Auxiliary supporting and mounting mechanism for tempered glass

A technology of auxiliary support and installation mechanism, applied in the direction of connecting components, building components, mechanical equipment, etc., can solve problems such as safety accidents, targeted adjustment, and inability to adjust installation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

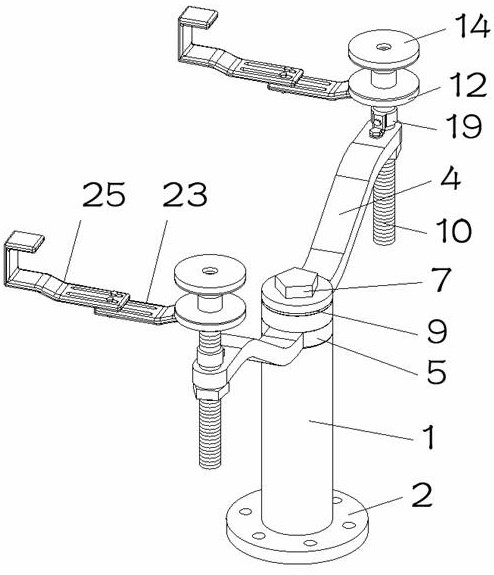

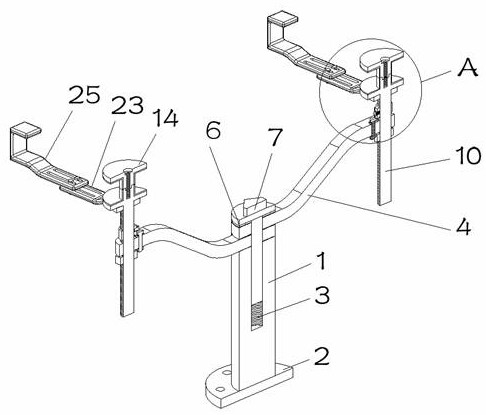

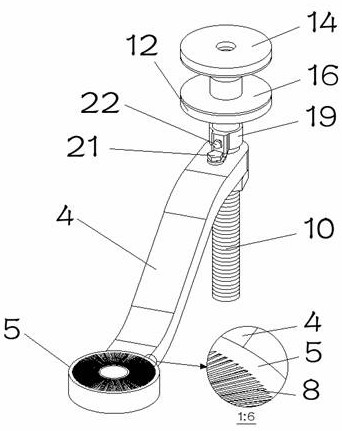

[0046] see Figure 1-7, a technical solution is provided in this solution: an auxiliary supporting installation mechanism for tempered glass, including: base column 1, fixing plate 2, locking hole 3, support arm rod 4, connecting sleeve plate 5, locking rod 6, operating convex Lifting 7, limit protrusion 8, limit clamp 9, support rod 10, limit nut 11, top platform 12, first connection hole 13, gland 14, insert rod 15, bottom gasket 16, top gasket 17, Second connection hole 18, limit sleeve 19, fixing hole 191, locking hole 192, installation hole 20, first fastening bolt 21, limit screw rod 22, extension plate 23, installation sleeve plate 24, pull plate 25, The strip groove 26 and the second fastening bolt 27 are used at the side positions where the two pieces of glass are in contact with each other. When in use, as figure 1 with image 3 In the middle, the support arm rod 4 is stacked correspondingly between the connecting sleeve plate 5 and the top of the base column 1, so...

Embodiment 2

[0052] see Figure 3-9 , a technical solution is provided in this solution: an auxiliary supporting installation mechanism for tempered glass, including: base column 1, fixing plate 2, locking hole 3, support arm rod 4, connecting sleeve plate 5, locking rod 6, operating convex Lifting 7, limit protrusion 8, limit clamp 9, support rod 10, limit nut 11, top platform 12, first connection hole 13, gland 14, insert rod 15, bottom gasket 16, top gasket 17, The second connection hole 18, the spacer sleeve 19, the fixing hole 191, the locking hole 192, the mounting hole 20, the first fastening bolt 21 and the spacer screw 22 are used in the middle position where the four pieces of glass are in contact with each other. When in use, as in the above-mentioned embodiment 1, the support arm rod 4 and the support rod 10 are adjusted and installed correspondingly, as in the above-mentioned embodiment 1, the top platform 12, the gland 14 and the limit sleeve 19 are correspondingly fixed, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com