Small-sized efficient cutting device for environment-friendly plate machining

A sheet metal processing and environmental protection technology, applied in metal processing and other directions, can solve the problems of inability to locate and transmit sheets, manual methods are inconvenient, and sheet cutting precision is low, and achieves cutting efficiency, practicability, and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

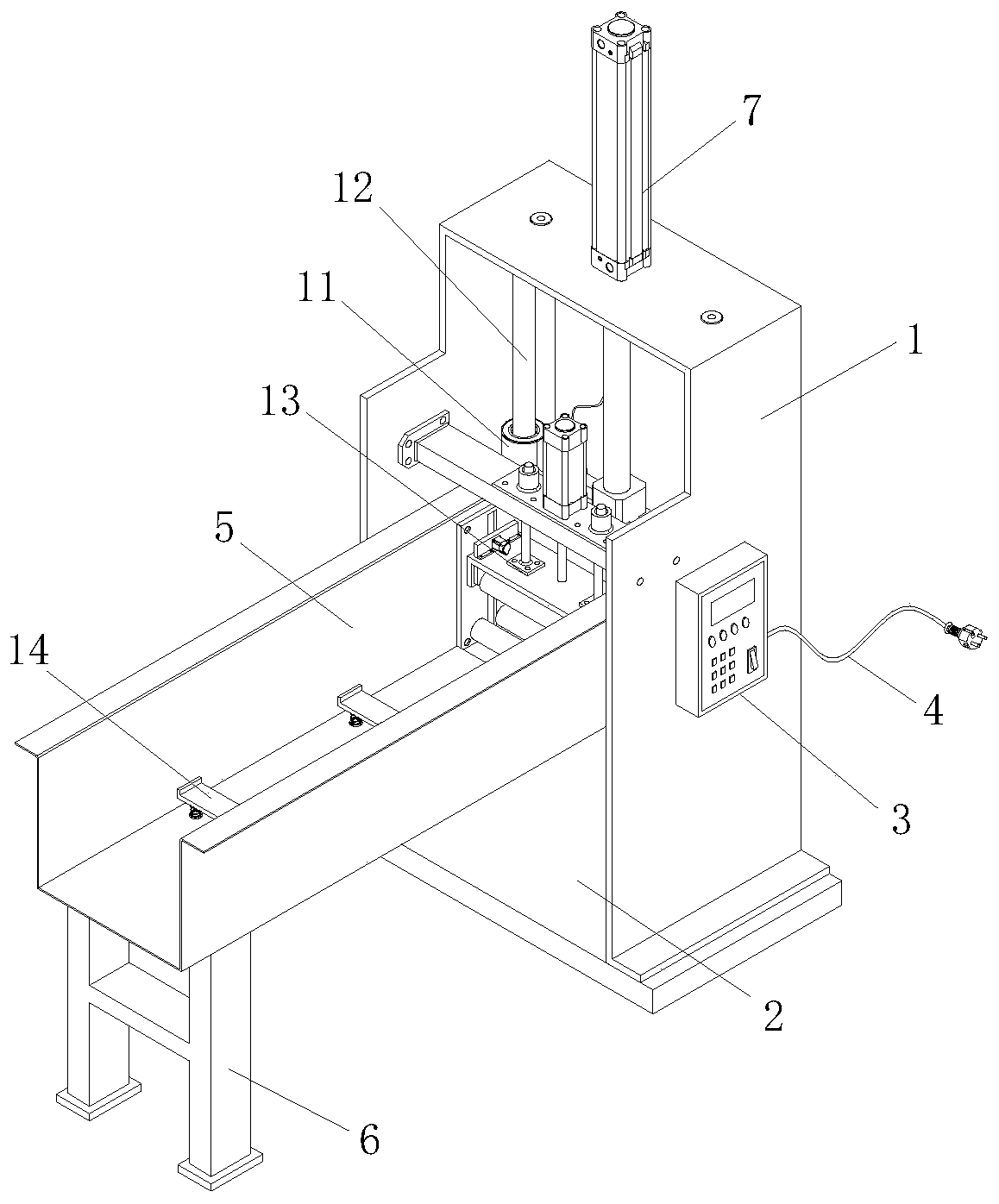

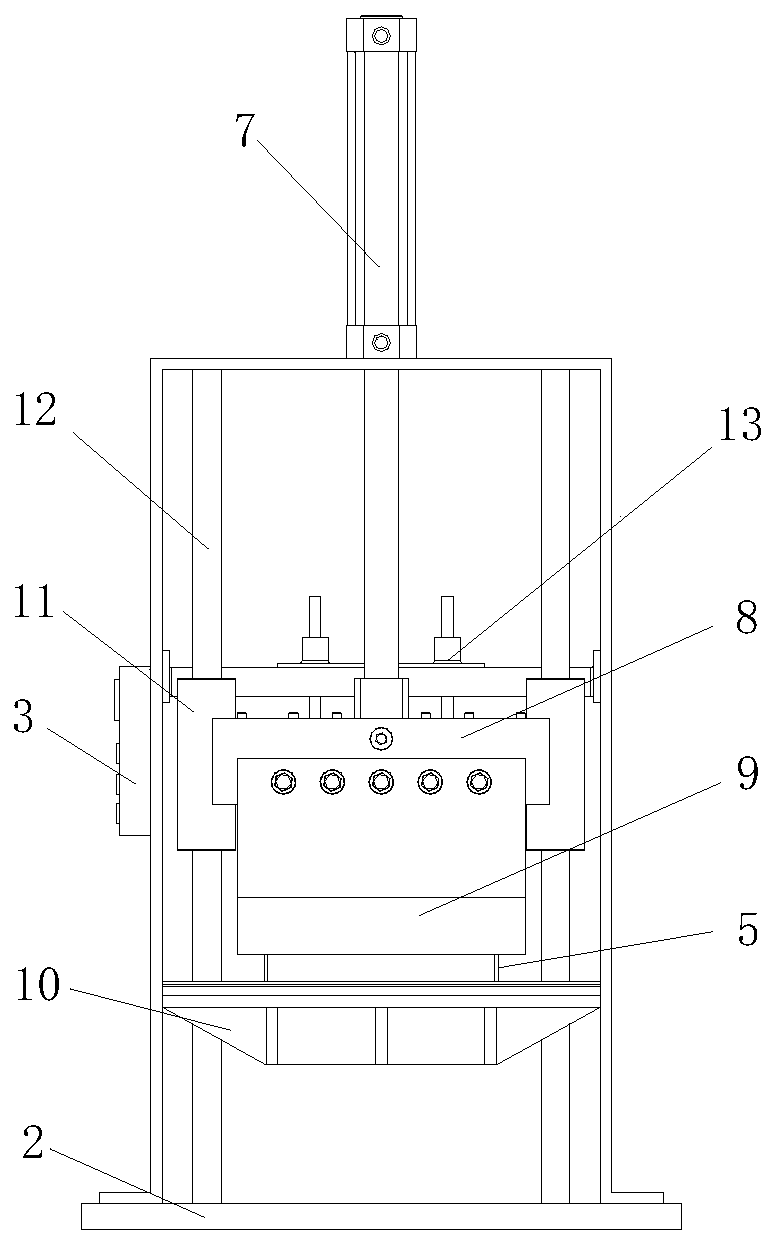

[0034] see figure 1 , figure 2 and Figure 11Shown, the present invention provides a kind of fire extinguisher fixing structure for fire-fighting with high-efficiency cutting device fire-fighting of small-scale environment-friendly sheet material processing through improvement here, comprises cutting frame 1, sheet material positioning mechanism 13 and sheet material auxiliary supporting device 14, cutting frame 1 A support base plate 2 is installed at the bottom, a control box 3 is installed in the middle part of the right side of the cutting frame 1, a power cord 4 is arranged on the rear side of the control box 3, a plate transfer warehouse 5 is installed in the middle part of the front end of the cutting frame 1, and the plate is conveyed The rear end of the bin 5 is fixed to the front two sides of the cutting frame 1, the bottom and front side of the plate transfer bin 5 is equipped with a support chassis 6, the middle part of the top of the cutting frame 1 is equipped ...

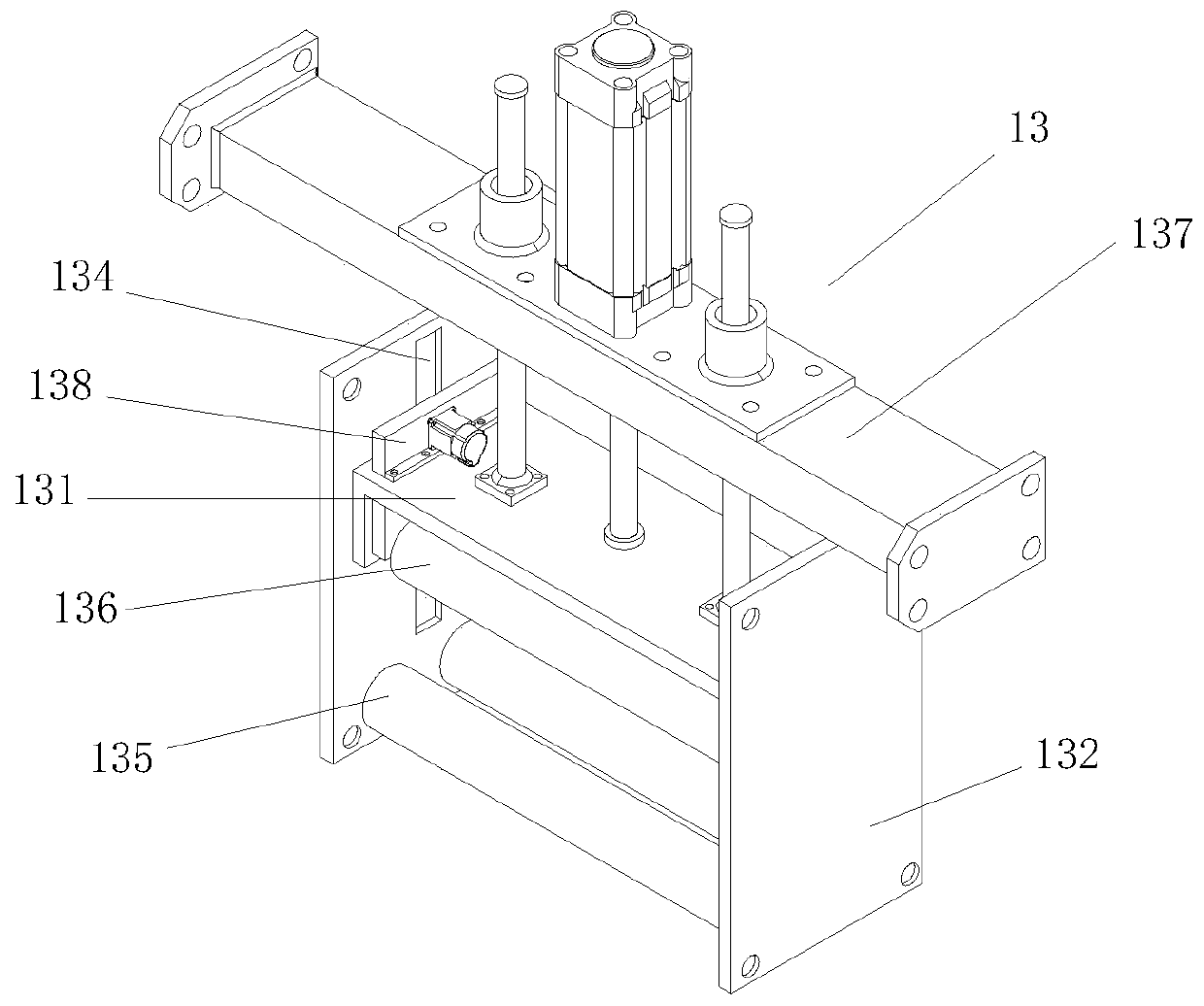

Embodiment 2

[0041] The present invention provides a kind of high-efficiency cutting device for small-sized environment-friendly plate processing through improvement. The two ends of the plate positioning mechanism 13 are fixed with the cutting frame 1. The plate positioning mechanism 13 maintains stability during operation. There are two rod seats 1374 and two positioning rods 1375, which are arranged symmetrically on the left and right, so that the pressure roller fixing plate 131 is used for guiding and positioning to keep it stable when the height is adjusted, and to support the beam. The inner side of 1371 is a hollow structure, which saves materials, and is made of No. 45 steel material with high strength. The left side of the pressure roller fixing plate 131 is provided with a rectangular through groove, which is used for the embedded installation of the pressure roller driver 138. The housing fixing plate 1382 is set as The upper and lower two are used to fix the outer shell 1381 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com