An automated palletizing device for logistics

A technology of automatic palletizing and palletizing device, which is applied in the direction of depalletizing, stacking, transportation and packaging of objects, and can solve problems such as collapse, feed inclination, uneven distribution of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

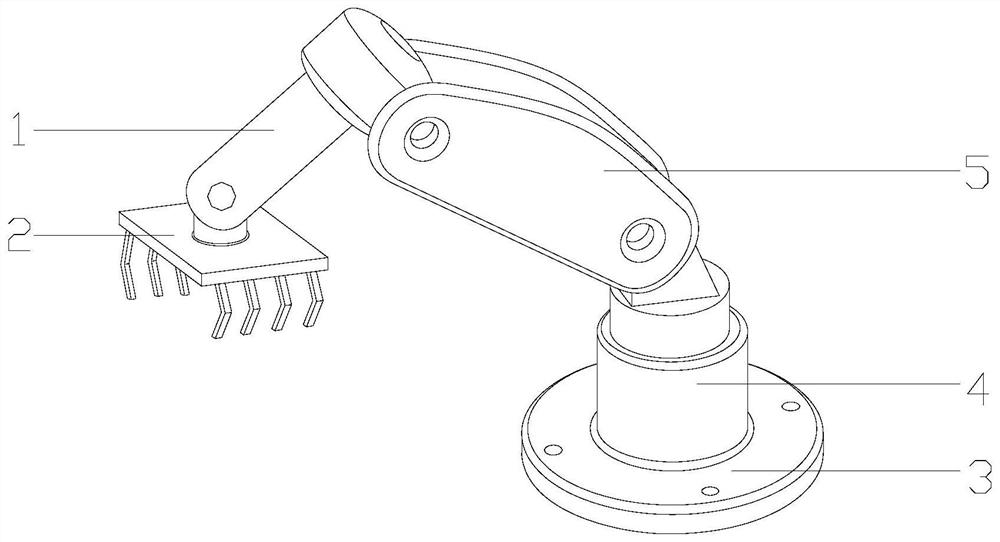

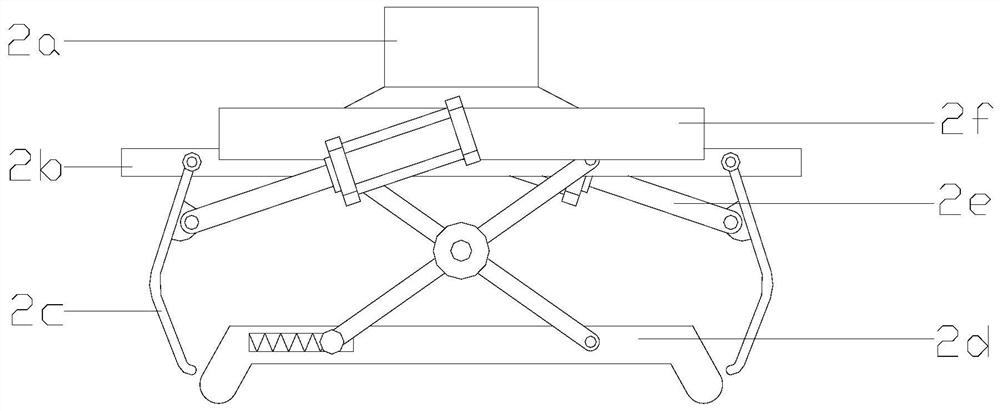

[0026] see Figure 1-Figure 2 , the present invention provides an automatic palletizing device for logistics, its structure includes a manipulator connecting arm 1, a material palletizing device 2, a fixed base 3, an automatic rotating seat 4, and a driving spindle 5, the fixed base 3 is a cylindrical structure and The bottom surface and the workshop floor are fixed together by bolts, the bottom of the automatic rotating seat 4 is welded to the middle of the upper surface of the fixed base 3, the bottom of the driving spindle 5 and the top of the automatic rotating seat 4 are fixed together by bolts, and the manipulator is connected The right end of the arm 1 is engaged with the top of the drive spindle 5. The material stacking device 2 is located below the connecting arm 1 of the manipulator and is parallel to the ground. The feed fixing hand grip 2c, the material shaking mechanism 2d, the hydraulic drive cylinder 2e, and the fixed plate guide rail 2f are composed of the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com