Filter, color wheel therewith and producing method thereof

A manufacturing method and color wheel technology, applied in the field of color filters, can solve problems such as damage, color filter cracks, increased noise, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

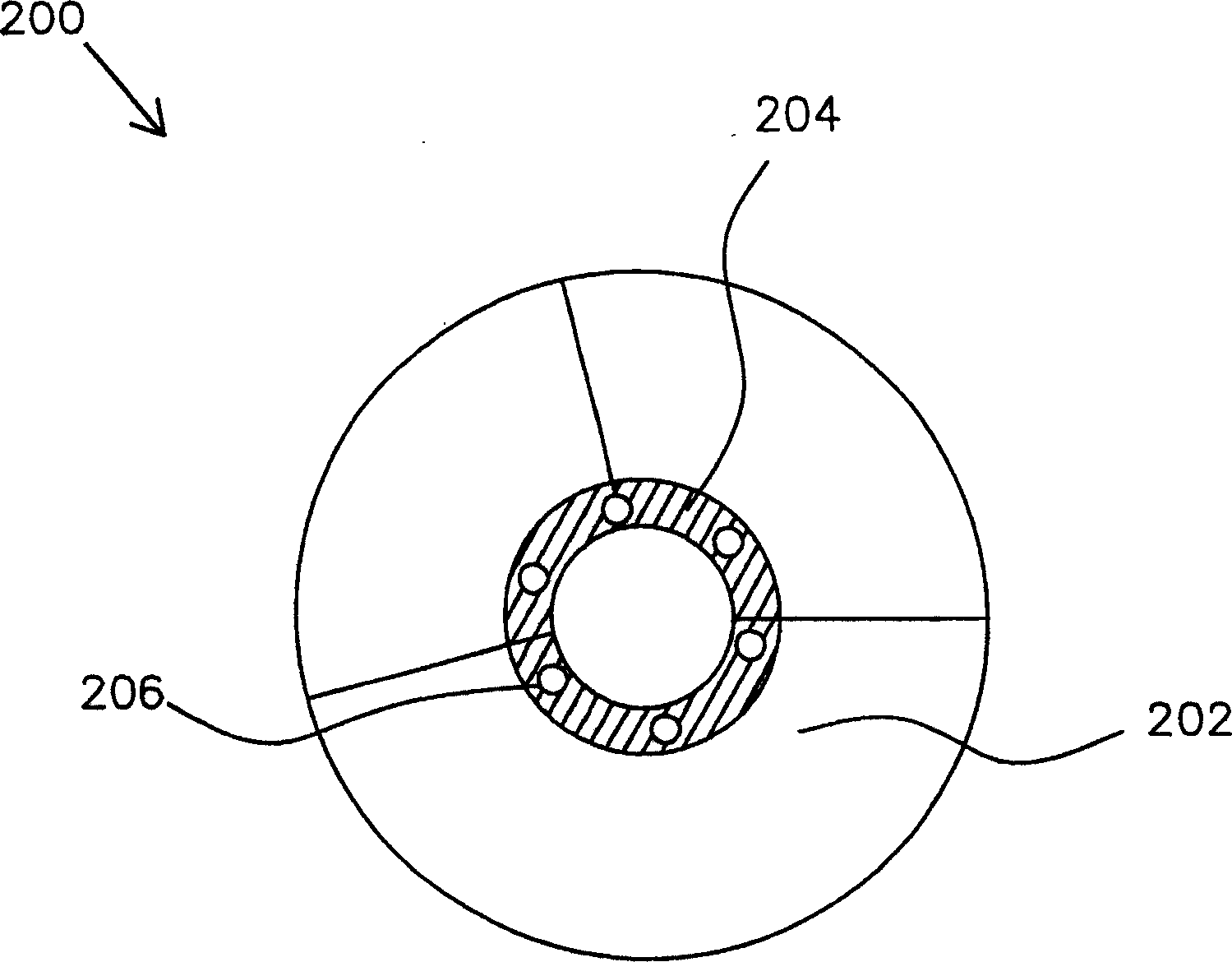

[0033] figure 2 A schematic diagram of a filter set according to a preferred embodiment of the present invention is shown. The filter set 200 of the present invention is composed of one or more filters. The filter set 200 is, for example, a planar circular sheet structure. The filter set 200 can be divided into a light-transmitting area 202 and a filter combining area 204 , and at least one recess 206 is formed in the filter combining area 204 .

[0034] The light-transmitting area 202 is used to provide high transmittance, and changes the color of the passing light after the light passes through. The light-transmitting region 202 is, for example, a region coated with an optical interference filter film.

[0035] The filter combination area 204 is the area where the filter set 200 is combined with the color wheel main body or carrier described later. The recessed portion 206 of the filter joint area 204 is used to provide a combination assembly fixedly connected to the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com