Waterproof flame-retardant ceiling coating material fabric and attaching device thereof

A technology of a laminating device and a waterproof layer, applied in the field of fabrics, can solve the problems of inconvenient disassembly and installation, affecting construction efficiency, poor lamination effect, etc., and achieve the effect of good lamination effect, quality improvement, and improvement of lamination degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

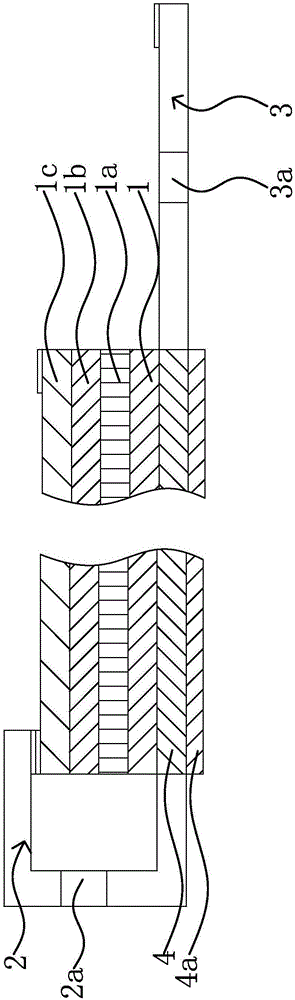

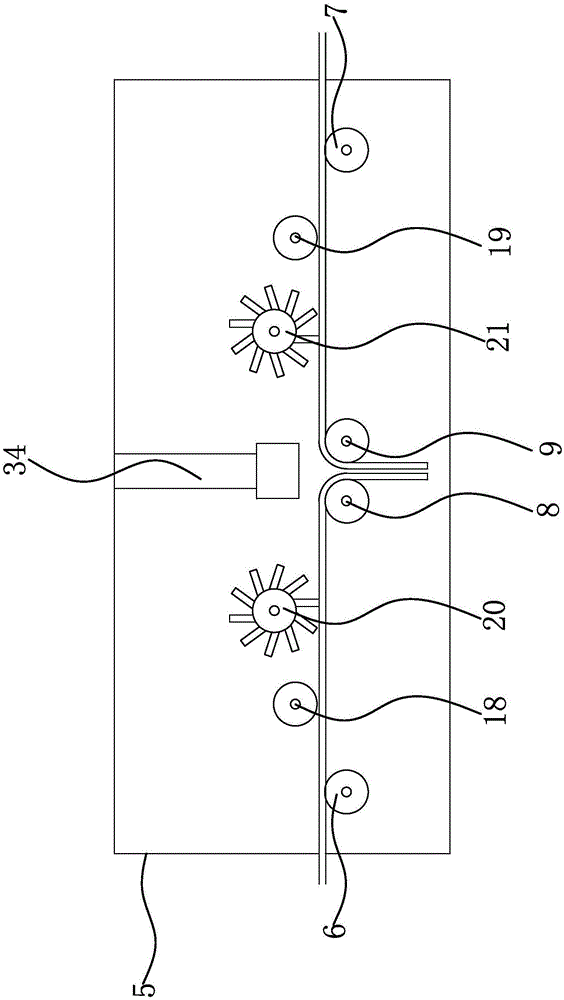

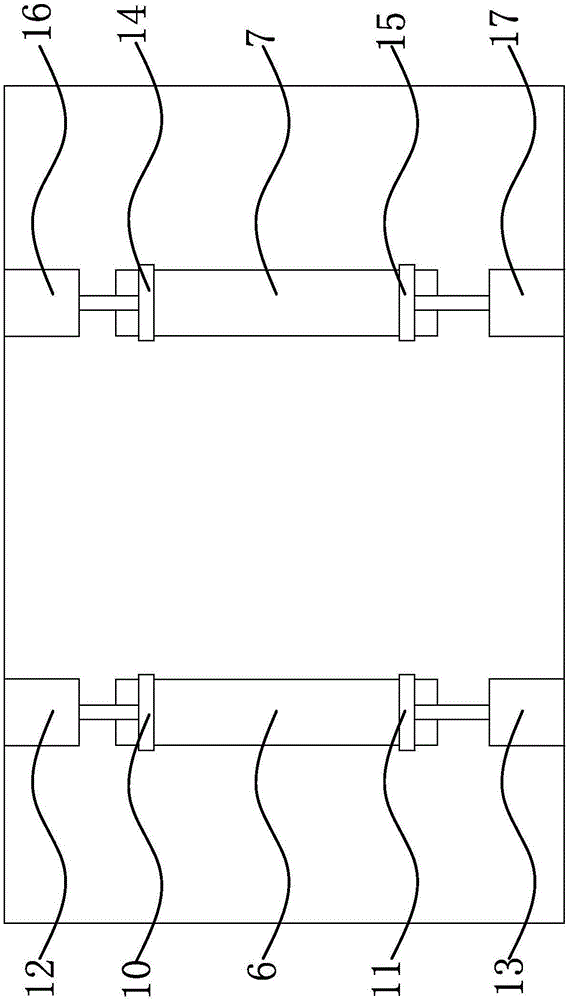

[0034] Such as figure 1 As shown, a waterproof and flame-retardant roof coating fabric includes a base fabric 1, the base fabric 1 is a non-woven fabric, and the front of the base fabric 1 is sequentially provided with a flame-retardant layer 1a, a corrosion-resistant layer 1b, a waterproof Layer 1c, on the reverse side of the base cloth 1, a side cloth 4 is pasted by a bonding device, the face cloth 4 is provided with a scratch-resistant layer 4a, and the side edge of the face cloth 4 is provided with a cloth strip-2, and one side of the cloth strip-2 It is fixed with the edge of one side of the base cloth 1, the other side of the cloth strip 2 is fixed with a Velcro male sticker 1, and the side edge of the waterproof lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com