Internal combustion engine flywheel inclined hole machining equipment

A technology for processing equipment and internal combustion engines, applied in metal processing equipment, drilling/drilling equipment, metal processing, etc., can solve the problems of cumbersome operation, uneven distribution of the inclined hole position of the flywheel, poor fixing effect, etc., to prevent loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

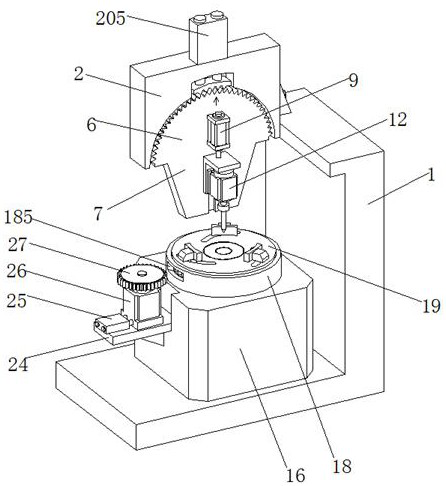

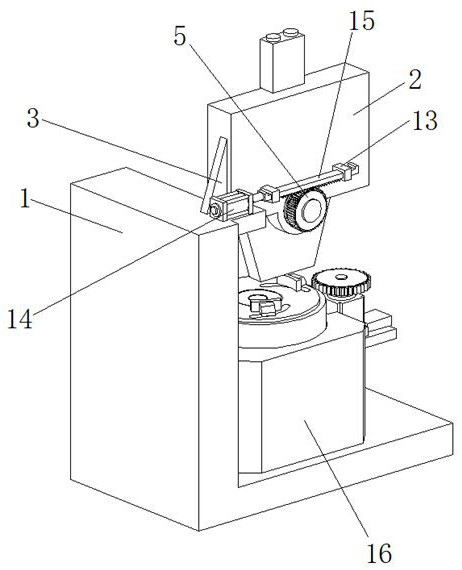

[0035] This embodiment 1 has introduced a kind of flywheel oblique hole processing equipment in the internal combustion engine, refer to the attached figure 1 And attached figure 2 , which includes an L-shaped base 1, the upper end of the L-shaped base 1 is fixedly connected with a vertical plate 2, and a triangular reinforcing rib 3 is also welded at the connection between the L-shaped base 1 and the vertical plate 2, which is used to strengthen the two The stability of the connection between them.

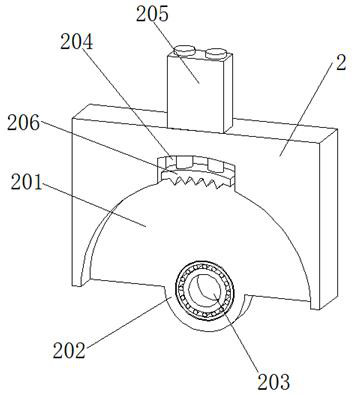

[0036] Reference attached image 3 , attached Figure 4 And attached Figure 5 , a semicircular groove 201 is provided at the lower end of the front side of the vertical plate 2, and a convex block 202 is connected to the center of the semicircular groove 201, and a first bearing 203 is arranged in the convex block 202. A rotating shaft 4 is rotationally connected in the first bearing 203, the rear end of the rotating shaft 4 is connected with the first gear 5, the front end...

Embodiment 2

[0041] Embodiment 2 introduces an improved flywheel oblique hole processing equipment based on Embodiment 1. Its similarities with Embodiment 1 will not be described again. For the differences, refer to the attached figure 1 , attached image 3 And attached Figure 4 .

[0042] In Embodiment 2, an arc-shaped tooth surface 601 is provided on the arc-shaped outer surface of the semi-circular loading plate 6 , and a receiving groove 204 is opened at the top of the semi-circular groove 201 . On the vertical plate 2 above the receiving groove 204, a third cylinder 205 is fixed, and the piston rod of the third cylinder 205 stretches into the lower end of the receiving groove 204 to be connected with an arc bead 206, and on the lower surface of the arc bead 206 There are occlusal teeth (not marked in the figure); by pressing down the arc-shaped bead 206, the occlusal teeth are engaged with the arc-shaped tooth surface 601 on the semicircular loading plate 6, so that the semicircula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com