[0004] The object of the present invention is to provide a

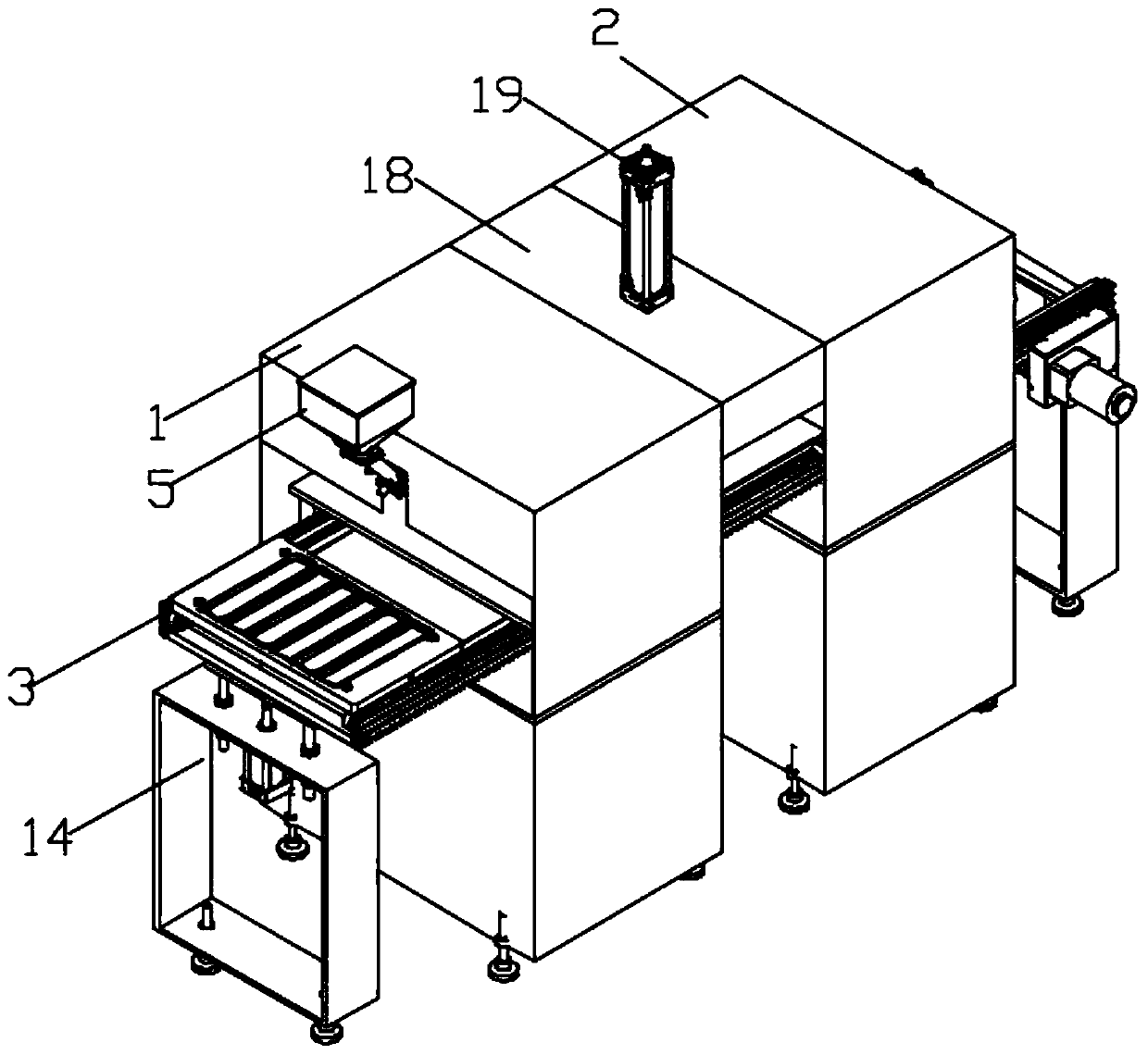

compression molding device for chocolate processing, which solves the following technical problems: (1) by pouring the chocolate stock solution into the stock solution bucket, the first motor is turned on, and the first motor drives the two driving wheels to rotate through the hexagonal rod , the two driving wheels cooperate with the two guide wheels and the two transmission wheels on the corresponding side strips to drive the two conveyor belts to rotate, and the two conveyor belts transport the conveyor discs, which are transported into the die frame, and the two conveyor belts The

piston rod of the first cylinder is inserted into the slots on both sides of the delivery plate, and then the

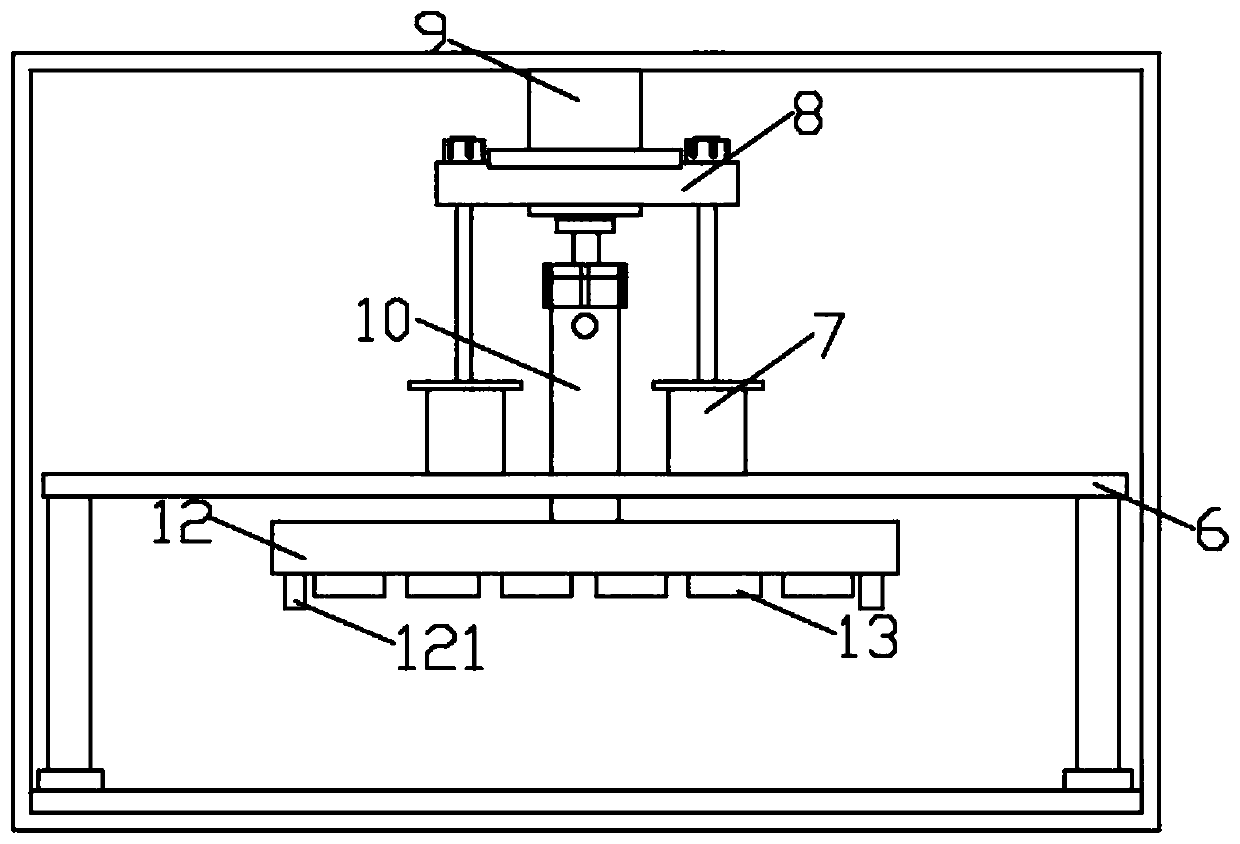

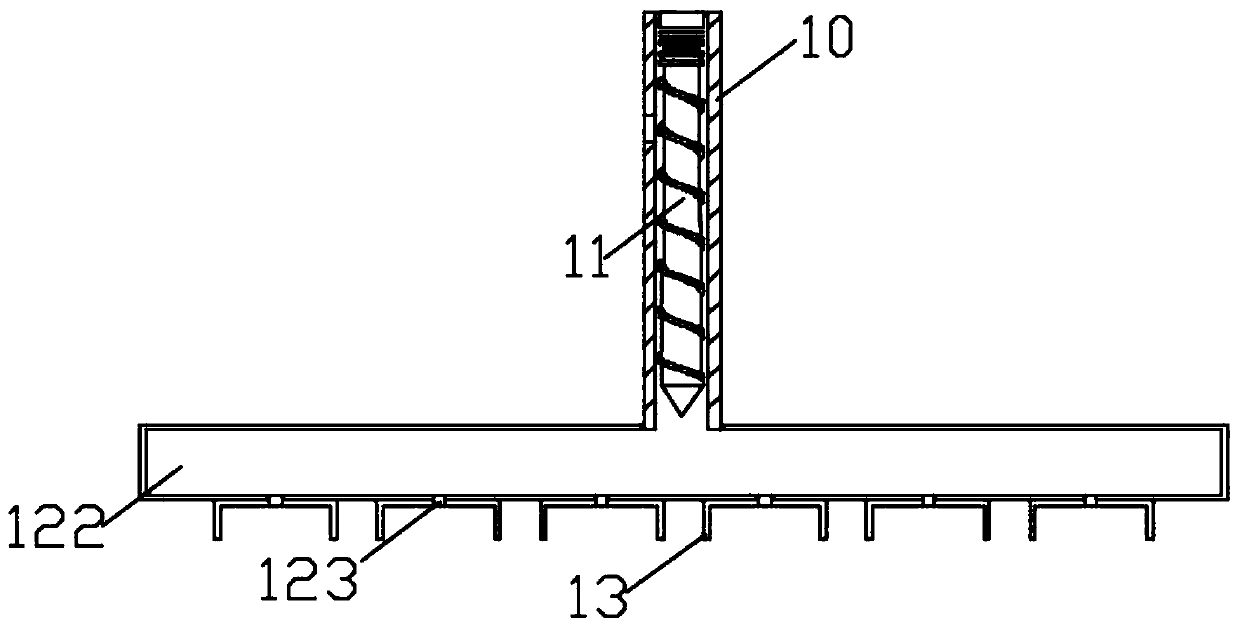

piston rod of the second cylinder shrinks, and the raw liquid delivery cylinder is driven down through the connecting plate, the raw liquid delivery cylinder drives the platen down, and the output shaft of the second motor drives the infusion rod to rotate. The infusion rod transports the chocolate stock solution poured from the stock solution hopper into the

liquid injection cavity, and the chocolate stock solution entering the

liquid injection cavity flows between the upper mold shell and the lower mold shell through the stock solution outlet, and then the

piston rod of the second cylinder continues to shrink. The three-cylinder

piston rod pushes the lifting plate upwards, and the lifting plate pushes the conveying mechanism up, and then drives the conveying plate to move upwards. The chocolate raw liquid between the upper mold shell and the lower mold shell is relatively squeezed, and then molded, which solves the problem in the prior art. It is easy to solidify before the original hydraulic mold of chocolate and cannot be molded due to high consistency. At the same time, the existing molding equipment can only complete the movement of the upper mold shell, and the molding efficiency is not high; (2) Through the two first cylinders The piston rod is inserted into the slots on both sides of the conveying plate. Through the above structure, after the conveying plate is transported to the molding frame and the

polishing frame, the conveying plate is fixed before the molding and

polishing, preventing the conveying during the molding and

polishing. If the plate is offset, the four first positioning rods at the bottom of the platen are respectively inserted into the four corresponding positioning holes on the conveying plate, and the conveying plate is transported to the bottom of the cooling shell by the conveying mechanism, and the fourth cylinder pushes the air-cooled shell downward. , the four second positioning rods at the bottom of the air-cooled shell are respectively inserted into the four positioning holes on the conveying tray, and the negative pressure

fan in the air-cooled shell performs air-cooling and shaping on the molded chocolate stock solution in the lower mold shell, through The design of the four first positioning rods on the pressing plate, the four second positioning rods on the air-cooled shell, and the positioning holes on the conveying plate enables the upper platen and the cooling shell to be aligned and transported during the compression molding and

air cooling of the compression molding equipment. (3) The conveying plate is transported to the polishing rack through the conveying mechanism, the piston rods of the two first cylinders are inserted into the slots on both sides of the conveying plate, the piston rod of the fifth cylinder pushes the lifting shell downward, and the lifting shell drives a number of polishing The piece descends and touches the upper surface of the shaped chocolate, and the fourth motor is turned on. The fourth motor drives a number of polishing pieces to rotate through the cooperation of several rotating rods and several gears. The polishing pieces polish the upper surface of the chocolate, and then the third motor cooperates with the screw rod and the The rod connection block drives the moving shell to move horizontally, and then drives several polishing pieces to move horizontally through the lifting shell, and polishes the upper surface of the chocolate. In the technology, there are bumps on the surface of the chocolate molded and cooled, which cannot be removed in time, and the subsequent polishing of the chocolate by polishing equipment causes the technical problem of low chocolate production efficiency

Login to View More

Login to View More  Login to View More

Login to View More