A metallized film capacitor winding machine

A technology of metallized film and capacitors, applied in the direction of winding capacitor machines, capacitors, capacitor manufacturing, etc., can solve the problems of reducing the speed of product production, complex winding structure, and many processes, so as to improve the use efficiency and reduce the workload. , the effect of simple scroll structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

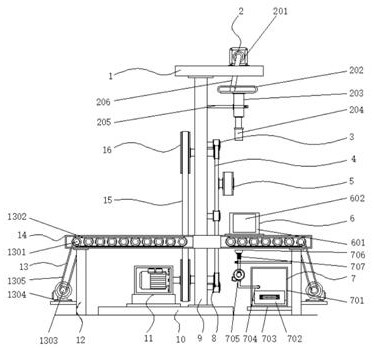

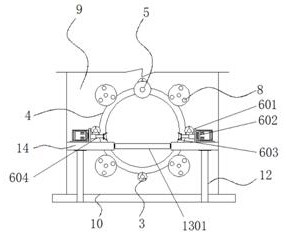

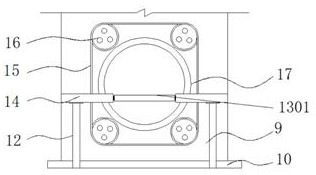

[0035] Example 1: See Figure 1-6 One metal thin film capacitor winding machine, including the bottom plate 10, one side of the top end of the bottom plate 10 fixedly connected to the vertical plate 9, the top end of the vertical panel 9 fixedly connected to the top plate 1, the top end of the top plate 1 is provided with a cutting mechanism 2, vertical On both sides of the plate 9 fixed to the table 14, the inner portion of the table 14 is provided with a conveying mechanism 13, and the two sides of the bottom end of the table 14 are fixedly connected to the leg 12, and the dust removal mechanism 7 is provided on one side of the bottom end of the table 14. On one side of the top end of the stage 14, a clamping limit mechanism 6 is provided, and the inner fixed connection between the vertical plate 9 is fixedly connected to the through hole 17, and the winding mechanism is provided on both sides of the through hole 17;

[0036] See Figure 1-6 One metal-based thin film capacitor win...

Embodiment 2

[0039] Example 2: The cutting mechanism 2 is composed of a first servo motor 201, a limiting block 202, a hydraulic telescoping rod 203, a cutting blade 204, a limit frame 205, and a restricted rod 206, and the first servo motor 201 fixedly connected to the top plate 1. On one side of the top, the model number of the first servo motor 201 can be an ACM. The output terminal of the first servo motor 201 is fixed to the top end of the shaft and the limit rod 206, and the bottom end activity of the limit rod 206 is in The interior of the limiting block 202, the limiting block 202 is disposed below the top plate 1, and the bottom end of the limit sleeve 202 is fixedly connected to the hydraulic telescopic rod 203, the model number of the hydraulic telescopic rod 203 can be SC200, hydraulic telescopic rod. The external portion of 203 is provided with a finite frame 205, and one side of the limit frame 205 is fixedly attached to one side of the tip end of the vertical plate 9, and the bo...

Embodiment 3

[0042] Example 3: The clamping limit mechanism 6 consists of a support seat 601, a hydraulic cylinder 602, a clamping block 603, and a retractable sleeve 604, and the support seat 601 is provided with two groups and two respectively coupled to two on the top of the table 14. At one end, one end of the support seat 601 is fixedly connected to the hydraulic cylinder 602, the model number of the hydraulic cylinder 602 can be SC, and the output terminal of the hydraulic cylinder 602 is fixed to the telescopic sleeve 604, and one end of the telescopic sleeve rod 604 is fixedly connected to the clamp block. 603, the clamping block 603 is semi-circular, and the clip block 603 regards the vertical centerline symmetry distribution of the vertical plate 9;

[0043] Specifically, such as figure 1 and figure 2 As shown, after the item is delivered to the specified position, the staff places a piece of article between the clamping block 603, activates the hydraulic cylinder 602, and the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com