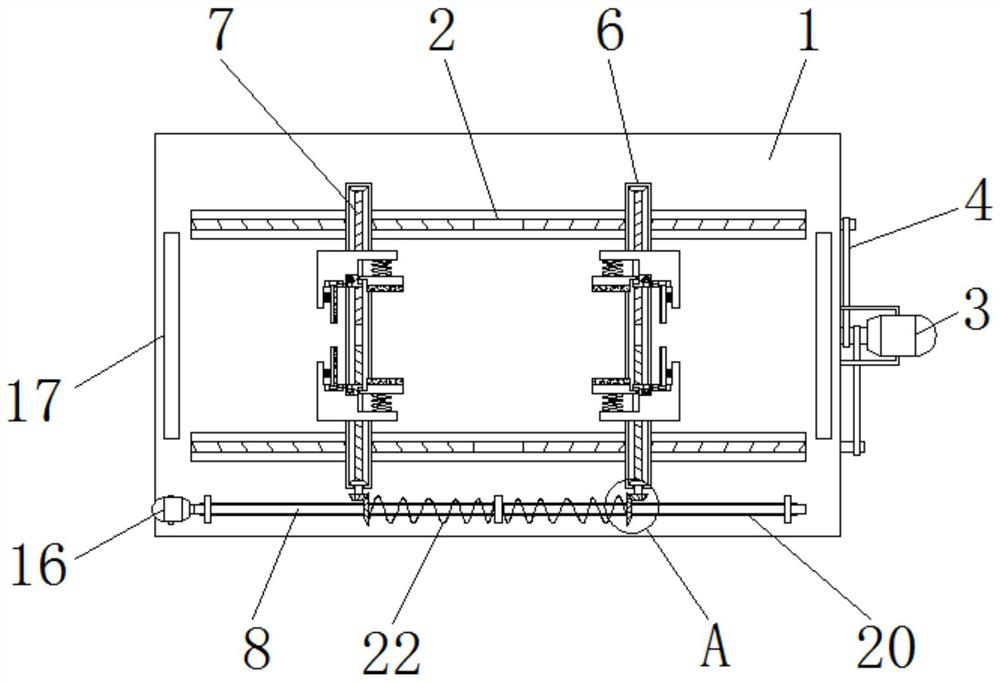

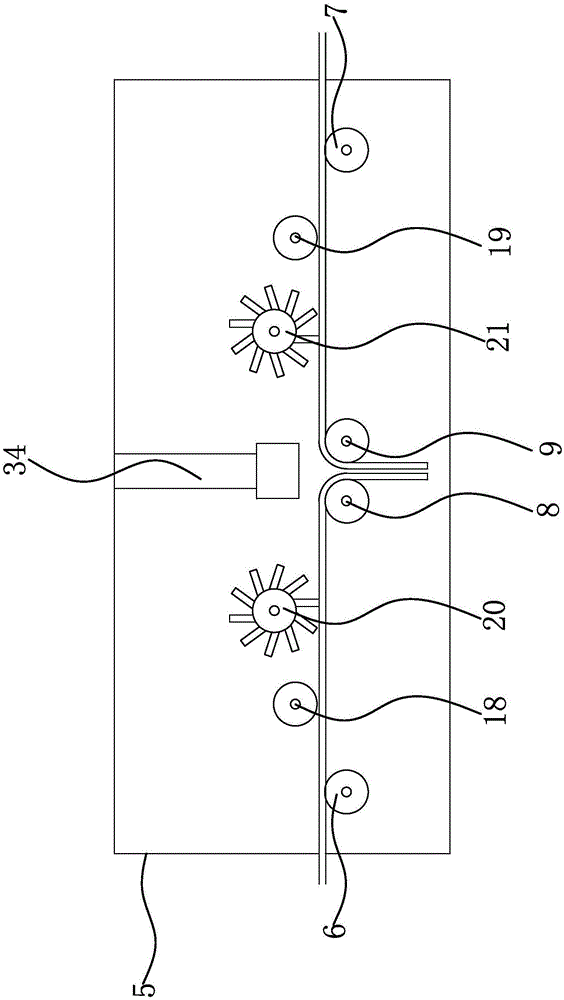

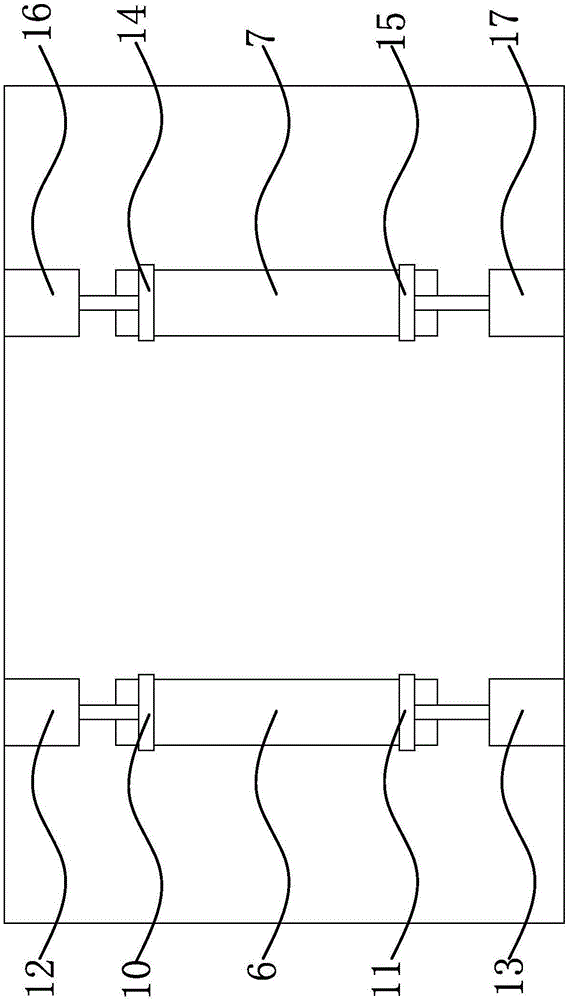

Anti-deviation printing machine

InactiveCN112357634ACases to prevent driftImplementation of the offsetRotary pressesPile receiversProcess engineeringManufacturing engineering

The invention relates to the field of printing machines, in particular to an anti-deviation printing machine. The anti-deviation printing machine comprises a support, a conveying structure, a printingstructure, an automatic adding structure, a clearing structure and a collecting structure. the conveying structure is arranged at one end of the support, and paperboards can be limited and fixed, sothat the situation that the paperboards deviate is prevented; the printing structure is arranged in a matched mode so that the paperboards with different thicknesses can be printed; the automatic adding structure is arranged at the top end of the printing structure, printing dye can be temporarily stored, and the automatic dye supplementing work can be automatically carried out on a printing assembly inside the printing structure, so that automatic continuous printing work is achieved, and the printing efficiency is greatly improved; the distance between the automatic adding structure and theprinting assembly can be automatically changed, so that the applicability of the device is improved; and the clearing structure is arranged in a matched mode, and paperboard chippings adhering to theprinting assembly can be swept and collected, so that the printing quality is improved.

Owner:朱顺华

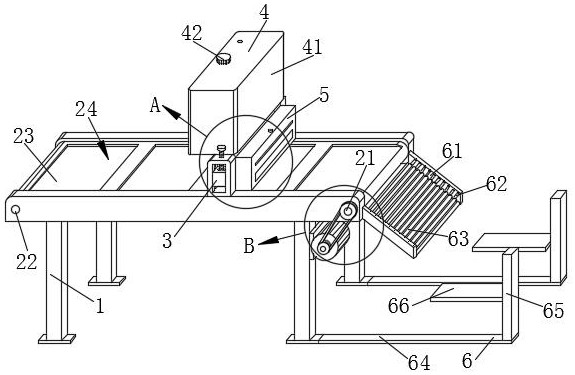

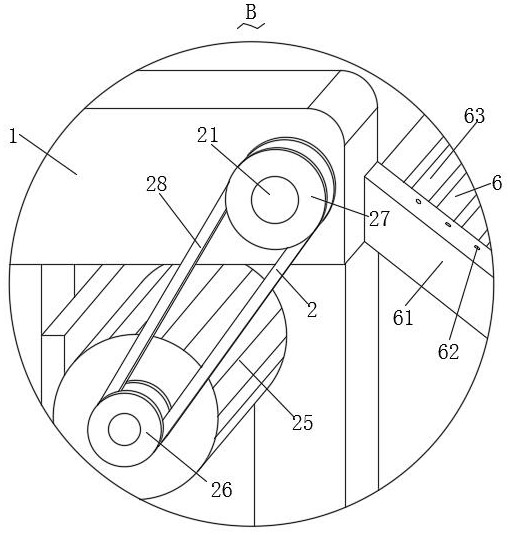

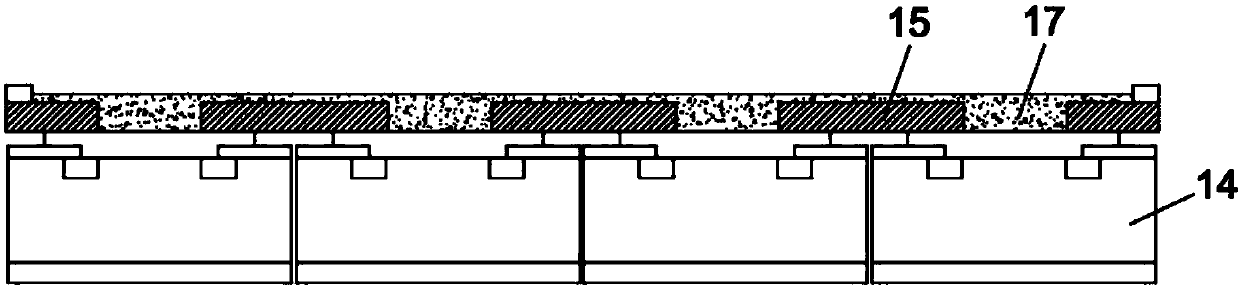

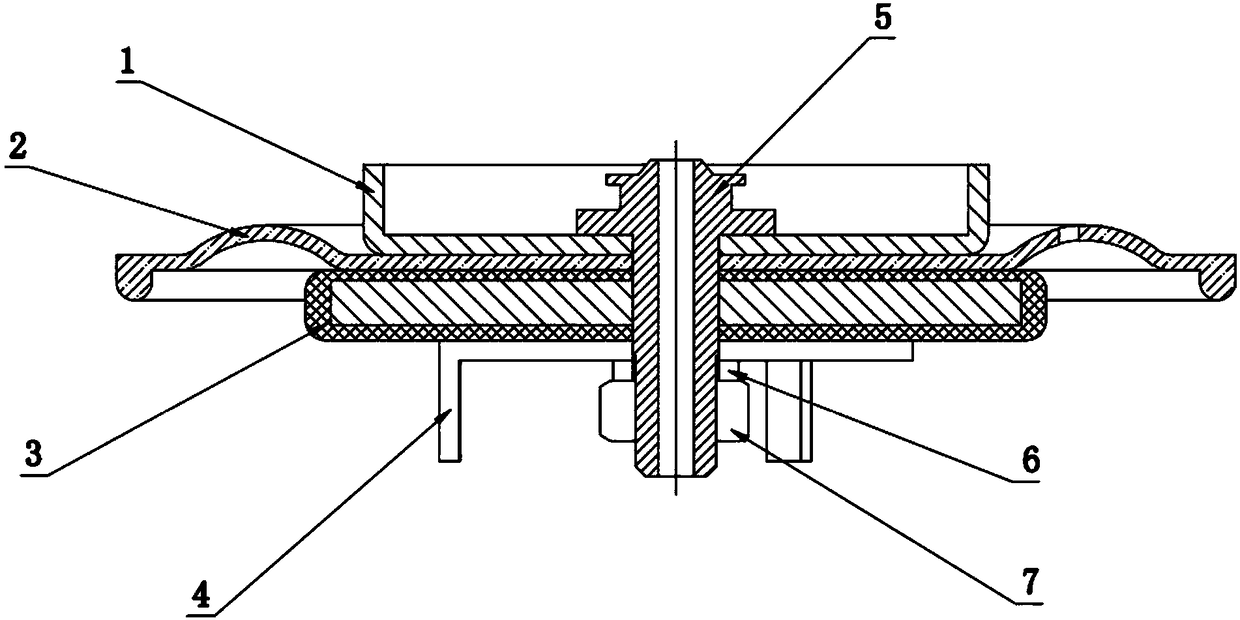

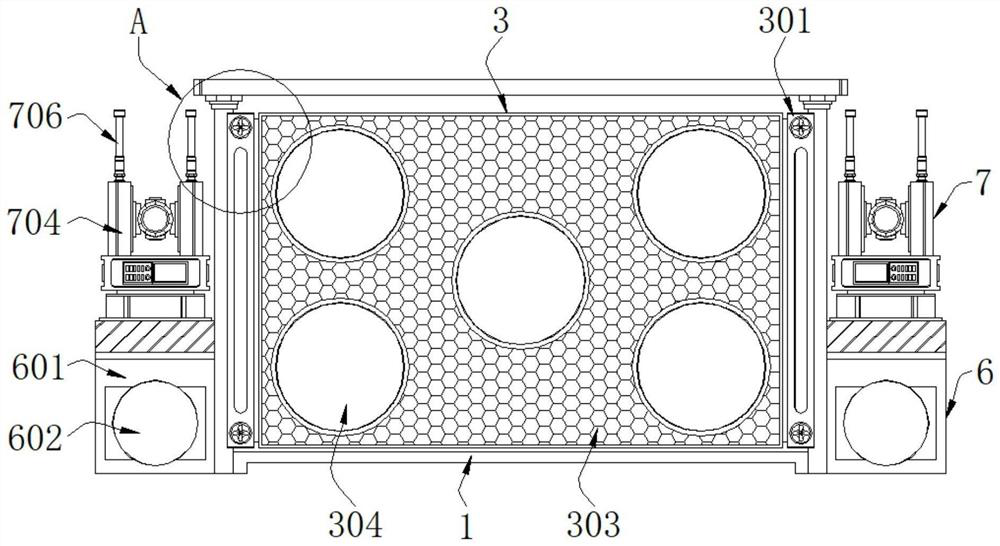

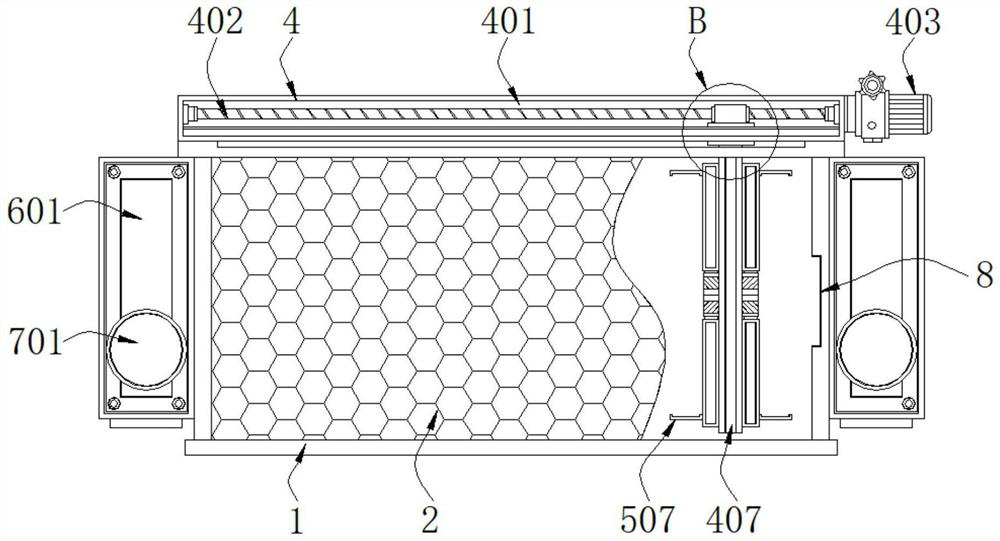

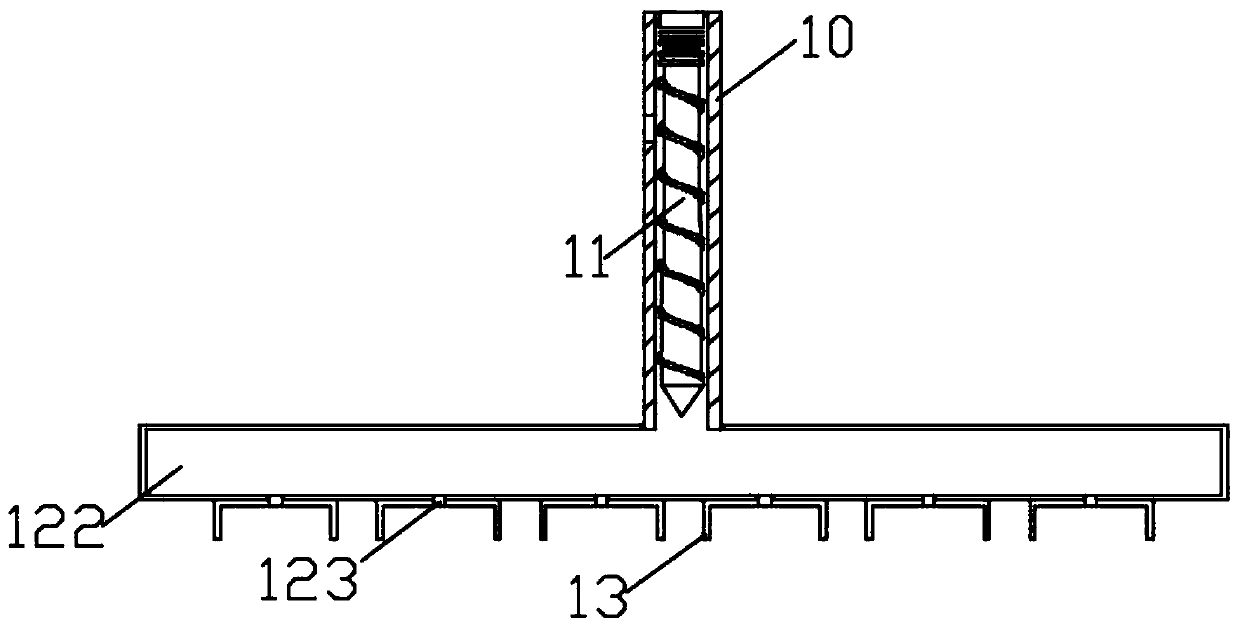

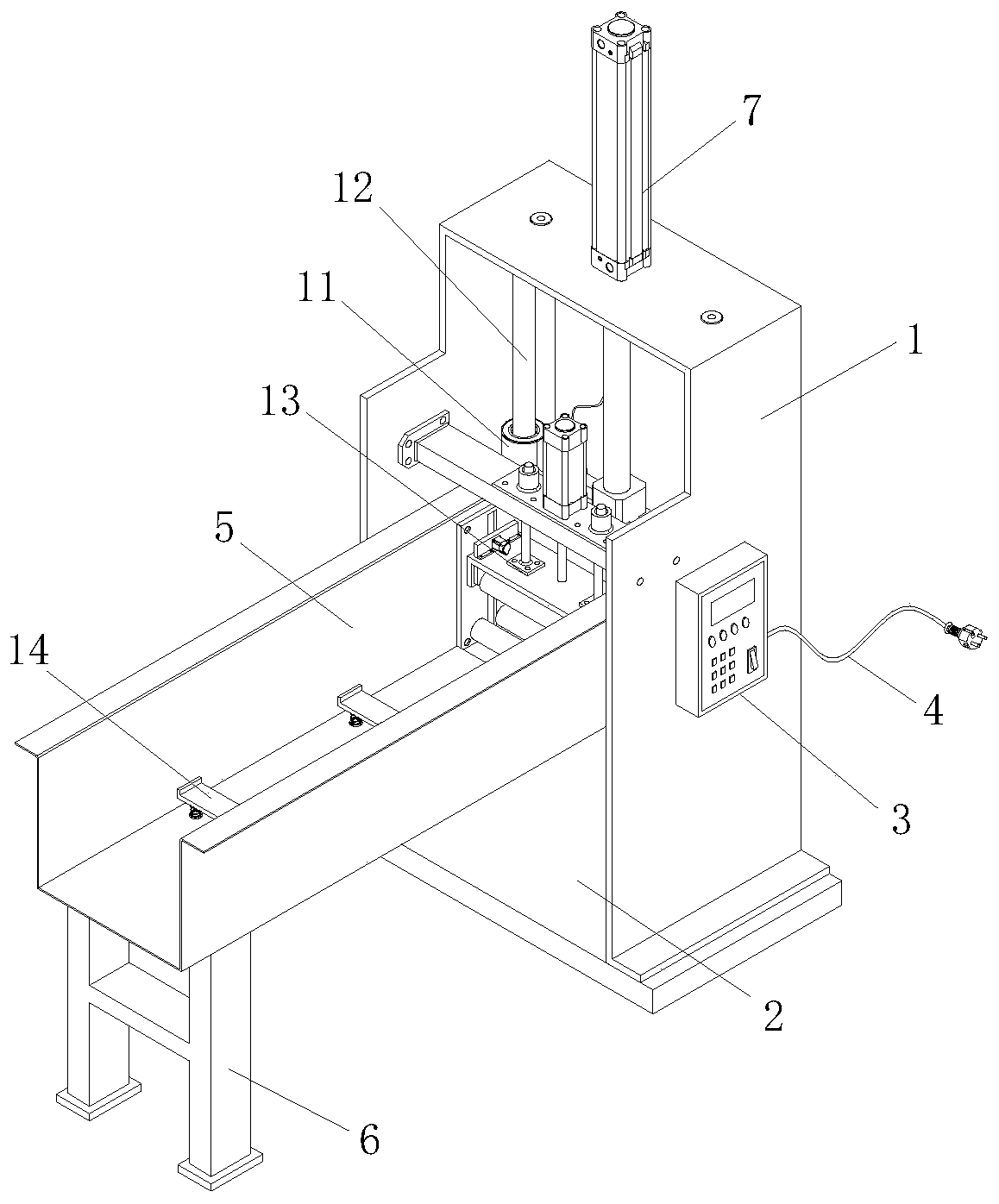

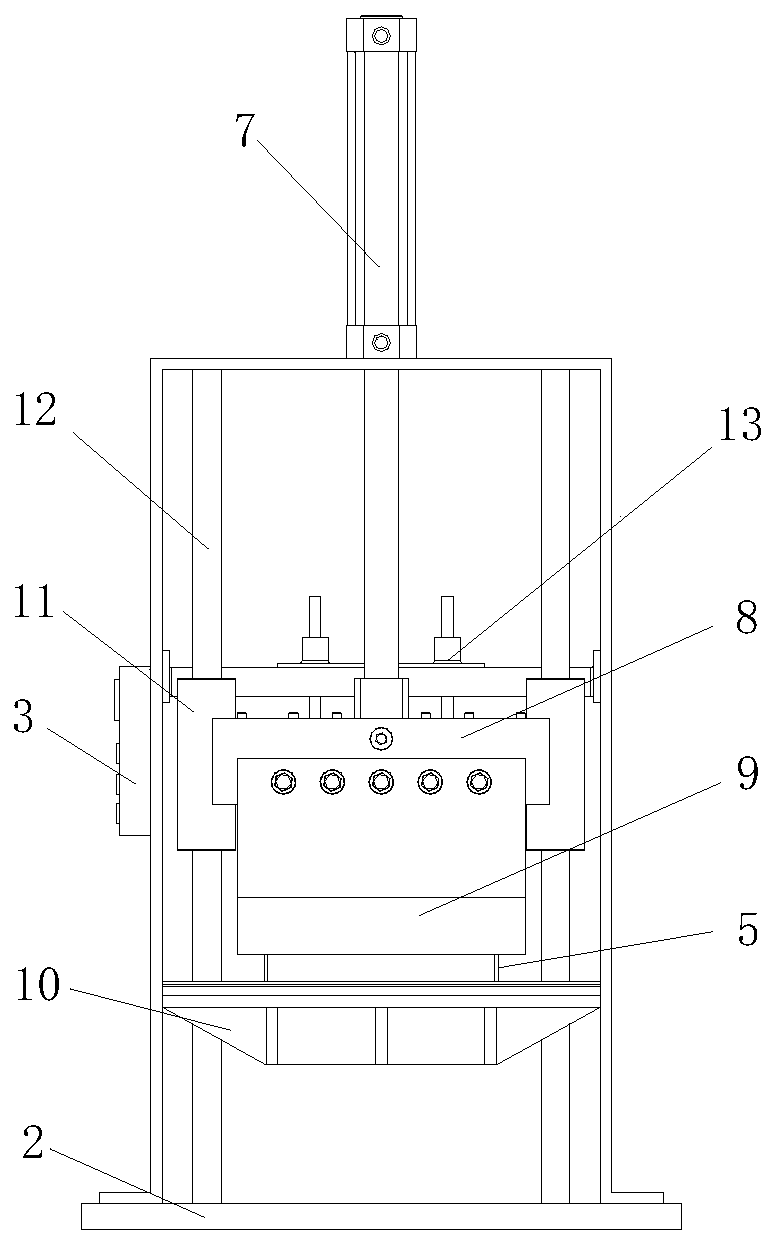

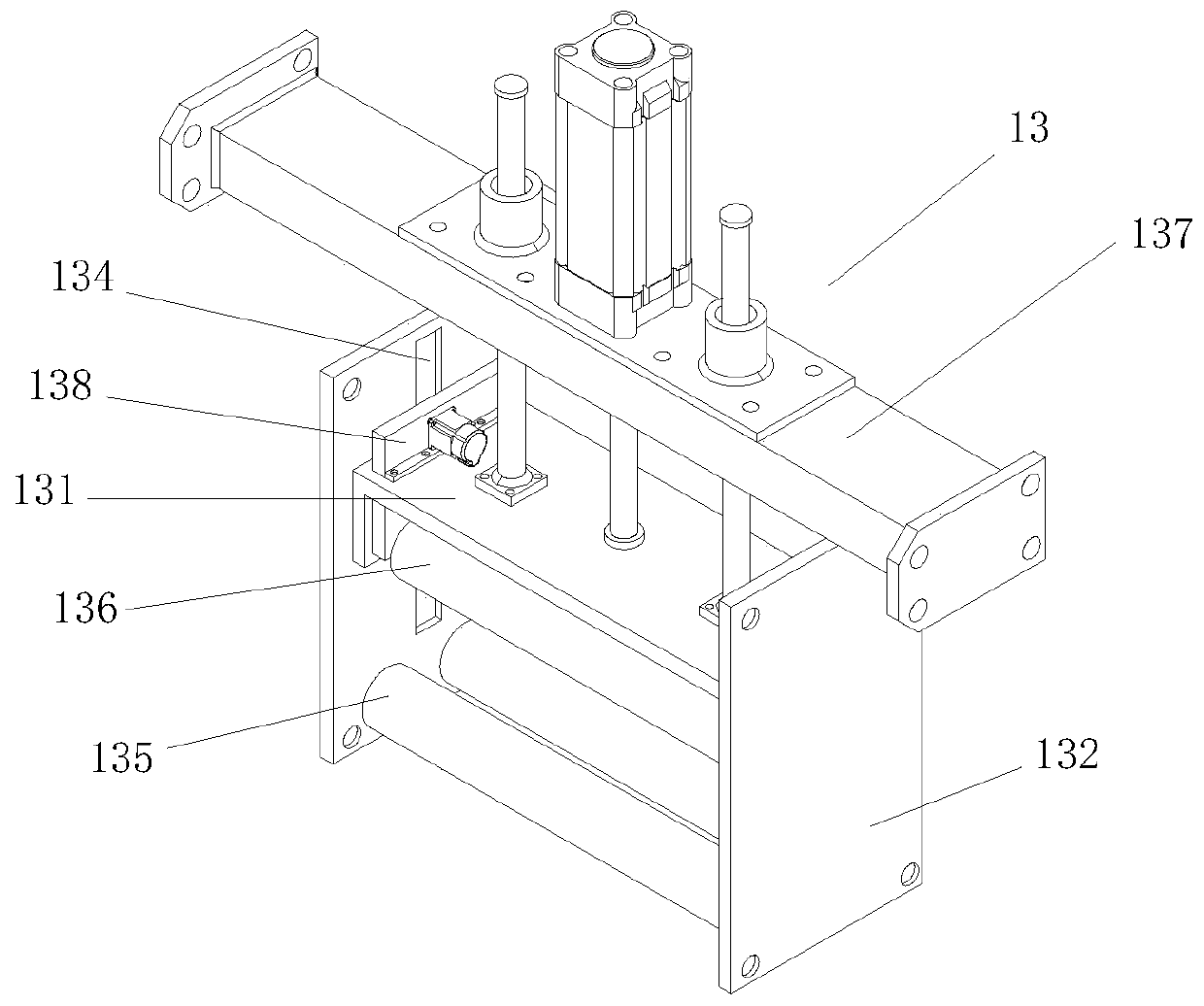

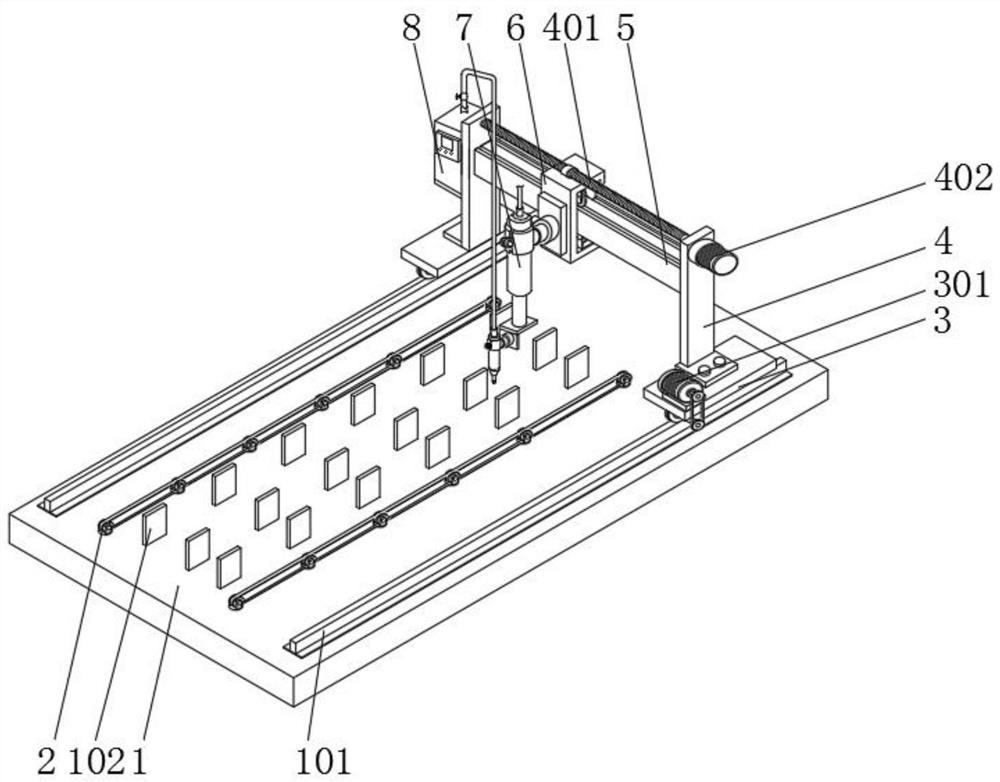

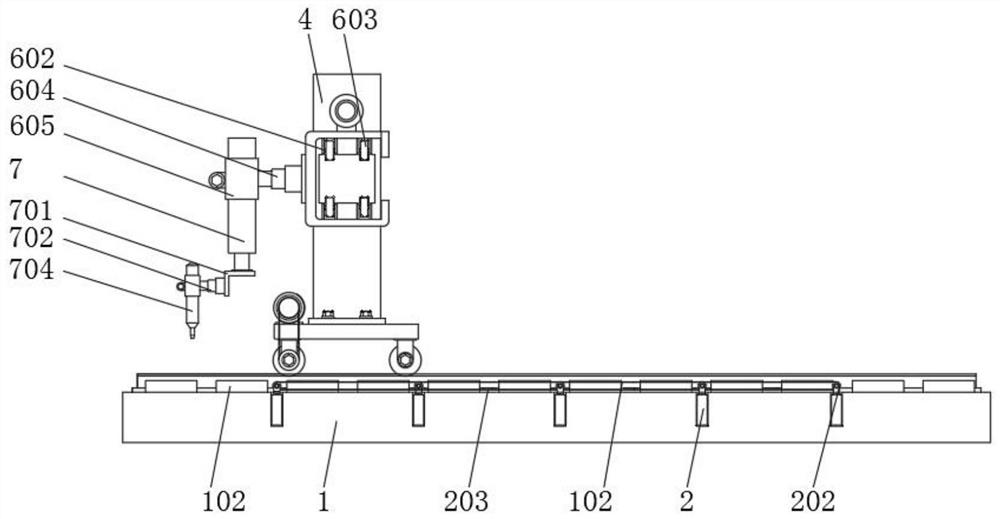

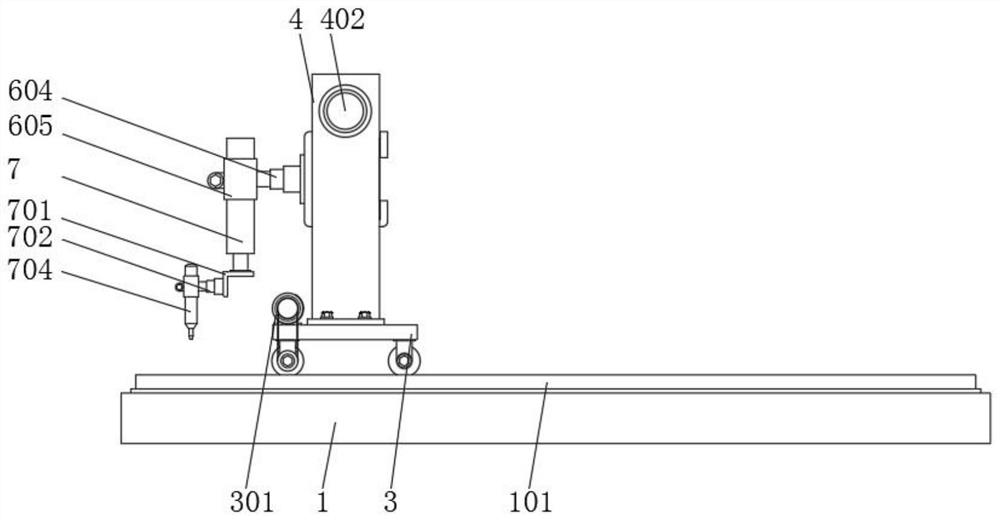

Photovoltaic panel machining and assembling equipment and working method thereof

InactiveCN111571012ASatisfy welding workImprove welding efficiencyLaser beam welding apparatusCells panelStructural engineering

The invention discloses photovoltaic panel machining and assembling equipment and a working method thereof. According to the photovoltaic panel machining and assembling equipment, the positions of right-angle clamping blocks are adjusted through a piston rod of a third air cylinder, the two sides of the bottom of each cell panel are clamped by the four right-angle clamping blocks, then a piston rod of a second air cylinder downwards pushes a lifting plate to descend, and then the cell panels are driven to descend; and the cell panels placed above the cell installation position of a photovoltaic panel, the piston rod of the third air cylinder extends, the cell panels are placed at the cell installation position of the photovoltaic panel, and then the belt continues to convey the photovoltaic panel to the position below a fixing box. The technical problems that in the prior art, when the photovoltaic panel is machined, as for a cell panel installing device for photovoltaic panel machining, after one previous cell panel is installed, an operator needs to supplement for the cell panels in time, and installation of the cell panels of different widths cannot be met at the same time are solved.

Owner:刘烨

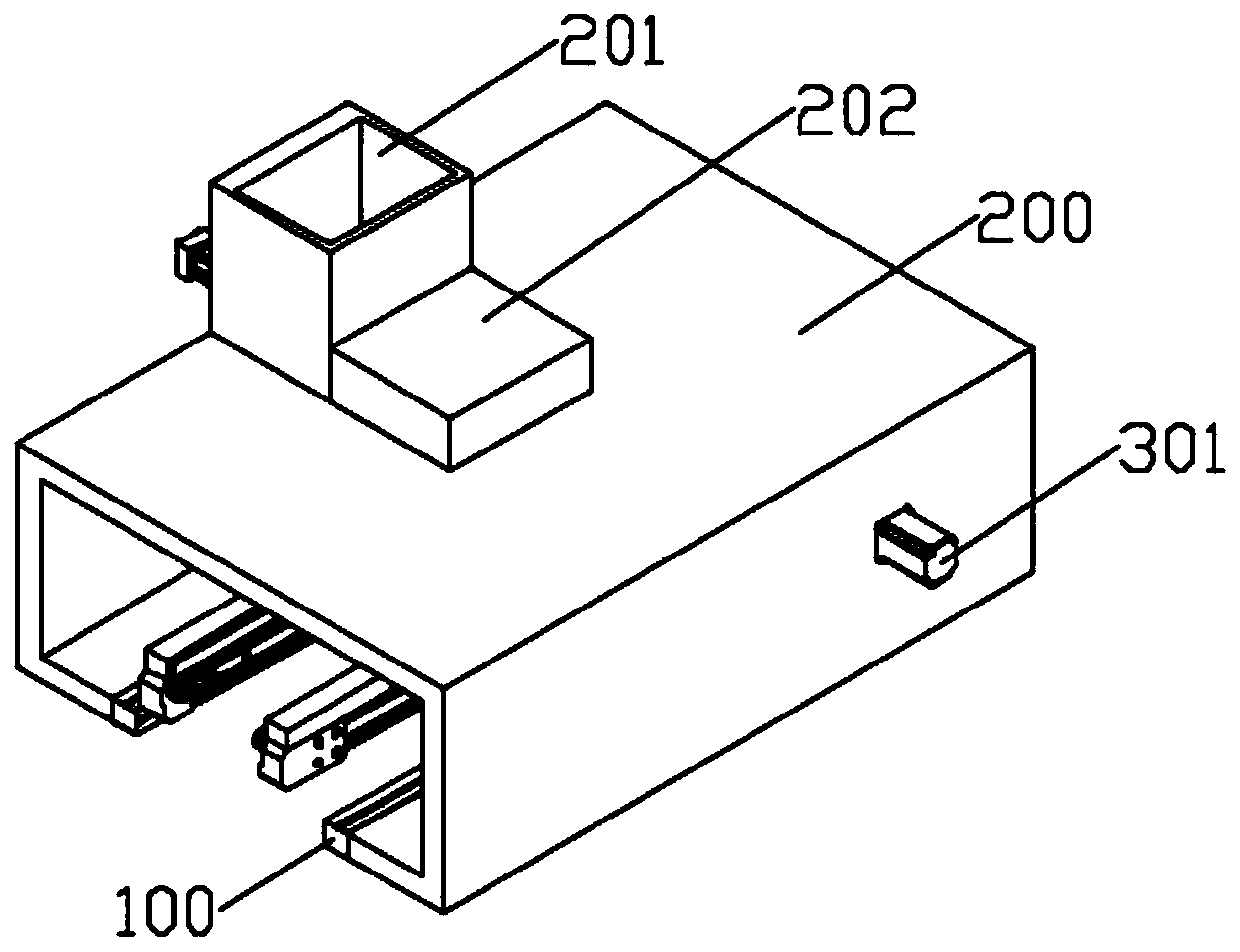

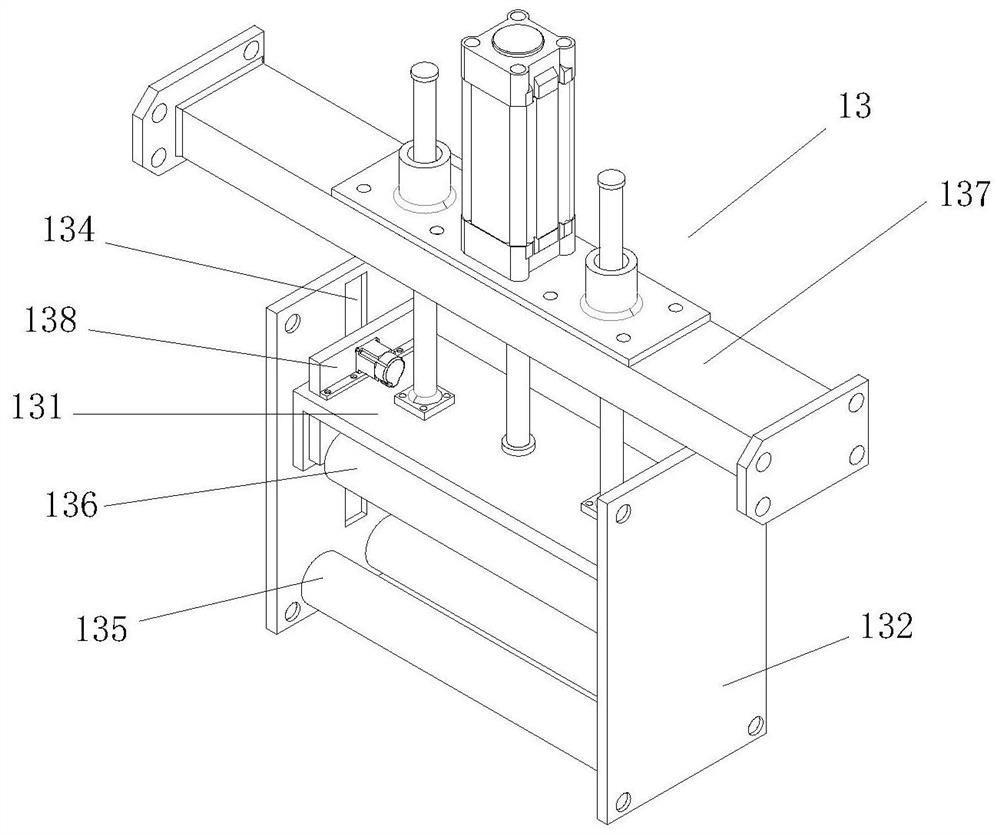

Sliding plate control device for converter sliding plate slag blocking

InactiveCN111235345AAvoid crackingExtended service lifeManufacturing convertersConvertersSlide plate

The invention relates to the technical field of converters, and discloses a sliding plate control device for converter sliding plate slag blocking. The sliding plate control device for converter sliding plate slag blocking comprises a mold frame, a right fixing plate is fixedly connected to the right end of the front of the mold frame, and a left fixing plate is fixedly connected to the left end of the front of the mold frame; and the front of the right fixing plate and the front of the left fixing plate are connected with fixing screws in a threaded mode, the middle parts of the left side andthe right side of the mold frame are fixedly connected with limiting blocks, the top ends and the bottom ends of the left side and the right side of the mold frame are fixedly connected with chucks,and positioning blocks are fixedly connected to the top and bottom of the right fixing plate. According to the sliding plate control device for converter sliding plate slag blocking, after a sliding plate is installed in the mold frame, and an adjusting screw is rotated to push a push plate to move downwards, so that a power arm moves inside a movable groove; two symmetrically arranged movable blocks hold the sliding plate tightly, so that the sliding plate is fixed in the mold frame; and the impact force of the sliding plate and a cushion block is used, cracks caused by the impact of the sliding plate are effectively avoided, and the service life of the sliding plate is prolonged.

Owner:ANHUI YUNTIAN METALLURGY TECH

Safety belt production device with cutting function

InactiveCN109500868ACases to prevent driftAvoid cut quality impactMetal working apparatusMechanical engineeringExtrusion

The invention discloses a safety belt production device with a cutting function. The device comprises a base; the base is provided with a first conveying belt; a first extension device is arranged above the first conveying belt; the first extension device comprises an extrusion plate, a shrinkage rod, a spring and an extension rod; the shrinkage rod is fixedly arranged on the extrusion plate; thespring is fixedly arranged at the upper end of the shrinkage rod, and is arranged in the extension rod; a rolling shaft is rotationally arranged on one side of the extension rod, and is provided witha cutting wheel; a second extension device is arranged on one side of the cutting wheel for preventing deviation of safety belts during cutting to prevent influence on the cutting quality, so that thenormal use and sale of the safety belts is guaranteed, the use cost is reduced, the cutting work can be continued, and the cutting efficiency is improved; meanwhile, the safety belts with different sizes can be cut; the cut safety belts can be timely collected; and the device is simple in operation, high in practicability and convenient for popularization and application.

Owner:安徽和泰汽车配件股份有限公司

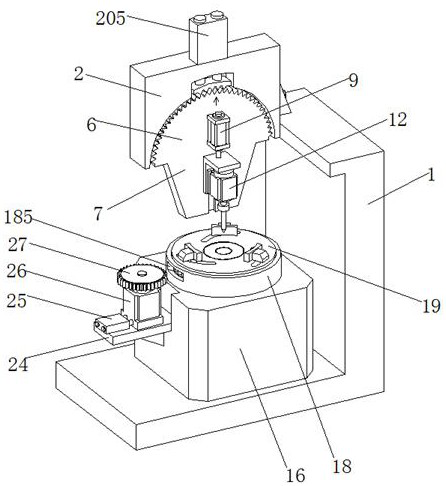

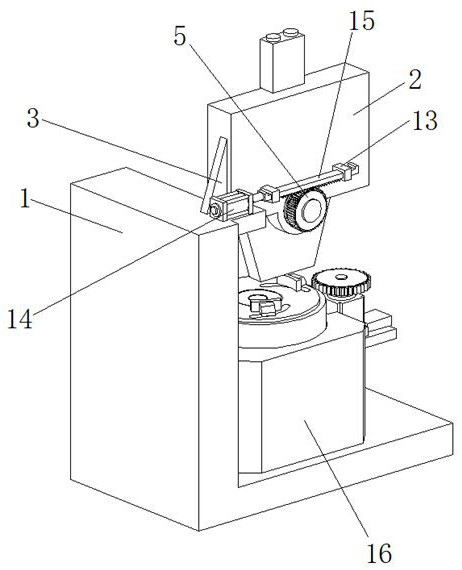

Internal combustion engine flywheel inclined hole machining equipment

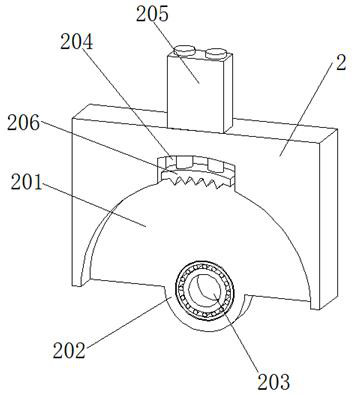

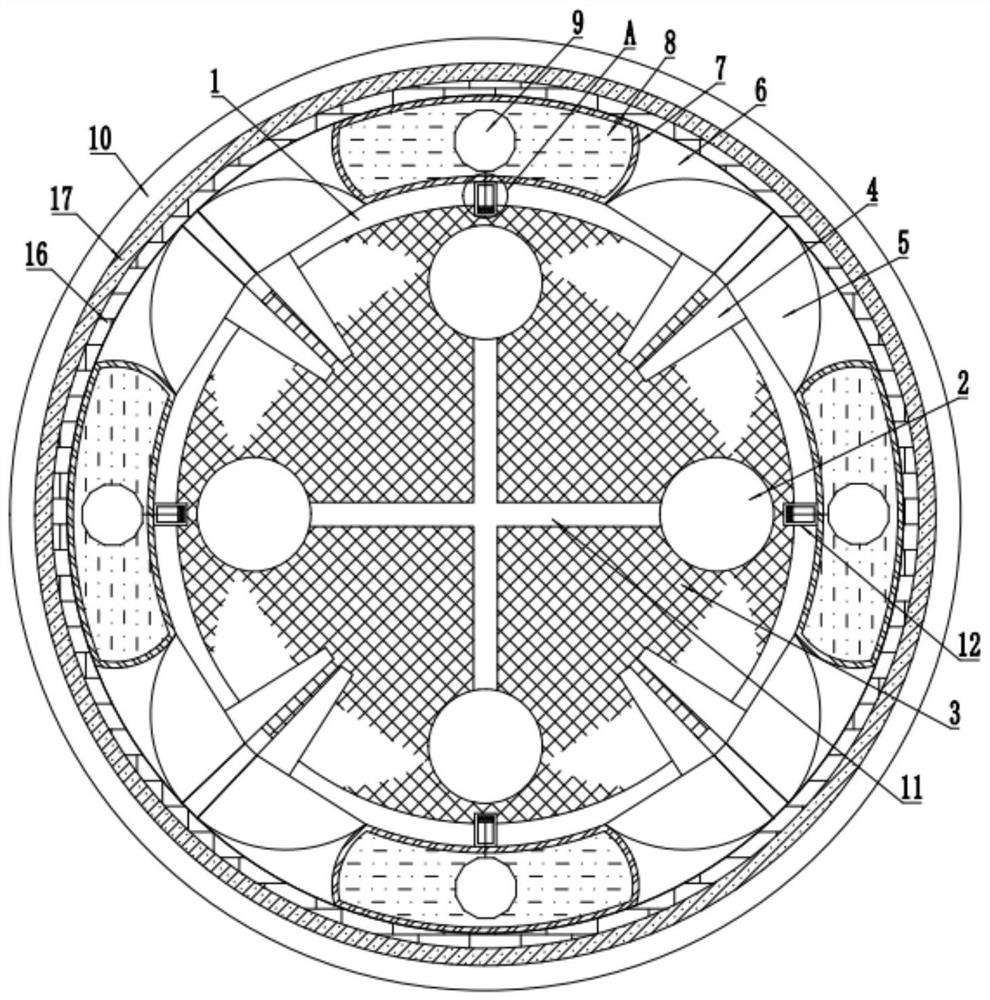

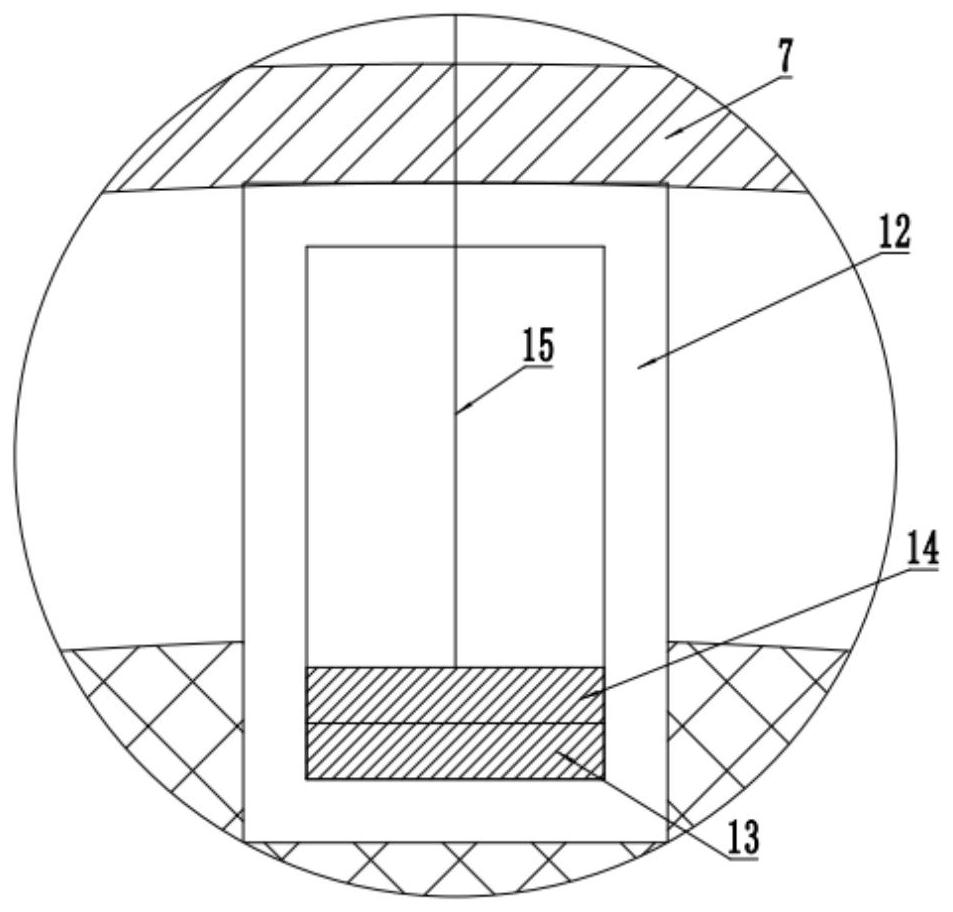

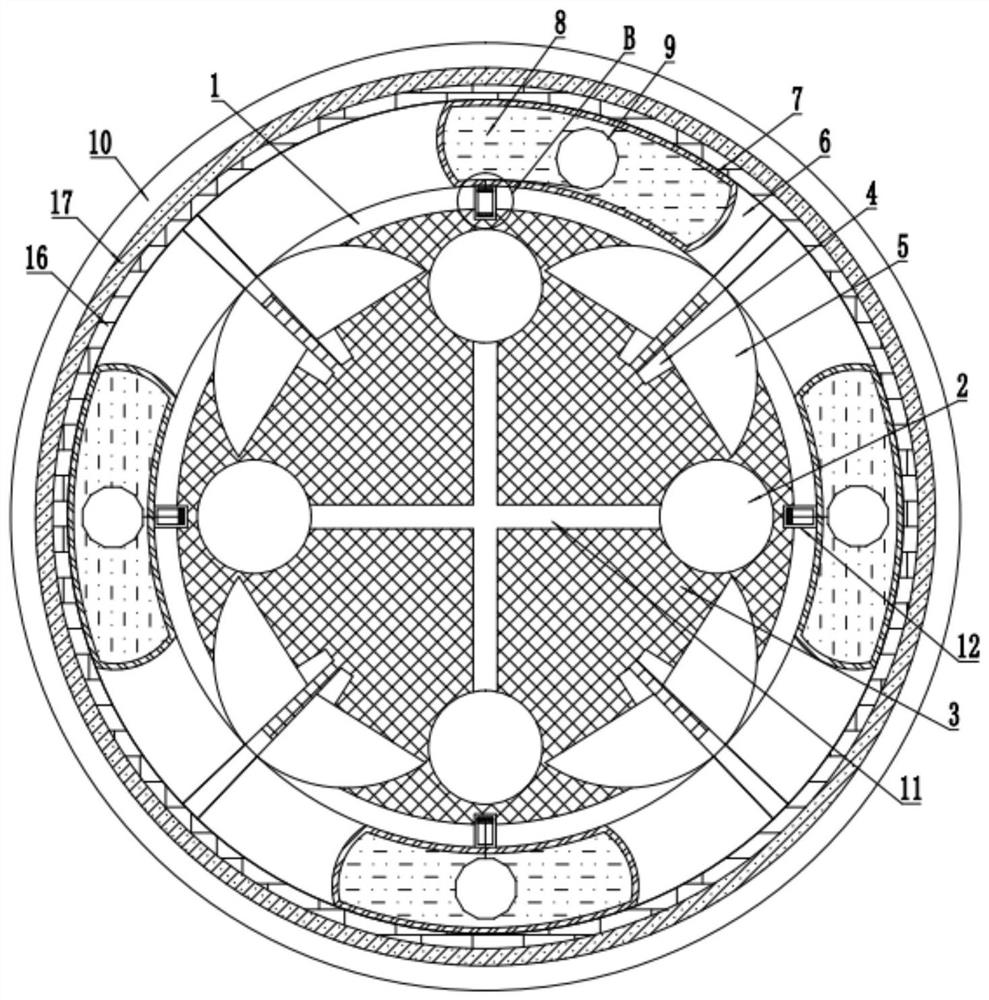

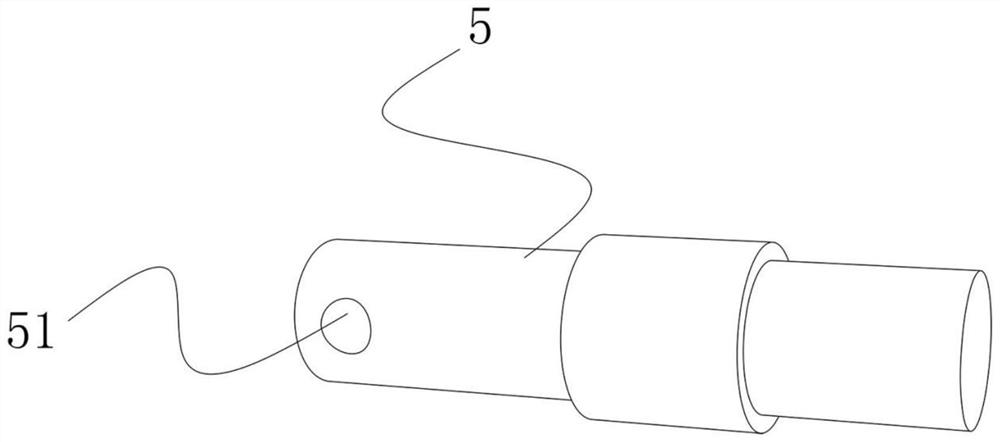

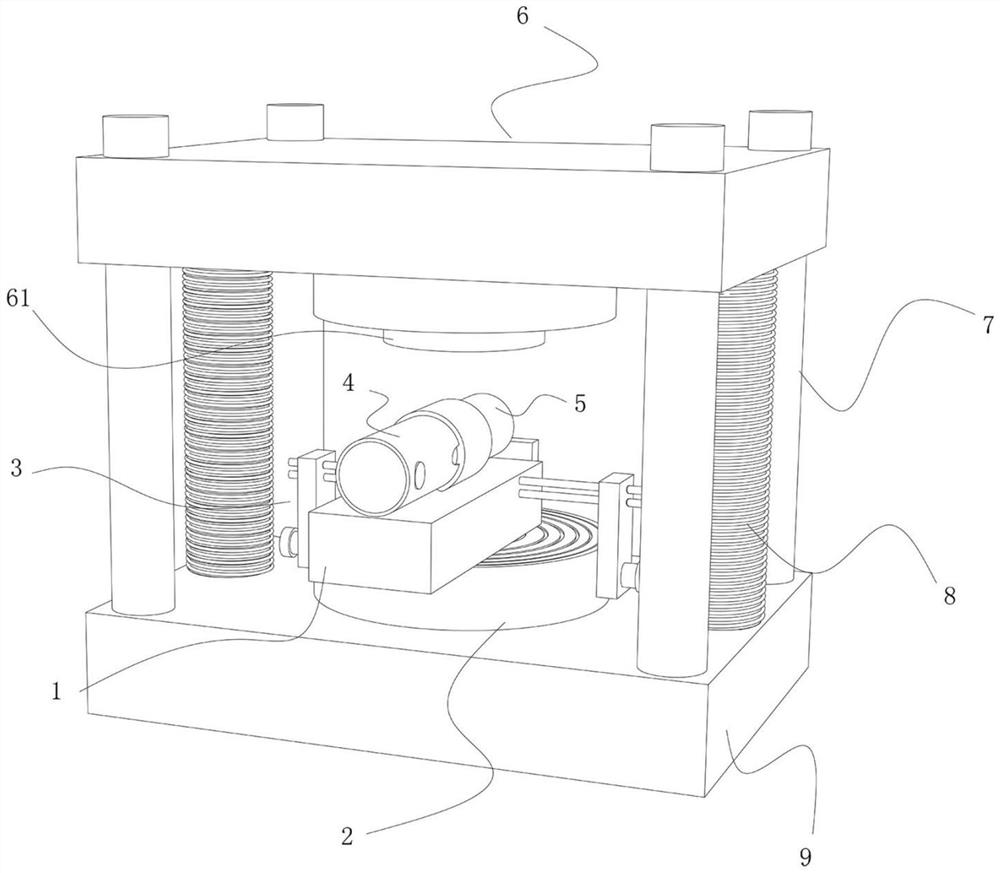

InactiveCN112427685AAchieve clamping and fixingPrevent looseningAutomatic control devicesFeeding apparatusHydraulic cylinderGear wheel

The invention relates to the technical field of flywheel machining equipment, and particularly discloses internal combustion engine flywheel inclined hole machining equipment. The internal combustionengine flywheel inclined hole machining equipment comprises an L-shaped base, a vertical plate is fixedly connected to the upper end of the L-shaped base, a first gear is connected to the rear end ofa rotating shaft, a semicircular loading plate arranged in a semicircular groove is connected to the front end of the rotating shaft, an extension plate is connected to the lower end of the semicircular loading plate, and vertical limiting sliding grooves are formed in the semicircular loading plate and the extension plate; and a hydraulic cylinder is fixed to the middle of the upper end of the front side face of the semicircular loading plate, the lower end of the hydraulic cylinder is connected with a sliding base, and a drilling motor is fixed in the sliding base. According to the whole flywheel inclined hole machining equipment, a flywheel can be firmly clamped before drilling machining is conducted on the flywheel, loosening in the machining process is prevented, and meanwhile the drilling inclined angle can be accurately adjusted through stretching or retracting of the first air cylinder; and in addition, inclined hole machining can be continuously carried out on different partsof the flywheel through a driving motor, and the flywheel inclined hole machining equipment is higher in machining efficiency and machining precision.

Owner:安徽万航轨道交通装备有限公司

Bridge equipment

InactiveCN108247355AReasonable designEasy to operateFeeding apparatusOther manufacturing equipments/toolsSteel platesEngineering

The invention discloses bridge equipment. The bridge equipment comprises a base plate and a cross beam; the cross beam is arranged at the top of the base plate; a first bearing mechanism and a secondbearing mechanism are arranged at the top of the base plate; the second bearing mechanism is arranged on one side of the first bearing mechanism; the first bearing mechanism and the second bearing mechanism both comprise support plates; rotating rods are arranged between the support plates; bearing rollers are arranged on the outer sides of the rotating rods; multiple electromagnets are arranged in the bearing rollers; conveying motors are arranged on the side surfaces of the support plates; movable grooves are formed in the two sides of the first bearing mechanism; bearing plates are arrangedon one sides of the movable grooves; and mobile terminals and control cabinets are arranged at the tops of the bearing plates. A drilling cutter or a grinding cutter moves to a proper position, and the drilling cutter is continuously rotated and descended or the grinding cutter is rotated, so that steel plates or steel materials are punched or grinded; and the bridge equipment is reasonable in design, convenient to operate and use and high in automation degree, and reduces labors.

Owner:ANHUI WEIHONG STEEL STRUCTURE GRP

Drilling device for stainless steel precision casting

InactiveCN113369925AEasy to clamp limitCases to prevent driftPositioning apparatusMetal-working holdersGear wheelElectric machinery

The invention discloses a drilling device for a stainless steel precision casting. The drilling device comprises a device body, a guide rotating rod, a clamping block, a supporting column and a limiting spring, main guide threaded rods are arranged on the front side and the rear side of the interior of the device body in a penetrating mode correspondingly, and a main motor is fixedly arranged in the middle of the outer wall of the right side of the device body; and the left end of a guide rotating rod on the top face of the device body is fixedly connected to the end of an output shaft of an auxiliary motor, supporting columns are fixedly arranged on the left side and the right side of the top face of the device body, protruding blocks are fixedly arranged on the left side and the right side of the outer wall of the guide rotating rod on the top face of the device body, and grooves are formed in the left side and the right side in a bevel gear on the outer wall of the guide rotating rod. According to the drilling device for the stainless steel precision casting, while the main guide threaded rods drive the clamping block to transversely move, auxiliary guide threaded rods drive the clamping block to longitudinally move, the clamping blocks of different specifications and sizes can be conveniently clamped and limited by the clamping block, and the situation that a drilling machine deviates when working is prevented.

Owner:陈海军

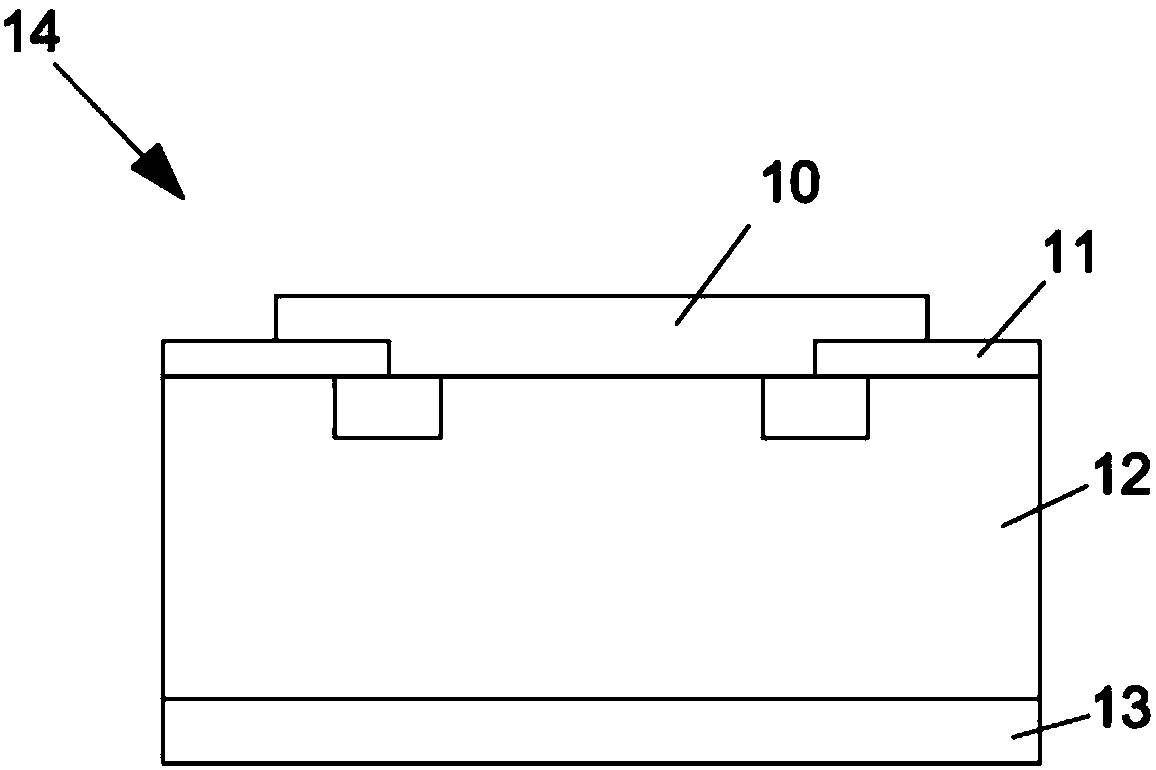

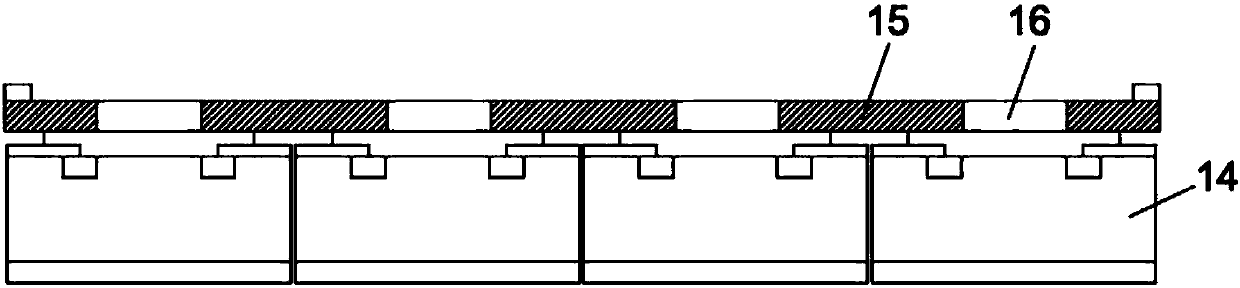

Pre-solder process for printing on wafer

InactiveCN107611038ACases to prevent driftEasy to assembleSemiconductor/solid-state device manufacturingSolder ballEngineering

The invention provides a pre-solder process for printing on a wafer. A layer of solder paste is printed on a TiNiAg layer of the wafer by adopting a steel mesh, and then the solder paste is subjectedto reflow soldering to form solder balls. The assembly of a diode support in the later stage is facilitated. The operation is simple and convenient. The tin deflection problem of the wafer and the diode support during the welding process is avoided. Therefore, the quality of products is improved, and the rejection rate of products is reduced.

Owner:东莞市佳骏电子科技有限公司

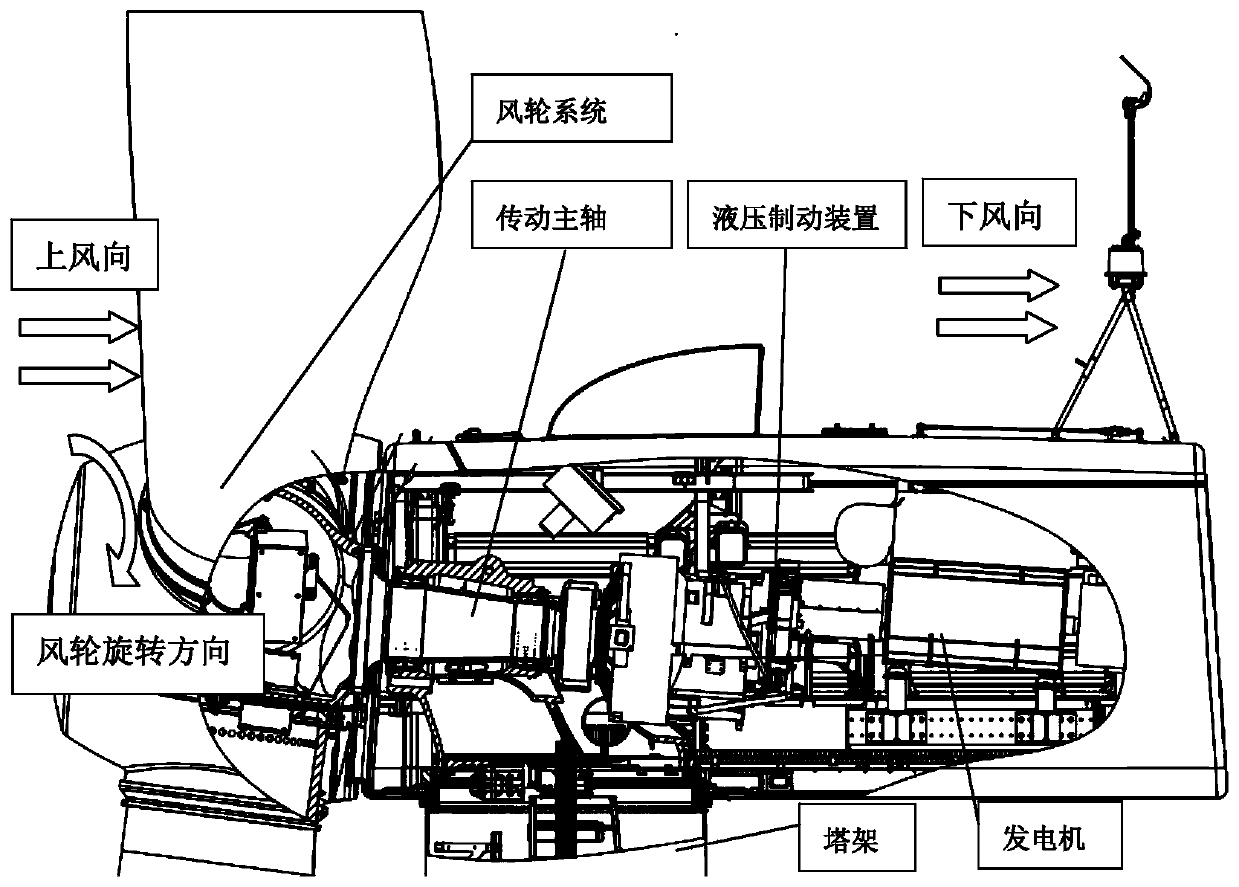

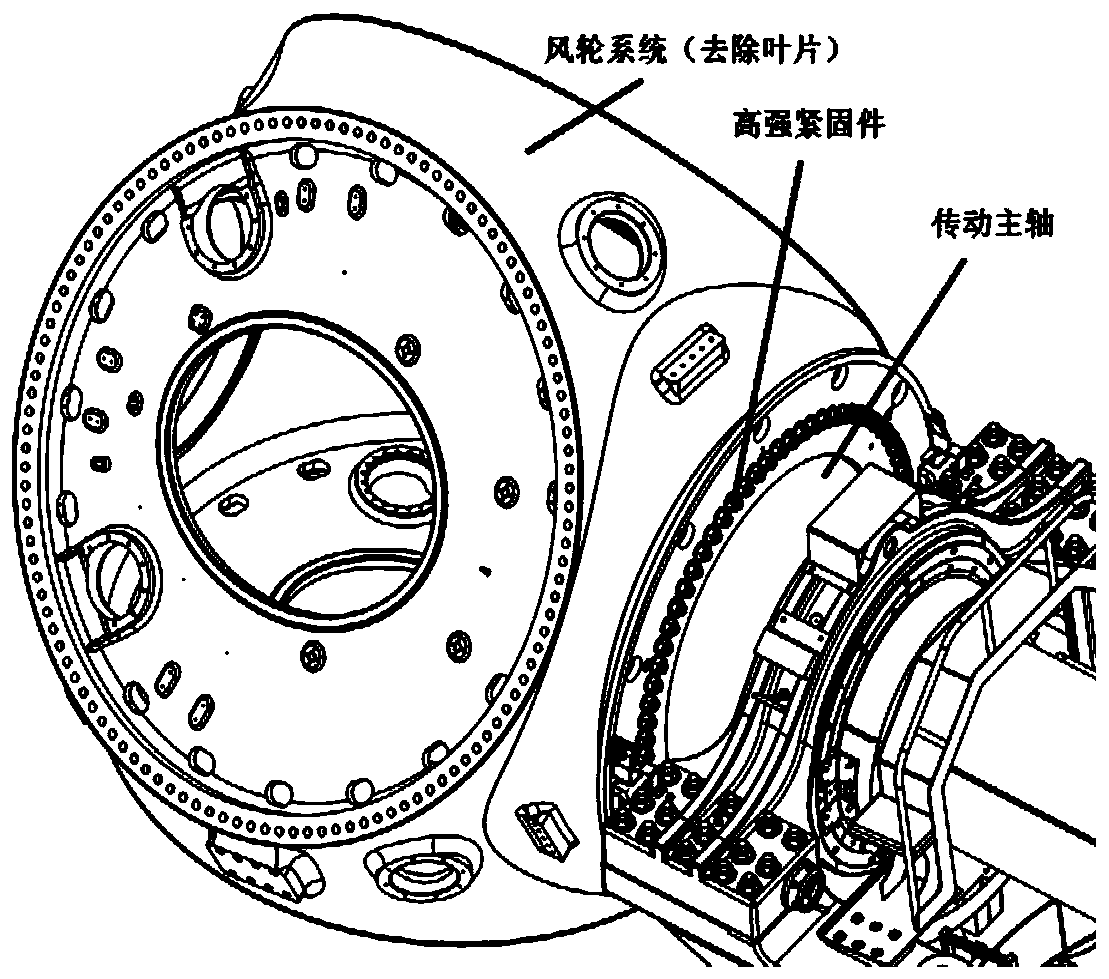

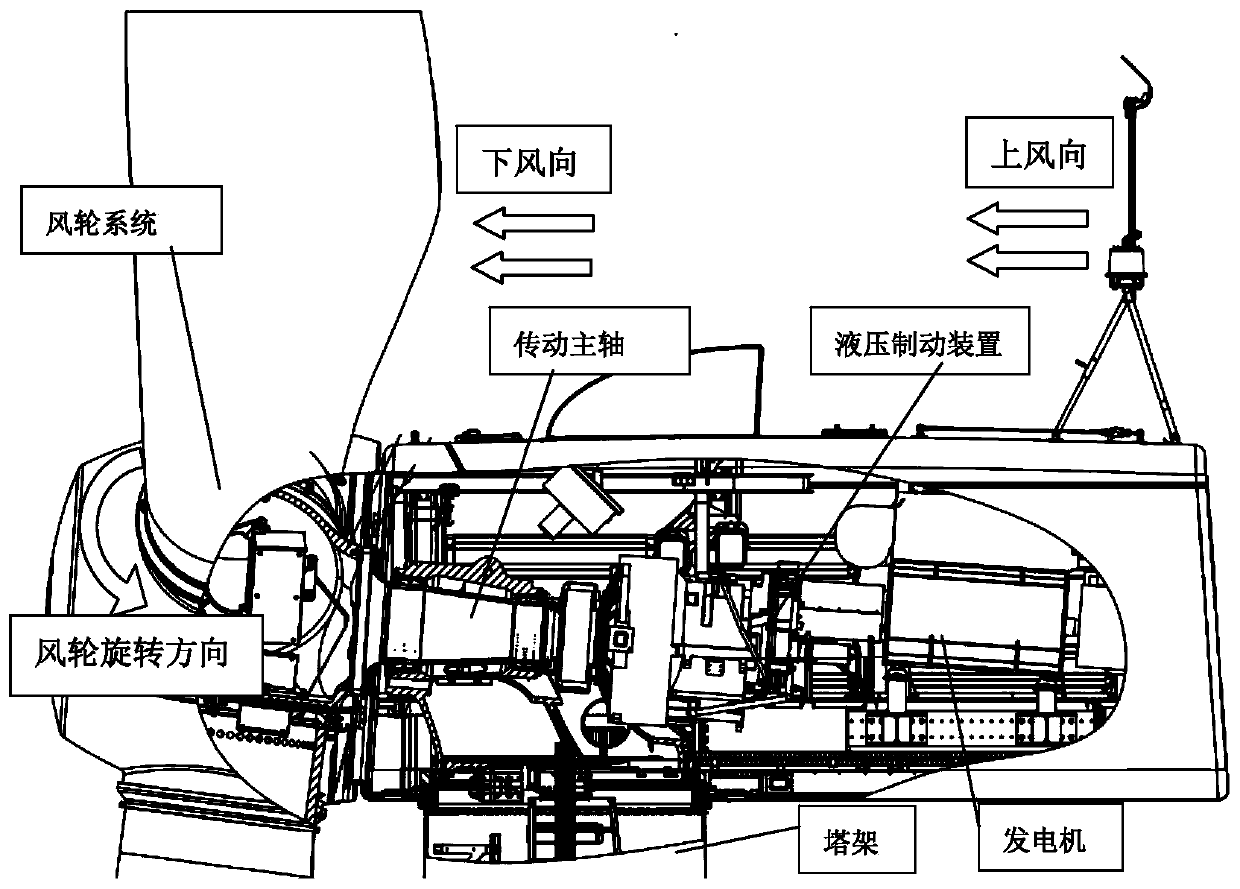

Method for correcting deviation of connecting surface of wind wheel system and transmission spindle of wind generating set

ActiveCN111306012AAvoid offsetReduce lossesWind motor controlMachines/enginesClassical mechanicsControl theory

The invention discloses a method for correcting deviation of a connecting surface of a wind wheel system and a transmission spindle of a wind generating set. The method comprises the following steps that the wind wheel system is reversed by using aerodynamic force, a hydraulic braking device of the wind generating set is adopted for braking, and after the reversing-braking cycle is repeated for multiple times, the deviation of the connecting surface of the wind wheel system and the transmission spindle is corrected. According to the method, the deviation of the connecting surface of the wind wheel system and the transmission spindle is corrected by adopting aerodynamic force and a wind turbine generator braking device, and the deviation of the connecting surface of the wind wheel system and the transmission spindle can be effectively solved.

Owner:CRRC WIND POWER(SHANDONG) CO LTD

Silk weaving extension device of textile machine

InactiveCN109052025AImprove accuracyImprove seismic performanceFilament handlingEngineeringUltimate tensile strength

The invention discloses a silk weaving extension device of a textile machine, and relates to the technical field of textile machines. The silk weaving extension device comprises a top seat, wherein side plates are fixedly connected to both ends of the bottom of the top seat, a connecting plate is fixedly installed at the bottoms of the side plates, studs are respectively inserted into the bottomsof the side plates and the top of the connecting plate, and elastic washers and nuts are fixedly installed on both ends of the studs in sequence from inside to outside. According to the silk weaving extension device of the textile machine, the earthquake resistant performance of the extension device is improved, small-scale elastic deformation can be performed, the damage to the extension device due to sliding is avoided, the service life is prolonged, the extension device is convenient to install and remove, the later maintenance is facilitated, the operation is simple and quick, the labor intensity of working personnel is reduced, the stability of the extension device is increased, the power transmission is guaranteed, and the height of the extension device can be accurately adjusted dueto special and novel structural design, so that the silk weaving accuracy is increased.

Owner:湖州曼哈丹纺织品有限公司

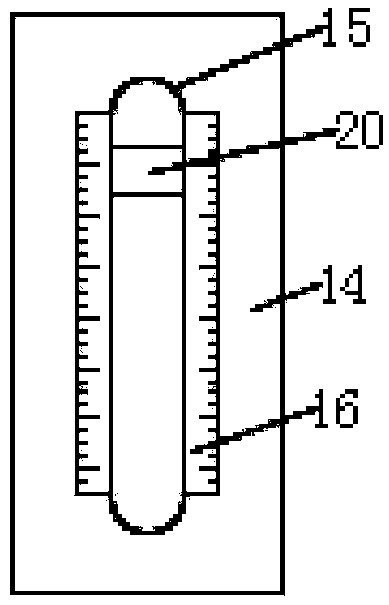

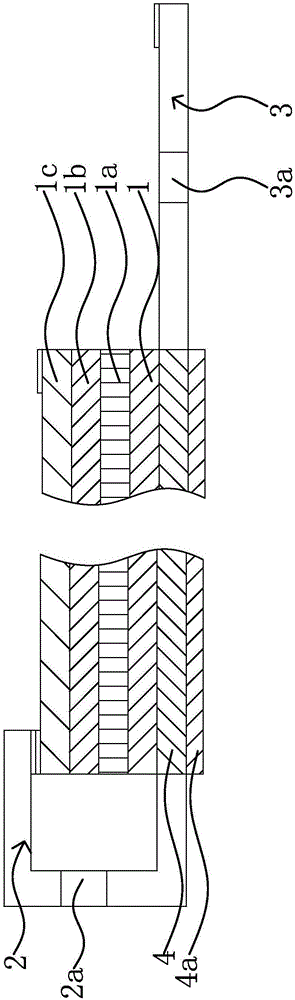

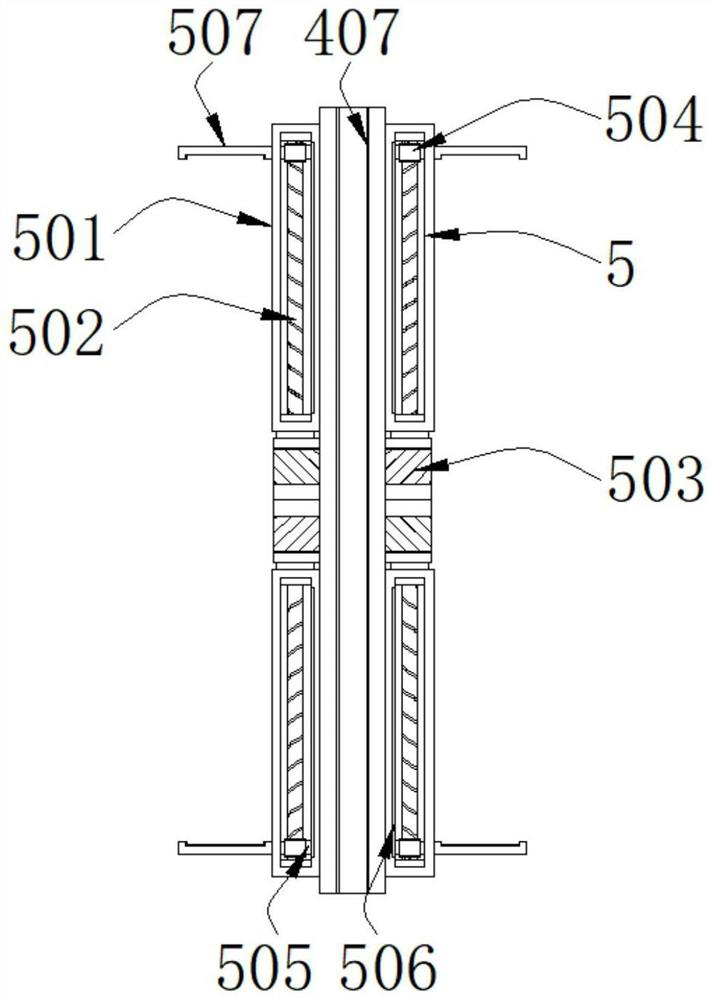

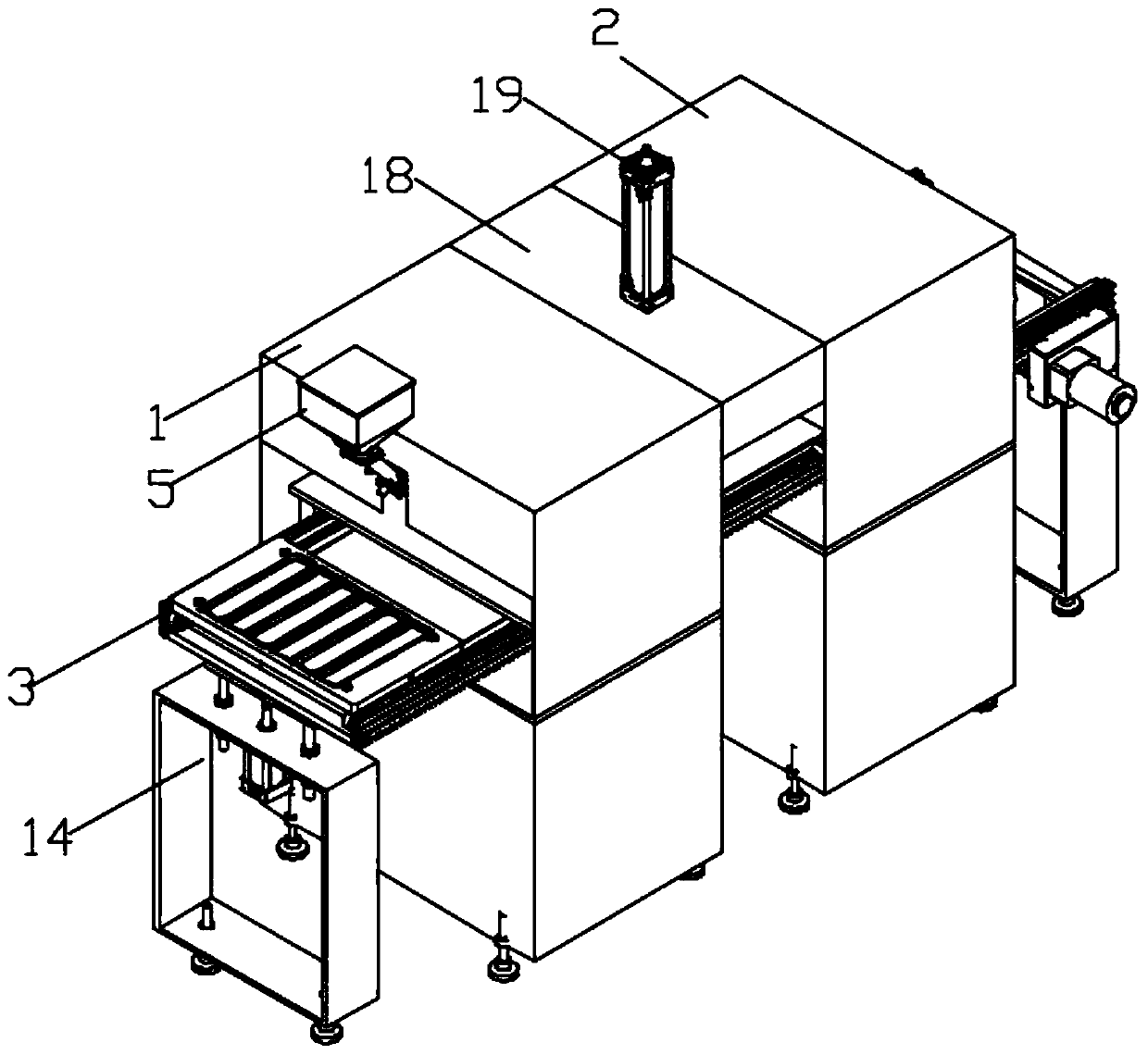

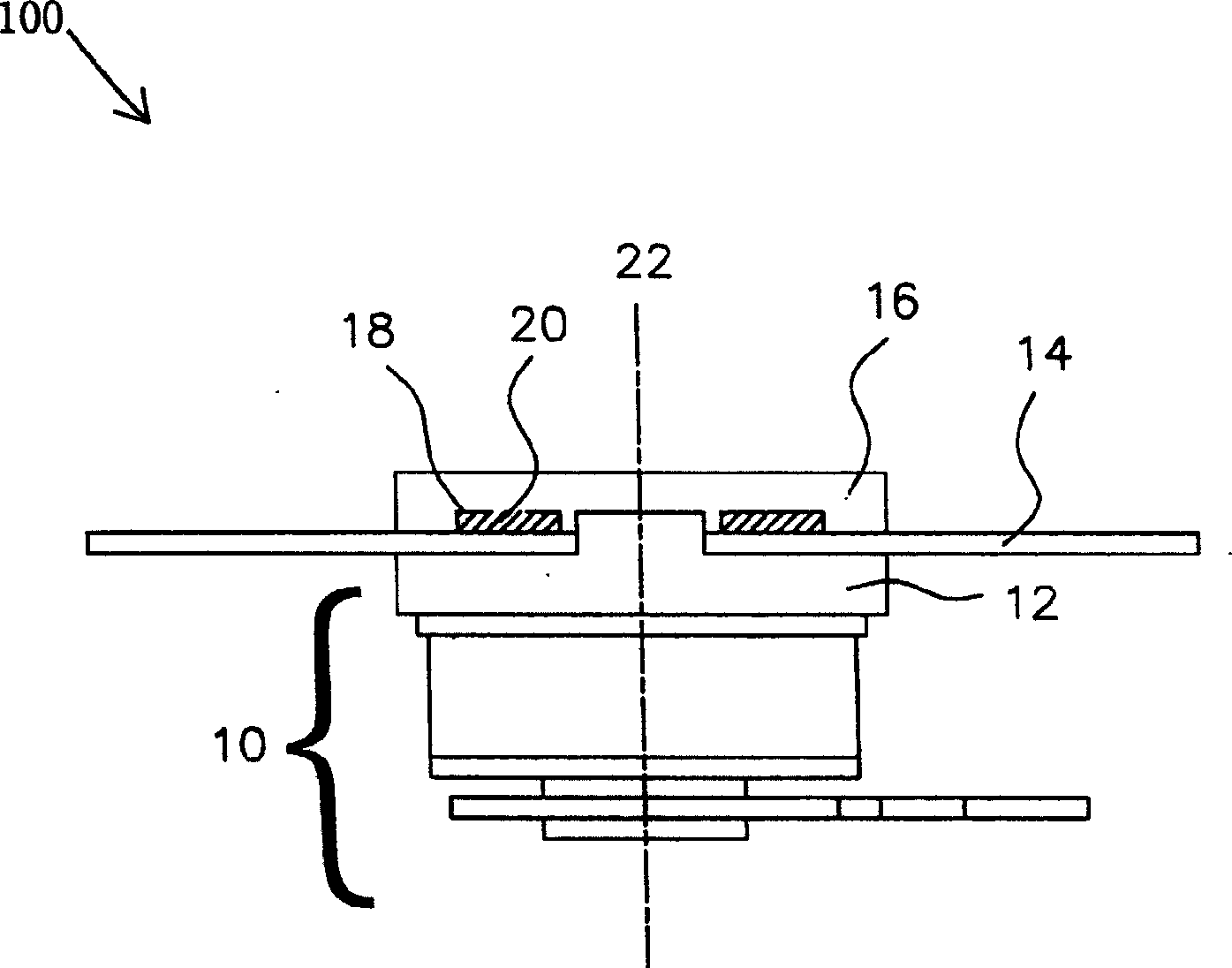

Solenoid valve diaphragm assembly

PendingCN108266558AImprove sealingHigh strengthOperating means/releasing devices for valvesSolenoid valveEngineering

The invention discloses a solenoid valve diaphragm assembly. The solenoid valve diaphragm assembly comprises a diaphragm pressing plate (1), a diaphragm (2), a valve opening sealing part (3), a diaphragm bottom plate (4) and a guide valve opening (5), wherein the guide valve opening (5) penetrates through the diaphragm pressing plate (1), the diaphragm (2), the valve opening sealing part (3) and the diaphragm bottom plate (4) in sequence from top to bottom and is fixed and locked through a spring gasket (6) and a nut (7); the diaphragm pressing plate (1), the diaphragm (2), the valve opening sealing part (3), the diaphragm bottom plate (4) and the guide valve opening (5) are coaxially distributed. With the adoption of the structure, the diaphragm is not in direct contact with a main valveopening, an impact force on the diaphragm is reduced and the service life of the diaphragm is effectively prolonged, so that the service life of a corresponding solenoid valve is prolonged and the solenoid valve diaphragm assembly is suitable for higher pressure and flow.

Owner:YUYAO SANLIXIN SOLENOID VALVE CO LTD

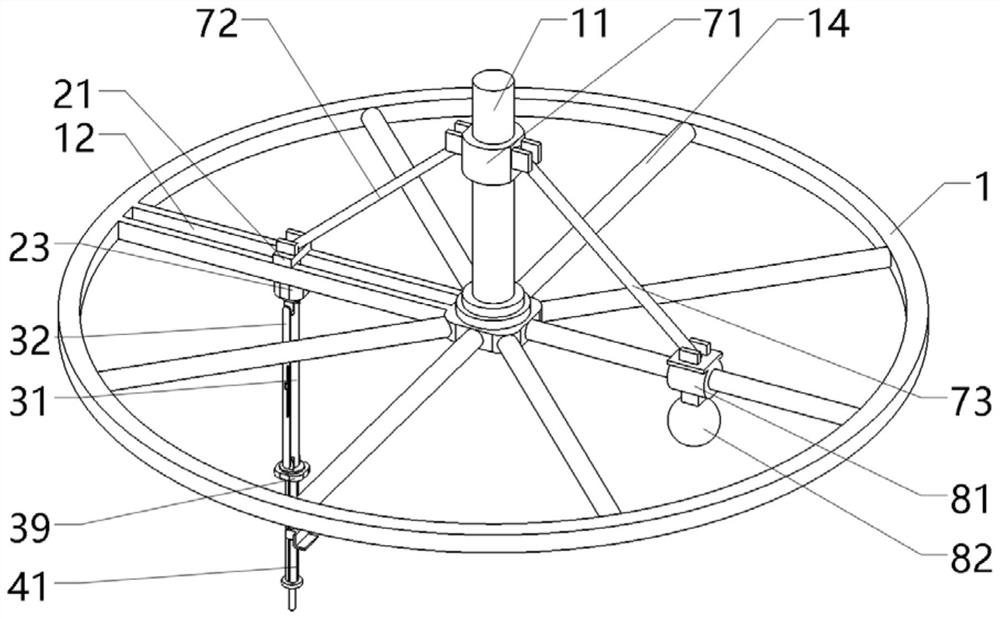

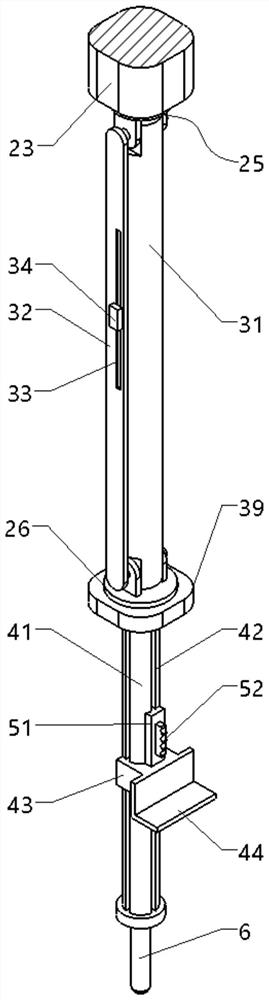

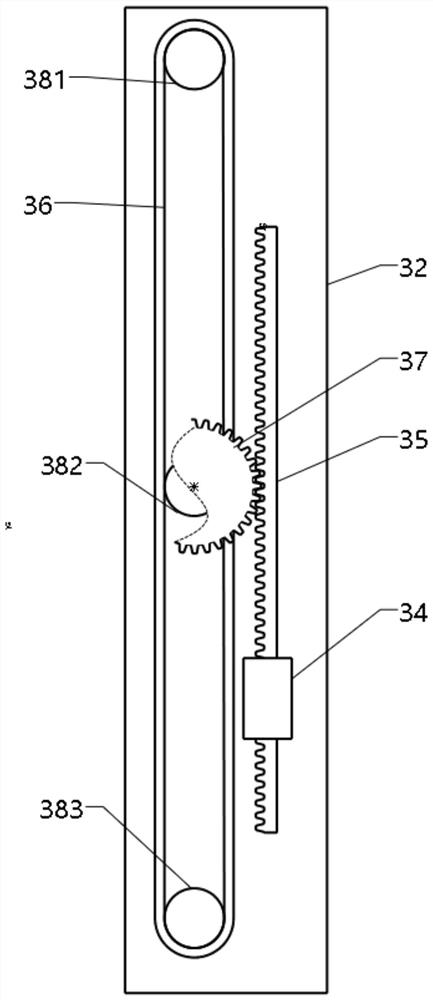

Stop motion animation shooting teaching device

ActiveCN113566095AAchieve the goal of stabilityCases to prevent driftStands/trestlesElectrical appliancesGear wheelControl theory

The invention discloses a stop motion animation shooting teaching device which comprises a rotating ring frame, a rotating shaft, a sliding mechanism, a connecting handle and a sliding rod. One end of the rotating shaft is fixedly installed on a ceiling, the rotating ring frame is pivoted to the bottom of the rotating shaft, a plurality of keels are fixedly installed in the rotating ring frame around a center line, a notch is formed in the rotating ring frame around the axis, the sliding mechanism is arranged in the notch in a sliding fit mode, a first fixing piece is pivoted to the bottom of a fixing block, one end of the connecting handle is hinged to the bottom of the first fixing piece, a second fixing piece is hinged to the bottom of the connecting handle, a bottom plate is pivoted to the bottom of the second fixing piece, the sliding rod is fixedly installed at the bottom of the bottom plate, a sliding rod sliding block is arranged on the sliding rod in a sliding fit mode, and a camera fixing mechanism is fixedly installed on one side of the sliding rod sliding block. According to the device, a rack is meshed with a rack gear, a first threaded rod and a second threaded rod are driven through rotation of a belt to tighten the hinged position, the connecting handle cannot move, and therefore the purpose of stability is achieved.

Owner:KEYI COLLEGE OF ZHEJIANG SCI TECH UNIV

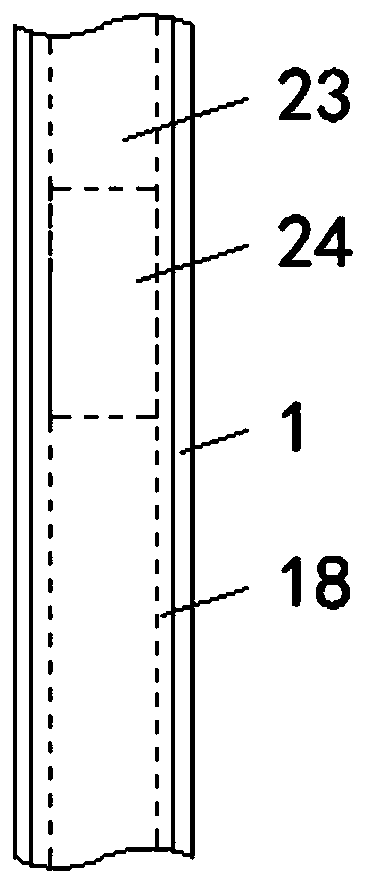

Electric heating tape with temperature detection function

PendingCN113329533AExtended service lifeImprove thermal conductivityOhmic-resistance electrodesHeating element shapesThermal dilatationEngineering

One or more embodiments of the invention provide an electric heating tape with a temperature detection function. The electric heating tape comprises an insulating layer extruded and coated on the outer layer and a plurality of built-in heating cores, a filling layer is arranged in the gap part between the insulating layer and the heating cores, a thermal expansion piece is arranged at the middle position of the interval between the adjacent heating cores, a positioning block is fixed to the outer end of the thermal expansion piece, detection interlayers are sequentially arranged on the outer ring of the insulating layer at intervals in the circumferential direction and correspond to the heating cores one to one, outer coatings are arranged in the detection interlayers, the outer coatings are filled with heat conduction liquid and temperature sensors in a sealed mode, and in the initial state, the thermal expansion piece is in a contraction state, so that the positioning block retracts into the core body. When the core body is electrified and heated, the thermal expansion piece is triggered to expand and extend outwards so as to drive the positioning block to extend and penetrate into the detection interlayer, so that the two ends of the outer coating are extruded to be positioned towards the middle, and the temperature sensor is enabled to be positioned on the outer side of the same radial direction of the corresponding heating core so as to accurately measure the temperature.

Owner:ANHUI HUARUI ELECTRIC

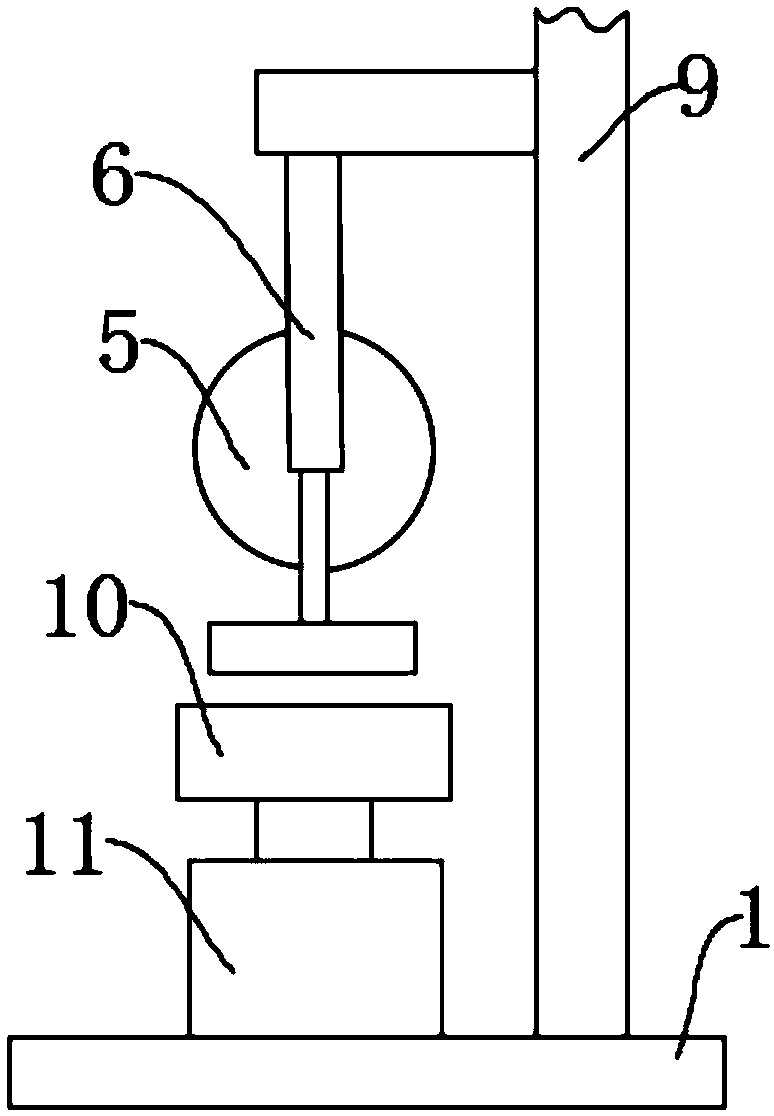

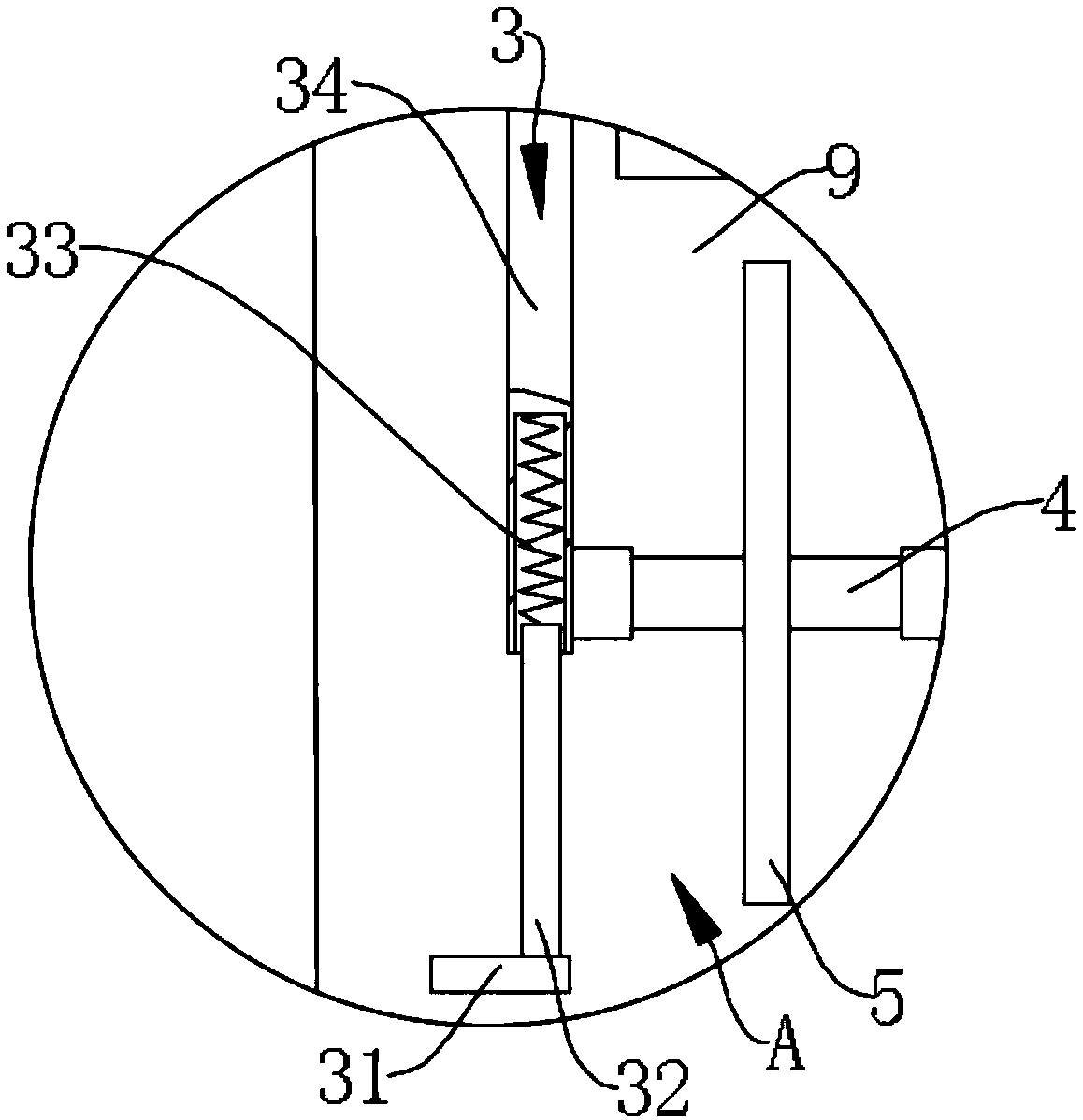

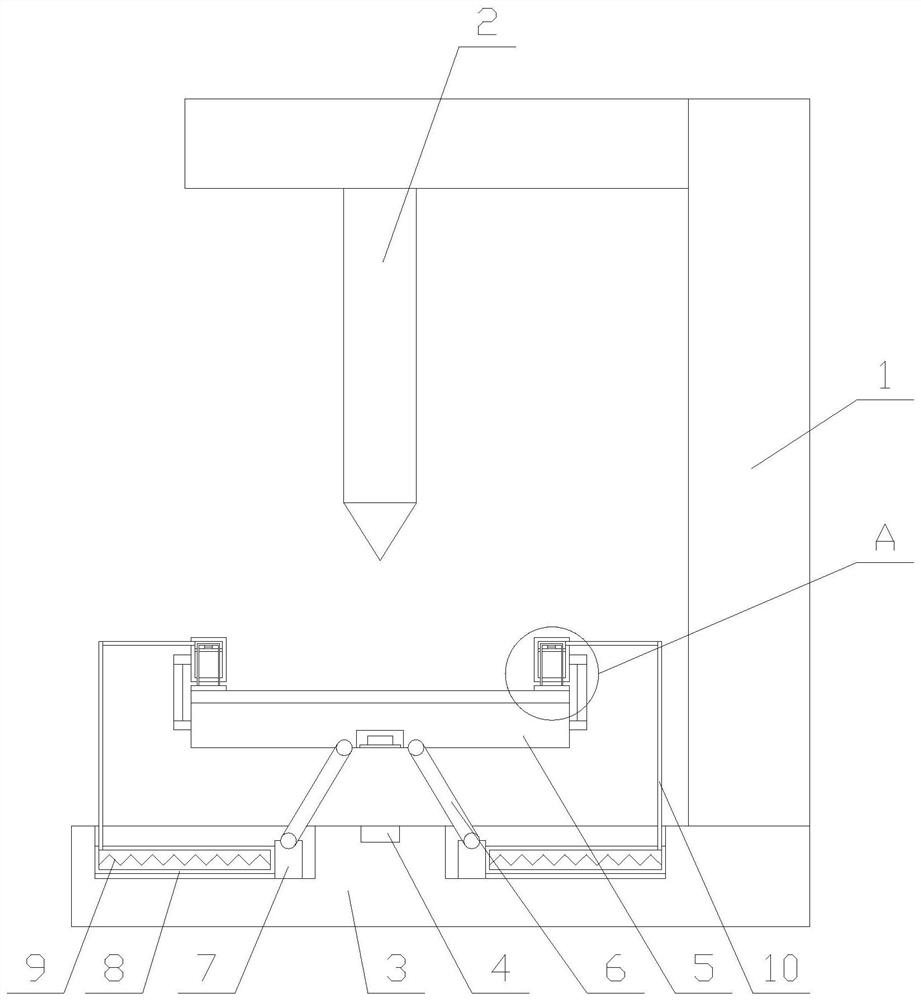

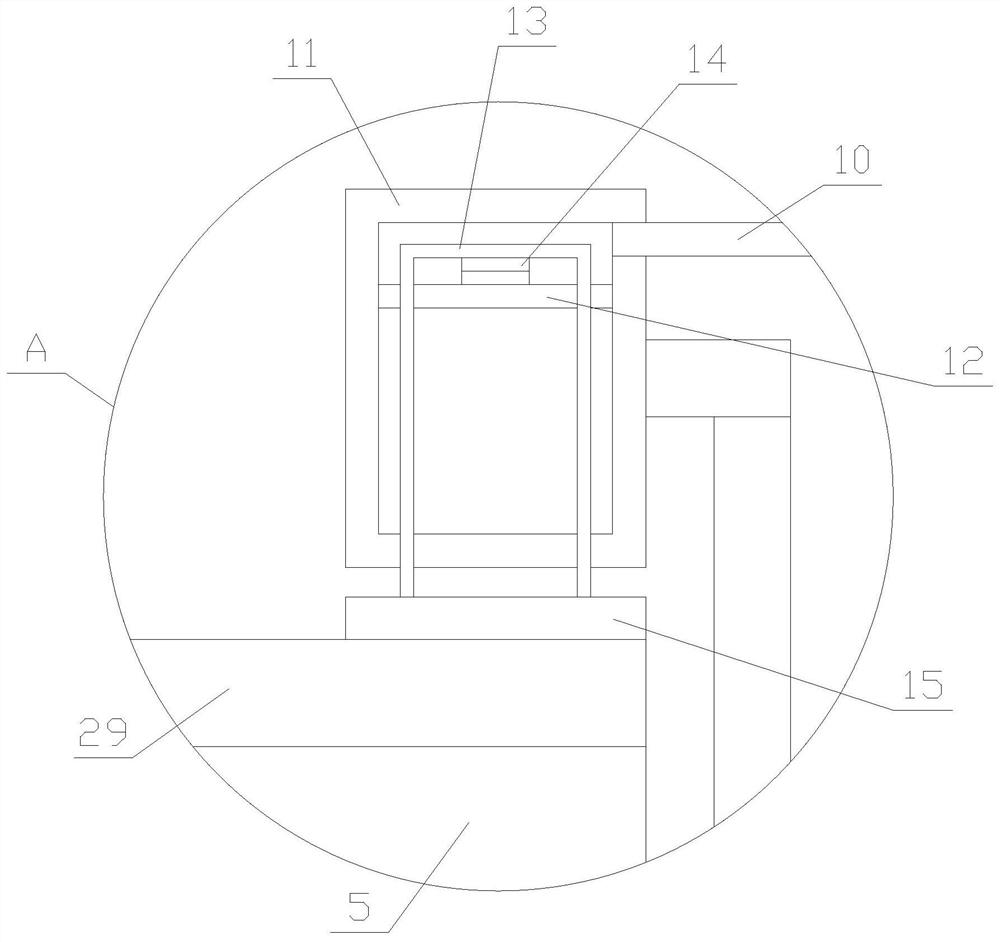

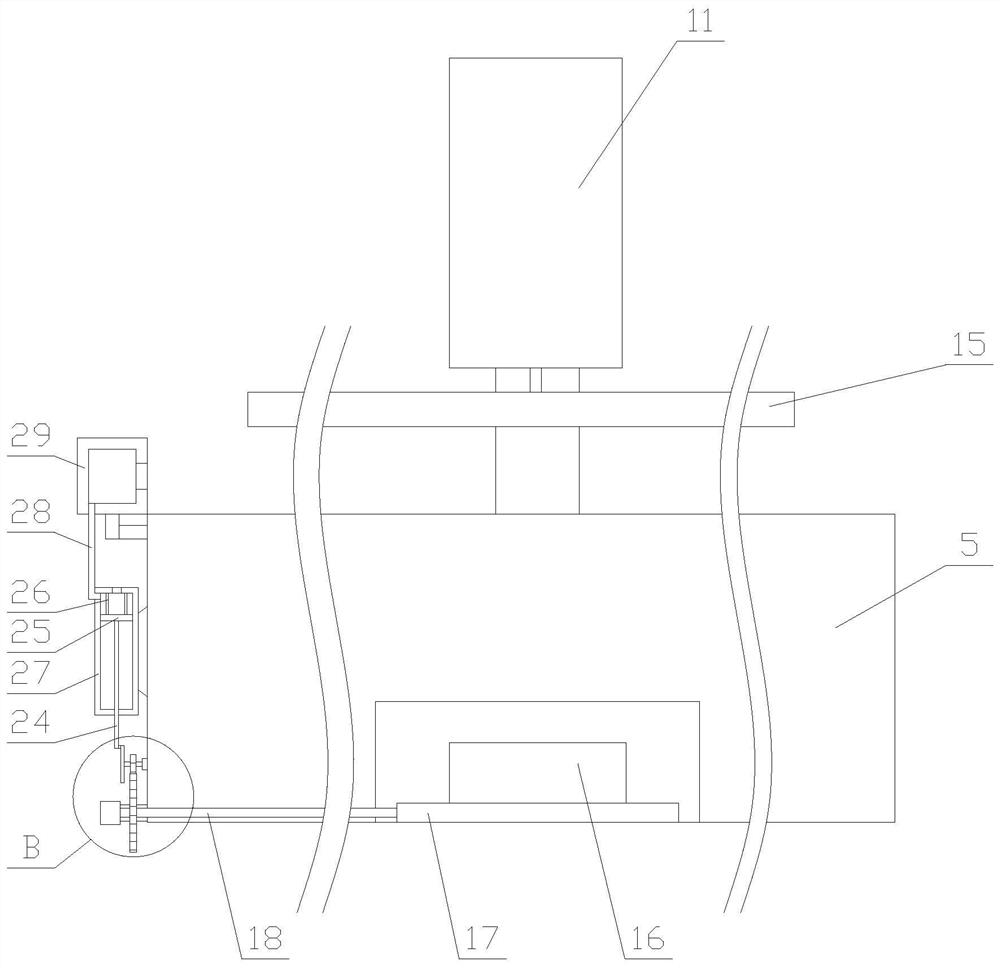

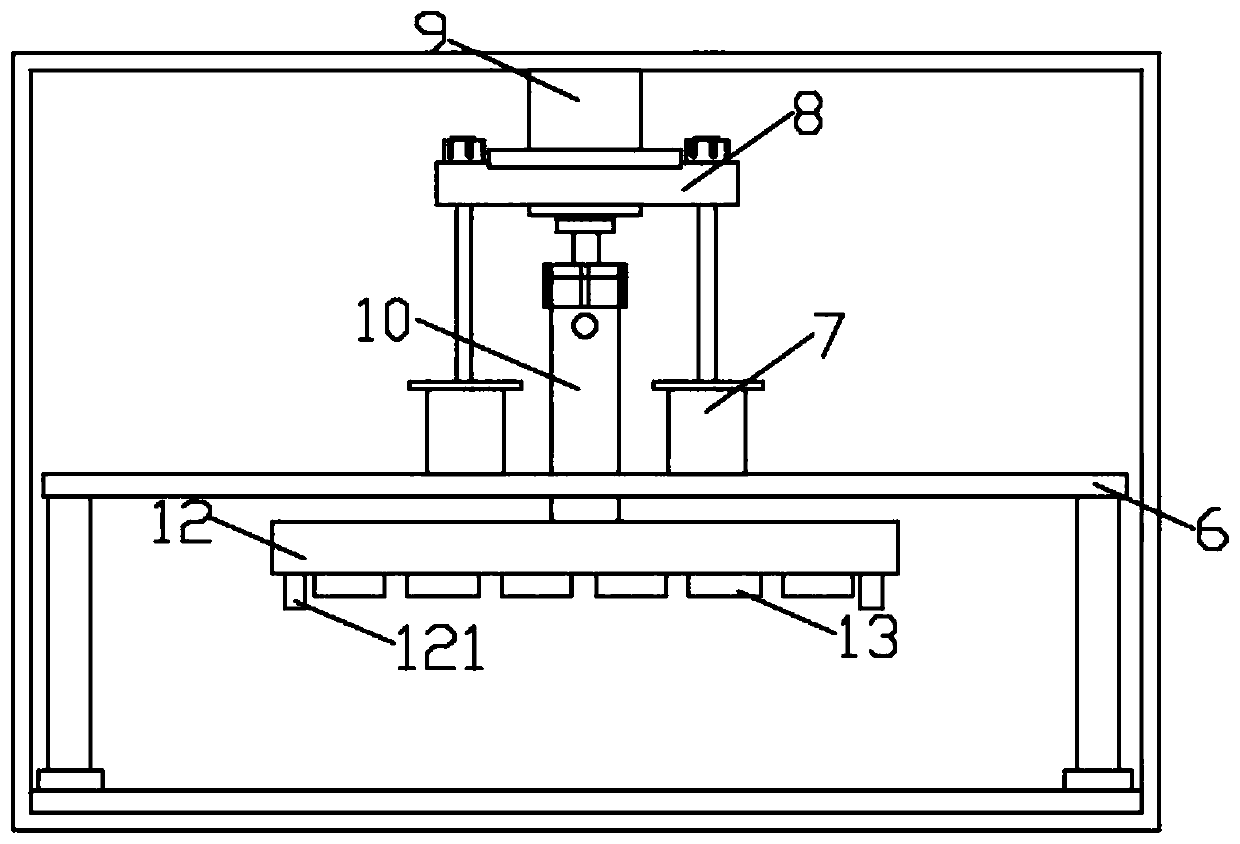

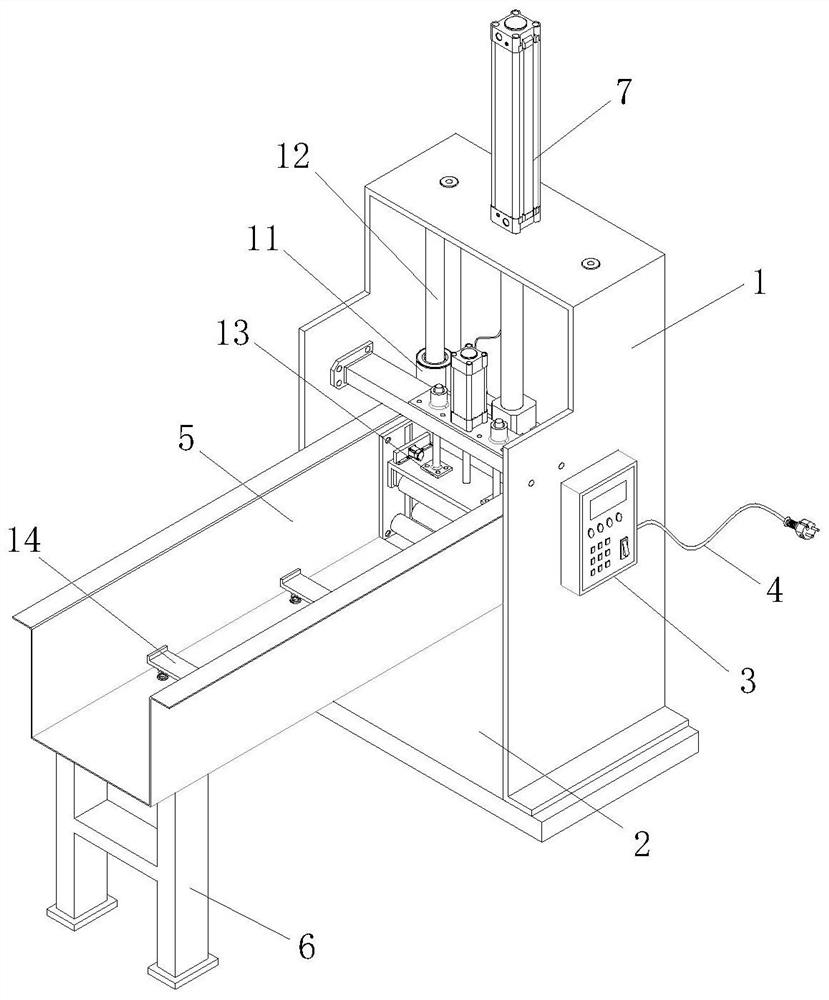

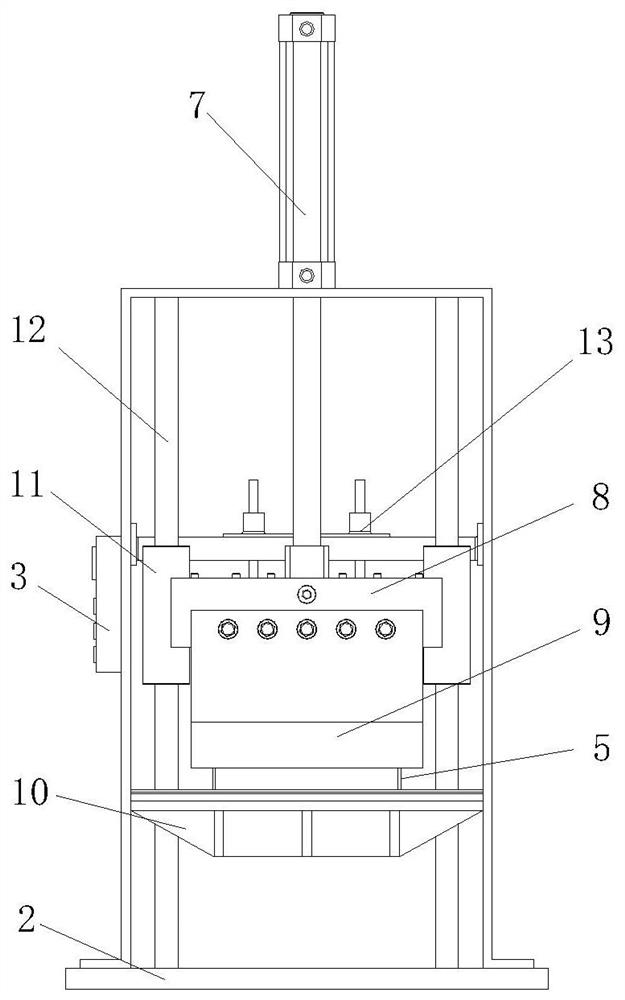

Sensor pressure detection tool

InactiveCN112345161ATo prevent sliding displacementImprove the accuracy of pressure detectionFluid pressure measurementForce/torque/work measurement apparatus calibration/testingWhole bodyMachine

The invention relates to a sensor pressure detection tool. The tool comprises a workbench arranged on a machine base, a coping assembly and a detection assembly used for loading a sensor. The workbench is located below the coping assembly, the workbench or the coping assembly is movably arranged on the machine base and can move upwards or downwards relative to the machine base, and the detection assembly is detachably arranged on the workbench; the coping assembly comprises a pressing head, and the pressing head is located over the workbench. During use, the workbench or the coping assembly moves towards the other side to clamp the sensor loaded in the detection assembly so as to detect the pressure range borne by the sensor; and the situation that the whole body deviates is prevented.

Owner:湖州智禾科技有限公司

Waterproof flame-retardant ceiling coating material fabric and attaching device thereof

The invention provides a waterproof flame-retardant ceiling coating fabric and an attaching device thereof, belongs to the technical field of fabrics and solves the problems of poor waterproof performance and poor flame retardance of the fabrics in the prior art. The waterproof flame-retardant ceiling coating fabric comprises base cloth, wherein the front side of the base cloth is sequentially provided with a flame-retardant layer, an anti-corrosion layer and a waterproof layer from bottom to top; surface cloth is attached onto the reverse surface of the base cloth through the attaching device; the surface cloth is provided with an anti-scraping layer. The attaching device of the waterproof flame-retardant ceiling coating fabric comprises a machine frame, wherein one end of the machine frame is provided with a base cloth unreeling mechanism used for conveying the base cloth; the other end of the machine frame is provided with a surface cloth unreeling mechanism used for conveying the surface cloth; a first glue coating mechanism and a second glue coating mechanism used for coating glue on the surface cloth are also arranged between the base cloth unreeling mechanism and the surface cloth unreeling mechanism; an attaching mechanism capable of attaching the base cloth and the surface cloth is arranged between the first glue coating mechanism and the second glue coating mechanism. The waterproof flame-retardant ceiling coating fabric has the advantages of waterproof performance and flame retardance.

Owner:ZHEJIANG FEIHU NEW MATERIAL CO LTD

Multi-surface grinding processing device for rectangular workpiece

ActiveCN111958354AImprove convenienceQuick gripGrinding carriagesGrinding drivesElectric machinerySurface grinding

The invention discloses a multi-surface grinding processing device for a rectangular workpiece. The multi-surface grinding processing device comprises a supporting base, a supporting guide column, a slide base, a first motor, a first lead screw, a grinding disc and a multi-surface regulating device. The multi-surface regulating device is arranged, a first bevel gear and a second bevel gear are inmatched transmission, and a right rotary disc is matched with the left rotary disc for driving the clamped rectangular workpiece to turn over after a left rotary disc rotates, so that regulation on angle of the rectangular workpiece is regulated, and therefore, multi-surface grinding processing on the clamped fixed workpiece can be achieved, the trouble of dismounting the workpiece back and forthoriginally is solved, and convenience is improved; and a quick clamping mechanism is arranged, a third bevel gear and a fourth bevel gear are in matched transmission, and a right clamping block and aleft clamping block synchronously and oppositely move after a first hand wheel is rotated, so that the rectangular workpiece can be quickly clamped, and the workpiece can be dismounted conveniently, and therefore, grinding processing efficiency is greatly improved.

Owner:佛山市耀凯五金机械设备有限公司

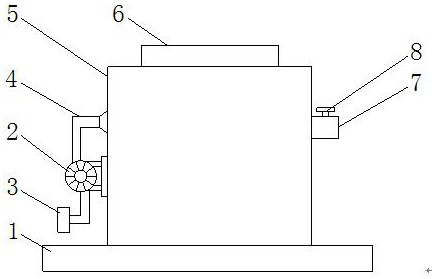

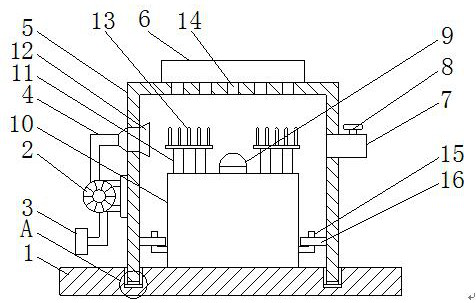

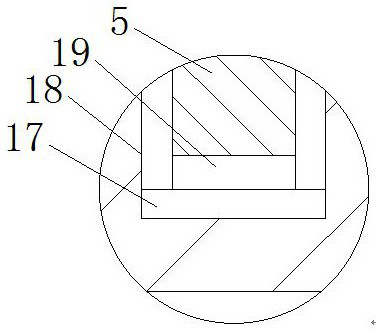

Computer intelligent heat dissipation system

PendingCN112306203AImprove stabilityCases to prevent driftFouling preventionDispersed particle filtrationThermodynamicsMechanical engineering

The invention discloses a computer intelligent heat dissipation system which comprises a base, a shell is arranged at the top of the base, a dustproof cover is fixedly installed at the top of the shell, an installation plate is fixedly installed on the left side of the shell, and a heat dissipation fan is fixedly installed on the left side of the installation plate. The base is arranged to be usedfor installing and supporting the shell, the stability of the shell is improved, so that the situation that the shell deviates in the using process is prevented; the cooling fan is arranged to be used for guiding outside air into the shell through an air inlet device and an air guide pipe, and then the outside air is exhausted out of the shell through the air outlet; meanwhile, the problems thatan existing computer does not have the intelligent heat dissipation function, the computer starts to run when a heat dissipation system is started, the heat dissipation efficiency of the heat dissipation system cannot be changed no matter how much the temperature of the computer is, and the heat dissipation mode wastes electric energy, causes electricity waste and is poor in heat dissipation effect are solved.

Owner:上海英众信息科技有限公司

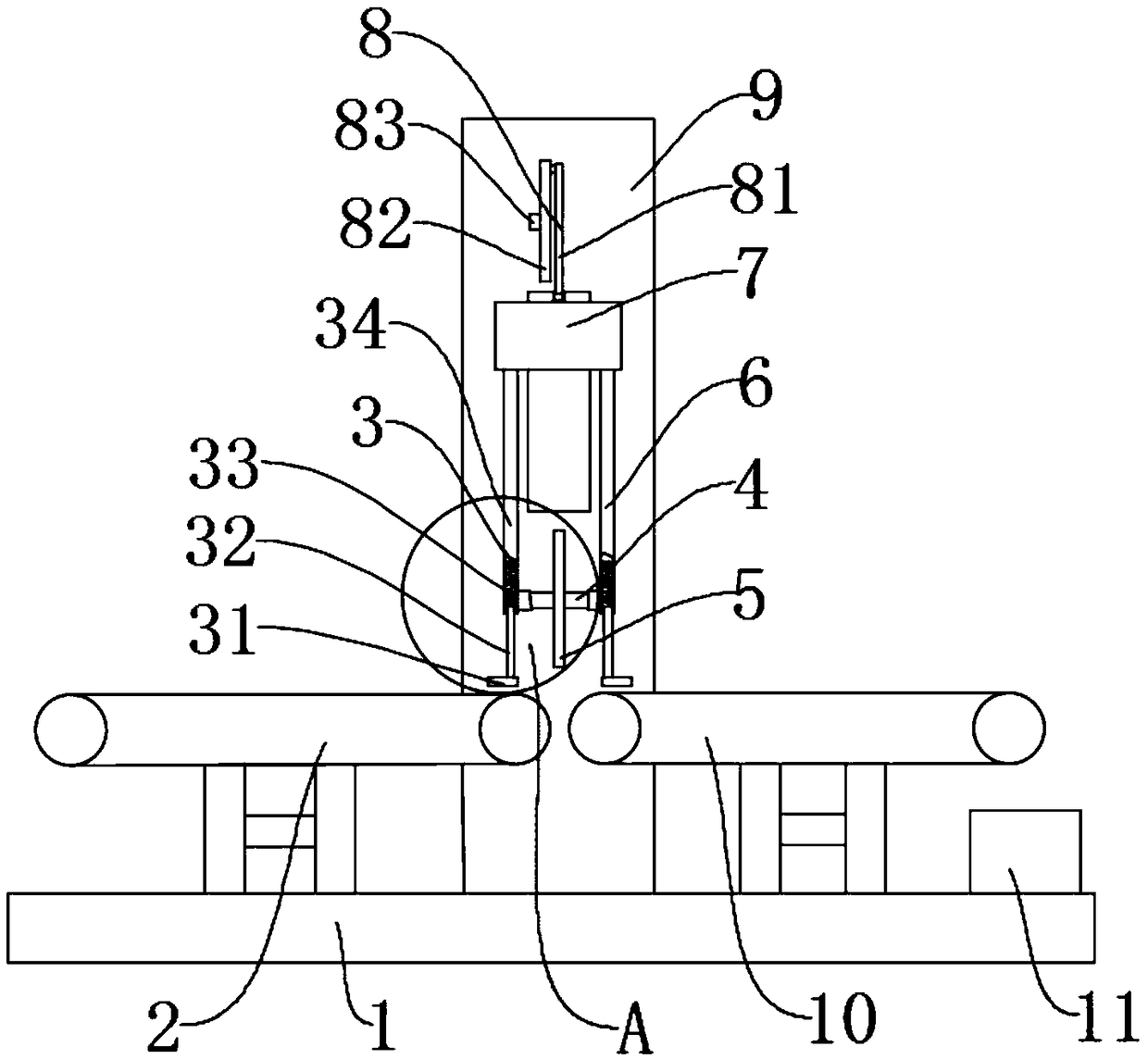

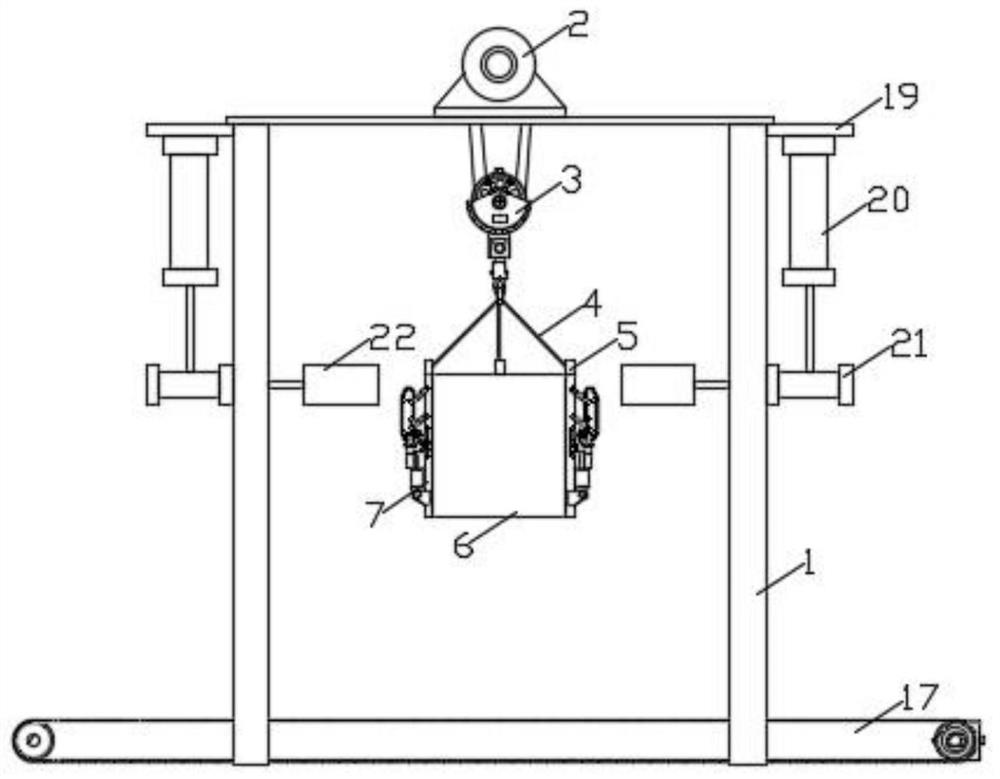

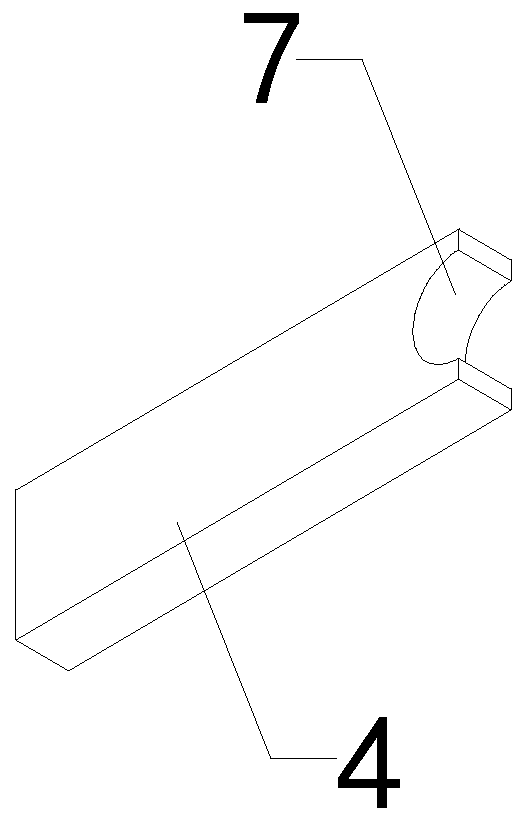

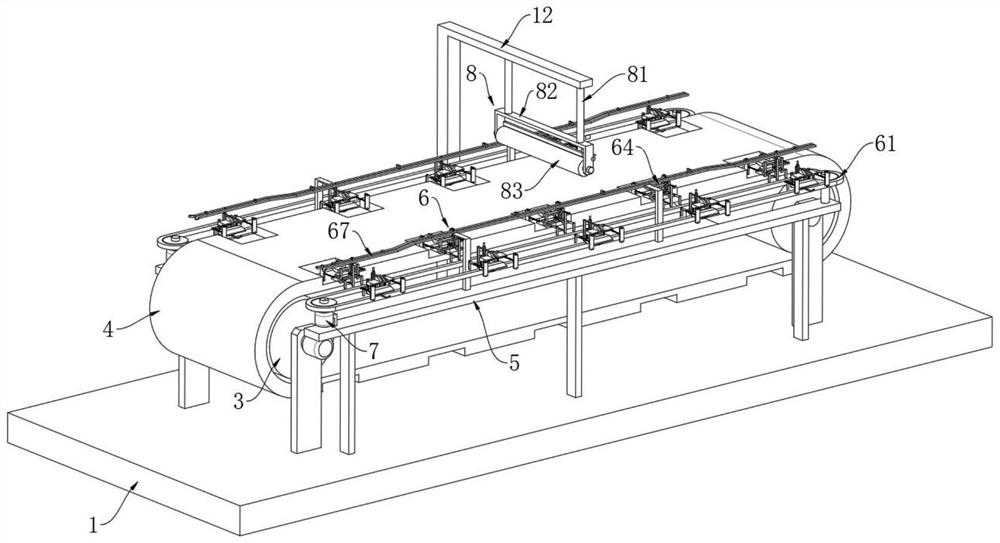

Liquefied natural gas cylinder liner mounting device and working method thereof

ActiveCN112340601AEasy to installEasy to fixBase supporting structuresBraking devices for hoisting equipmentsThermodynamicsGas cylinder

The invention discloses a liquefied natural gas cylinder liner mounting device and a working method thereof. According to the device and the method, a liquefied natural gas cylinder is conveyed through a conveying belt, so that the automation degree of the liquefied natural gas cylinder liner mounting process in the whole process is high, and meanwhile, the liquefied natural gas cylinder is effectively fixed during mounting, so that the liquefied natural gas cylinder is prevented from deviating in the liner mounting process; and a liner is conveyed to the bottom of an inner cavity of the liquefied natural gas cylinder through a mounting belt, and a lifting cylinder does not need to enter the inner cavity of the liquefied natural gas cylinder, so that the lifting cylinder is prevented fromcolliding with a bottle opening of the liquefied natural gas cylinder when rising from the inner cavity of the liquefied natural gas cylinder, and meanwhile, the liner mounting efficiency is effectively improved.

Owner:ANHUI FANGYUAN PRESSURE VESSEL MFR

Football shooting practice device with football returning function for physical training

PendingCN114159759AImprove efficiencyImprove the actual use effectBall sportsTraining effectEngineering

The invention discloses a football shooting practice device with a football returning function for physical training, and relates to the technical field of physical training, the football shooting practice device comprises a door frame and a ball returning assembly, the inner side of the door frame is provided with a goal net, and the front end of the door frame is provided with an orientation assembly for positioning training; a ball driving assembly used for driving is arranged on the lower portion of the rear end of the door frame. According to the football shooting practice device, training personnel do not need to pick back a shooting football, the shooting practice efficiency is improved, meanwhile, corresponding adjustment work can be conducted according to different positioning shooting trainings, the football shooting practice device can achieve training work at different shooting positions, the actual use effect of the football shooting practice device is improved, and the practical use effect of the football shooting practice device is improved. Meanwhile, parabola detection work can be carried out on the shooting track, direction and strength of the football player so as to assist the football player to carry out targeted shooting training and enhance the training effect, and detection data can be remotely transmitted, so that comparison and analysis can be conveniently carried out on the detection data, and the effectiveness of the data is ensured.

Owner:郑州大学体育学院

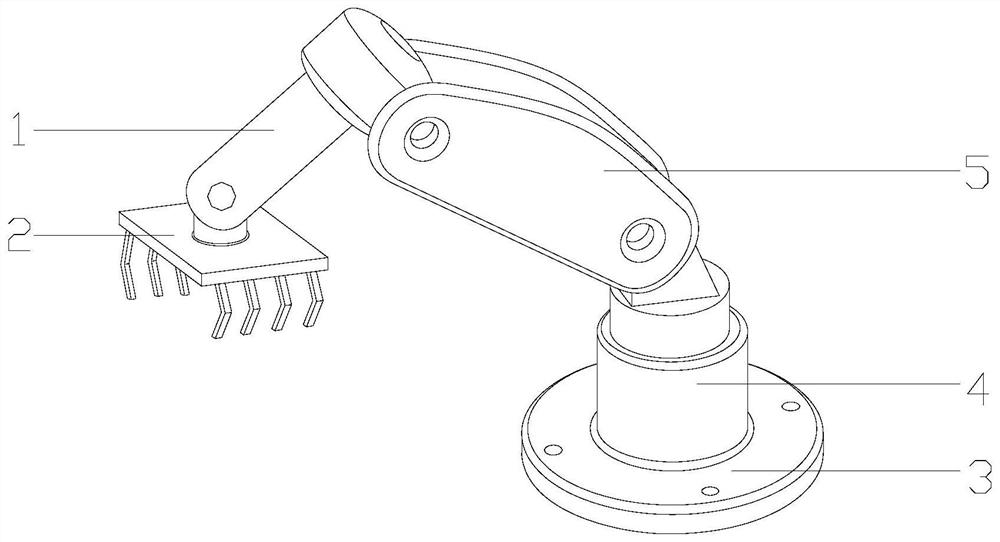

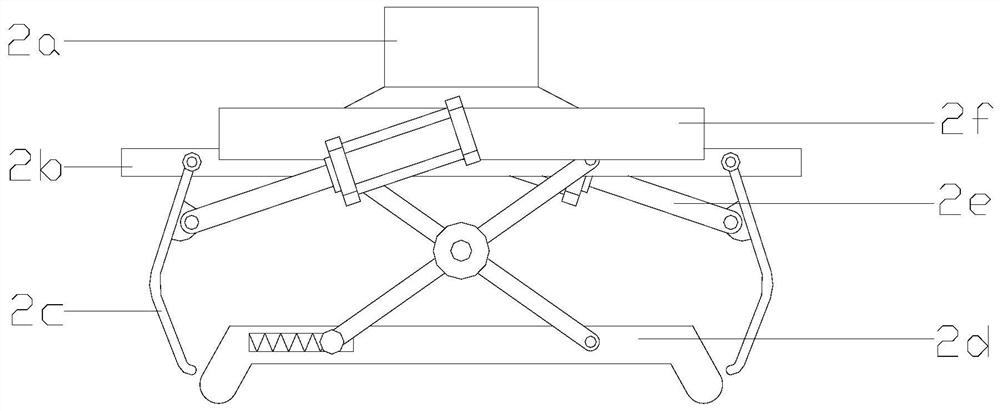

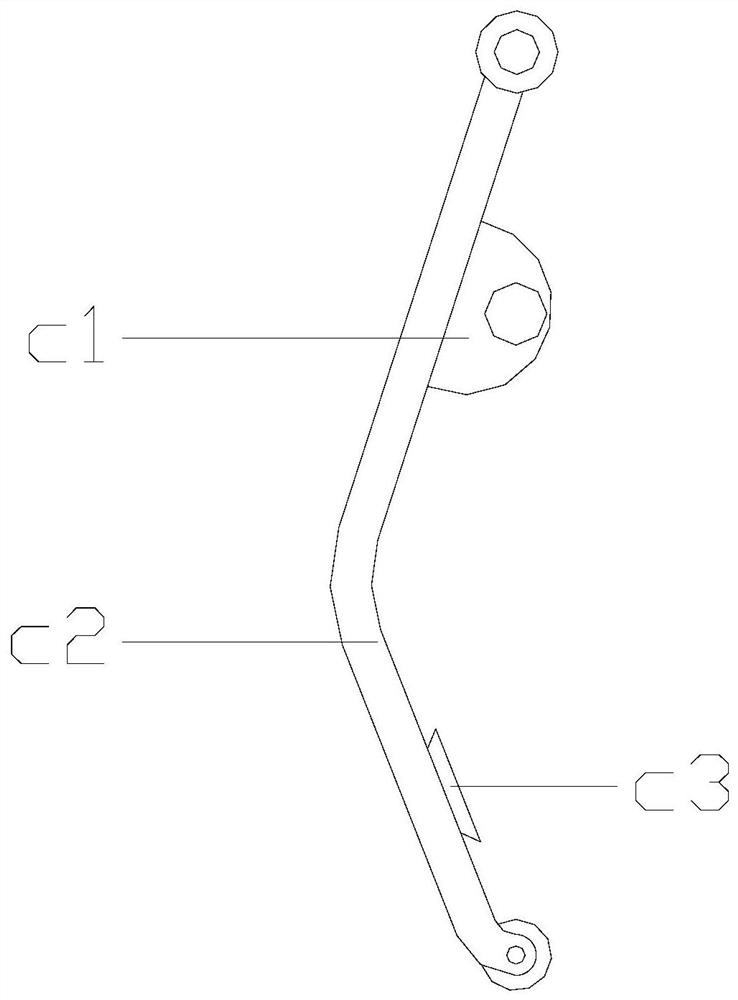

An automated palletizing device for logistics

ActiveCN110386467BAvoid tilting and collapsing situationsImprove stabilityStacking articlesDe-stacking articlesLogistics managementControl engineering

The invention discloses an automatic palletizing device for logistics. Its structure includes a manipulator connecting arm, a material palletizing device, a fixed base, an automatic rotating seat, and a driving spindle. In combination, when the palletizer is clamping the feed, the material shaking mechanism will automatically level the upper surface of the feed bag to avoid uneven distribution of the feed in the bag, causing uneven packaging bags to pile up and causing the feed to tilt In the case of collapse, the stability of feed palletizing is improved, and the work efficiency is improved; at the same time, it can prevent the deviation of the feed bag when the palletizer drives the feed bag to rotate, so that the falling position of the feed bag is consistent with the preset position, and the stability of feed palletizing is improved. Stability and balance.

Owner:姚伟波

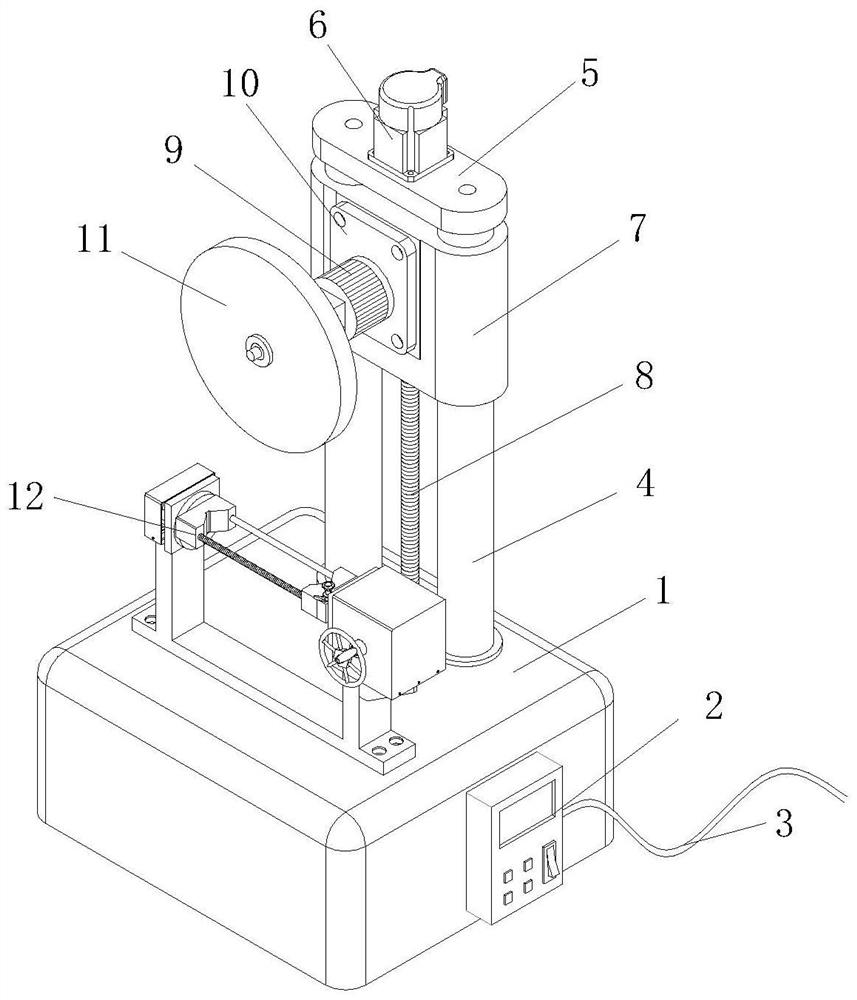

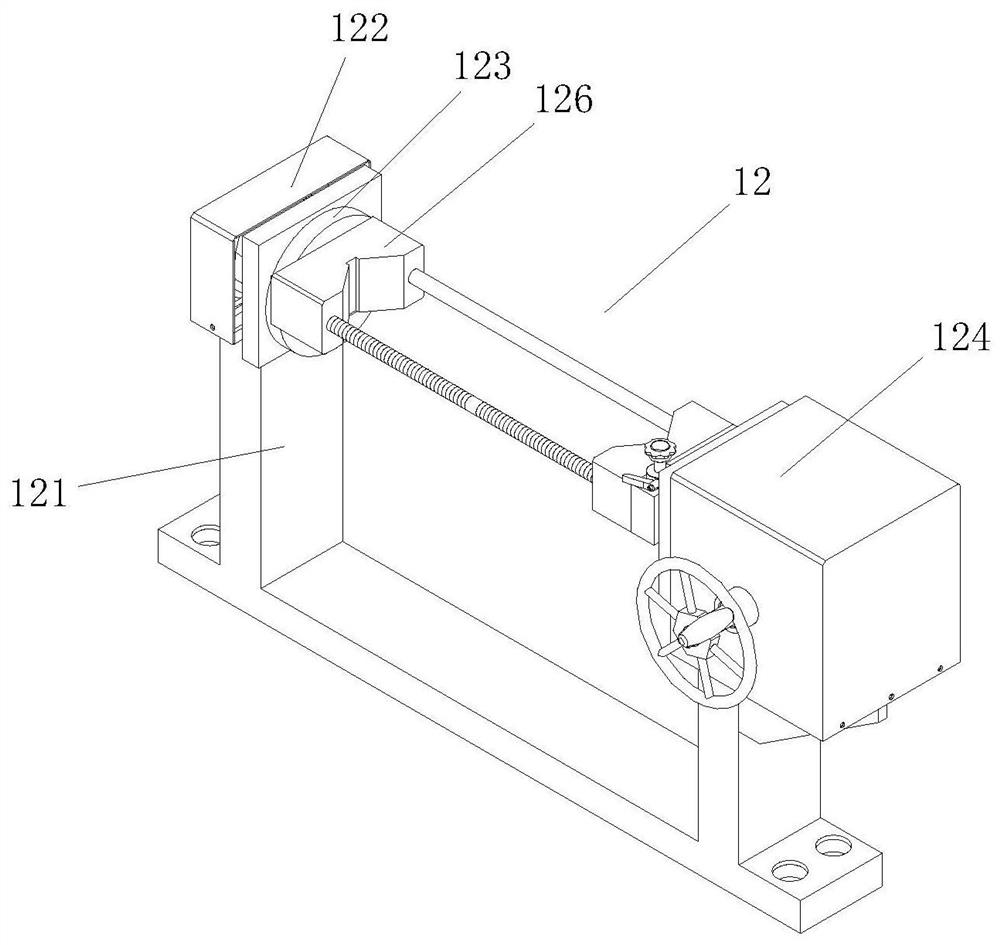

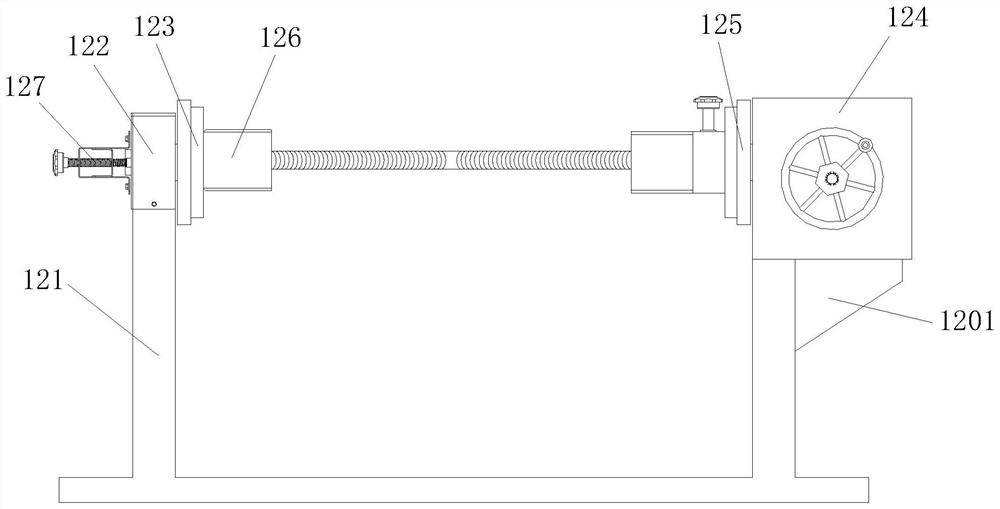

High-reliability bench drill

PendingCN113909941AHigh precisionImprove reliabilityPositioning apparatusBoring/drilling componentsDrill holeStructural engineering

The invention relates to a high-reliability bench drill, which comprises a base, a supporting rod and a drilling device and further comprises a fixing mechanism and a dust removal mechanism, wherein the fixing mechanism comprises a supporting plate, a first magnet block, an auxiliary assembly and two fixing assemblies, and the dust removal mechanism comprises a dust removal box, a supporting rod, a power assembly, an air cylinder, a power plate, a supporting pipe and two elastic ropes. According to the high-reliability bench drill, through the fixing mechanism, the function of fixing the position of a workpiece is achieved, the situation that the position of the workpiece deviates during punching is prevented, and therefore, the machining precision is improved, the reliability of equipment is improved, workpieces with different thicknesses can be fixed, and the use range is widened; and when the workpiece is placed on the supporting plate, fixing work can be conducted, the working efficiency is improved, the function of blowing air to the surface of the workpiece can be achieved through the dust removal mechanism, chippings generated during punching on the surface of the workpiece are blown away, the function of cleaning the workpiece is achieved, manual cleaning is not needed, and more convenience is achieved.

Owner:扬州市明和机械有限公司

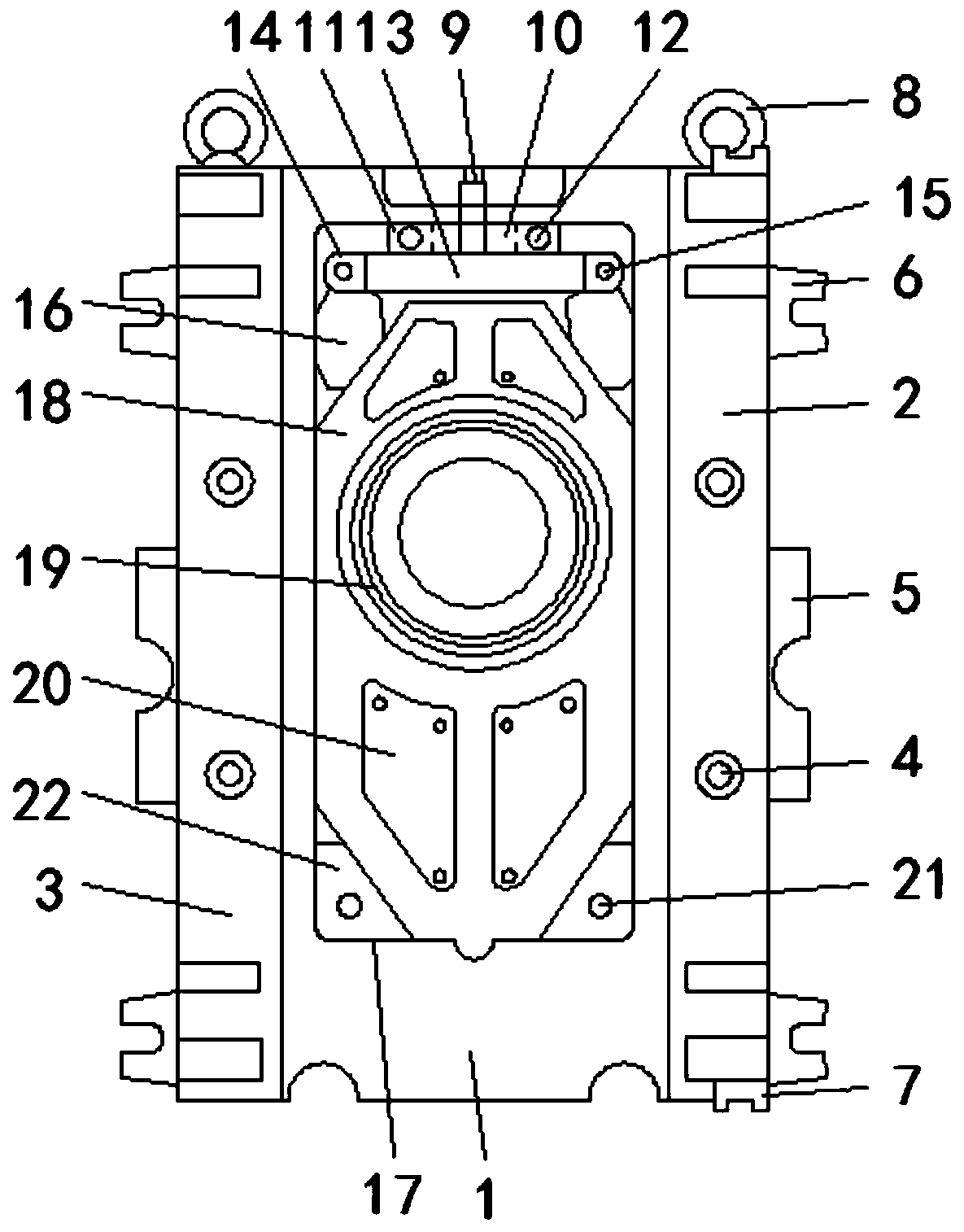

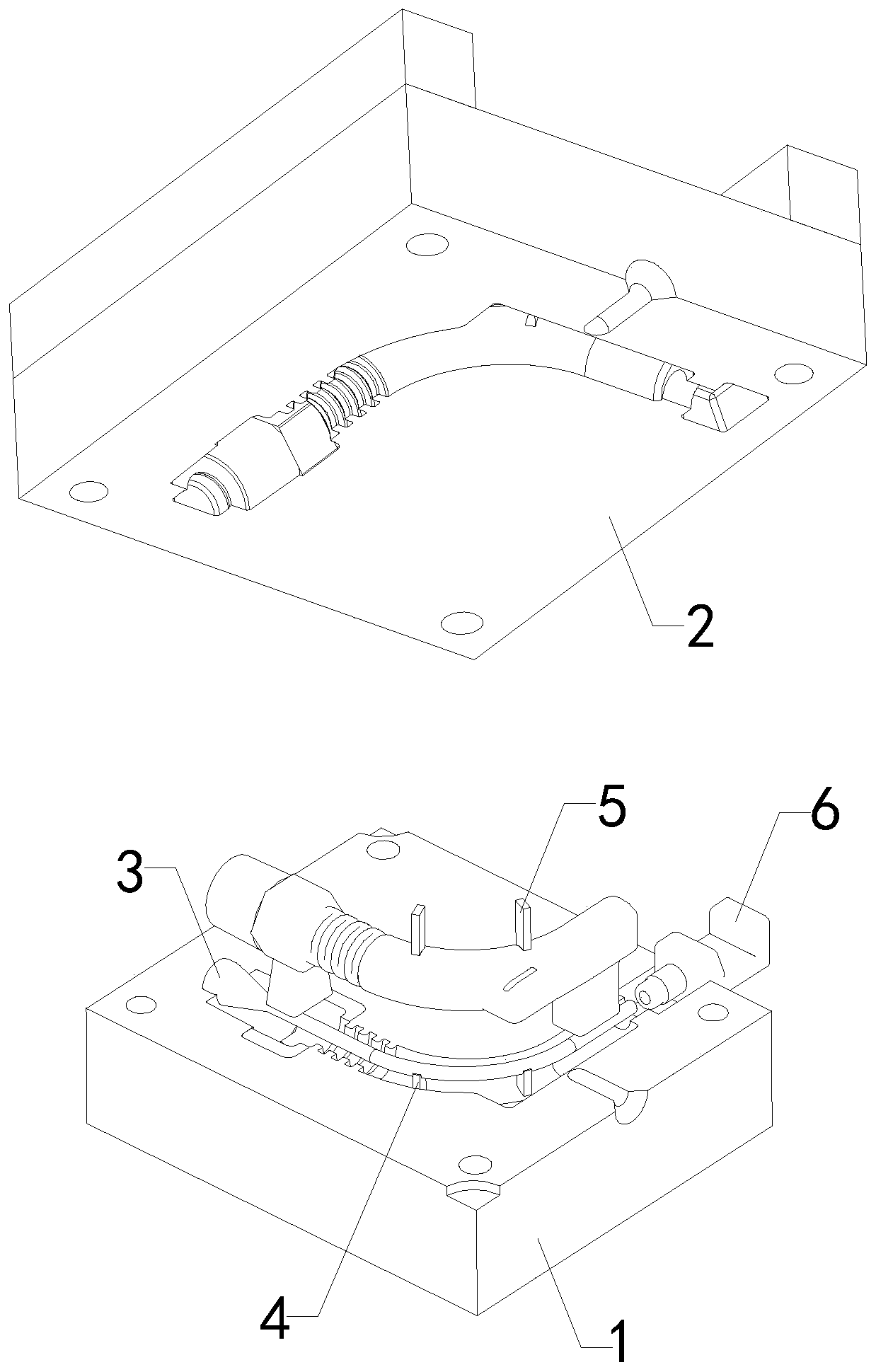

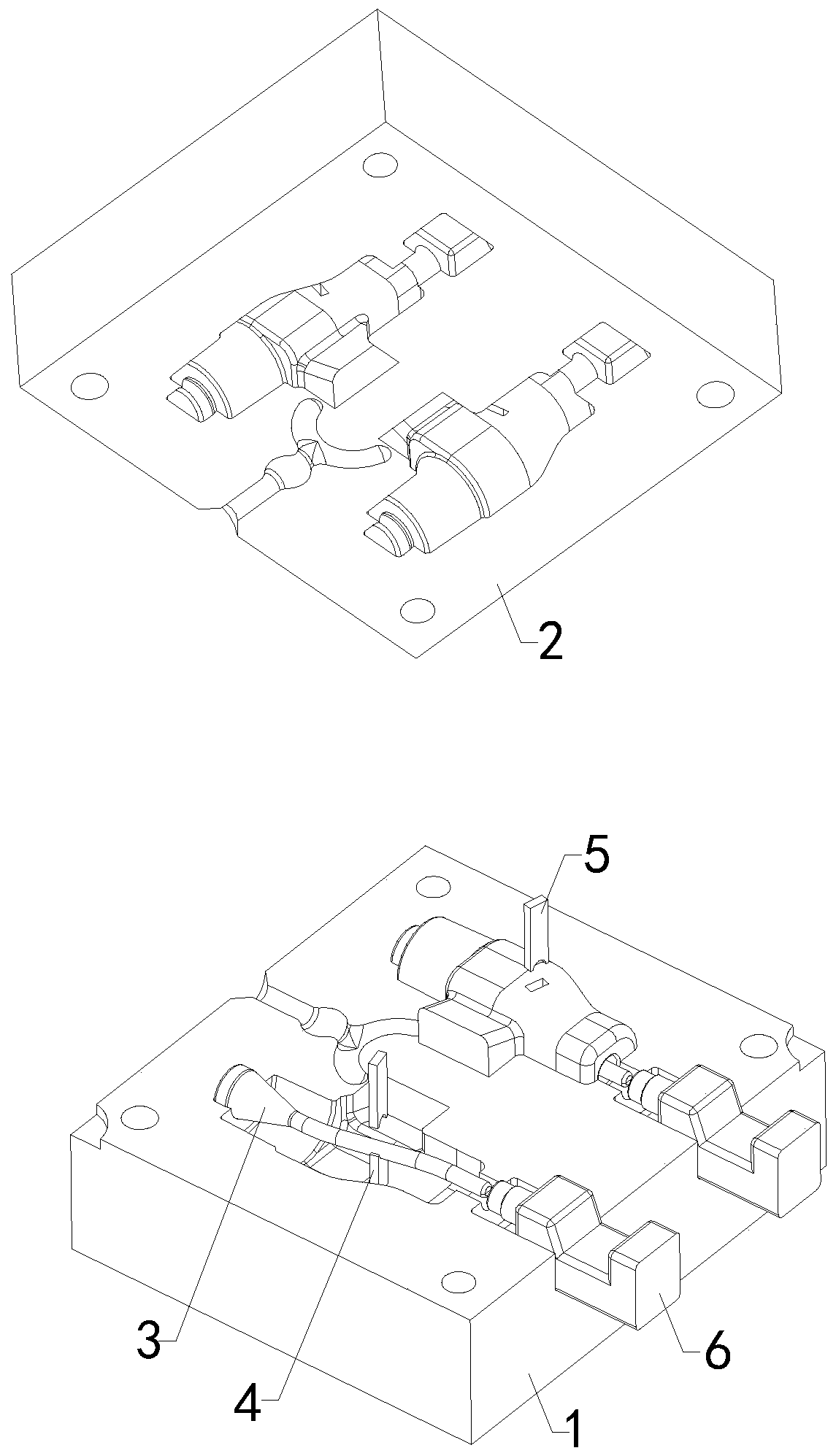

Precision casting complex core mold and use method thereof

PendingCN111230043ACases to prevent driftReduce distortionFoundry mouldsFoundry coresCasting moldMolten steel

The invention relates to the technical field of casting molds, in particular to a precision casting complex core mold and a use method thereof. The mold comprises a mold base and a mold upper mold which are matched up and down, a mold cavity is formed between the mold base and the mold upper mold, a ceramic core is mounted in the mold cavity, a lower core support for supporting the ceramic core ismounted on the mold base, an upper core support for fixing the ceramic core is mounted on the bottom end of the mold upper mold, one end of the mold cavity is provided with a sliding block for fixingthe ceramic core, the material of the upper core support and the material of the lower core support are the same with the material of pour steel, the ceramic core is supported through the upper coresupport and the lower core support to obtain a wax part with a core support, through the wax part, a shell is made, molten steel is poured into the shell, through the upper core support and the lowercore support, the ceramic core is supported, and the condition that due to molten steel instant impact and pressure, the position of the ceramic core is deviated can be effectively prevented.

Owner:河北光德精密机械股份有限公司

Pressing die device for chocolate processing

PendingCN111406821ACases to prevent driftImprove polishing efficiencyCocoaProcess engineeringMechanical engineering

The invention discloses a pressing die device for chocolate processing. According to the pressing die device for chocolate processing disclosed by the invention, a chocolate stock solution poured froma stock solution hopper is transported to a solution injecting cavity through a solution transporting rod; the chocolate stock solution entering the solution injecting cavity flows to a position between an upper die housing and a lower die housing through a stock solution outlet; a piston rod of a second cylinder continues to contract; a rising and falling plate is pushed upwards by a piston rodof a third cylinder; a transporting mechanism is pushed by the rising and falling plate to rise, and then a transporting disk is driven to move upwards; and the chocolate stock solution between the upper die housing and the lower die housing is relatively extruded, and then die pressing and shaping are performed. Through the adoption of the structures, the upper die housing and the lower die housing of the pressing die device can oppositely move, so that the die pressing of the chocolate stock solution is quicker, and the situation that the die pressing is failed is avoided; and a raw materialtransporting cylinder is designed, so that the chocolate raw materials are transported, and besides, the situation that the chocolate stock solution high in consistency is solidified and die pressingcannot be performed is avoided.

Owner:安徽省好朋友食品有限公司

Small-sized efficient cutting device for environment-friendly plate machining

ActiveCN111152285AImprove cutting efficiencyHigh precisionMetal working apparatusEngineeringMachining

The invention discloses a small-sized efficient cutting device for environment-friendly plate machining. The small-sized efficient cutting device comprises a cutting rack, a plate conveying bin, an air cylinder, a cutter fixing plate, a cutting knife, a cutting platform, a guide sleeve, a guide column, a plate positioning mechanism and a plate auxiliary supporting device. According to the efficient cutting device, the plate positioning mechanism is arranged, under the condition that a compression roller driving mechanism drives upper compression rollers to rotate, the upper compression rollersare cooperated with lower compression rollers to position and convey plates before cutting, and therefore an original manual plate pushing and cutting mode is changed, meanwhile, the situation that the plates deviate in the cutting process is prevented, the cutting efficiency is improved, and the plate cutting precision is improved; an arranged height adjusting mechanism is used for adjusting thedistance between the upper compression rollers and the lower compression rollers and adapting to the plates of different sizes, so that practicability is improved; and meanwhile, the arranged plate auxiliary supporting device is used for ensuring the front-back parallelism of the plates when the plates are positioned and conveyed, thereby improving the cutting precision and improving the efficiency.

Owner:浙江恋尚家居品有限公司

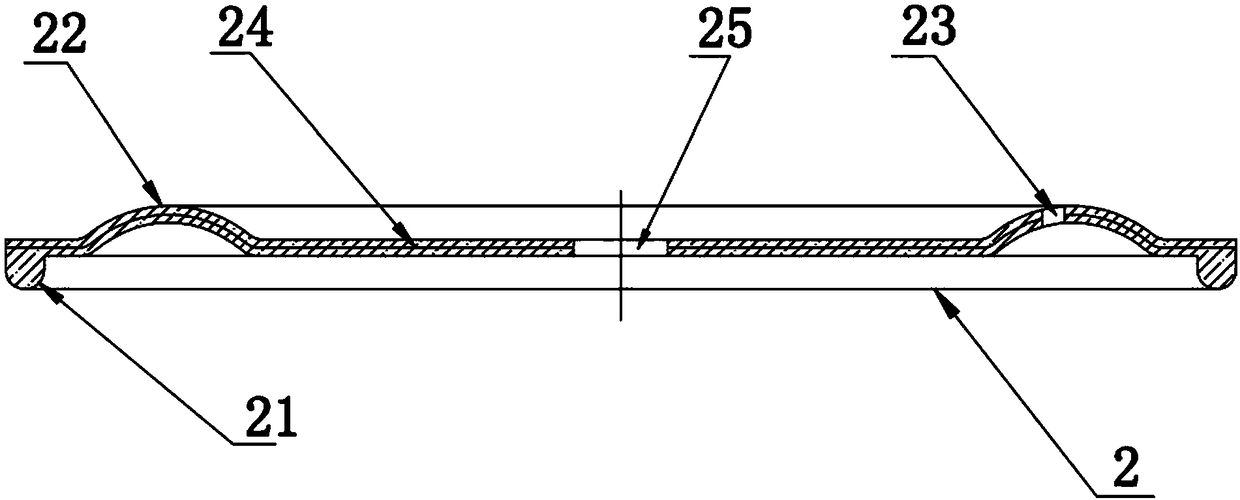

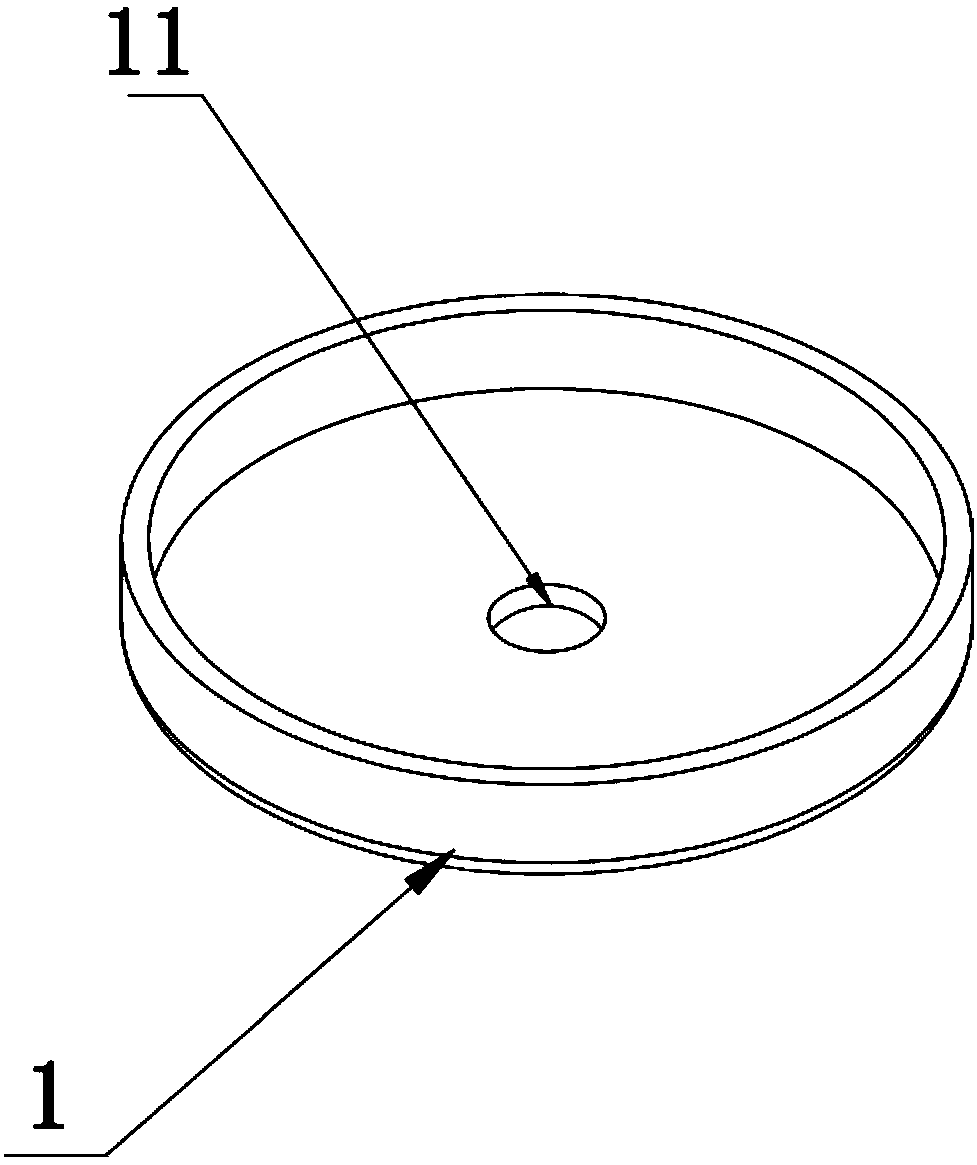

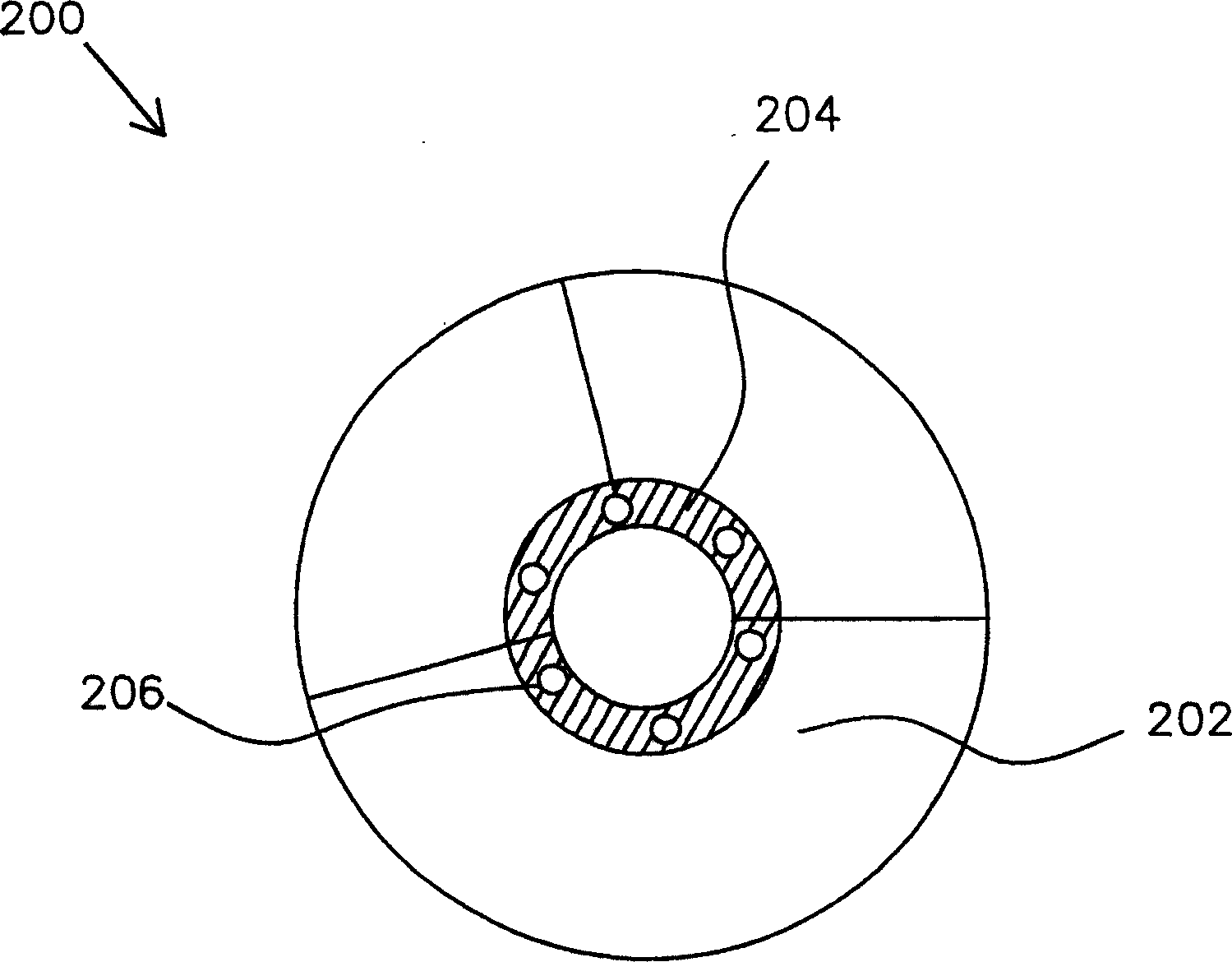

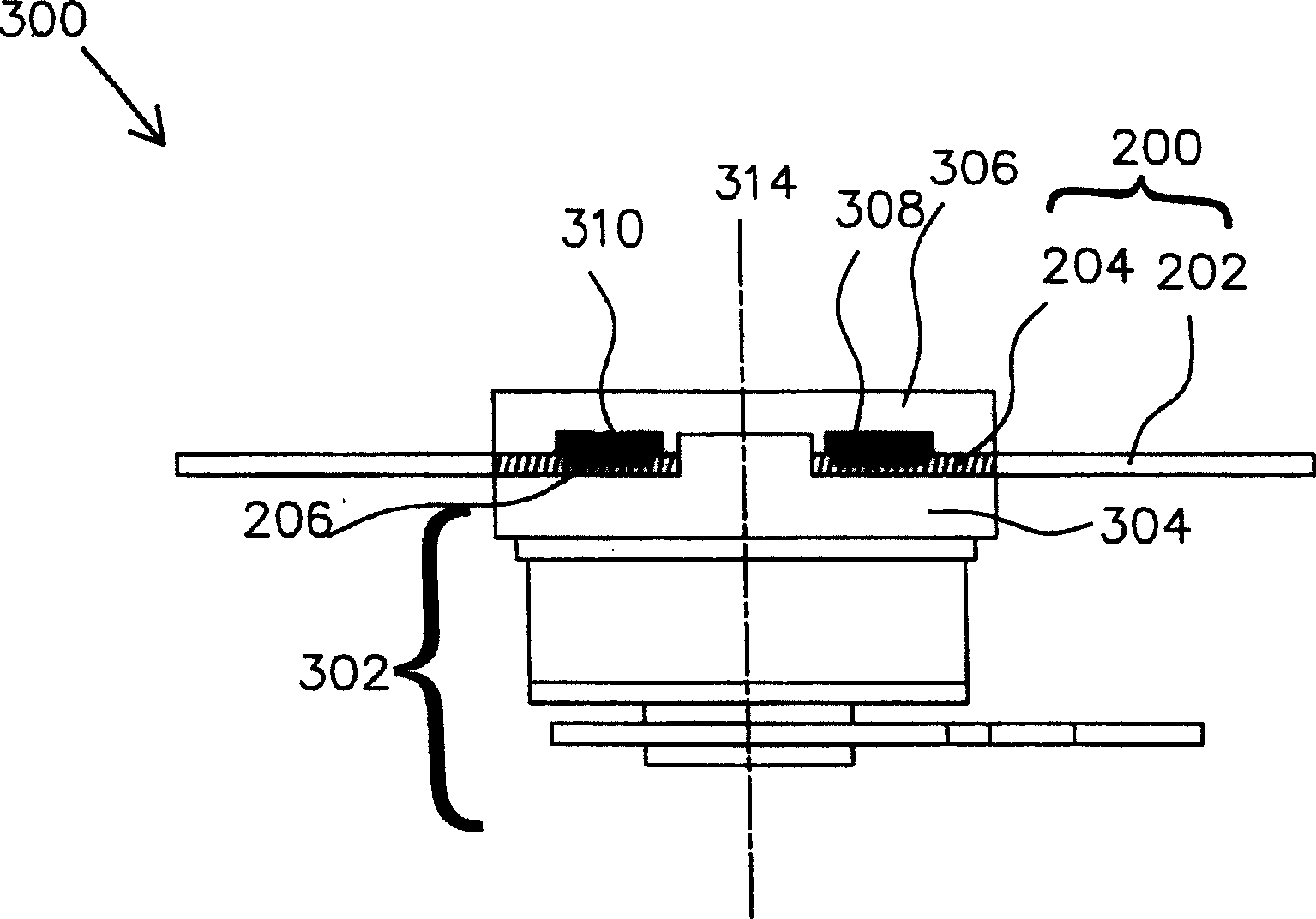

Filter, color wheel therewith and producing method thereof

InactiveCN1553278ATolerance Accuracy RelaxationLow costOptical filtersProjectorsEngineeringColor wheel

A colour wheel consists of bearing component, filter element set and combination piece as bearing component comprises central axis, the first bearer having at least one concave portion and the second bearer as well as can rotate around central axis, filter element set comprises light transmission area and filter element combination area as central axis is shared by both of filter element set and bearing component with filter element combination area having at least a concave portion, combination piece is located simultaneously in both of concave portions for the first bearer and filter element combination area so as to fix filter element combination area of filter element set at position in between the first bearer and the second bearer.

Owner:DELTA ELECTRONICS INC

Carton printing treatment system and printing treatment method

InactiveCN114803289AGuaranteed accuracyCases to prevent driftConveyorsConveyor partsCartonPrinting press

The invention discloses a carton printing treatment system and a carton printing treatment method, and relates to the technical field of carton printing. The carton printing treatment system comprises a base, two rotating shafts are rotationally connected to the upper end face of the base in a bilateral symmetry mode through a vertical plate, a conveying belt is jointly rotationally connected to the exteriors of two mounting cylinders, and straightening mechanisms used for neatly arranging cartons are mounted on the upper end faces of transverse plates; by means of the carton conveying device, cartons in an offset state can be automatically centered and rectified, the cartons can be clamped and limited in the conveying process, the offset condition in the moving process is prevented, the accuracy of printed patterns is guaranteed, and the printing efficiency is improved. And the ink is intermittently conveyed and smeared to the surface wall of the printing roller, waste caused by too much ink or unclear printing caused by too little ink is avoided, and the printing effect is improved.

Owner:武汉商后商贸股份有限公司

A high-efficiency cutting device for small environmental protection plate processing

ActiveCN111152285BCases to prevent driftHigh precisionMetal working apparatusEngineeringMechanical engineering

The invention discloses a high-efficiency cutting device for small environment-friendly plate processing, which includes a cutting frame, a plate conveying bin, an air cylinder, a knife fixing plate, a cutting knife, a cutting platform, a guide sleeve, a guide column, a plate positioning mechanism, Auxiliary support device for sheet metal, the present invention sets the sheet material positioning mechanism, the upper pressure roller is driven to rotate by the pressure roller driving mechanism, and cooperates with the lower pressure roller to perform positioning and transmission before the sheet material is cut, which changes the original method of manually pushing the sheet material to cut. At the same time, it prevents the deviation of the plate during cutting, increases the cutting efficiency and improves the precision of plate cutting, and the height adjustment mechanism is set to adjust the distance between the upper and lower pressure rollers to adapt to different sizes. Plates increase practicability. At the same time, the auxiliary support device for plates is used to ensure the parallelism of the front and back of the plates during the positioning and transmission of the plates, increase the cutting accuracy and improve the efficiency.

Owner:浙江恋尚家居品有限公司

Flame cutting equipment for machining mechanical parts

InactiveCN112536503APrevent flying outCases to prevent driftGas flame welding apparatusMechanical componentsEngineering

The invention discloses flame cutting equipment for machining mechanical parts. The flame cutting equipment comprises a base,moving tables and supporting plates, wherein telescopic rods are installedin the base, rails are welded to the top of the base and located at the outer sides of the telescopic rods, and moving wheels are installed at the tops of the rails; and the tops of the moving wheelsare fixed to the bottom of the moving tables through connecting parts, the supporting plates are installed at the tops of the moving tables through bolts, a transverse supporting column is installed at one side of each supporting plate, a moving base is movably installed on the outer side of each transverse supporting column, and a first fixing rod is installed at the front end of each moving basethrough bolts. According to the flame cutting equipment, a protective cover is installed at the outer side of a flame gun and covers the outer side of the flame gun, and when a workpiece is cut, flame cuts the workpiece to generate a large number of particle chippings, the chippings are splashed out, the protective cover blocks splashed particles, the particles are prevented from flying out, andthe safety of workers is guaranteed.

Owner:广州诺星智能科技有限公司

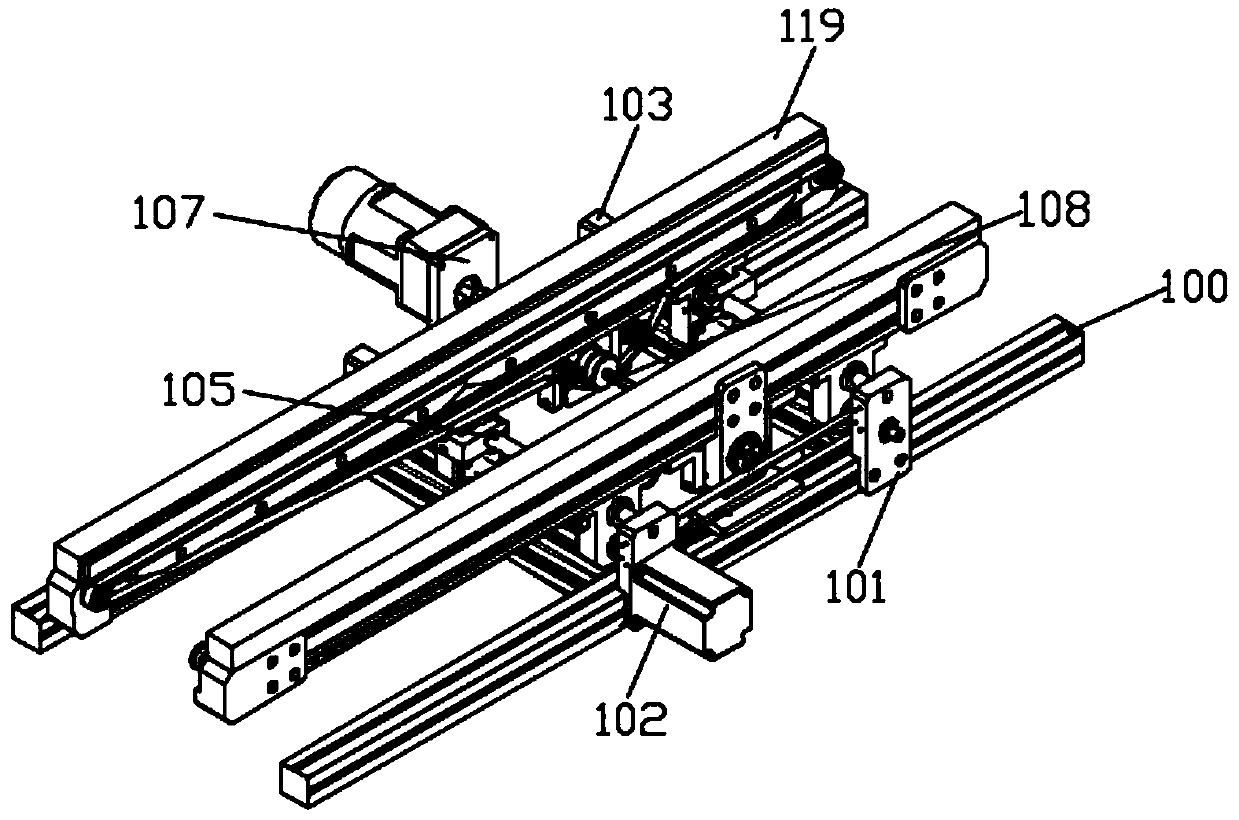

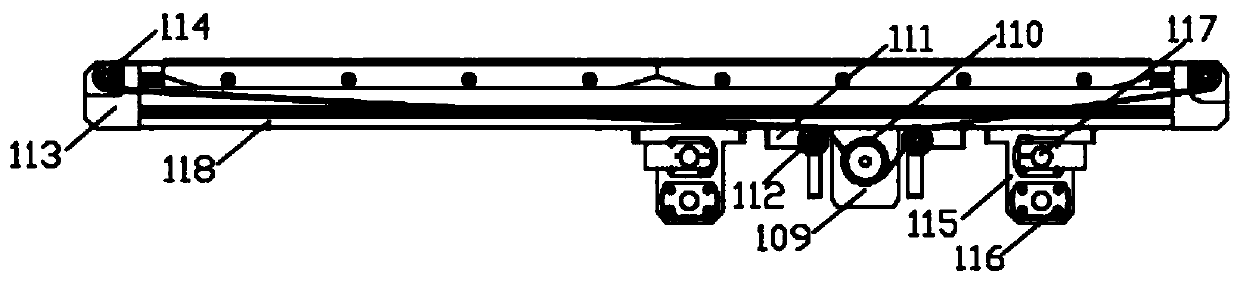

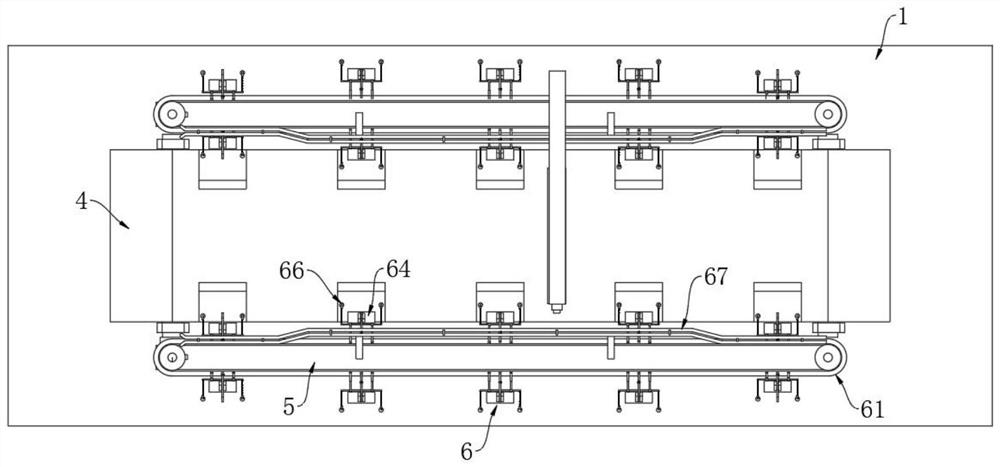

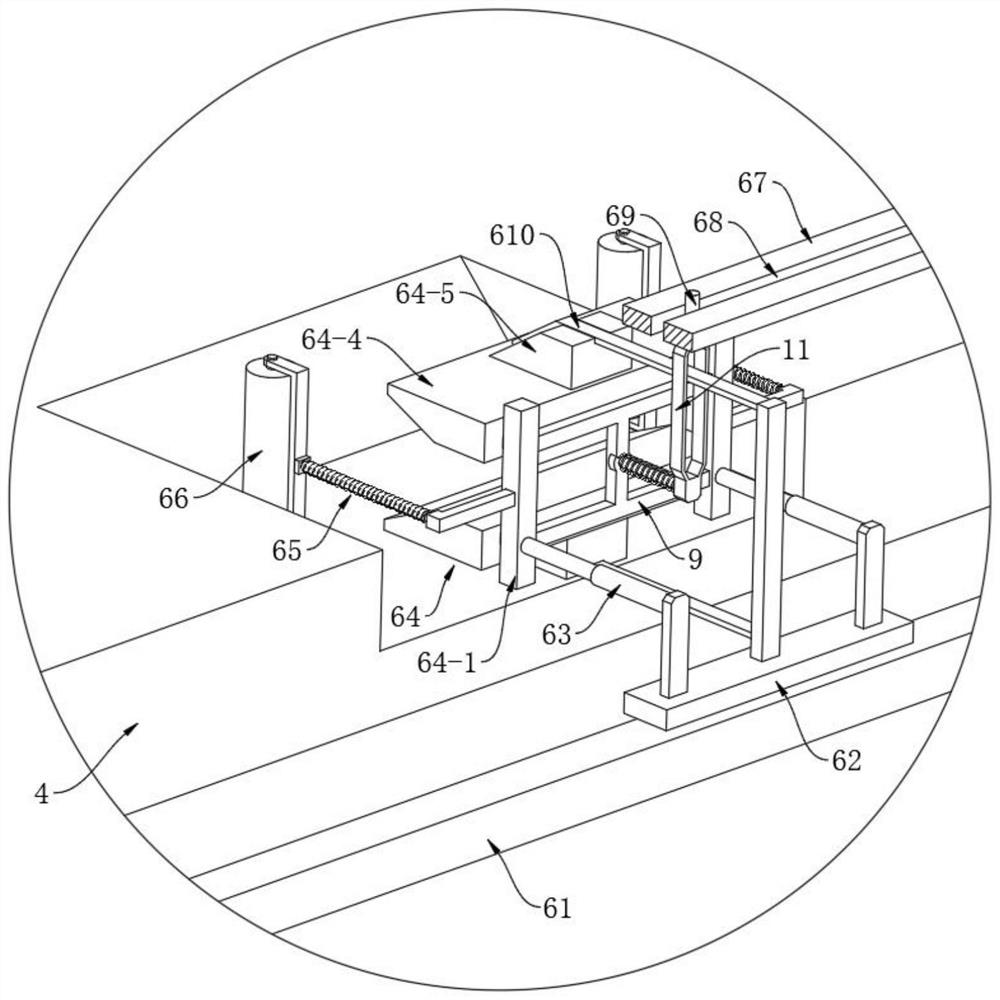

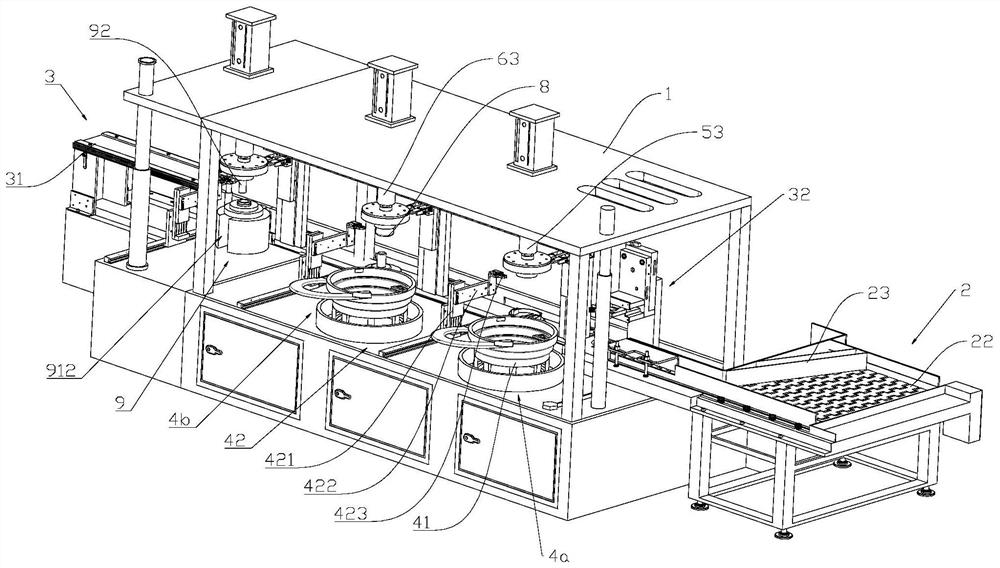

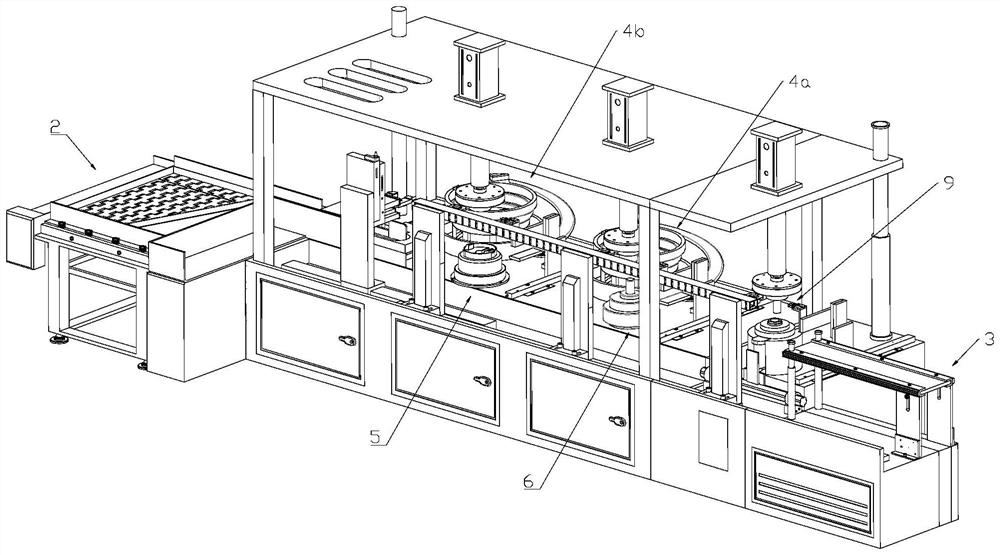

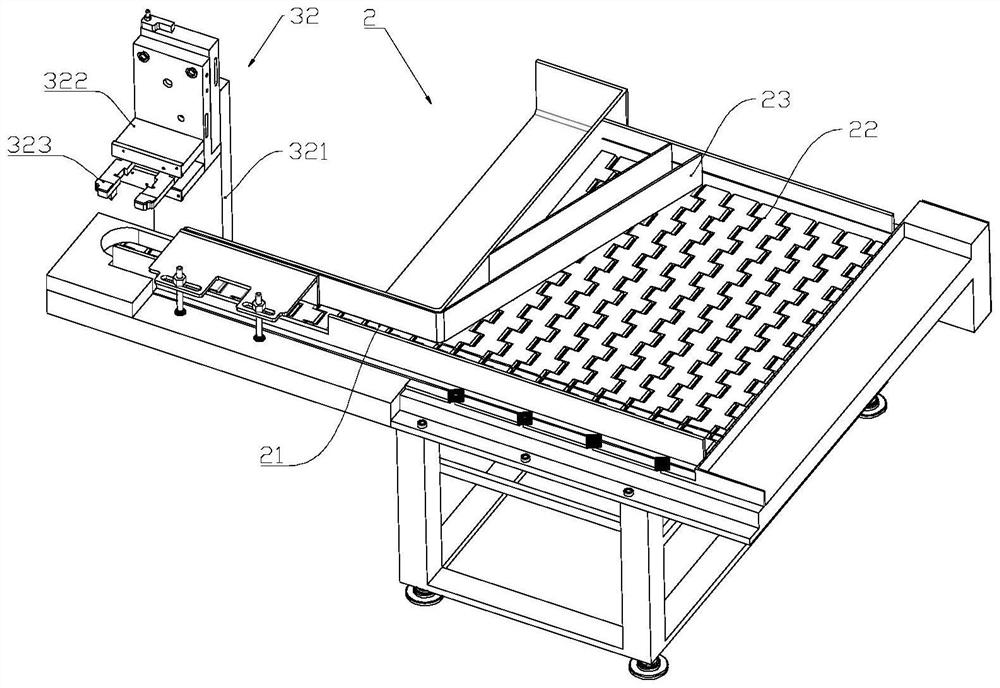

Gear type isolator bushing press-fitting line

ActiveCN114749914AAvoid CatonAvoid offsetAssembly machinesMetal working apparatusEngineeringWorkbench

The invention provides a gear type isolator bushing press-fitting line which comprises a workbench, a workpiece feeding mechanism and a semi-finished product discharging mechanism are arranged on the workbench, and a first bushing feeding mechanism and a second bushing feeding mechanism are arranged between the workpiece feeding mechanism and the semi-finished product discharging mechanism in a spaced mode. The first lining feeding mechanism and the second lining feeding mechanism are matched with the first press-fitting mechanism and the second press-fitting mechanism correspondingly so that the two linings can be pressed into the upper portion and the lower portion of the workpiece correspondingly. The bushing press-fitting device solves the technical problem that in the prior art, bushing press-fitting is not in place.

Owner:玉环普天单向器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com