Sensor pressure detection tool

A technology for detecting tooling and sensors, which is applied in the field of sensor detection, and can solve problems such as easy displacement, low data accuracy, and sliding displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

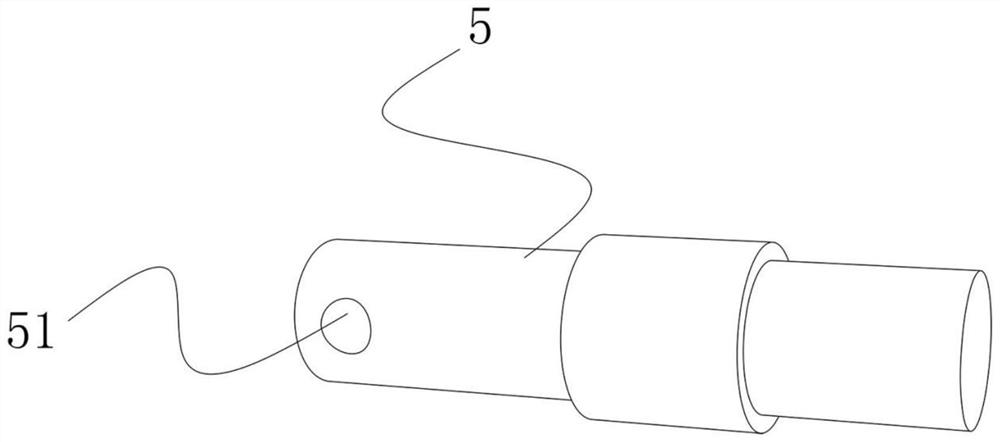

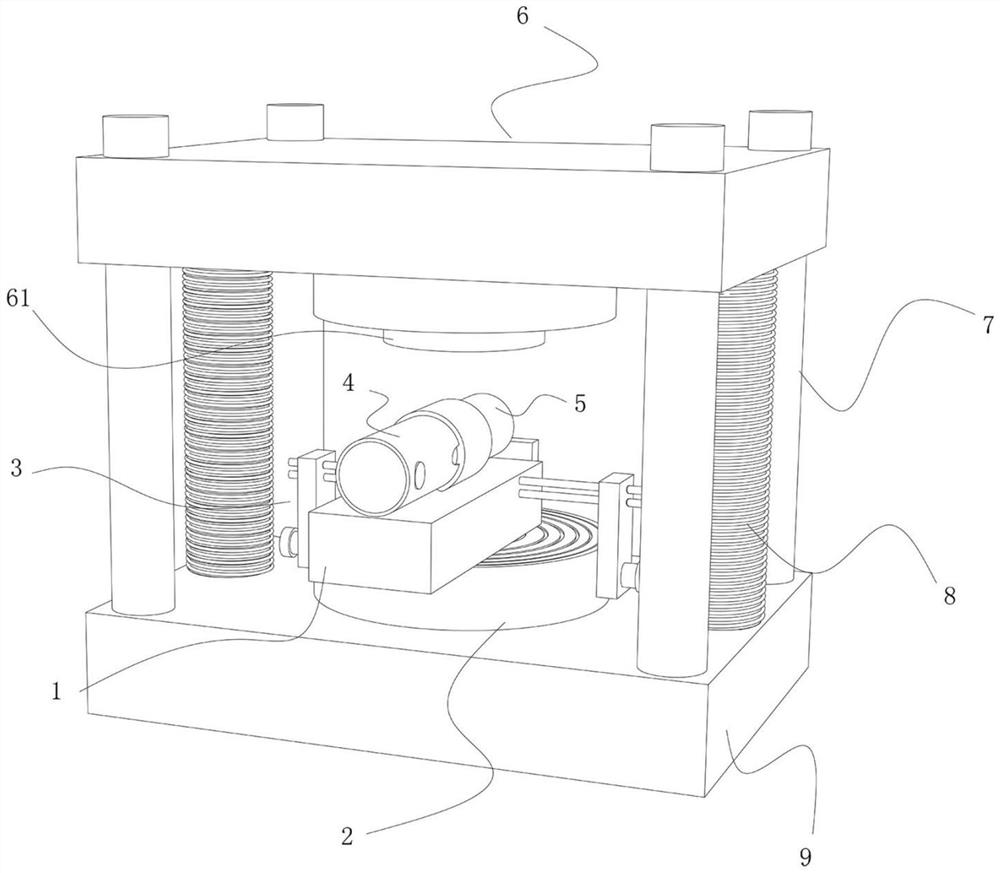

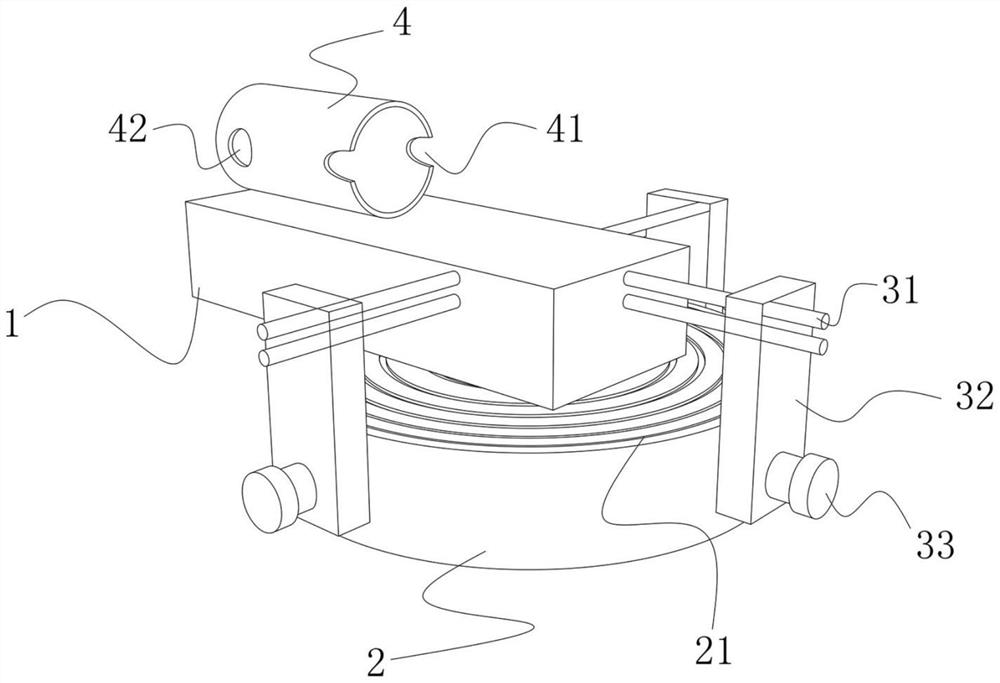

[0025] With reference to the accompanying drawings of the description of the present invention Figure 1 to Figure 5 As shown, a sensor pressure detection tooling according to a preferred embodiment of the present invention is illustrated, including a workbench 2 arranged on a machine base 9, a pressing assembly 6 and a detection assembly for loading a sensor 5, the workbench 2 Located below the top pressing assembly 6, the workbench 2 or the top pressing assembly 6 is movably arranged on the machine base 9 and can move up or down relative to the machine base 9, the detection assembly is detachably arranged on the workbench 2, the top pressing The assembly 6 includes a pressing head 61, and the pressing head 61 is located directly above the workbench 2; when in use, the workbench 2 or the pressing assembly 6 moves toward the other side, clamping the sensor 5 loaded in the detection assembly to detect the sensor The range of pressure that 5 can withstand, this technical solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com