Multi-surface grinding processing device for rectangular workpiece

A processing device and workpiece technology, which is applied in the field of multi-face grinding processing devices for rectangular workpieces, can solve the problems of inability to adjust the position and angle, cumbersome clamping and positioning of workpieces, and affecting the efficiency of grinding and processing, so as to increase convenience and improve the efficiency of grinding and processing , the effect of quick clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

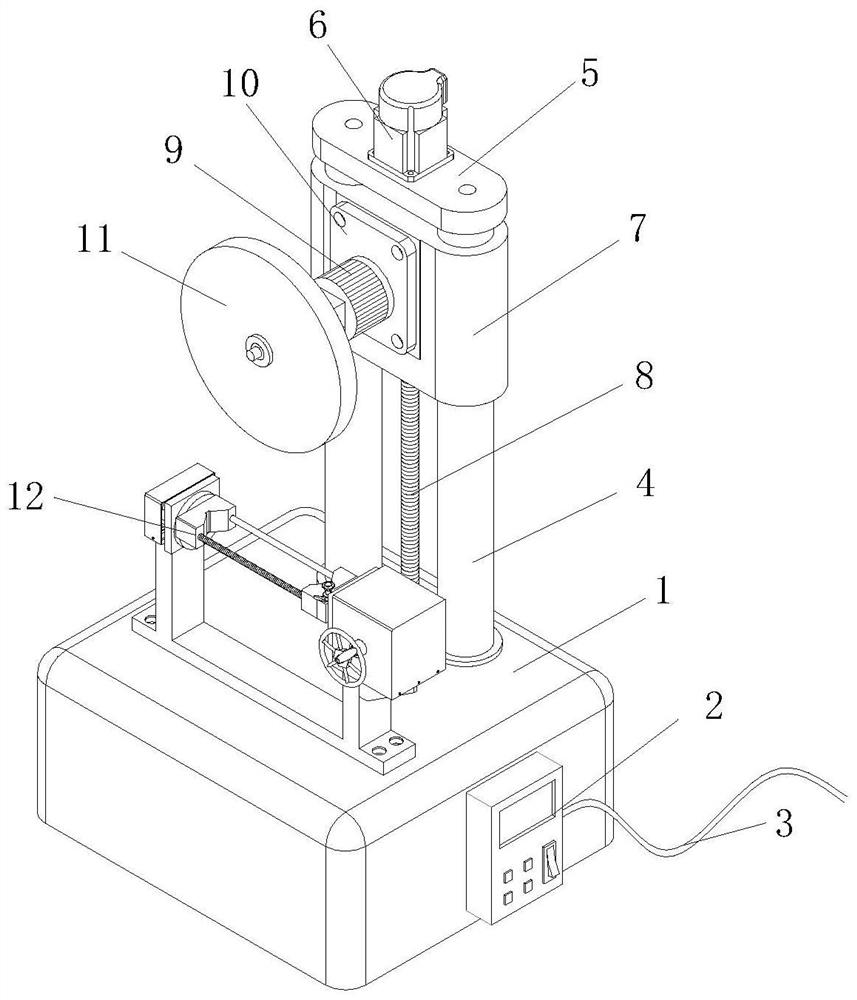

[0031] see figure 1As shown, the present invention provides a multi-faceted grinding and processing device for a rectangular workpiece through improvement, including a support base 1, a control panel 2, an external power cord 3, a support guide post 4, a top plate 5, a first motor 6, and a sliding seat 7 , the first screw mandrel 8, the second motor 9, the rear seat plate 10, the grinding disc 11 and the multi-face adjustment device 12, and the control panel 2 is arranged in the middle part of the right side of the support base 1, which can control the energized elements of the device, and the control panel 2 is connected to There is an external power cord 3, which can be connected to an external power supply to supply power to the device. Two support guide columns 4 are installed on the rear side of the top of the support base 1 for sliding support. The tops of the two support guide columns 4 are connected and fixed through the top plate 5. The first motor 6 is installed on t...

Embodiment 2

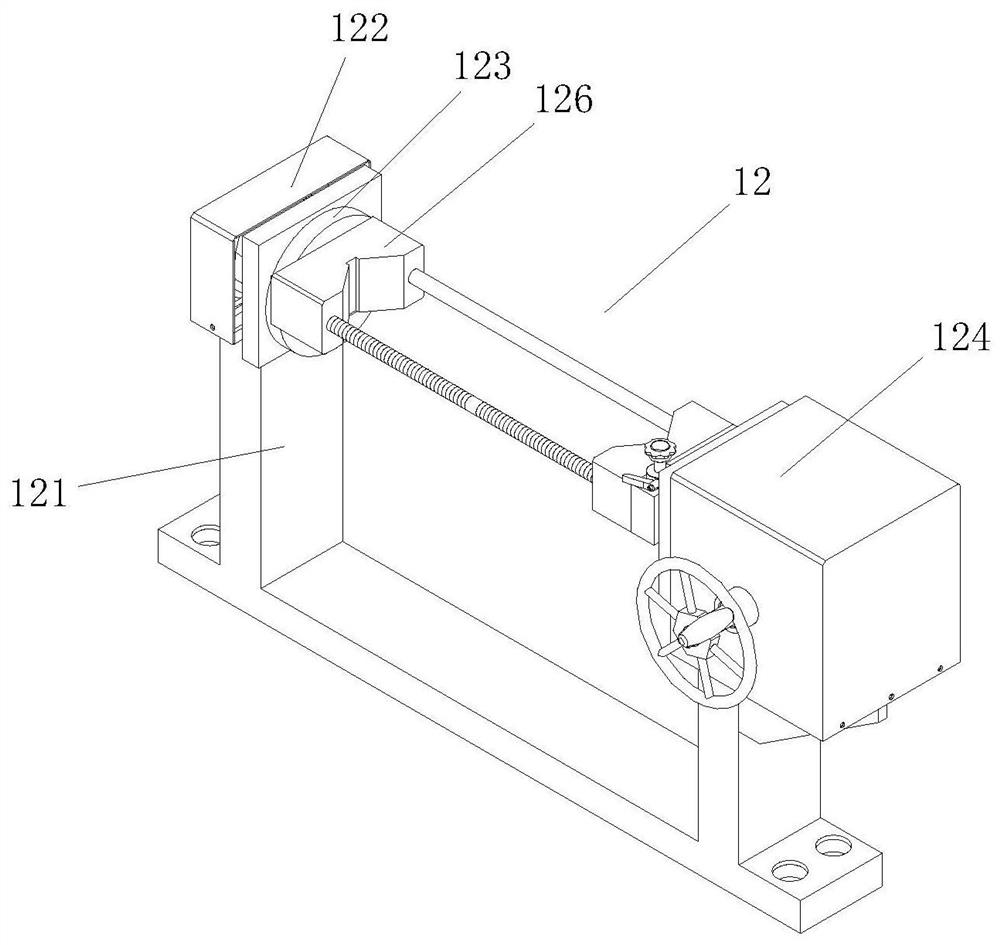

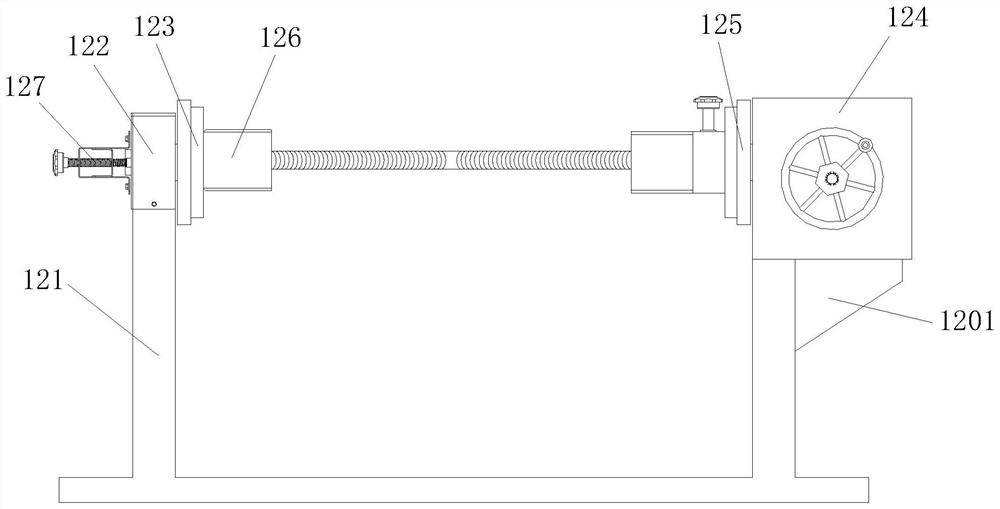

[0038] The present invention provides a multi-faceted grinding and processing device for rectangular workpieces through improvement. The clamping rod 1275 of the angle locking mechanism 127 passes through the rotation positioning seat 122 and abuts against the left side of the left turntable 123, so that the angle locking mechanism 127 can be aligned to the left. The turntable 123 is locked to position the adjusted rectangular workpiece to prevent it from drifting autonomously during grinding. The drive shaft 1243 is connected with the middle part of the right turntable 125 so that the drive shaft 1243 can drive the right turntable 125 to rotate The hand turntable 1248 is arranged in the front middle part of the first outer frame 1241, which is convenient to rotate it better. Connected, and the right side passes through the right clamping block 1261 and is connected with the spacing adjustment mechanism 1265, after the spacing adjustment mechanism 1265 is operated, after the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com