Patents

Literature

37results about How to "Improve slippage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

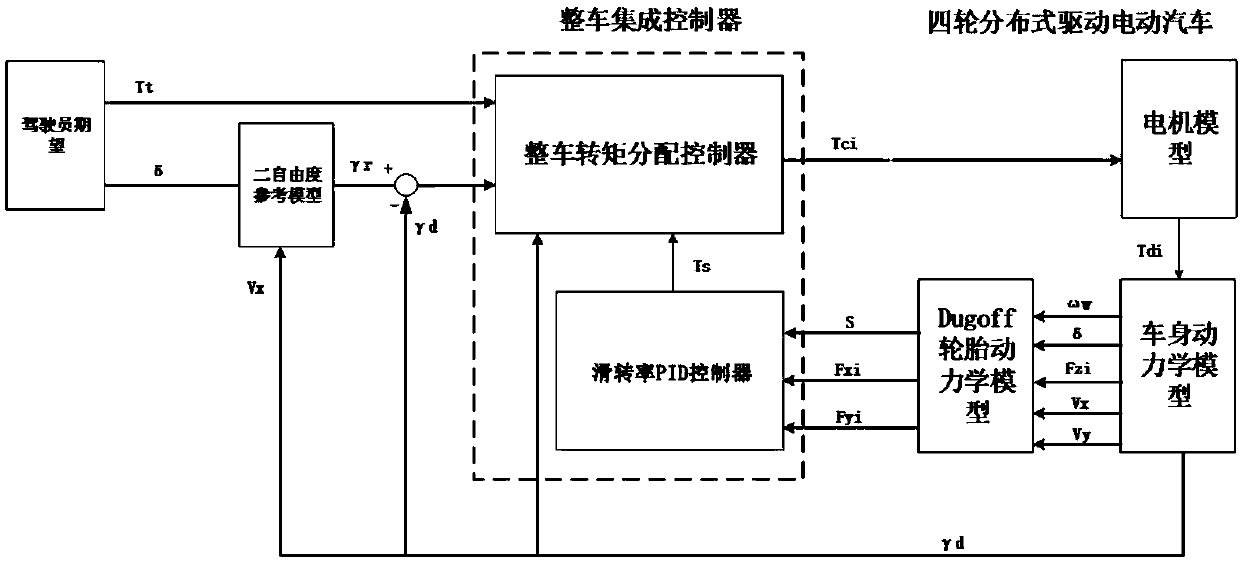

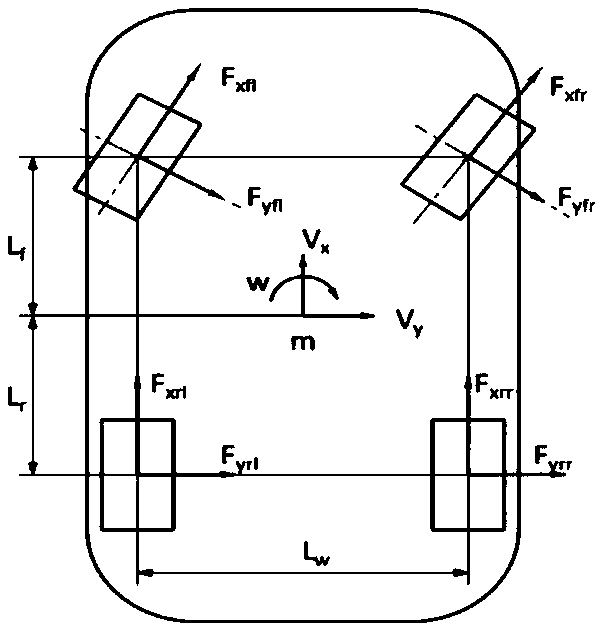

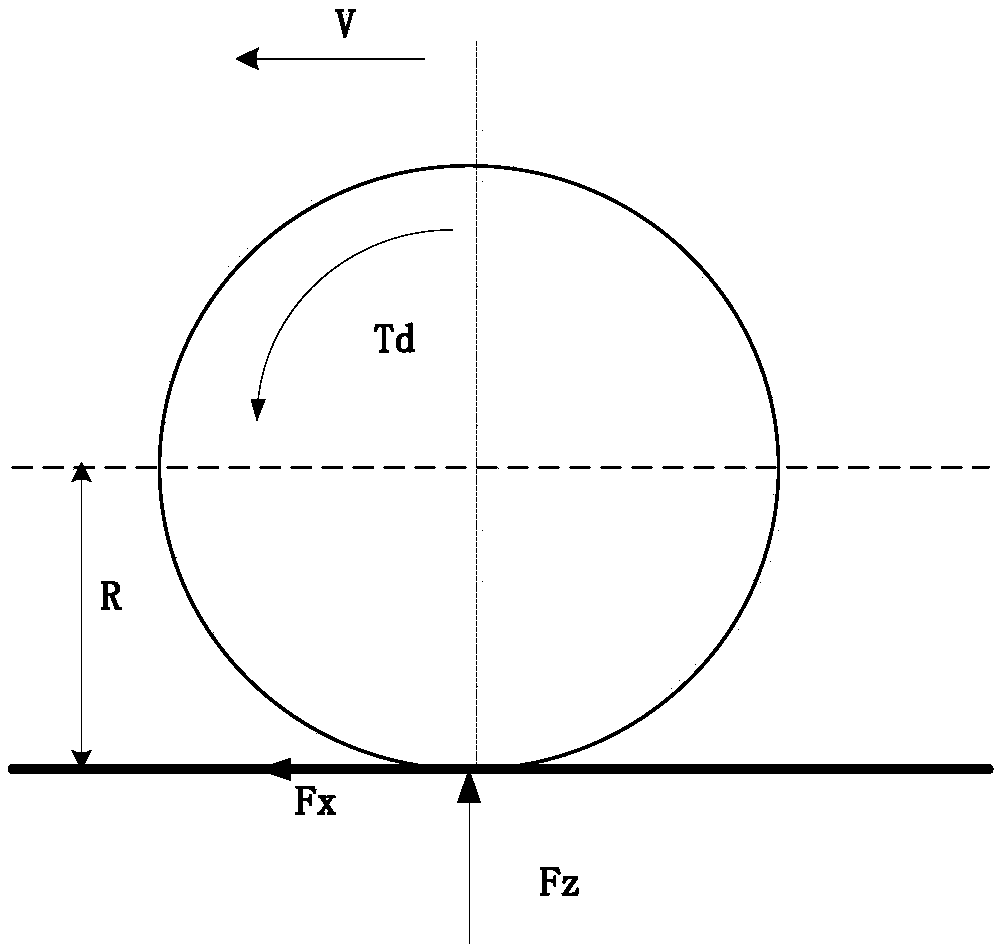

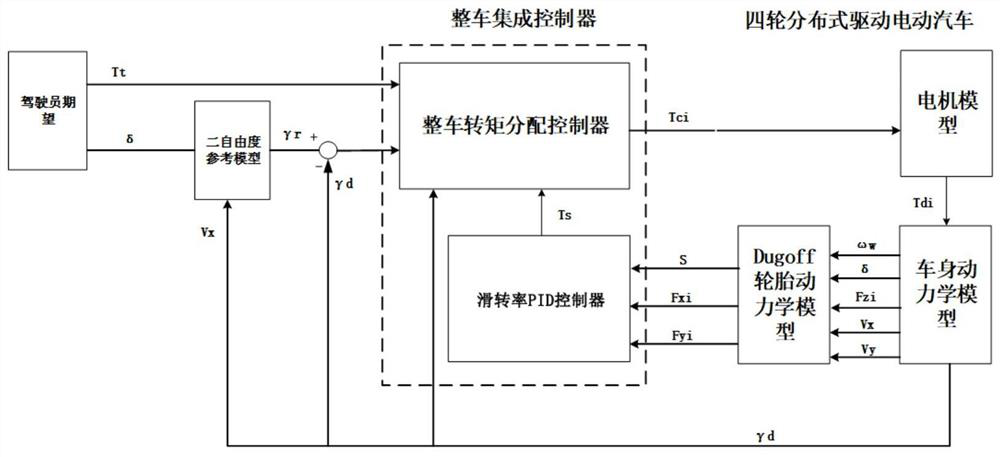

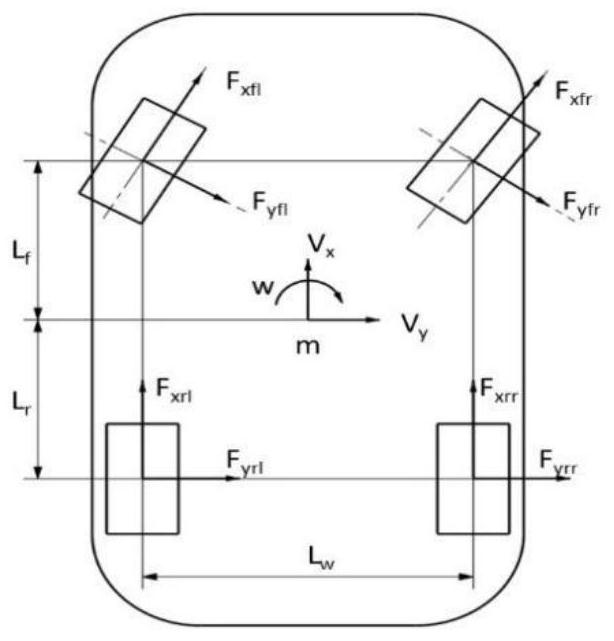

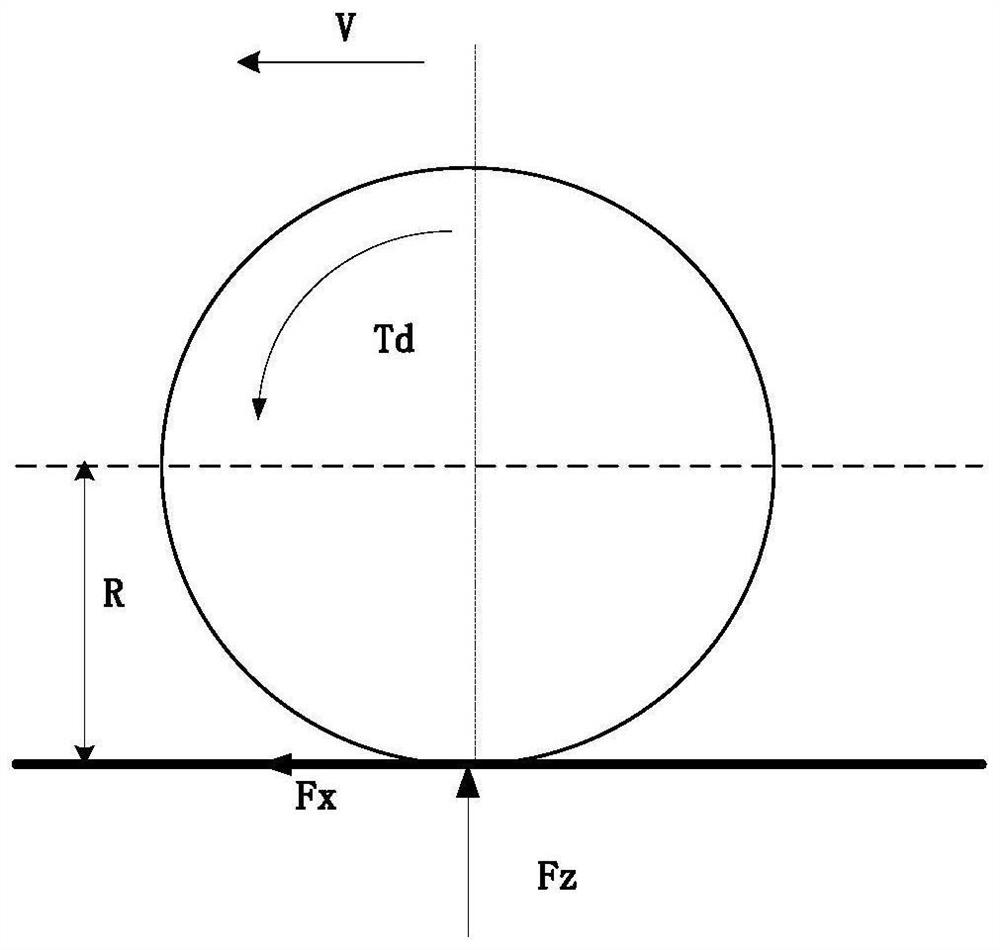

Distributed driving electric automobile torque vector control method based on double-layer control

ActiveCN109606133AImprove driving stabilityEasy rideSpeed controllerElectric energy managementVehicle dynamicsDrive wheel

The invention discloses a distributed driving electric automobile torque vector control method based on double-layer control. The control method comprises the following steps: establishing a vehicle dynamic model, and calculating a tire slip rate by utilizing a Dugoff tire model; establishing a torque distribution controller based on the vehicle dynamic model and the Dugoff tire model, wherein thetorque distribution controller comprises an upper controller and a lower controller; calculating the current drive torque of each driving wheel of the vehicle by the upper controller according to body yawing angular velocity; calculating a compensating torque needed for remaining an ideal slip rate of each driving wheel by the lower controller according to the ideal slip rate of each driving wheel serving as a control objective, and further performing compensation distribution on the driving torque, so that an actual torque is output to the driving wheel, and torque vector control is completed. According to the control method disclosed by the invention, the automobile torque can be effectively subjected to vector distribution, the vehicle driving stability and smoothness are improved, theoperating burden of the driver is obviously decreased, and the driving safety is improved.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

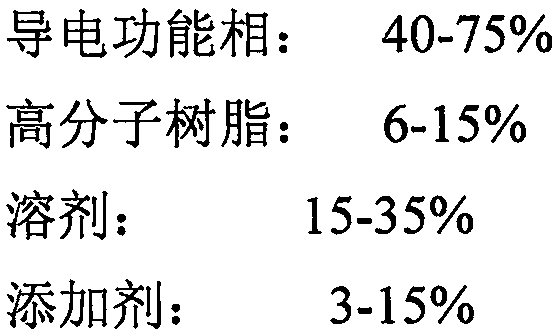

Special ultralow temperature cured laser etching conductive silver paste for mobile phone touch screen

ActiveCN108022669AAchieve solidificationStable storageNon-conductive material with dispersed conductive materialMetal/alloy conductorsSilver pasteLaser etching

The invention relates to a special ultralow temperature cured laser etching conductive silver paste for a mobile phone touch screen. The conductive silver paste mainly comprises the following components: 40%-75% of a conductive function phase, 6-15% of macromolecule resin, 15-35% of a solvent and 3-15% of an additive. The preparation of the silver paste comprises the steps of macromolecule regioncarrier preparation, conductive silver paste preparation and conductive silver paste post-processing. The conductive silver paste can be completely cured under the condition of an ultralow temperatureof 80-110 DEG C, the temperature is reduced by 20-50 DEG C compared with a curing condition of 130 DEG C of the existing conductive silver paste, and shrinkage, folding and deformation of a substratemembrane material during high-temperature curing are reduced. The paste has excellent laser etching performance, and a clear pattern with the line width / line spacing being 30 microns / 30 microns can be etched; the paste has good adhesion on PET, an ITO film, a silver nanowire conductive film, TIO glass and ordinary glass, the pencil hardness is above 2H, and the square resistance can reach up to 20m[Omega] / square@1mil. In addition, the conductive silver paste is sintered and molded at an ultralow temperature, low in production cost, energy-saving and free of halogen, thereby being an environment-friendly product.

Owner:NANO TOP ELECTRONICS TECH

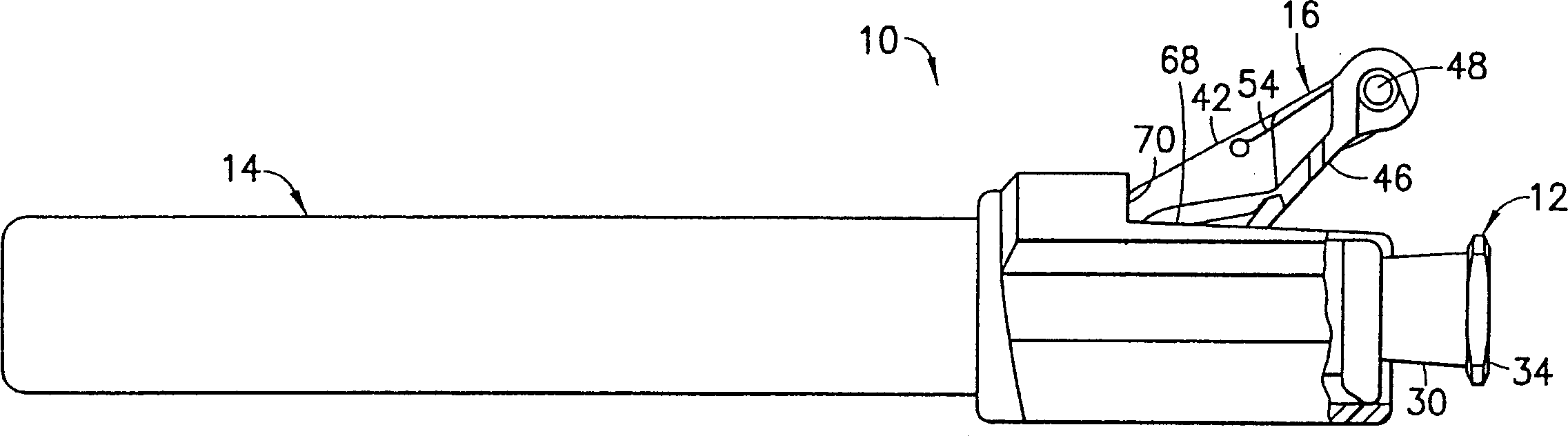

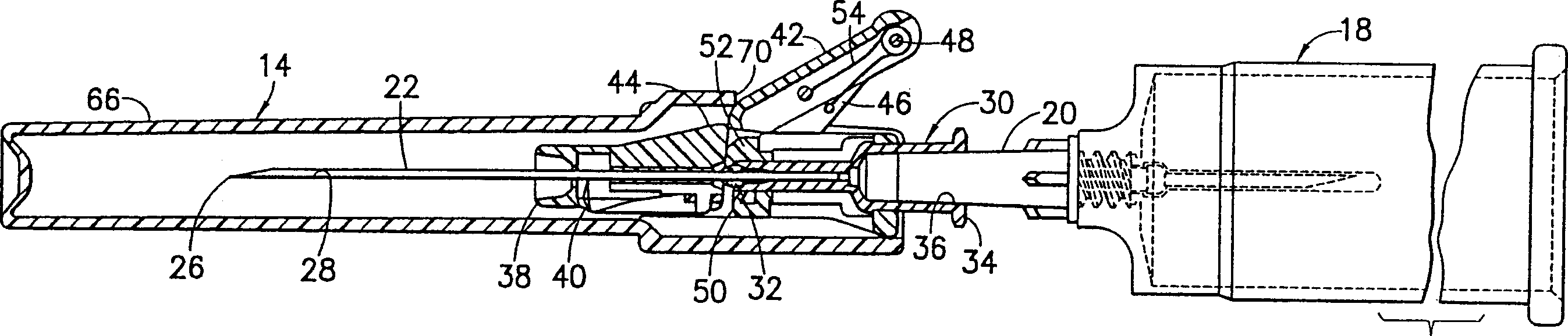

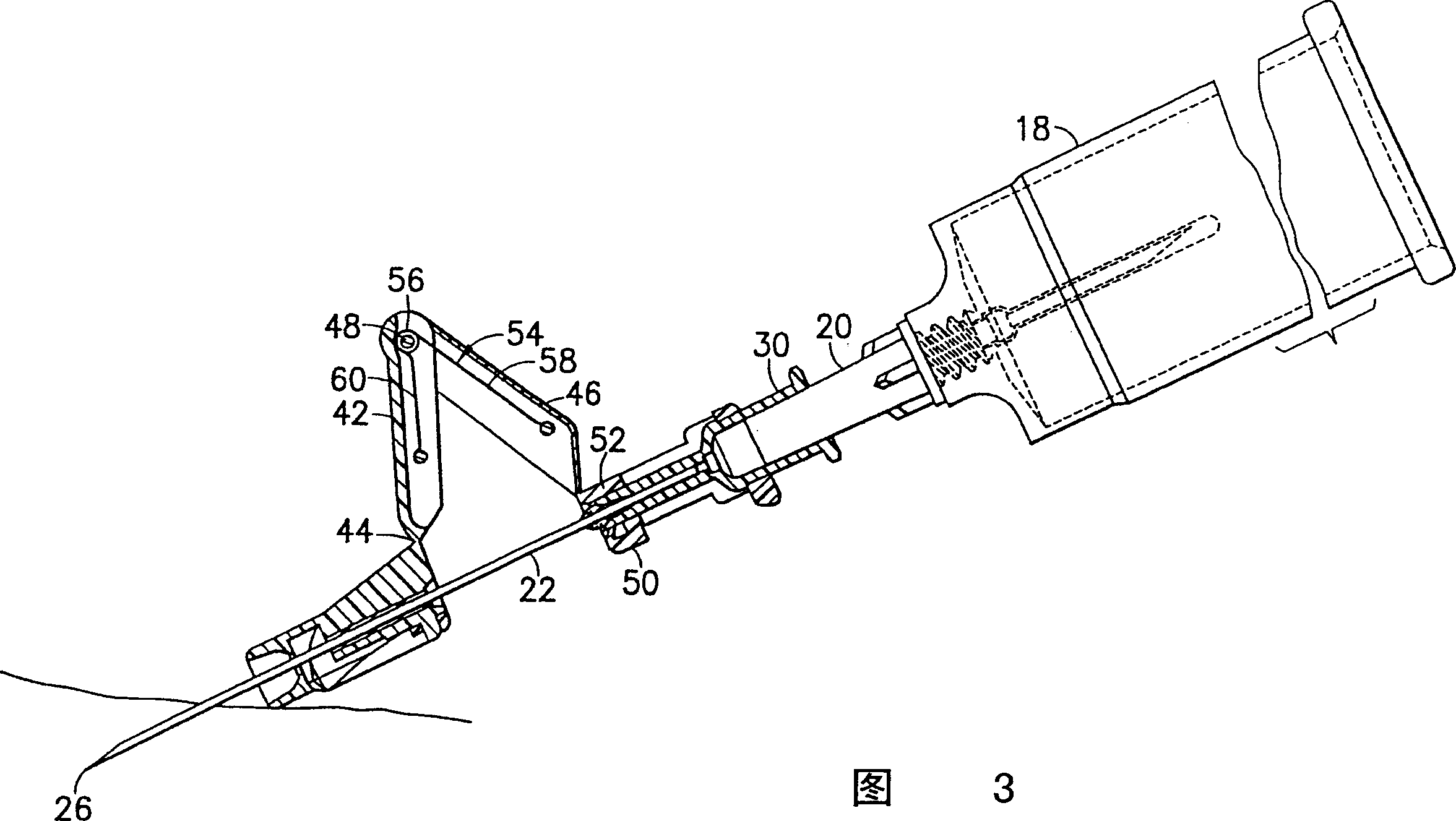

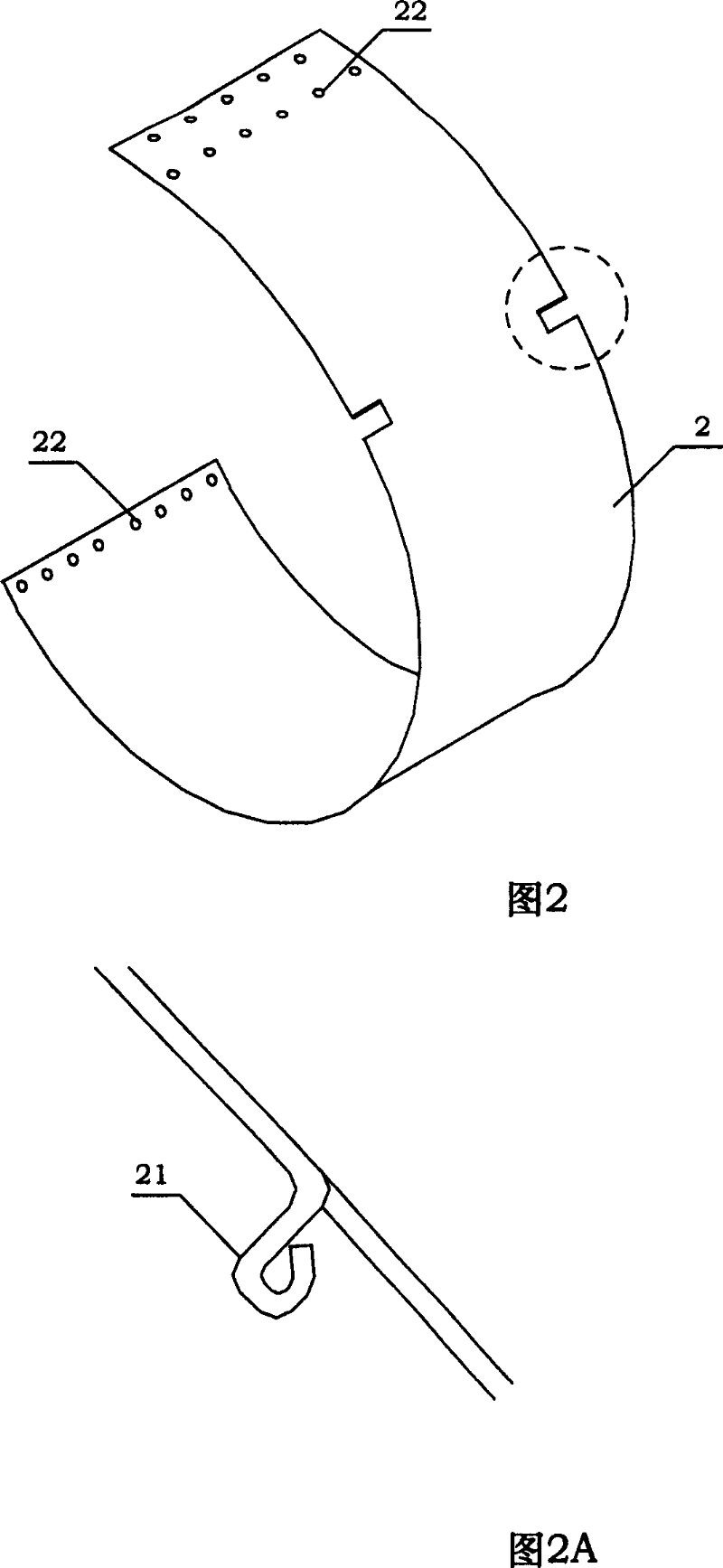

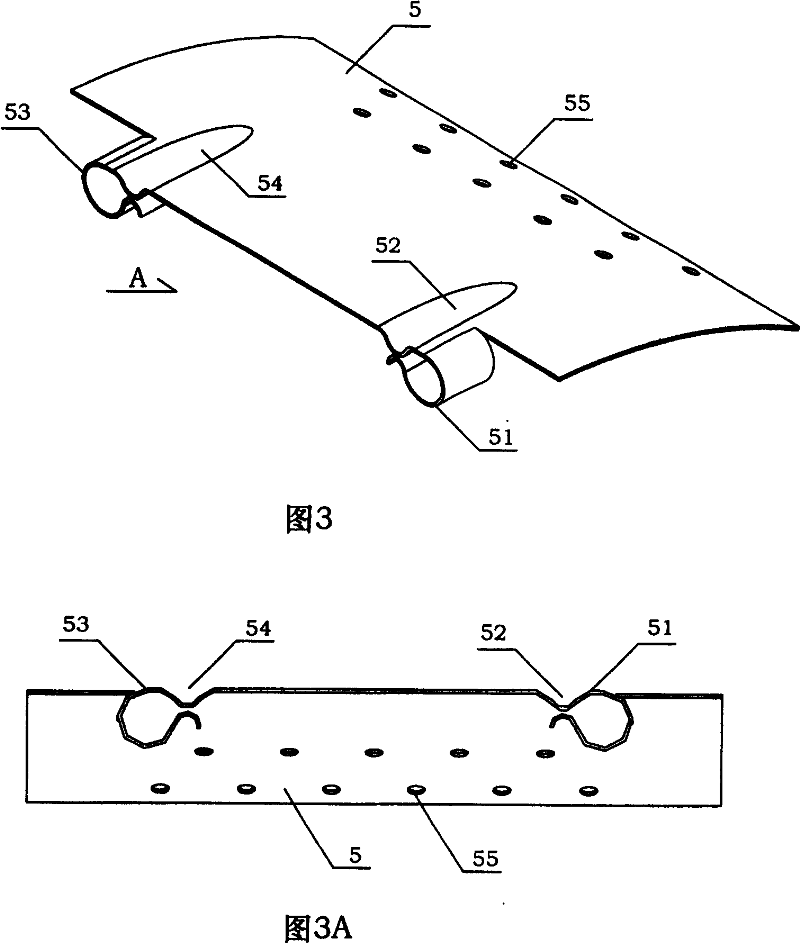

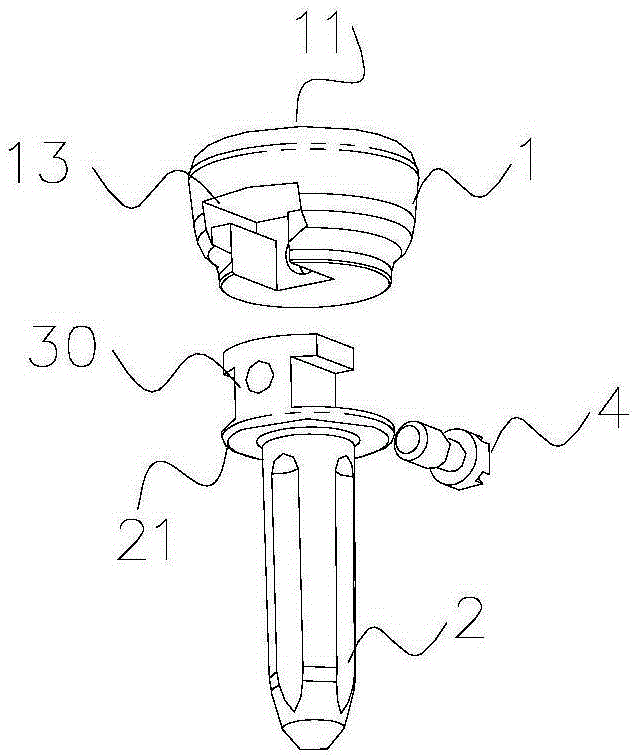

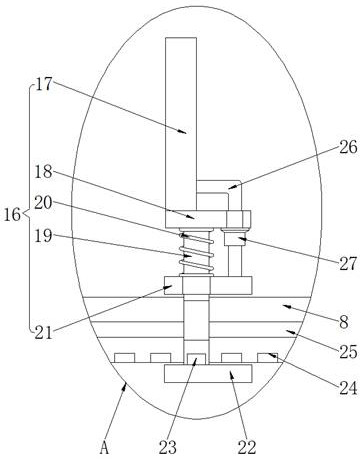

Passively-driven safe needle

InactiveCN1383899AImprove slippagePrevent Accidental Needle SticksSurgeryCatheterBiomedical engineeringSafety needles

A passively driven safety needle assembly includes a needle assembly, a shielding assembly and a safety cap. The needle assembly includes a socket and a needle tube protruding from the socket. The shield assembly includes a safety sheath installed to slide along the needle tube. The shield assembly also includes a plurality of arms that are hinged to each other to allow the safety sheath to slide along the needle tube from a proximal position to a distal position shielding the tip of the needle tube. A spring is secured to the shield assembly and uses it to drive the safety sheath from its proximal position to its distal position. The safety helmet mounts over the shield assembly and retains the shield assembly in the proximal position. Hold the arm during use of the safety needle. Upon releasing the arm, the spring automatically drives the sheath distally without any user actuation.

Owner:BECTON DICKINSON & CO

New energy automobile driving method

PendingCN111645533AImprove slippageImprove acceleration performanceSpeed controllerElectric energy managementAuto regulationDriver/operator

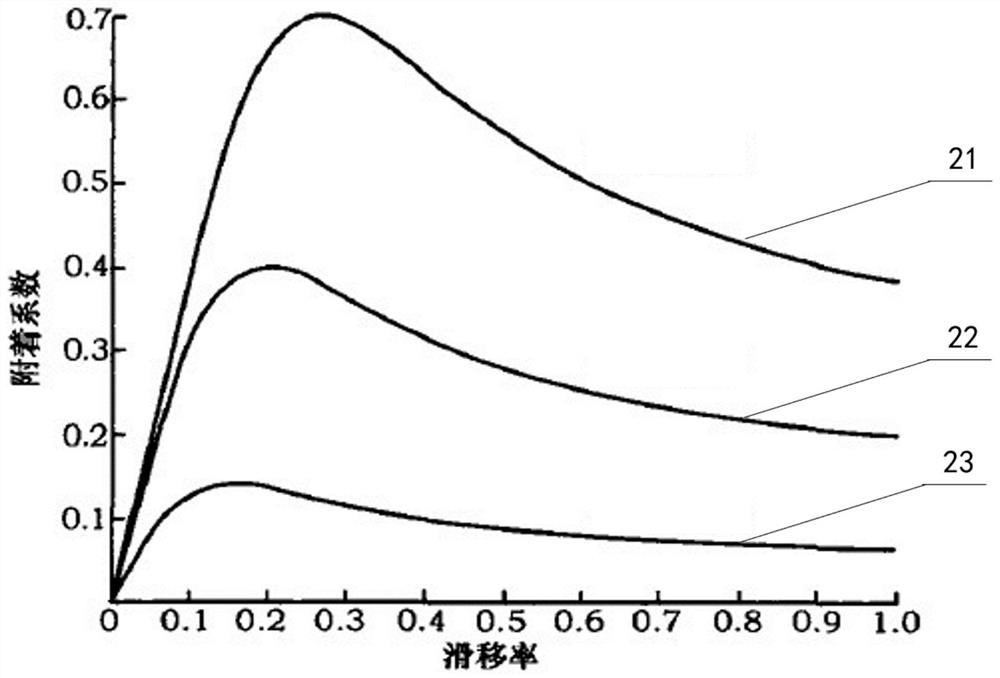

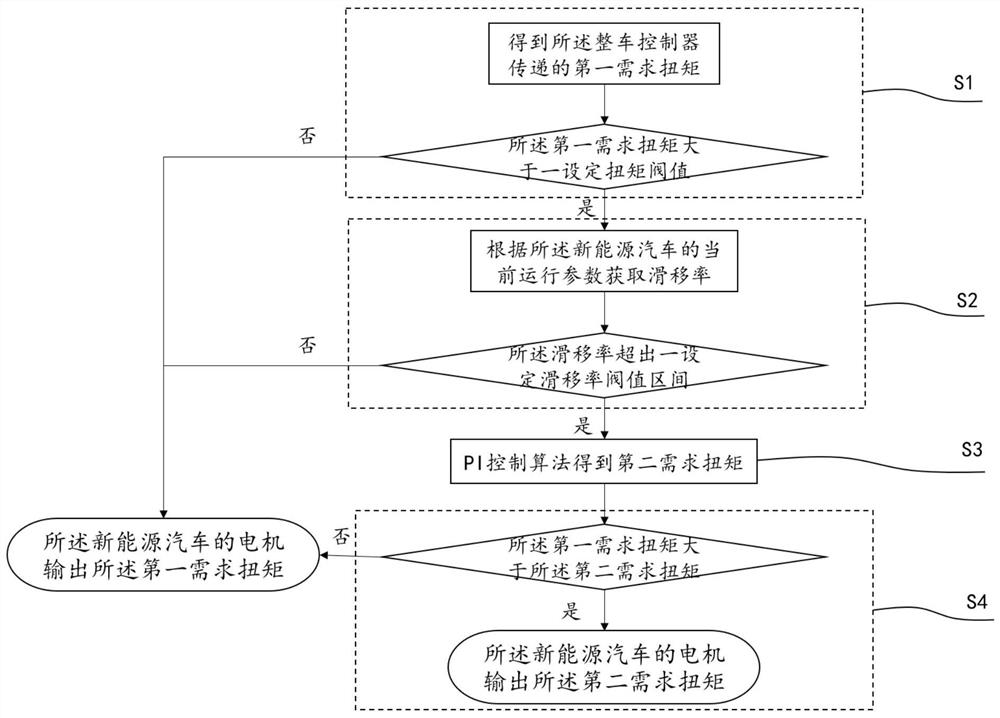

The invention provides a new energy automobile driving method. A mode of adjusting motor driving torque is adopted, after the slip rate exceeds an optimal slip rate control interval, a classic PI control mode is adopted, the slip rate is made to return to the optimal slip rate control range, and when the slip rate is located in the optimal interval, the required torque of a whole automobile, namely an accelerator pedal of a driver, is directly output. The real-time, continuous and automatic adjustment of the slip rate is realized; compared with a traditional ESP (Electronic Stability Program)system, under the condition that the hardware cost is not increased, starting and driving torque output of the whole automobile on a wet and slippery road surface can be improved, the adjusting precision is improved, abrasion of a brake pad is reduced, and automobile torque fluctuation and automobile body shaking caused when the driving anti-skid function plays a role are further avoided.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

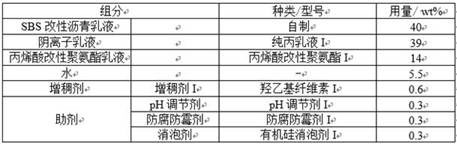

Facade anti-skid waterproof coating composition and application thereof, coating and preparation method and application thereof

ActiveCN114196325AHigh peel strengthIncreased shear strengthConjugated diene hydrocarbon coatingsPolyurea/polyurethane coatingsPolymer scienceUltimate tensile strength

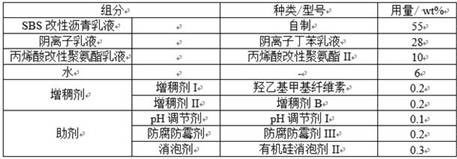

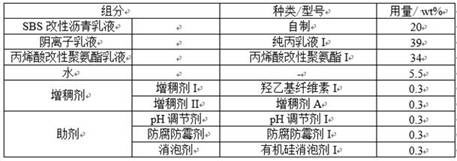

The invention relates to the field of coatings, and discloses a facade anti-skid waterproof coating composition and application thereof, and a coating and a preparation method and application thereof. The coating composition contains the following components which are stored independently or stored in a mixed manner: 40-65 wt% of an SBS modified asphalt emulsion, 20-40 wt% of an anionic emulsion, 8-16 wt% of an acrylic acid modified polyurethane emulsion, 3-8 wt% of water, 0.3-0.8 wt% of a thickening agent and 0.3-1.0 wt% of an auxiliary agent, wherein the thickening agent is composed of a thickening agent I and a thickening agent II in a weight ratio of (1-5): 1. The coating composition provided by the invention has the advantages of water-based environmental protection, sagging resistance of a vertical surface, high bonding strength with a base surface, high stripping and shearing strength when compounded with an asphalt coiled material, and the like.

Owner:KESHUN WATERPROOF TECH CO LTD

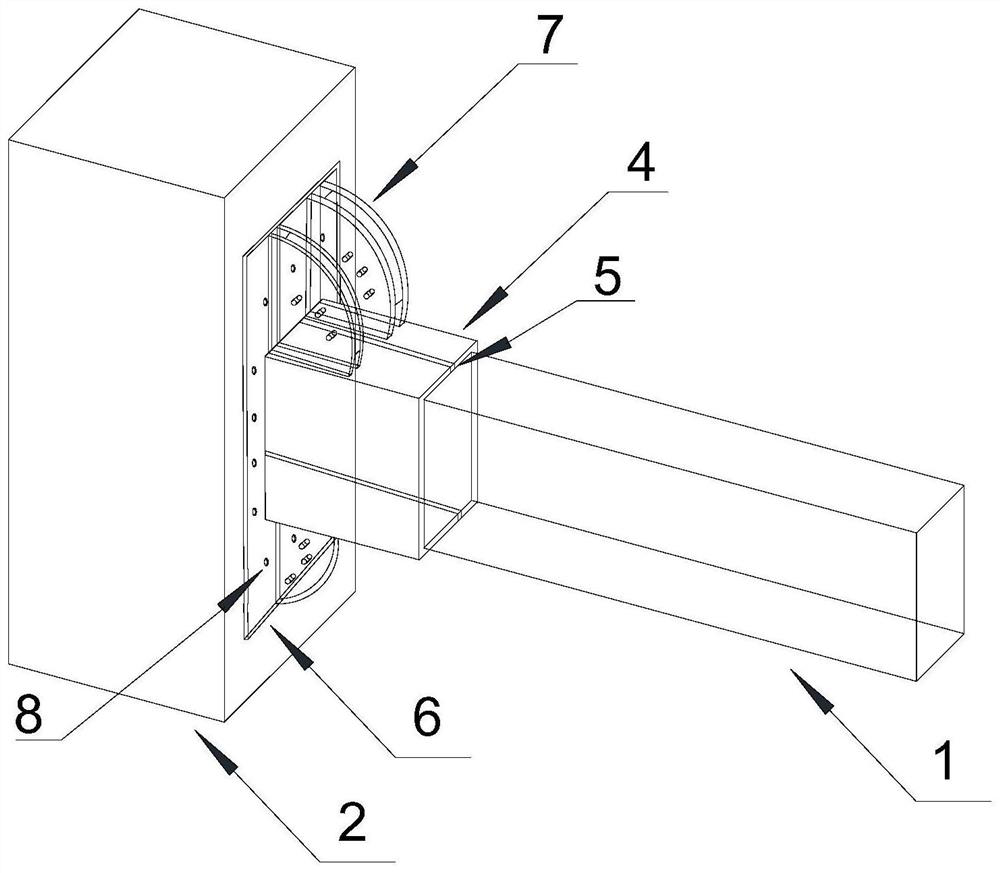

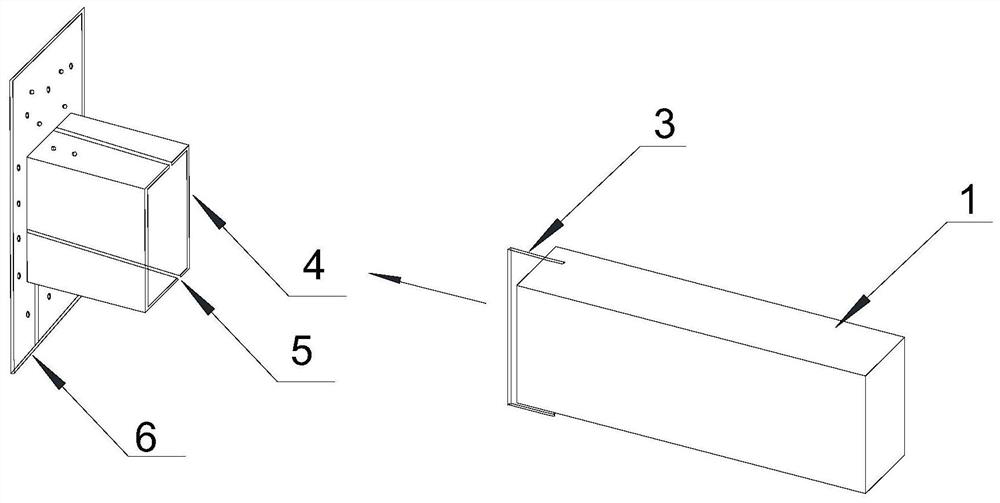

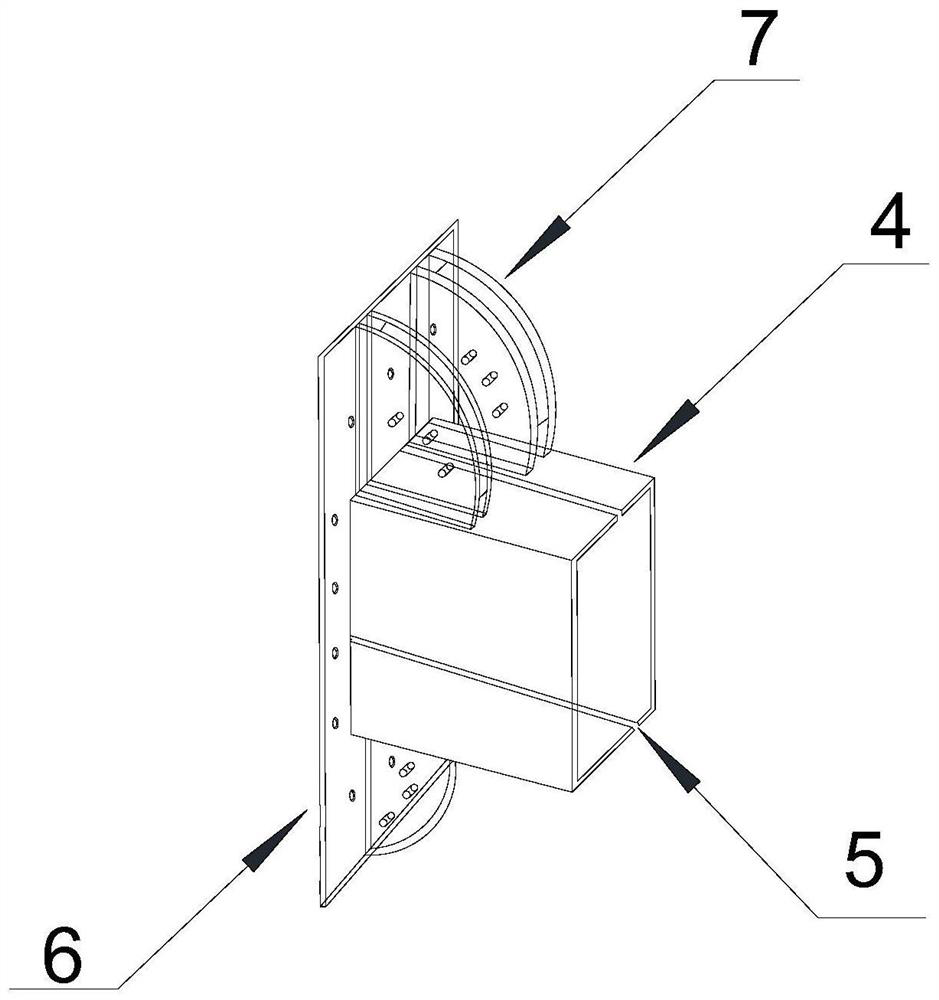

Prefabricated reinforced concrete beam-column edge joints

ActiveCN111719692BEasy to assembleHigh degree of industrializationBuilding constructionsReinforced concrete columnArchitectural engineering

Owner:YANGZHOU UNIV

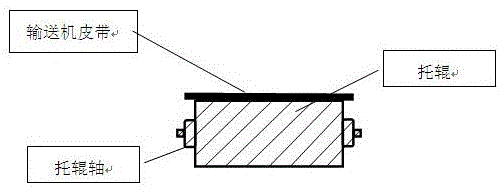

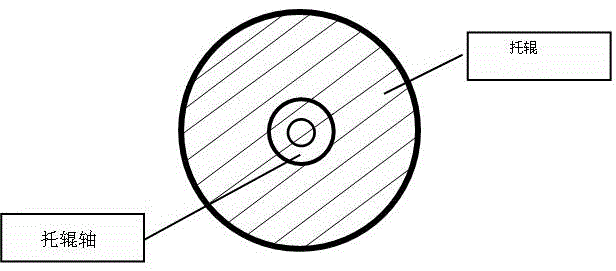

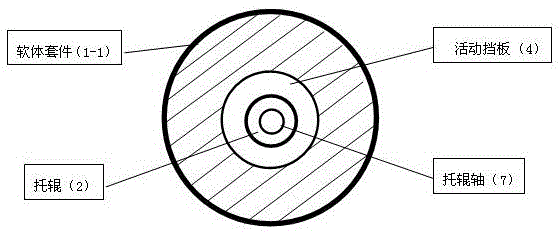

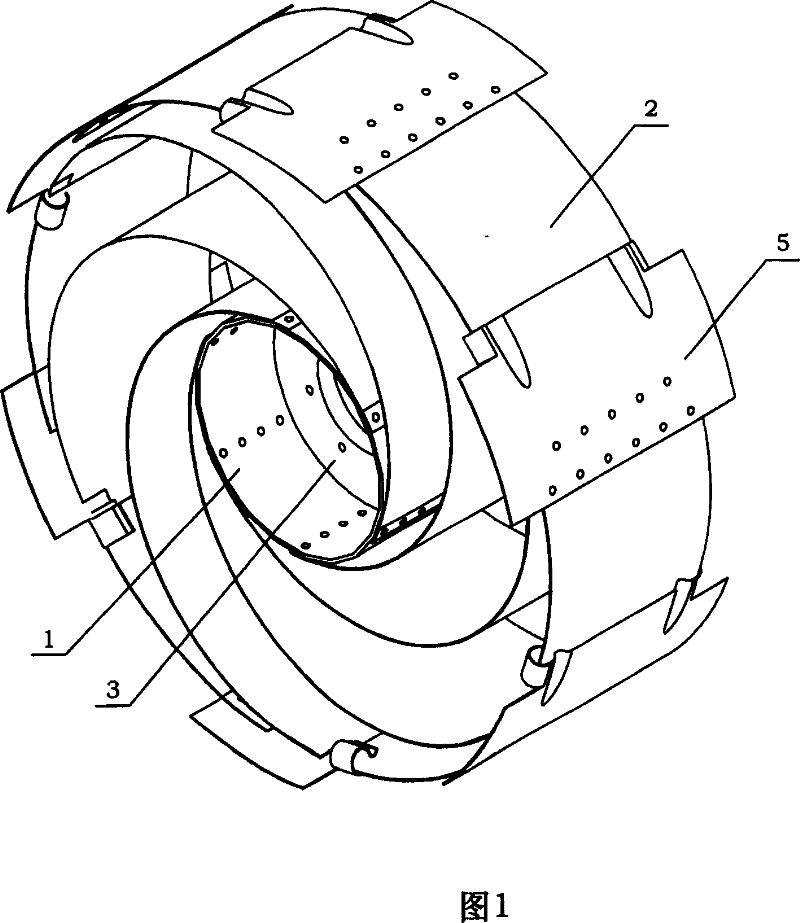

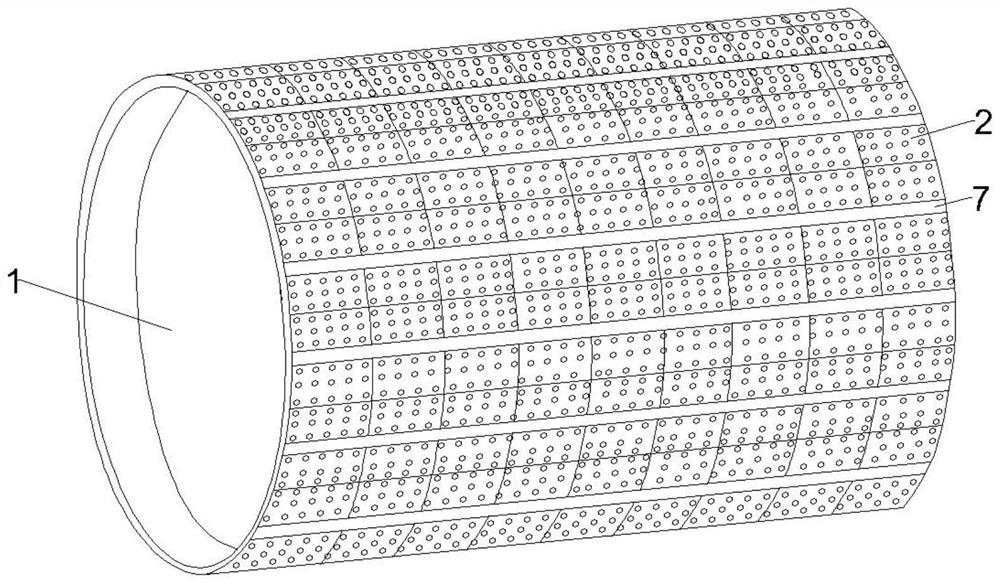

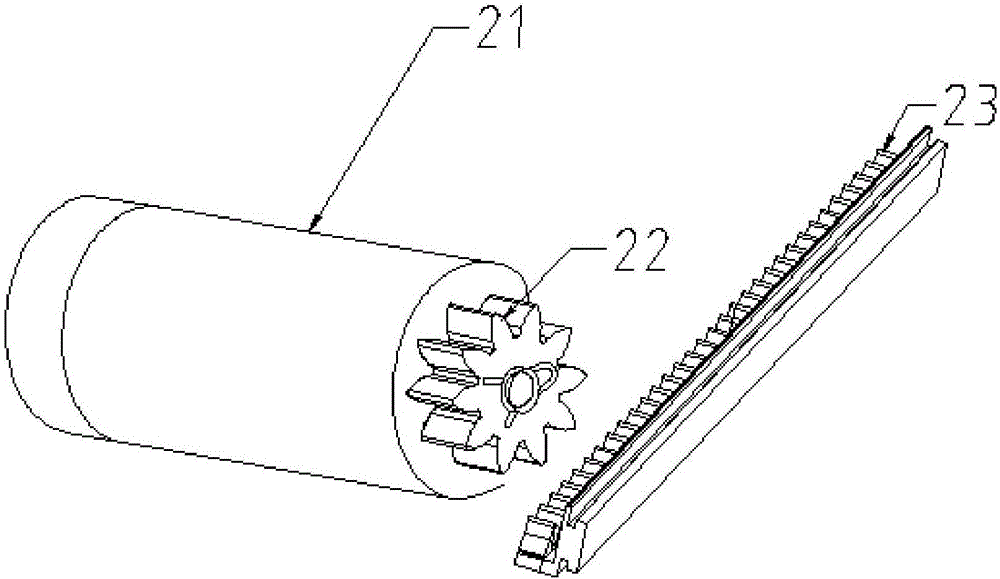

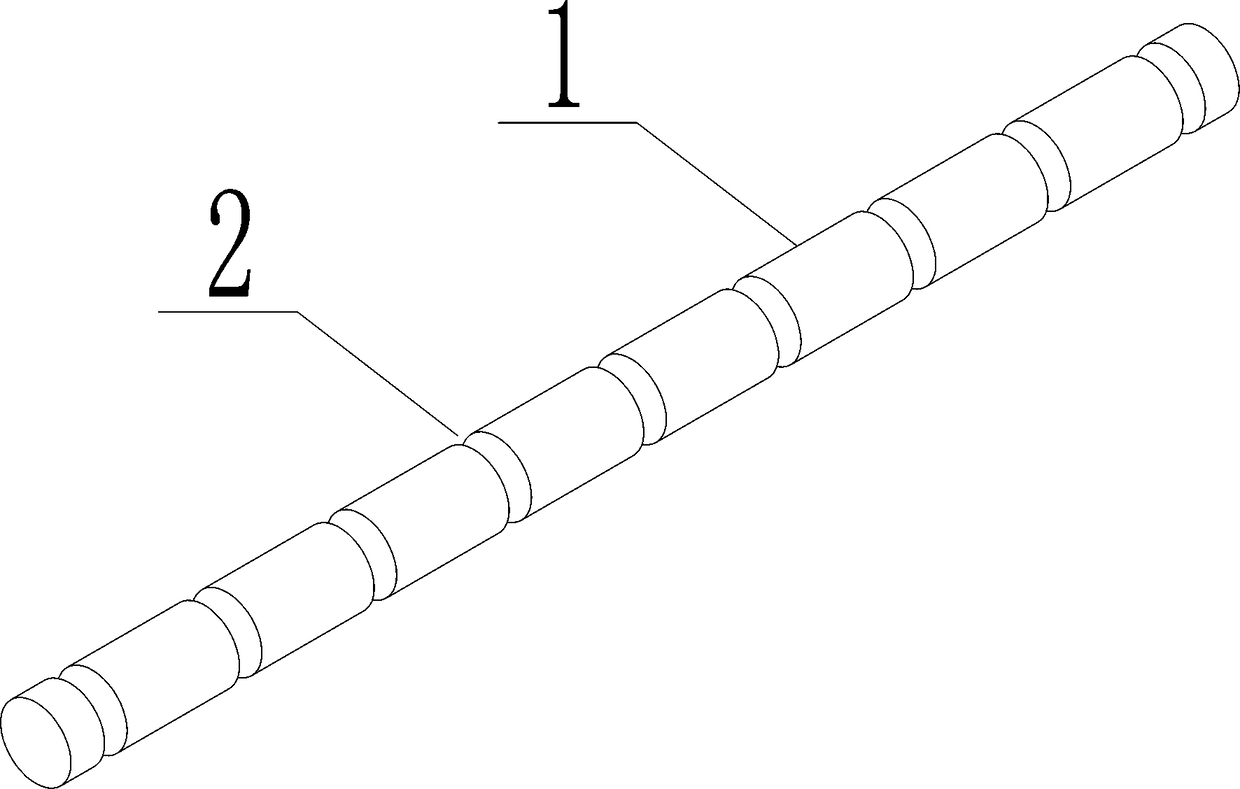

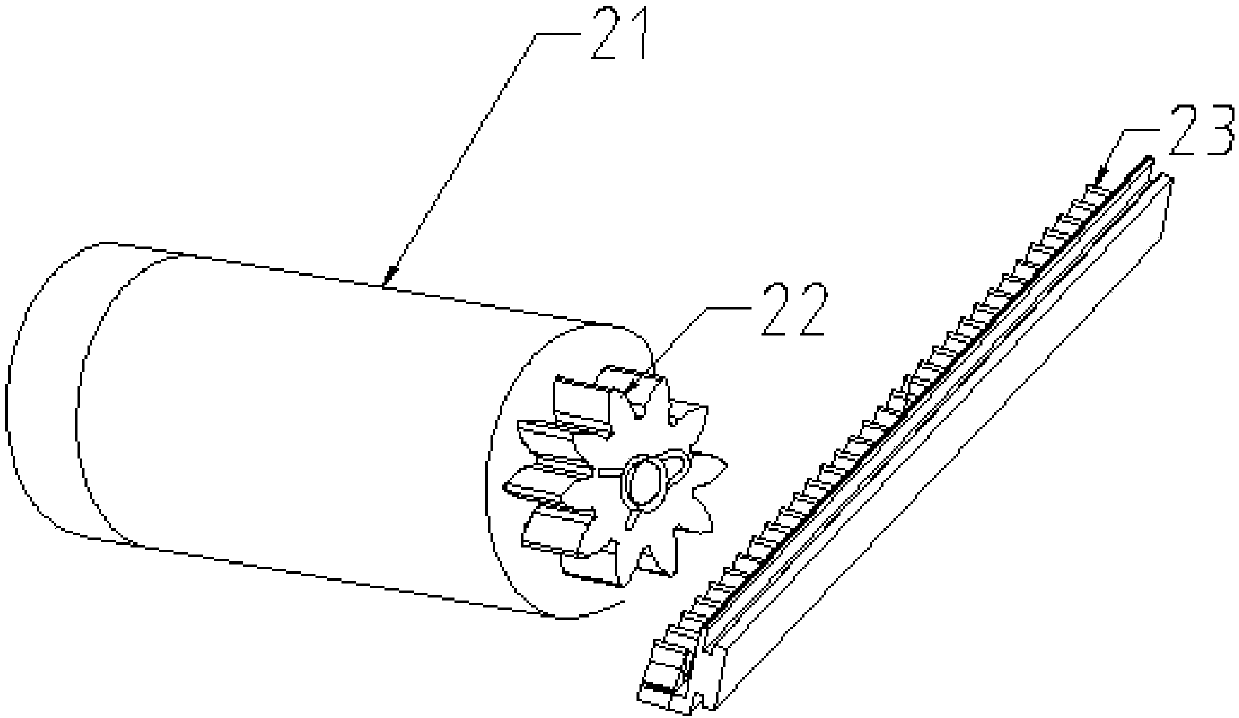

Novel radian-controllable carrier roller

The invention discloses a novel radian-controllable carrier roller used on a belt conveyor for conveying bulk materials. The novel radian-controllable carrier roller is composed of a carrier roller with an embossed surface, flexible wear-resistant sleeving elements capable of sleeving the carrier roller and easy to assemble and detach, and detachable movable baffles and fastening staple bolts which are arranged at the two ends of the carrier roller. According to the invention, the phenomenon that the bulk materials are liable to fall off from a belt, and the potential safety hazards generated due to that a metal steel wire in the belt is exposed and forms friction with the carrier roller after the belt is broken, are solved; the roller diameter of the carrier roller is effectively reduced; the production and maintenance costs are saved; the service lives of the carrier roller and the belt are prolonged; the shortage of a small contact surface of the original carrier roller is overcome, the transmission efficiency is improved; and meanwhile, the possible phenomenon of slip due to contact between metal and the belt of the conveyor is also improved.

Owner:安徽冠东电子科技有限公司

Variable diameter flexible wheel

InactiveCN100355589CLarge diameterImprove obstacle performanceWheels with spade lugsFlangeCivil engineering

Owner:BEIHANG UNIV

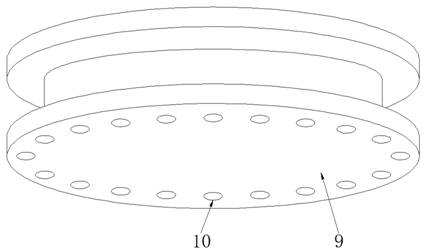

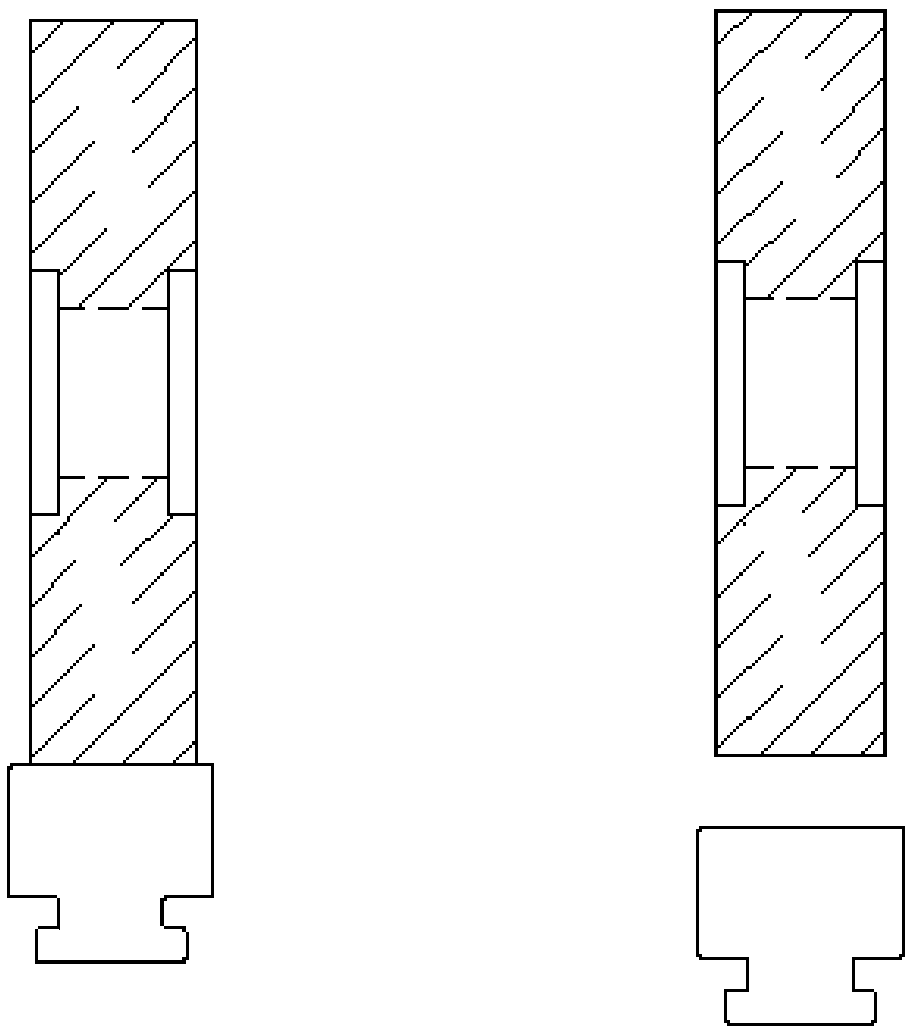

Capitulum radius replacement prosthesis

ActiveCN105193522AIn line with the characteristics of daily behavior sportsImprove stabilityAnkle jointsJoint implantsArticular surfacesHuman anatomy

The invention provides a capitulum radius replacement prosthesis. The capitulum radius replacement prosthesis comprises a capitulum radius and a radius broach, wherein the capitulum radius is in the shape of a circular truncated cone, the end face of the large-diameter end of the capitulum radius serves as the articular surface and is sunk inwards to form a spherical articular cavity, and the sphere center of the spherical articular cavity is located on the axis of the radius broach; a round connecting plane is arranged at the end of the radius broach, the diameter of the connecting plane is identical with that of the small-diameter end of the capitulum radius, and the small-diameter end of the capitulum radius is connected with the connecting plane of the radius broach through a connecting part in a matched mode. The capitulum radius replacement prosthesis accords with human anatomy and daily performance kinetic characteristics and has high stability and safety. Through the improvement of bone cement constituents, biocompatibility between the capitulum radius replacement prosthesis and bone substances is improved, complications such as deviation, looseness, infection and instability do not occur easily, service life is long, and different connecting parts can be adopted according to the conditions of patients to guarantee the optimal using effect of the capitulum radius replacement prosthesis.

Owner:北京威高亚华人工关节开发有限公司

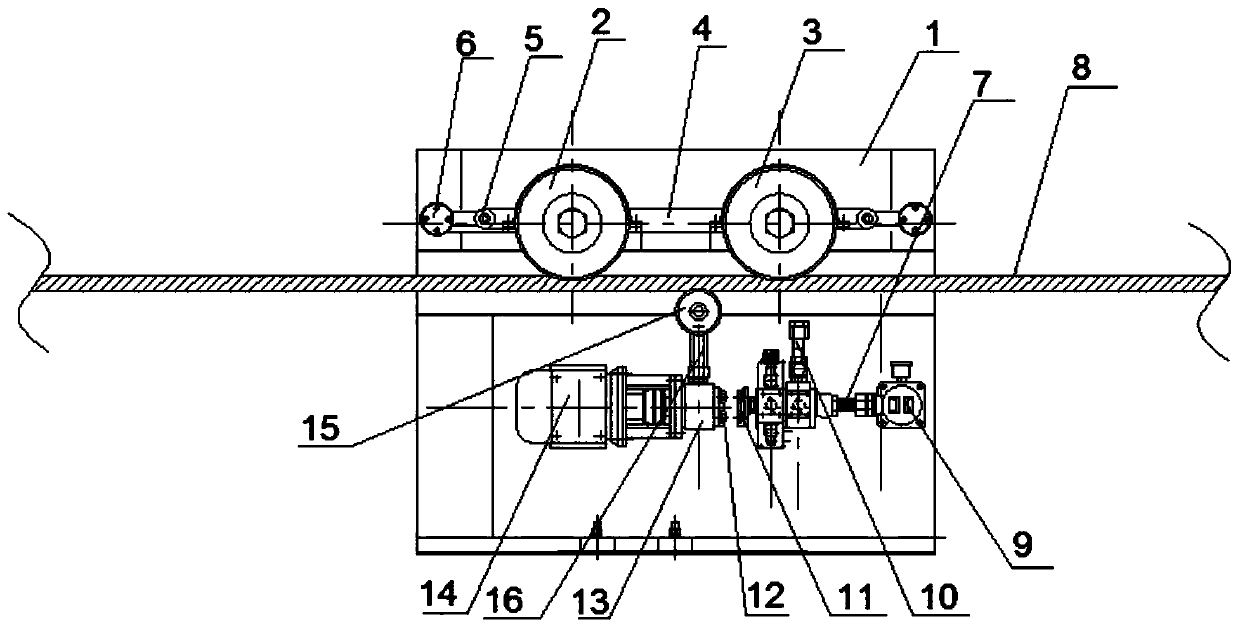

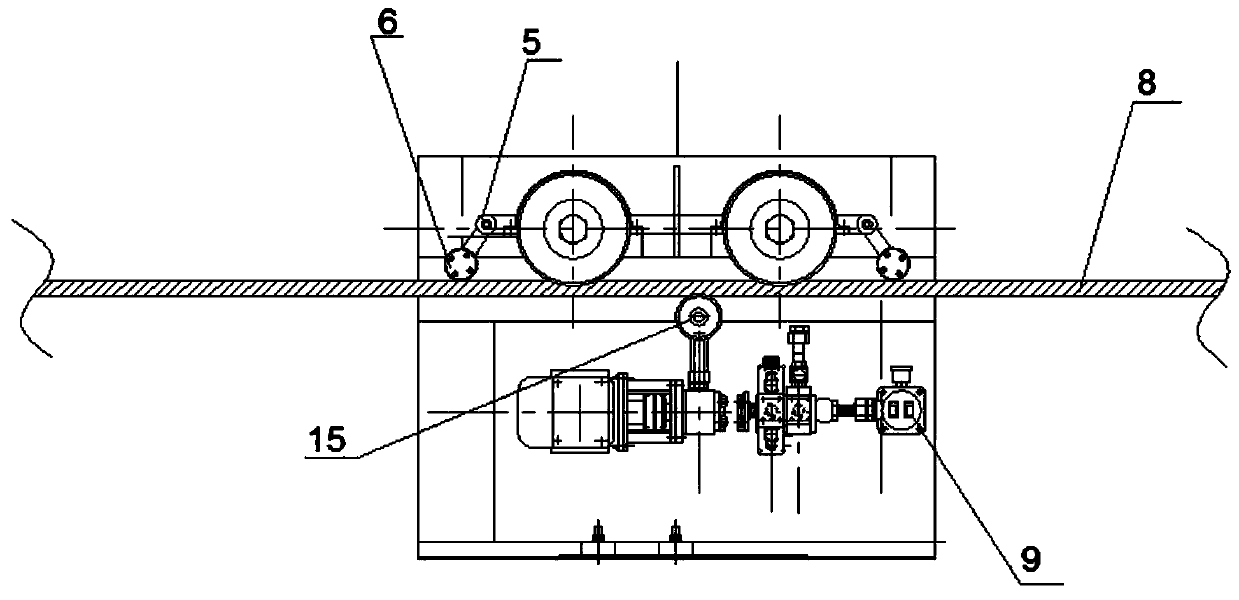

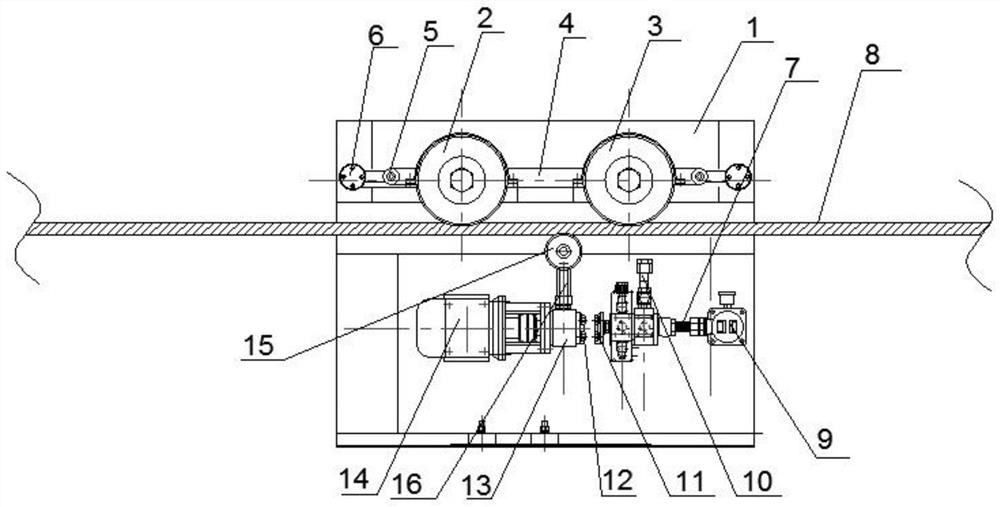

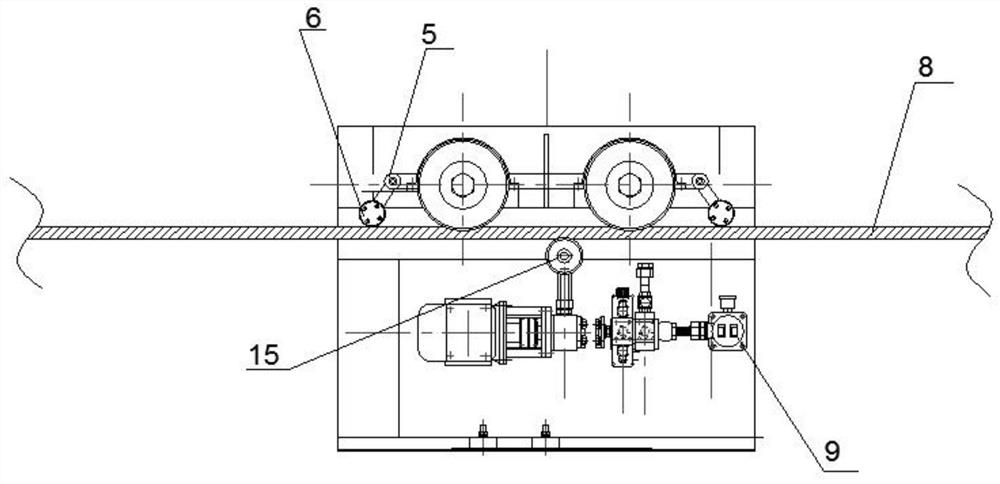

Intelligent inspection device for overhead power line

ActiveCN111009850ASolve slippageExtend the scan rangeApparatus for overhead lines/cablesElectric machineryEngineering

The invention discloses an intelligent inspection device for an overhead power line. An anti-slip and out-of-control mechanism is arranged, the slipping problem of the inspection device in the walkingprocess can be effectively solved, the slip problem can be effectively solved, particularly, when an ice layer appears on the overhead wire in winter, a walking wheel set cannot effectively grasp thewalking surface of the wire, the forward failure is caused, when the slip problem occurs, the anti-skid wheel is driven by a micro-swing motor to perform micro-amplitude swing, through the swing, theanti-skid wheel and the walking wheel set can walk forwards and backwards by utilizing inertia and swinging friction force, when a scanning mechanism detects that a certain position breaks down or isabnormal, the micro-swing motor can further drive the scanning mechanism to swing so as to expand a scanning range, meanwhile, the walking mechanism can move front and back to conduct scanning multiple times, and the inspection capacity is improved.

Owner:XUCHANG UNIV

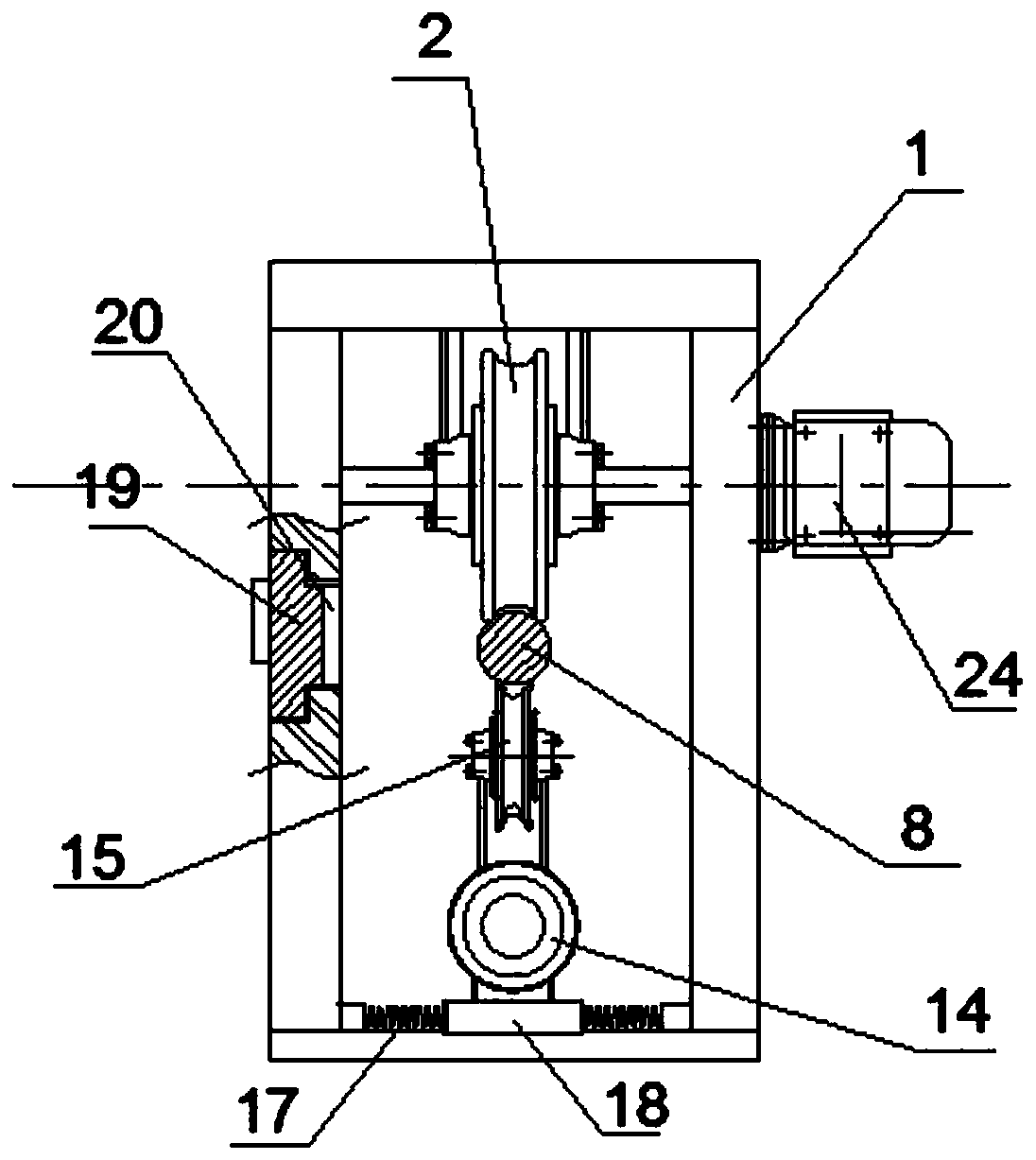

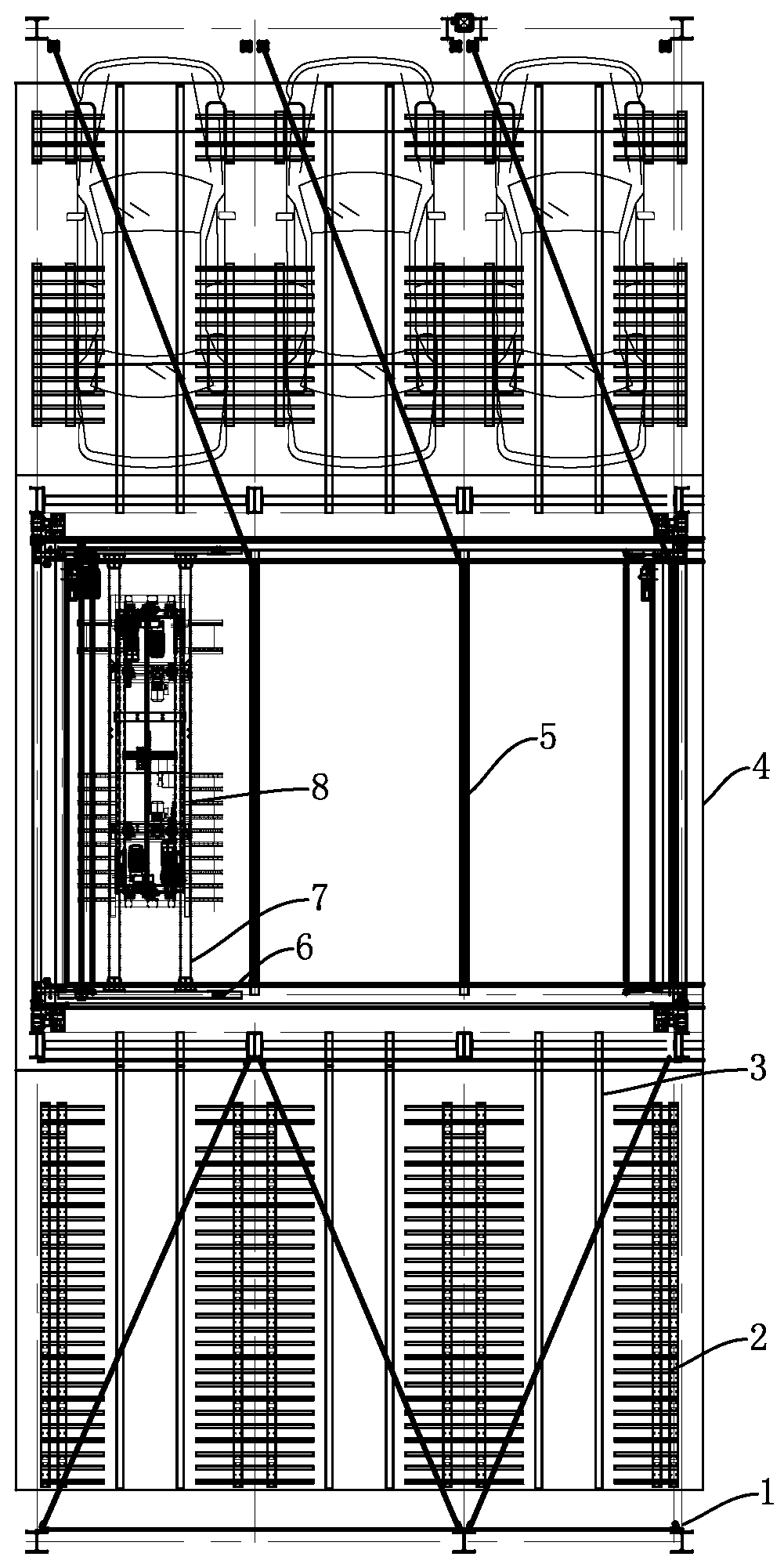

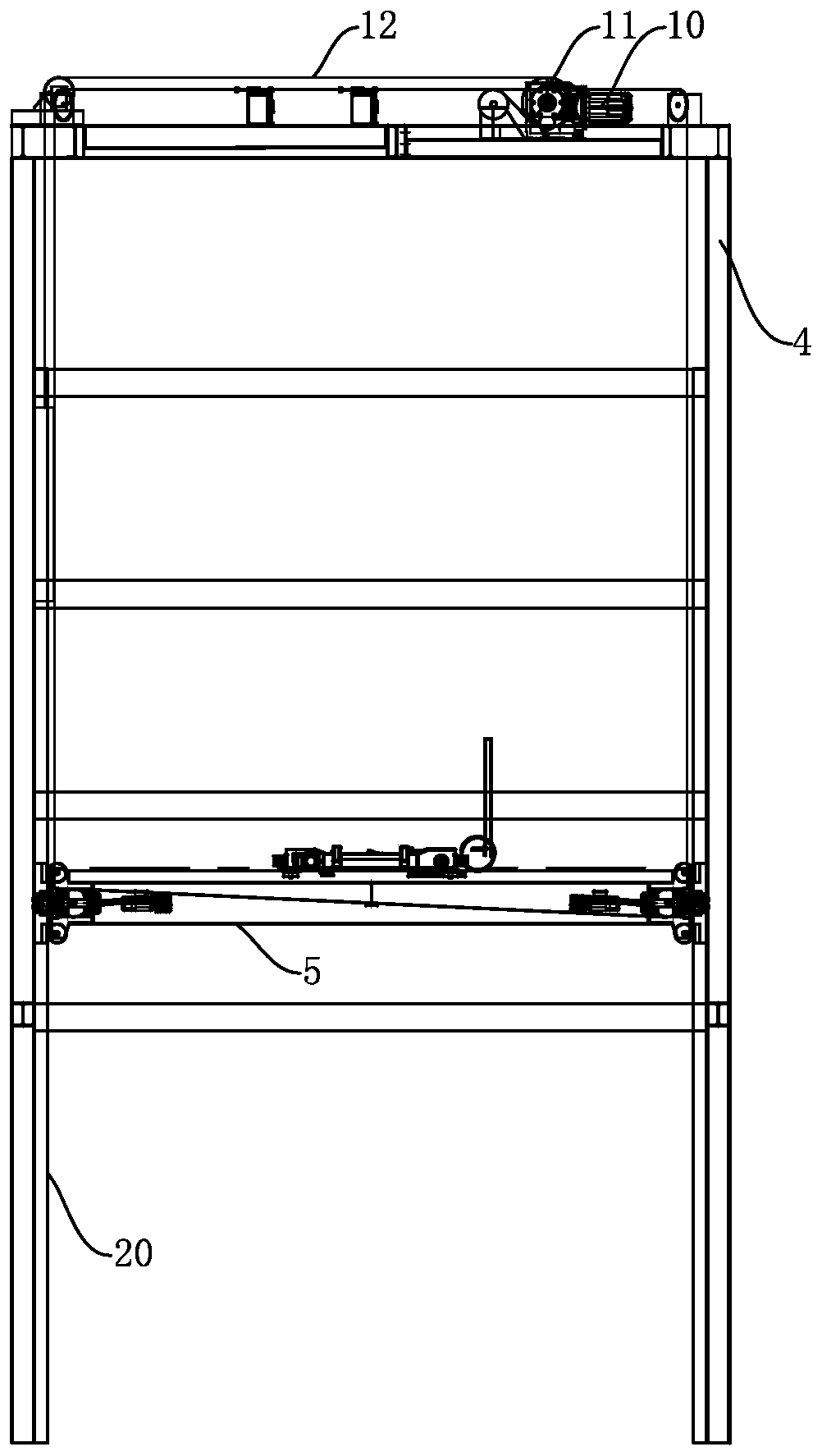

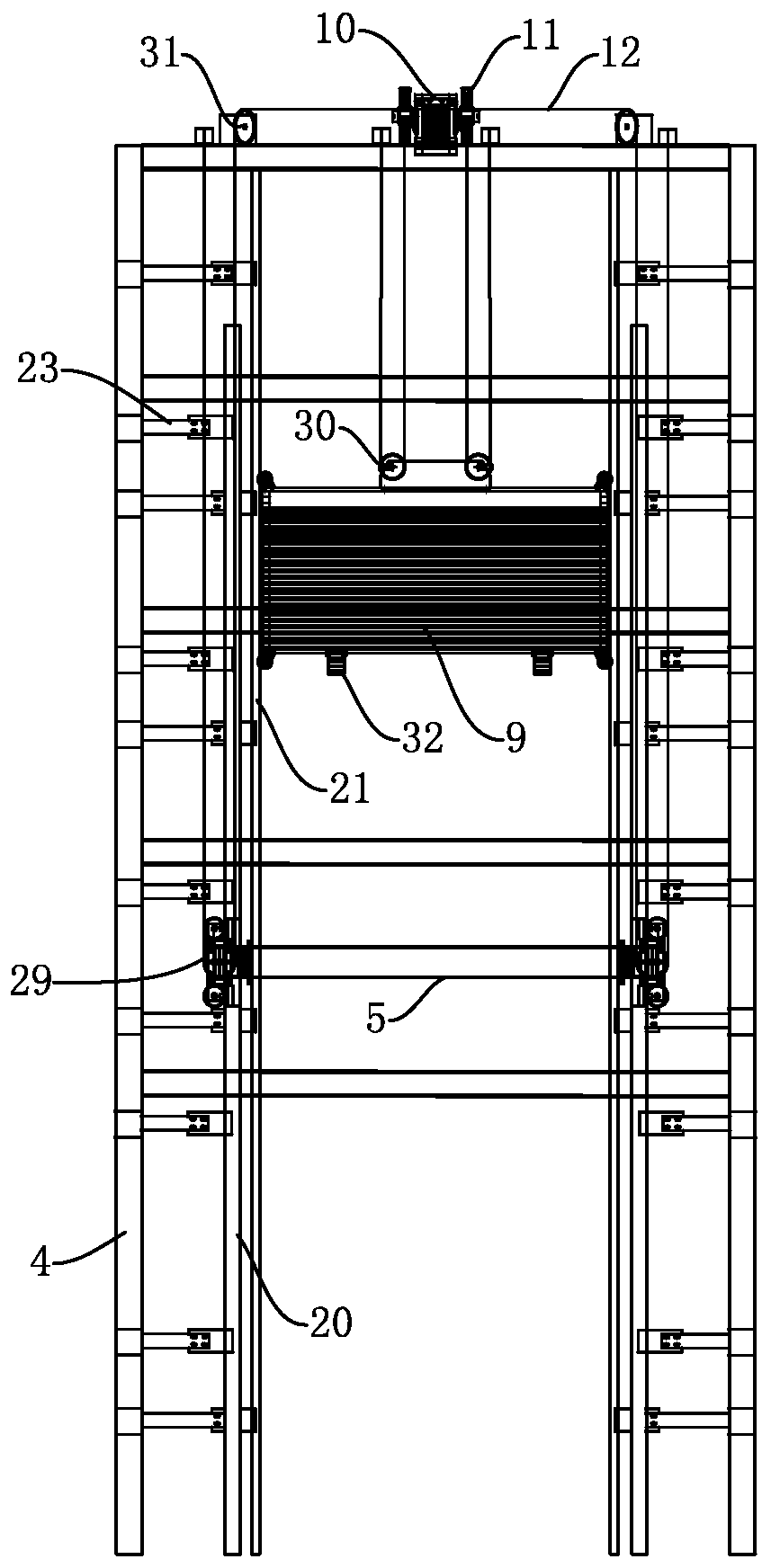

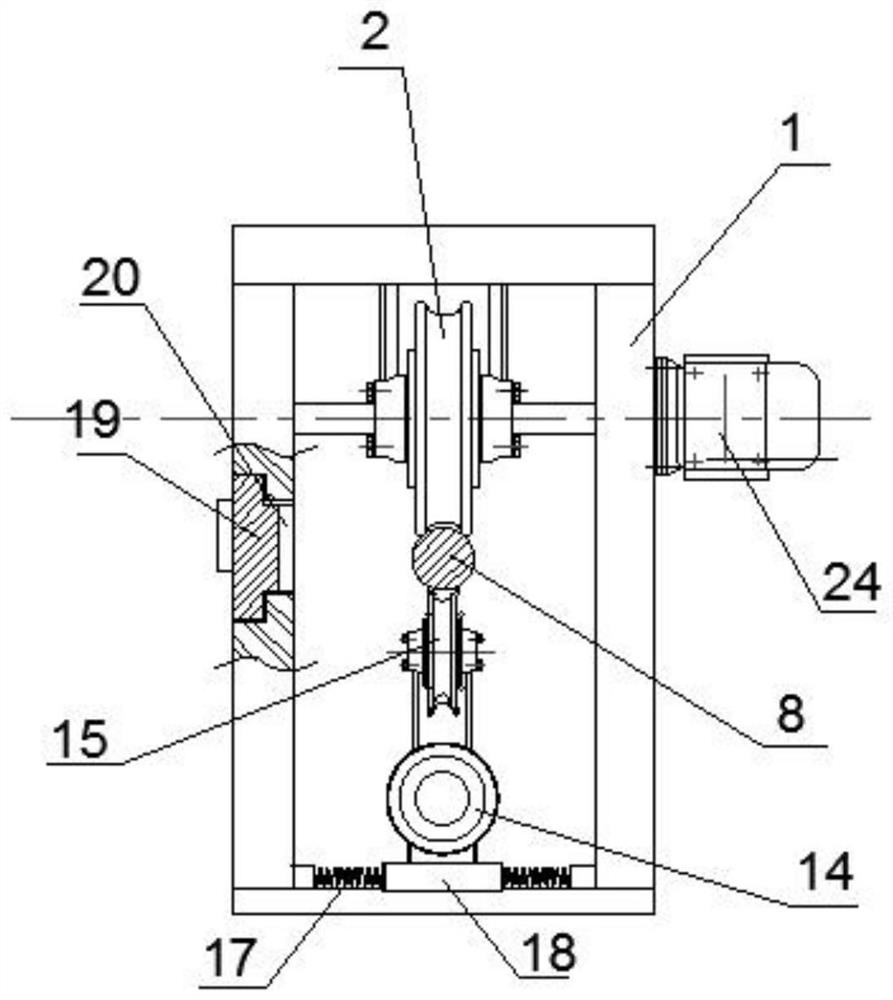

Stereo garage achieving traction drive

The invention discloses a stereo garage achieving traction drive, and belongs to the technical field of stereo garages. The stereo garage comprises a steel structure framework. A lifter framework is mounted in the steel structure framework. A car and a counter-weight are vertically mounted in the lifter framework in a sliding manner. A traction wheel is mounted at the top of the lifter framework.Four lifting steel wire ropes are wound on the traction wheel. Each lifting steel wire rope is correspondingly connected with the counter-weight and the car. Four balance steel wire ropes are arrangedbetween the car and the lifter framework. Two balance pulleys are arranged at each of the four corners of the bottom plane of the car. One end of each lifting steel wire rope is fixed to the top of the lifter framework, and the other end of each lifting steel wire rope is sequentially wound through the balance pulleys at one corner and the other balance pulley located on the same side at anothercorner and then is fixed to the bottom of the lifter framework. The technical problems that the gravity center of the car is not stable, consequently, the traction wheel cannot be used normally, and traction drive cannot be used in the lifting transverse movement stereo garage are solved. The stereo garage is widely applied to stereo garages.

Owner:DAYANG PARKING CO LTD

Sizing-coated carbon fiber bundle, thermoplastic resin composition, molded body, method for manufacturing sizing-coated carbon fiber bundle, and method for manufacturing molded body

Provided is a sizing-coated carbon fiber bundle that exhibits good spreadability in a step for spreading sizing-coated carbon fibers even in the case in which said carbon fibers exhibit a high adhesiveness with respect to a thermoplastic resin. Provided is a sizing-coated carbon fiber bundle that contains, as sizing components, at least a compound (A) containing an amino group or an amide group.

Owner:TORAY IND INC

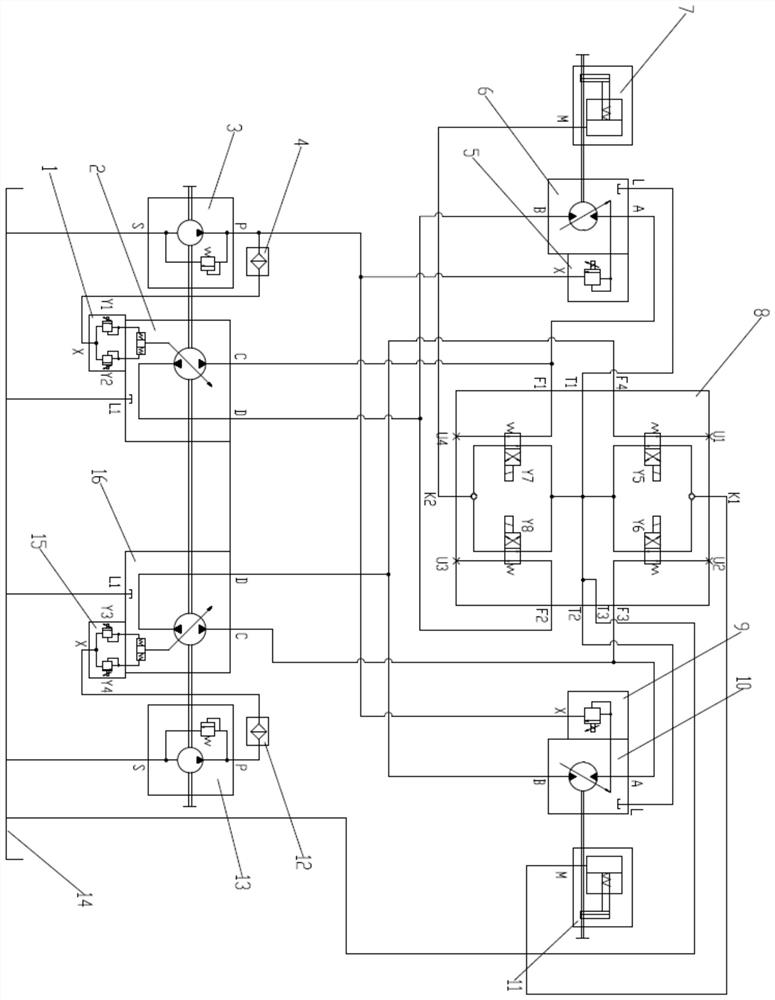

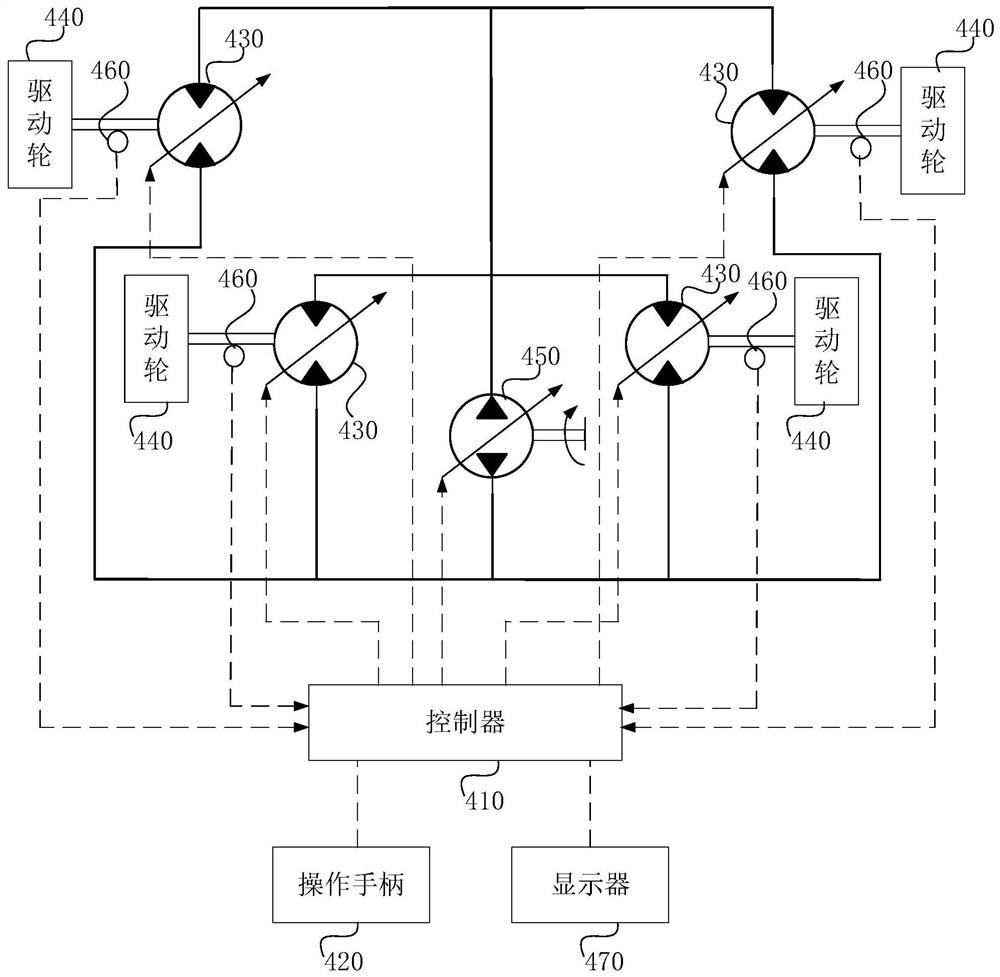

Road grader front wheel auxiliary driving electro-hydraulic control system and road grader

InactiveCN111677029AFlexible controlCompact structureMechanical machines/dredgersDrive wheelControl system

The invention discloses a road grader front wheel auxiliary driving electro-hydraulic control system and a road grader, and belongs to the technical field of road graders. The road grader front wheelauxiliary driving electro-hydraulic control system and the road grader are used for solving the technical problem that in the prior art, due to the fact that the wheel slip phenomenon is prone to happen under the condition that the foothold of a road grader is quite bad, the construction efficiency is affected. The system comprises plunger pump control valves, plunger pumps, oil supplement pumps,filters, motors, motor control valves, speed reducers, a front driving control valve, a hydraulic oil tank and the like. By means of the connection of components, a front wheel auxiliary driving hydraulic circuit is finally formed, and the driving force is provided for wheel front wheels; and the driving wheel state and driving-wheel-free state are flexibly switched according to the actual usage environment, the road grader can have a two-wheel driving mode, a four-wheel driving mode and a six-wheel driving mode, the road grader wheel slip phenomenon is effectively improved under the conditionthat the foothold is quite bad, and the construction efficiency of the road grader is greatly improved.

Owner:XUZHOU XUGONG ROAD CONSTR MACHINERY

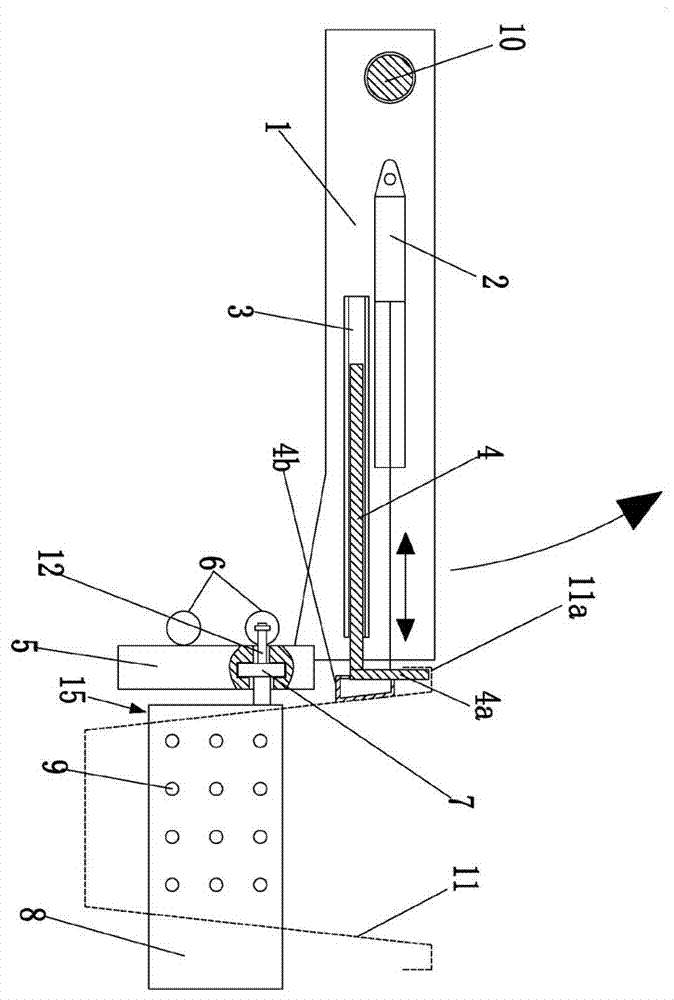

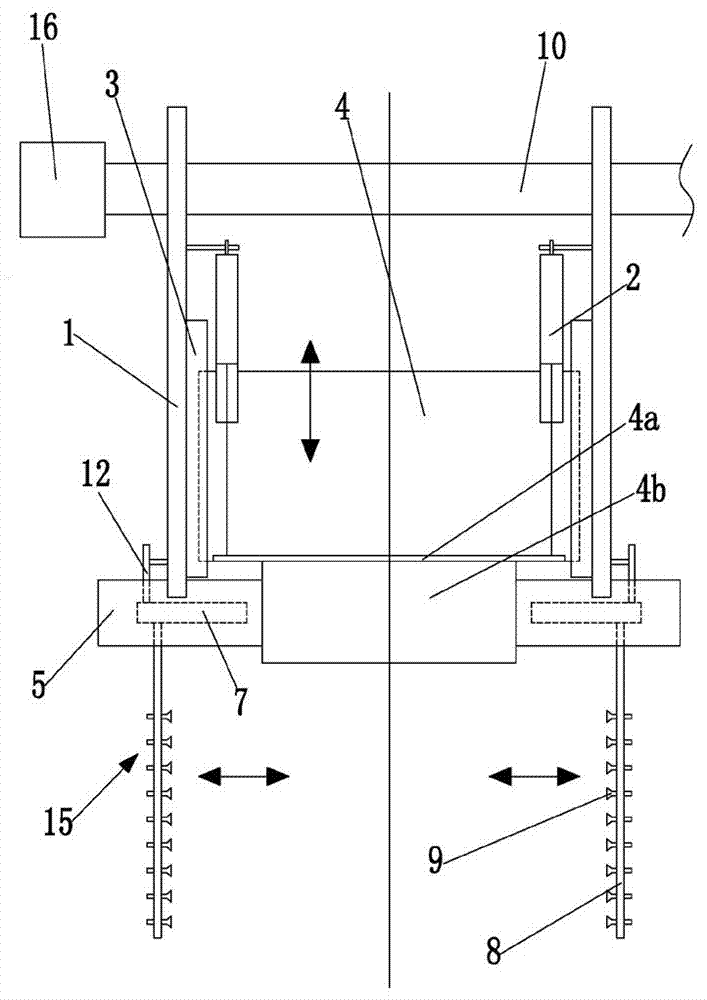

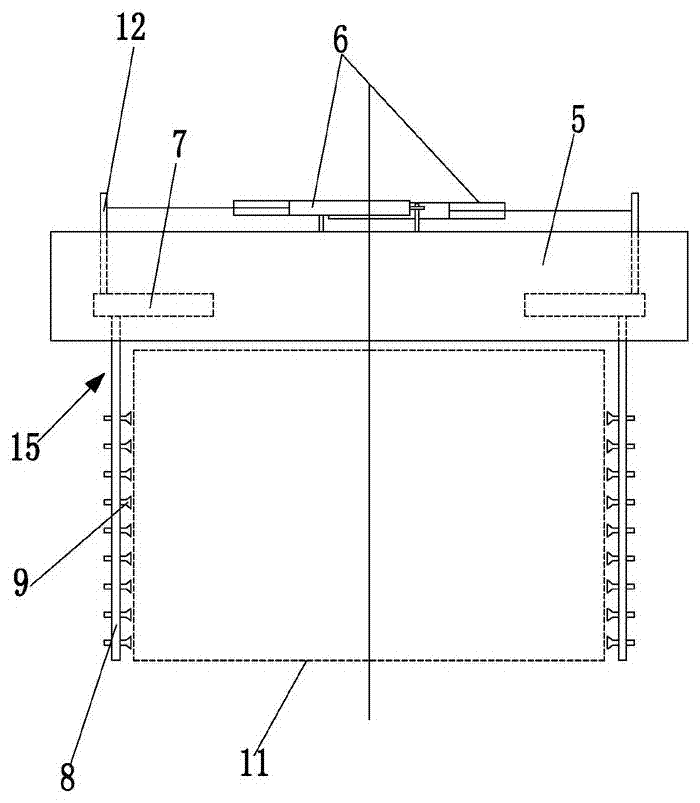

Automatic bucket holding device based on automatic positioning

PendingCN107052008ALock firmlySatisfy the cleaning operationHollow article cleaningEngineeringHooking

The invention discloses an automatic bucket holding device based on automatic positioning in the technical field of garbage bucket washing. The automatic bucket holding device comprises a rotation driving mechanism, an overturning main shaft, an overturning support and a holding unit, and further comprises a negative pressure adsorption unit, a vacuum generator and an automatic positioning mechanism; the holding unit comprises a clamping base and a pair of movable clamping parts oppositely arranged on the clamping base, and the negative pressure adsorption unit is controlled by the vacuum generator to generate negative pressure so that an garbage bucket outer wall can be attracted; the automatic positioning mechanism comprises a deflection air cylinder, a displacement guide rail and a movable limiting base, the movable limiting base is installed on the displacement guide rail in a sliding manner, a cylinder barrel of the deflection air cylinder is hinged to the overturning support, and a piston rod of the deflection air cylinder is hinged to the movable limiting base; and a bucket hooking plate used for hooking the bucket edge of the garbage bucket is arranged on the movable limiting base. Slippage of the garbage bucket in the clamping and overturning process can be thoroughly prevented, any damage to the garbage bucket is avoided, and the clamping effect is stable and reliable.

Owner:YANGZHOU JINWEI ENVIRONMENTAL PROTECTION TECH CO LTD

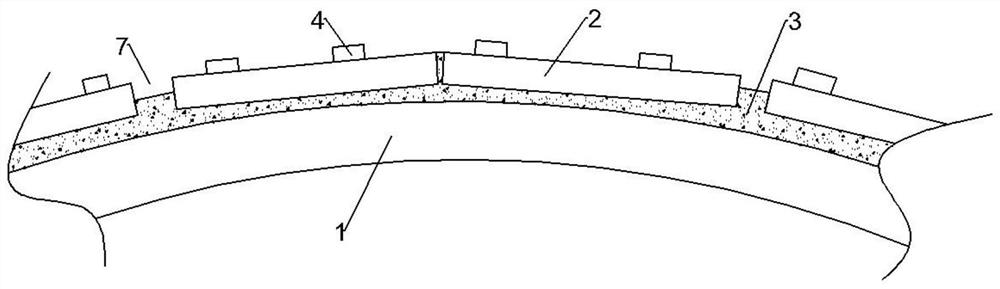

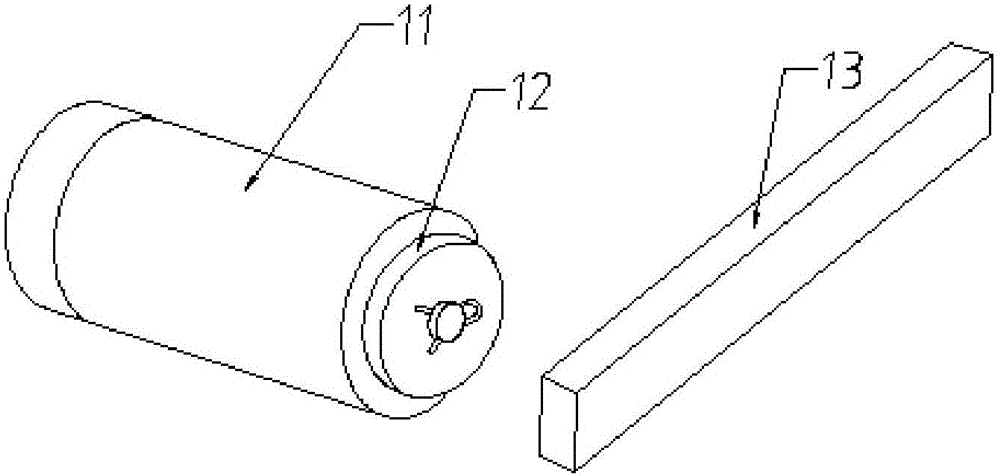

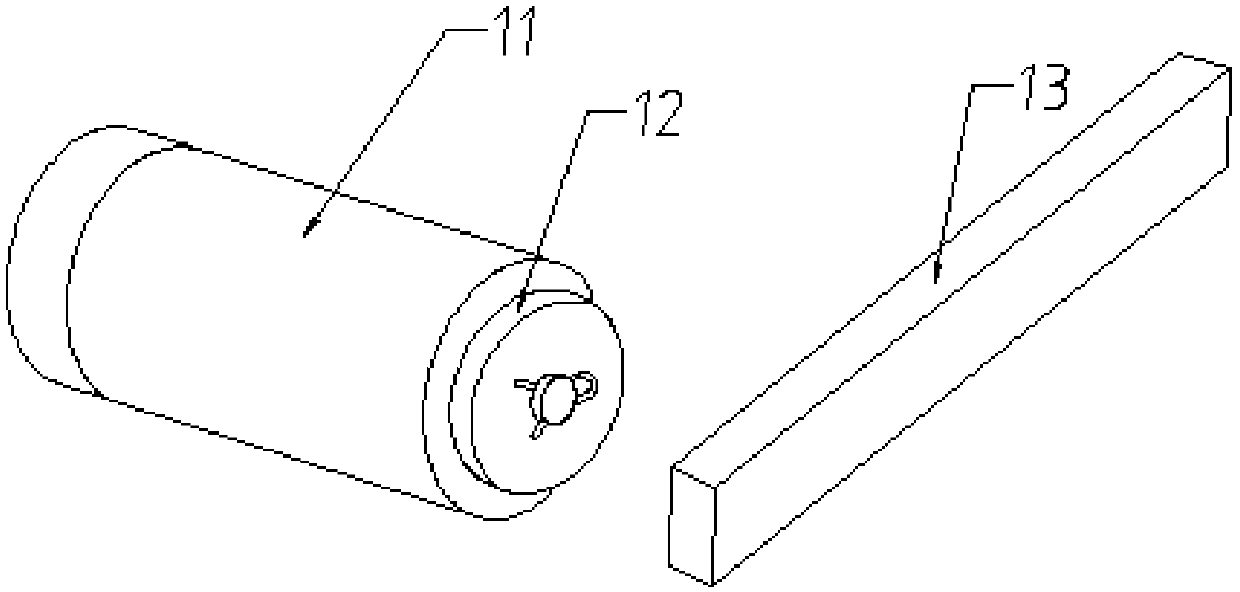

A direct-bonded ceramic patch conveyor belt roller

The invention provides a direct-adhesion ceramic patch conveyor belt roller, which relates to the technical field of conveyor belt automation to solve the technical problem of easy slippage between the roller and the conveyor belt in the prior art. The device comprises a roller, a ceramic sheet and an adhesive layer, wherein the roller is connected with a ceramic sheet through the adhesive layer, and the surface of the ceramic sheet is provided with anti-skid protrusions. The present invention is used to increase the frictional force between the drum and the conveyor belt.

Owner:天津初阳机械制造有限公司

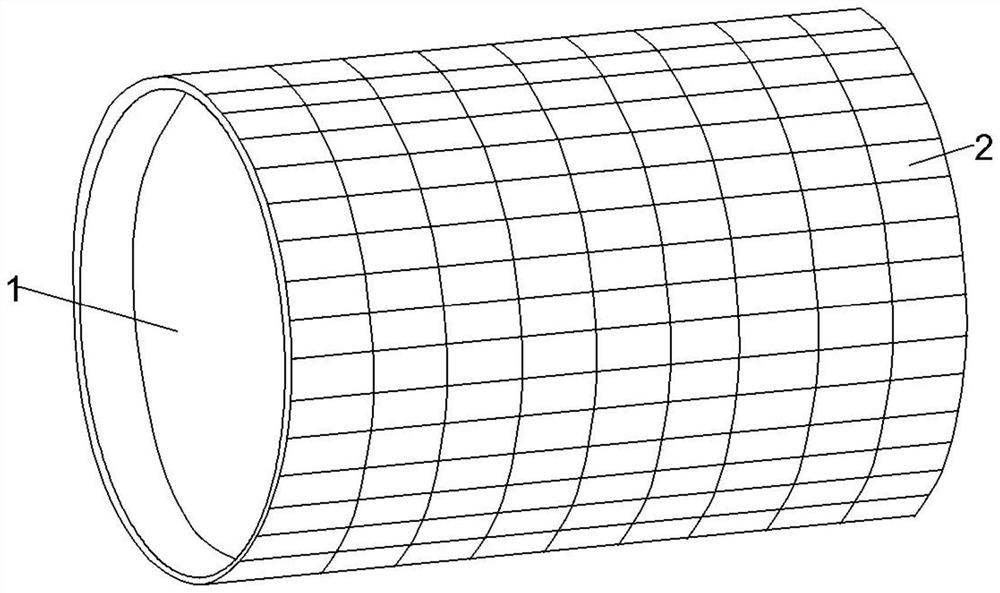

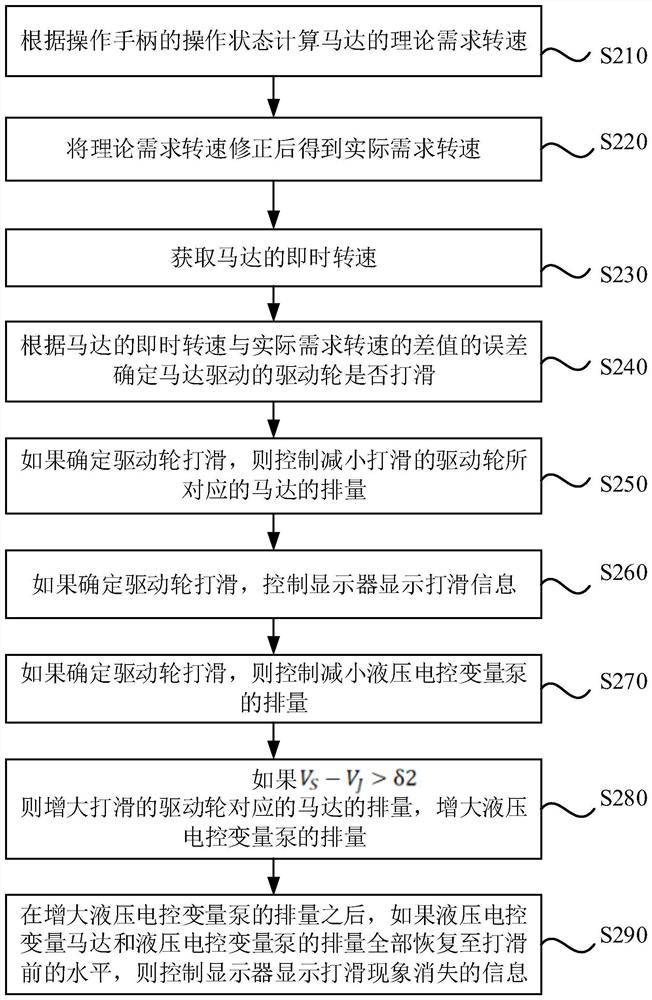

Anti-skid method of milling machine and milling machine

ActiveCN113026502AInstant speed reductionImprove slippageSpeed controllerRoads maintainenceEngineeringPower loss

The invention discloses an anti-skid method of a milling machine and the milling machine. The anti-skid method of the milling machine comprises the steps of calculating a theoretical required rotating speed of a motor according to an operation state of an operation handle; correcting the theoretical required rotating speed to obtain an actual required rotating speed; obtaining the instant rotating speed of the motor; determining whether a driving wheel driven by the motor slips or not according to the error of the difference between the instant rotating speed and the actual required rotating speed of the motor; and if it is determined that the driving wheel slips, controlling the displacement of the motor corresponding to the slipped driving wheel to be reduced. Whether the vehicle slips or not can be accurately judged, the anti-slip effect is improved, the control stability of a walking system of the milling machine is enhanced, power loss caused by slipping of a walking hydraulic system of the milling machine is avoided, and the milling machine can always maintain high operation efficiency during working.

Owner:SHANTUI CONSTR MASCH CO LTD

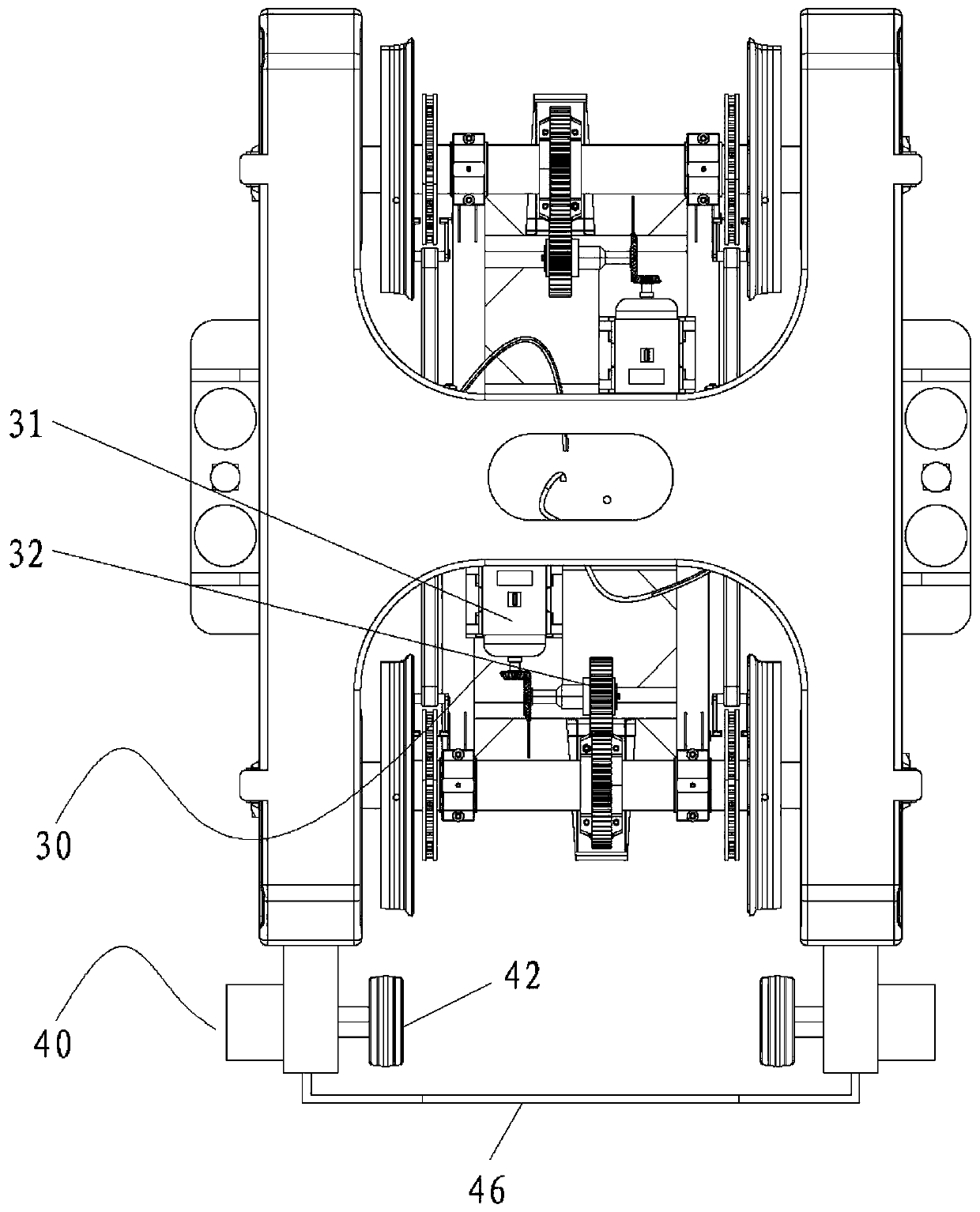

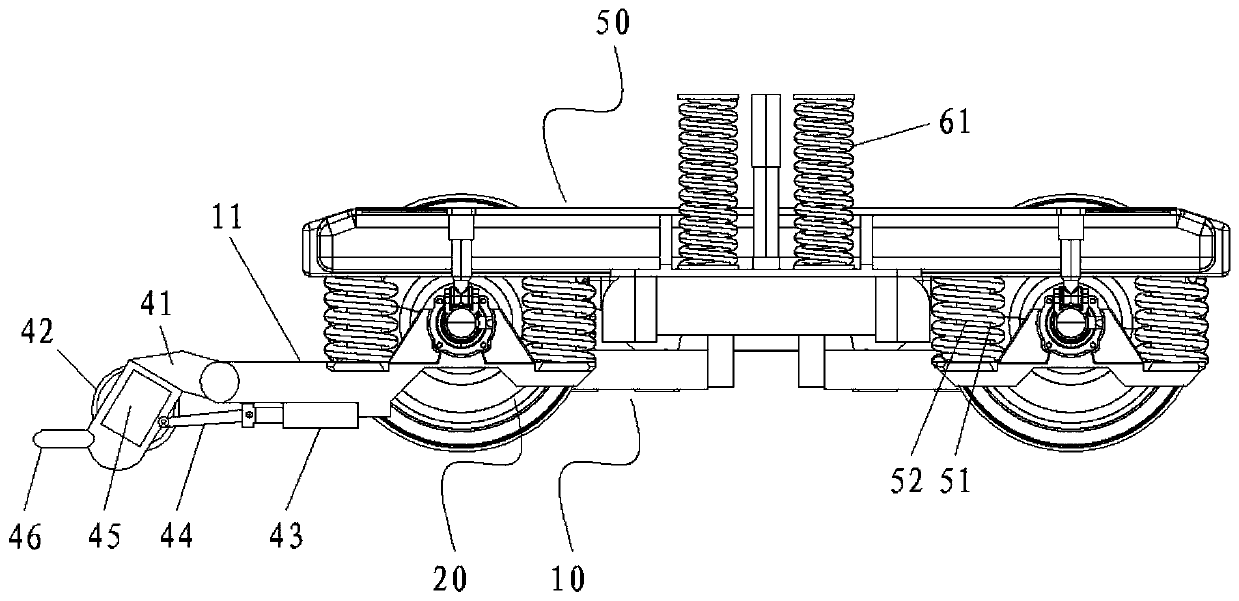

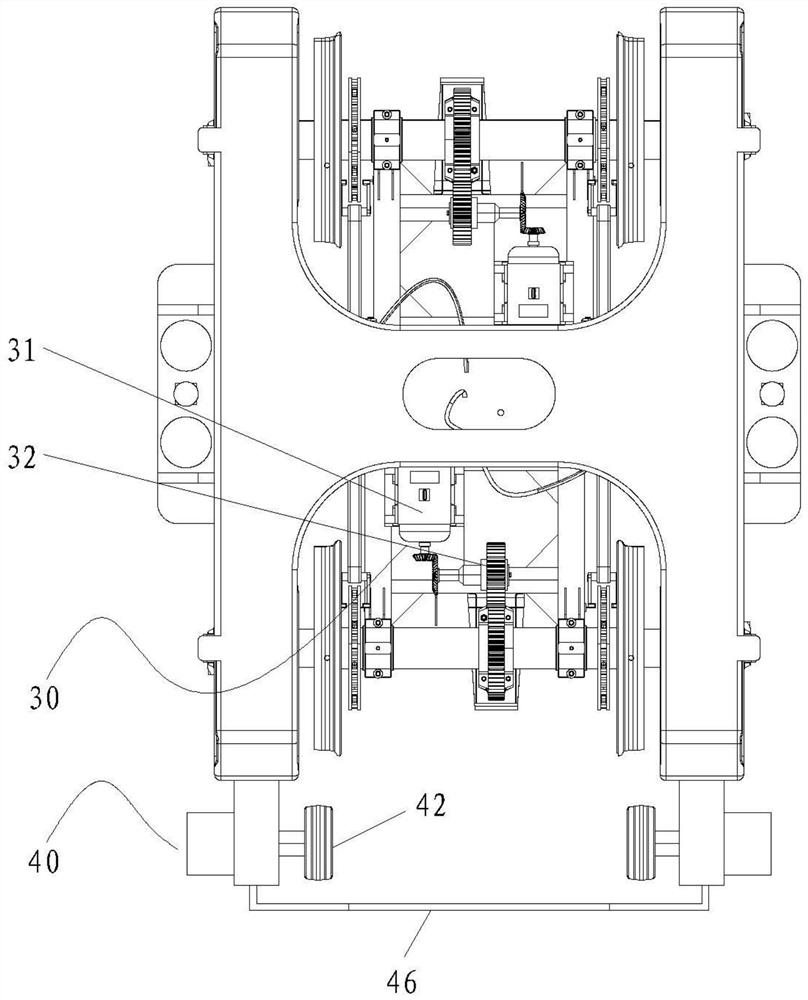

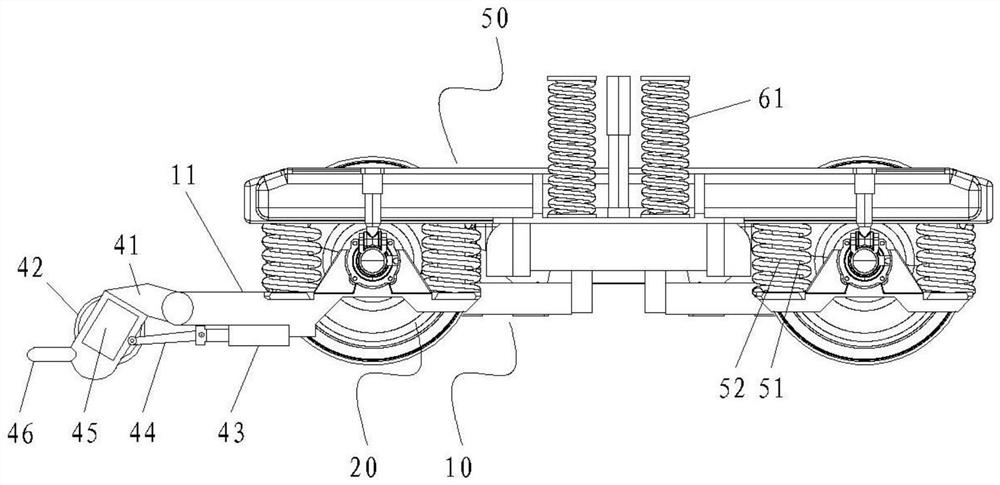

Light rail bogie

The invention discloses a light rail bogie. The light rail bogie comprises a wheel frame, wheels installed on the wheel frame, a power assembly driving the wheels to rotate, and a climbing auxiliary assembly connected to the front end and / or the rear end of the wheel frame. The climbing auxiliary assembly comprises a climbing auxiliary support installed on the wheel frame in a vertical swing modeand a climbing auxiliary wheel installed on the climbing auxiliary support in a running fit mode. According to the invention, the climbing auxiliary support can be driven to vertically swing; in the light rail climbing or downhill process, the climbing auxiliary support swings downwards, the climbing auxiliary wheel is pressed on the rail to increase a friction between the wheel and rail, overcomea wheel skipping phenomenon, improve the operational stability of the light rail and prevent safety accidents caused by slip; and when the light rail runs horizontally, the climbing auxiliary supportswings upwards to enable the climbing auxiliary wheel to be erected above the rail, and at the moment, the climbing auxiliary wheel is separated from the rail, so that the running resistance is reduced.

Owner:李富盈

An intelligent inspection device for overhead power lines

ActiveCN111009850BImprove slippageImprove inspection effectApparatus for overhead lines/cablesElectric machineryControl theory

The invention discloses an intelligent inspection device for an overhead power line. An anti-slip and out-of-control mechanism is arranged, the slipping problem of the inspection device in the walkingprocess can be effectively solved, the slip problem can be effectively solved, particularly, when an ice layer appears on the overhead wire in winter, a walking wheel set cannot effectively grasp thewalking surface of the wire, the forward failure is caused, when the slip problem occurs, the anti-skid wheel is driven by a micro-swing motor to perform micro-amplitude swing, through the swing, theanti-skid wheel and the walking wheel set can walk forwards and backwards by utilizing inertia and swinging friction force, when a scanning mechanism detects that a certain position breaks down or isabnormal, the micro-swing motor can further drive the scanning mechanism to swing so as to expand a scanning range, meanwhile, the walking mechanism can move front and back to conduct scanning multiple times, and the inspection capacity is improved.

Owner:XUCHANG UNIV

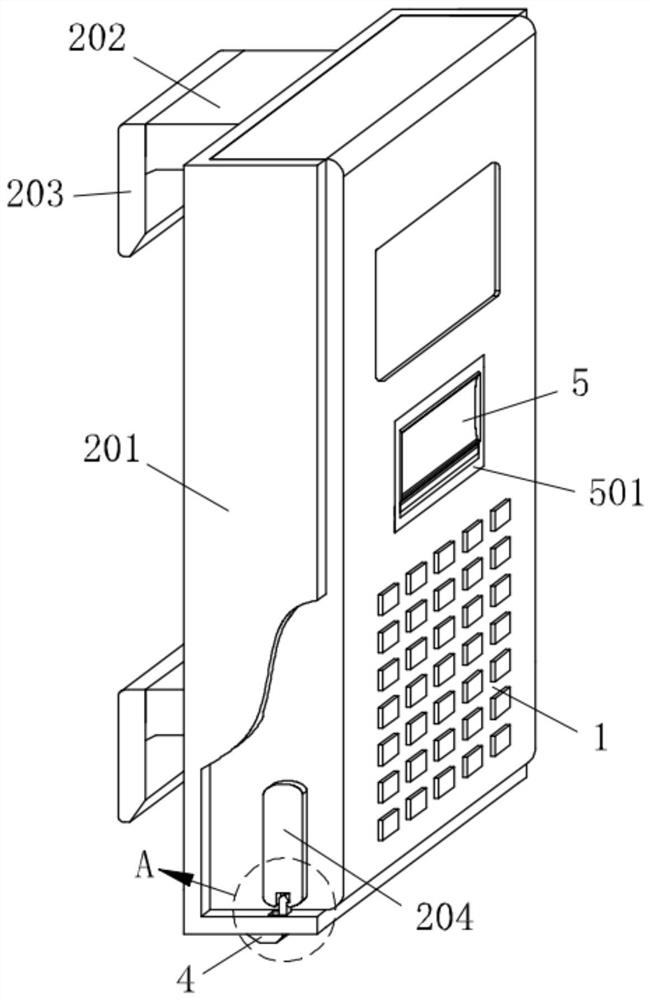

Data acquisition and transmission equipment for industrial Internet of Things

ActiveCN114445923AEasy to assemble and disassembleEasy to install and connectRegistering/indicating time of eventsTelemetry/telecontrol selection arrangementsLocking mechanismProtection mechanism

The invention relates to the technical field of data acquisition and transmission, in particular to data acquisition and transmission equipment for industrial Internet of Things, which comprises a fingerprint machine, a fixing mechanism is mounted on the fingerprint machine, a fastening mechanism is mounted on the fixing mechanism, a locking mechanism is connected to the fixing mechanism, a protection mechanism is mounted on the fingerprint machine, and the locking mechanism is connected to the protection mechanism. A cleaning mechanism is mounted on the protection mechanism, and a scraping mechanism is connected to the cleaning mechanism; under the action of the fixing mechanism and the fastening mechanism, the fingerprint machine and an external fixing frame can be conveniently and stably installed and conveniently disassembled, meanwhile, under the action of the locking mechanism, the fingerprint machine and the fixing mechanism are stably connected and do not slip, and under the action of the protection mechanism, the interior of the fingerprint machine can be conveniently protected; and through the action of the cleaning mechanism and the scraping mechanism, the dust and the sundries in the fingerprint machine can be conveniently scraped and cleaned, and the recognition efficiency is improved.

Owner:优网云计算有限公司

Sizing-coated carbon fiber bundle, thermoplastic resin composition, molded body, method for manufacturing sizing-coated carbon fiber bundle, and method for manufacturing molded body

Provided is a sizing-coated carbon fiber bundle that exhibits good spreadability in a step for spreading sizing-coated carbon fibers even in the case in which said carbon fibers exhibit a high adhesiveness with respect to a thermoplastic resin. Provided is a sizing-coated carbon fiber bundle that contains, as sizing components, at least a compound (A) containing an amino group or an amide group.

Owner:TORAY IND INC

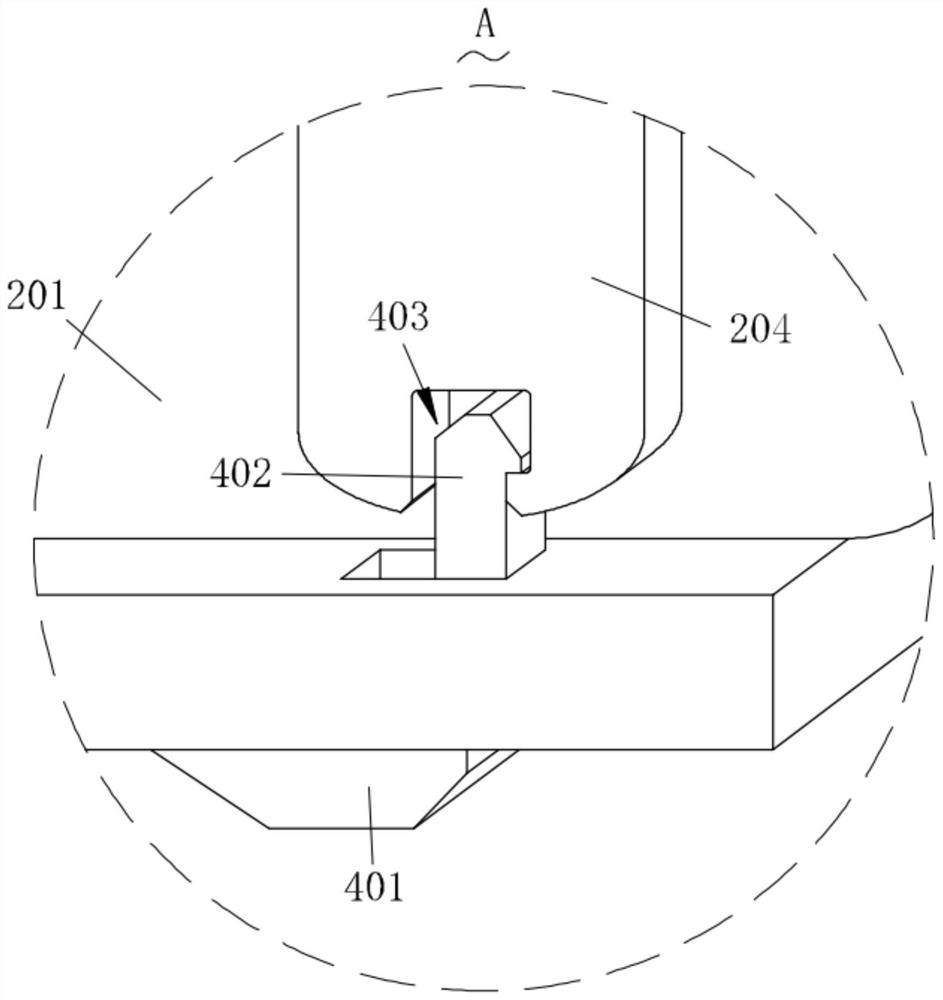

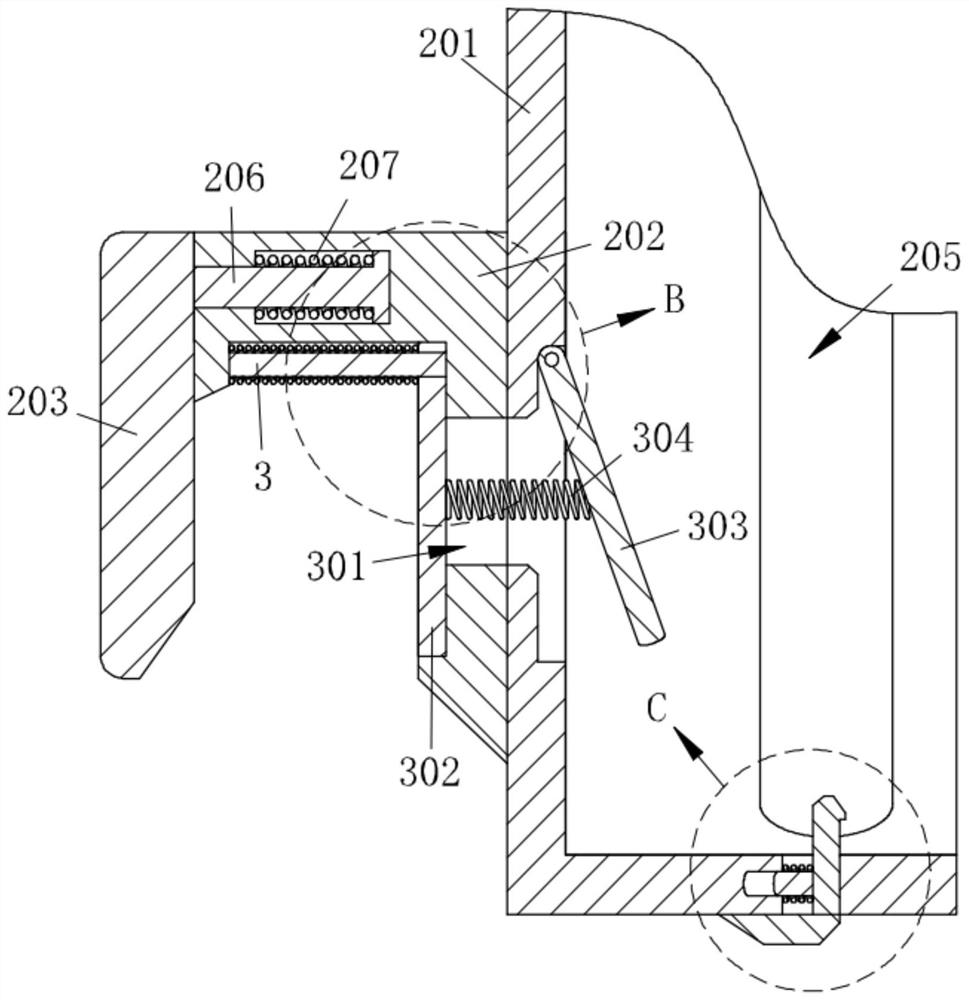

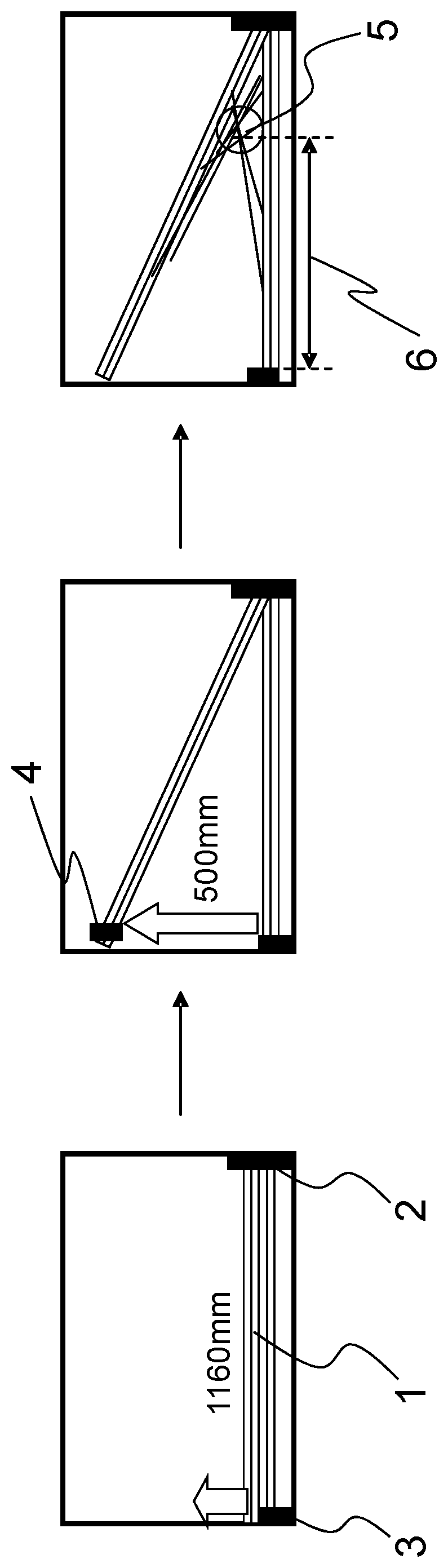

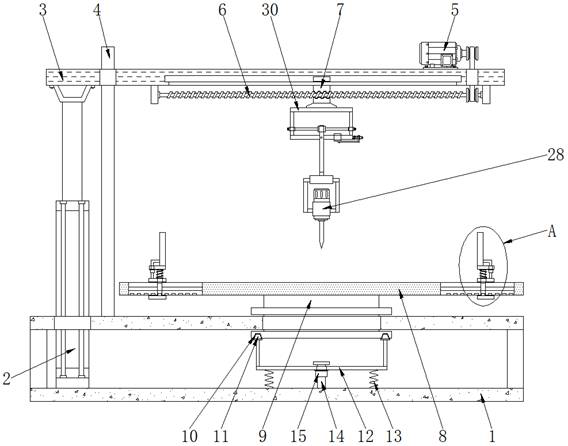

Non-slip multi-angle adjustable drilling device for hardware machining

InactiveCN114472952AImprove slippagePrevent slippageAutomatic control devicesFeeding apparatusStructural engineeringMachining process

The multi-angle adjustable drilling device comprises a base directly arranged on the ground or a workbench, a drilling table, a drilling machine, a bearing column, a clamping mechanism, a mounting sleeve and a fixing mechanism, the drilling table is arranged above the base, the drilling machine is arranged above the drilling table, the bearing column is arranged above the drilling machine, and the clamping mechanism is arranged above the mounting sleeve. The bearing column and the base are connected in a rotating mode, the clamping mechanisms are arranged on the edge of the drilling table at equal angles, the mounting sleeve is used for limiting the position between the mounting support and the fixing frame, and the fixing mechanism is arranged on the right side of the fixing frame. According to the multi-angle adjustable drilling device not prone to slipping and used for hardware machining, machined hardware is clamped and limited, slipping is prevented in the machining process, the angle of the drilling machine is conveniently adjusted, and when different positions of the same hardware are drilled, the hardware does not need to be repeatedly disassembled and clamped.

Owner:姜汇溪

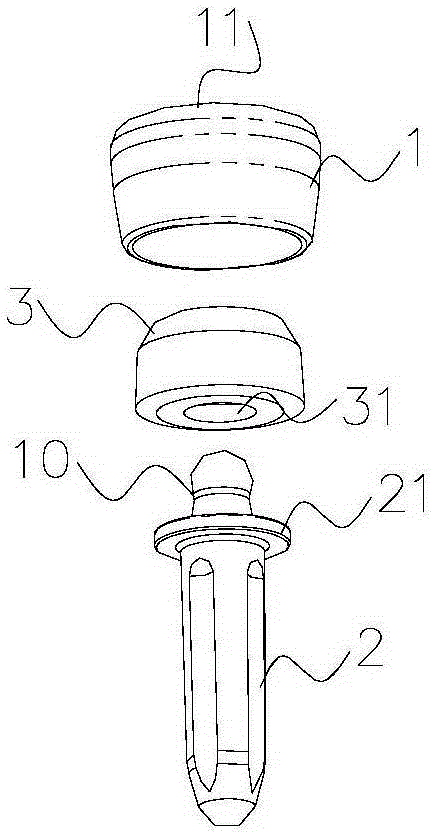

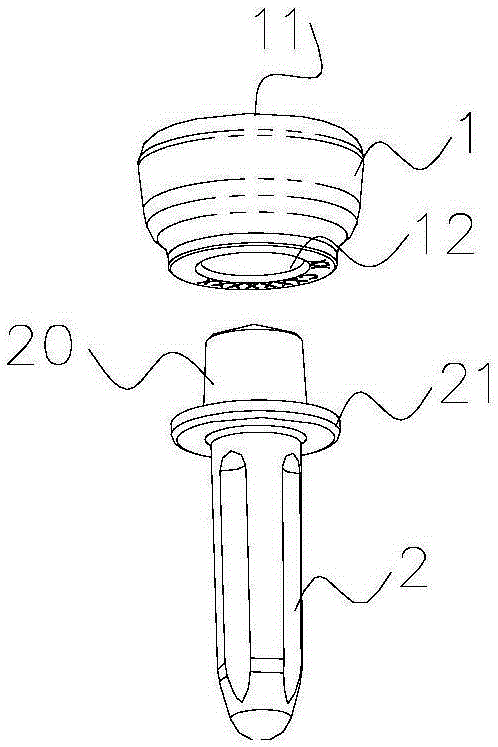

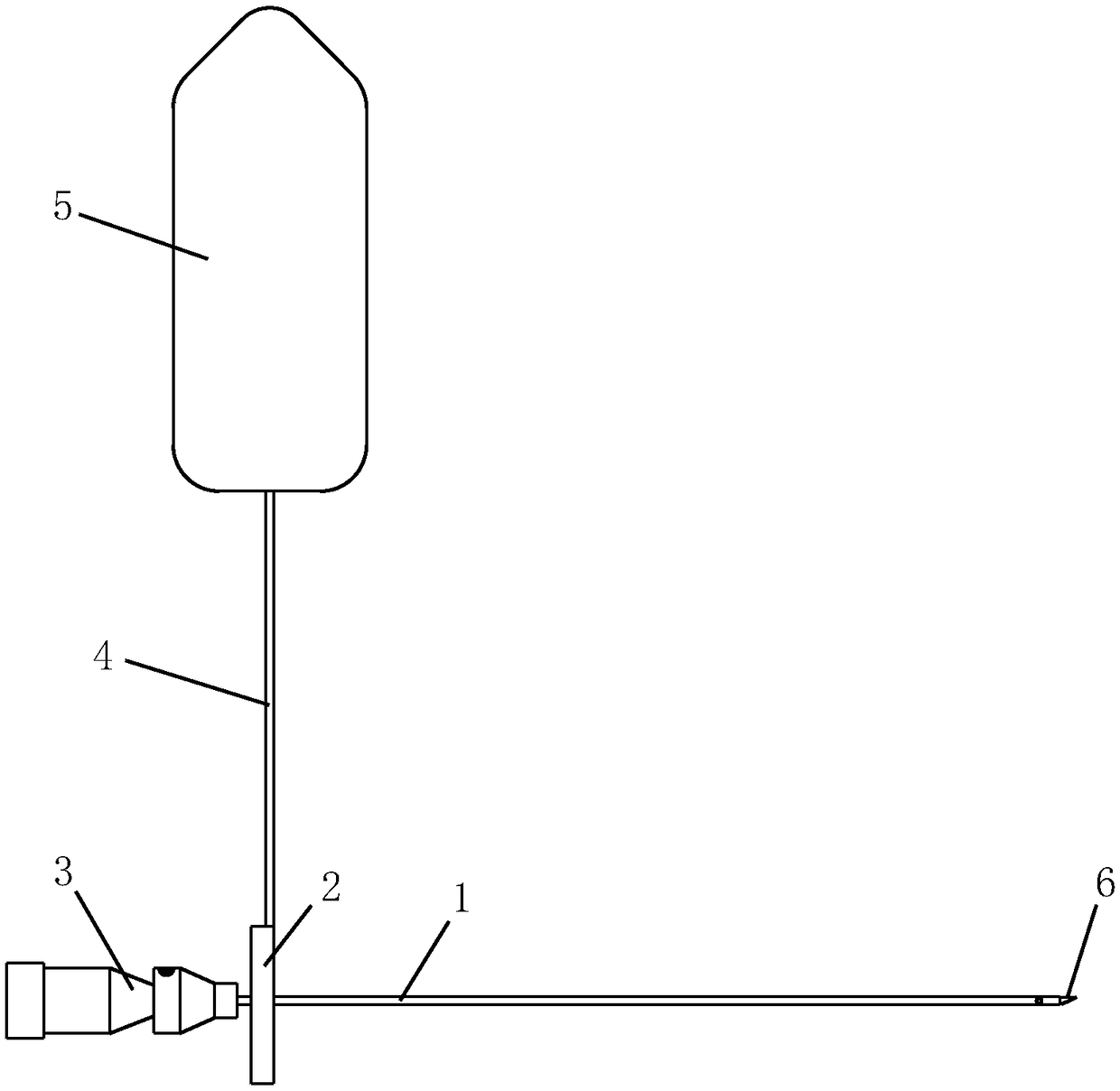

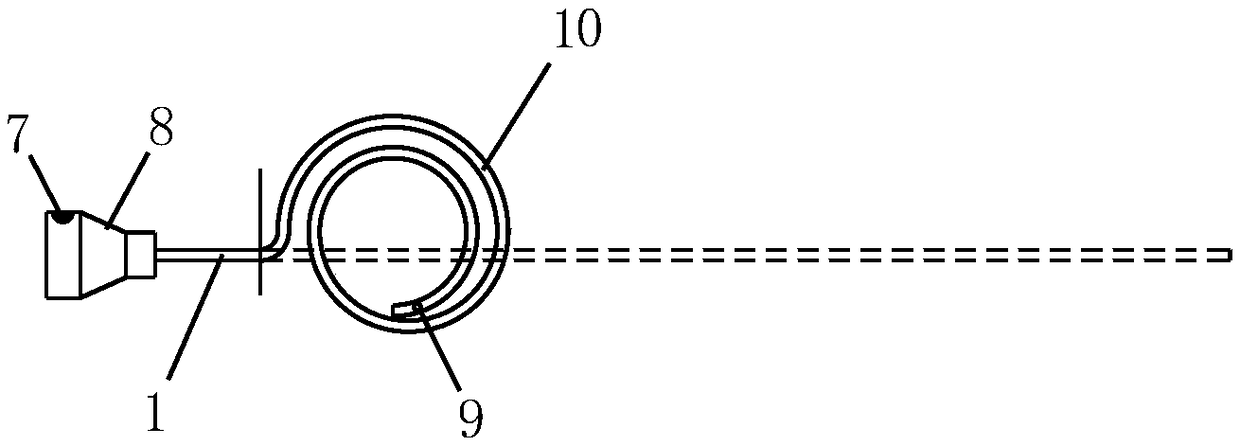

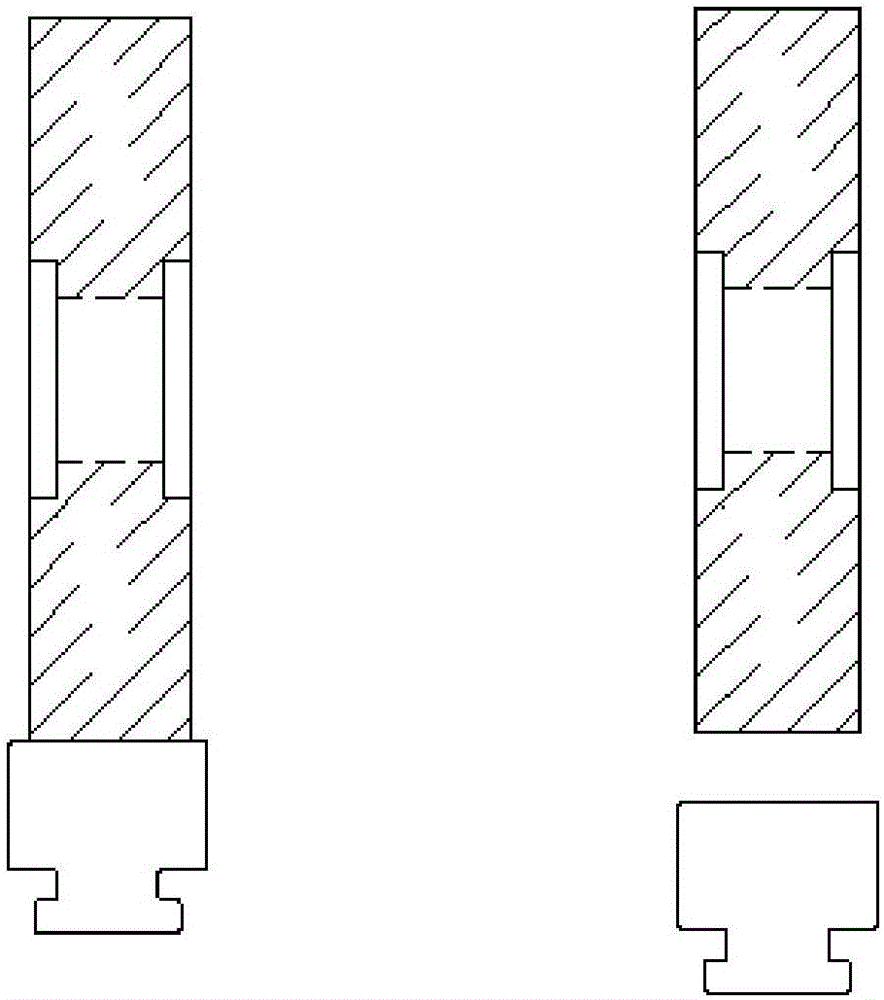

Vestibular large gland cyst ostomy

PendingCN109171906AFunction as a fixed positionEasy to fixCannulasSurgical needlesAbdominal trocarFixed position

A vestibular large gland cyst ostomy comprises a trocar puncture needle composed of a trocar (1) and a needle core (3). The needle core is inserted into the trocar, the tip (6) of the needle core is exposed from the front end of the trocar, the trocar is flexible, and after the needle core is withdrawn from the trocar, the front part (10) of the trocar is bent into a right angle and then curled into a circular ring shape; Comprises a button-like fixture (2) and a fixing block (5), the button-like fixture and the fixing block are connected by a flexible connecting rod (4), a hole (12) is arranged in the center of the button-like fixture, and a trocar is inserted into the hole in the center of the button-like fixture. During the treatment, the puncture needle was inserted into the cyst, after withdrawing the needle core, decompression and drainage were performed by the cannula, and the anterior part of the cannula was naturally curled into a circular ring in the cyst cavity, which playeda role of fixing position. Place the fixation block in the vagina and remove the button-like fixator to help position the cannula locally within a few days.

Owner:JIAXING NO 1 HOSPITAL

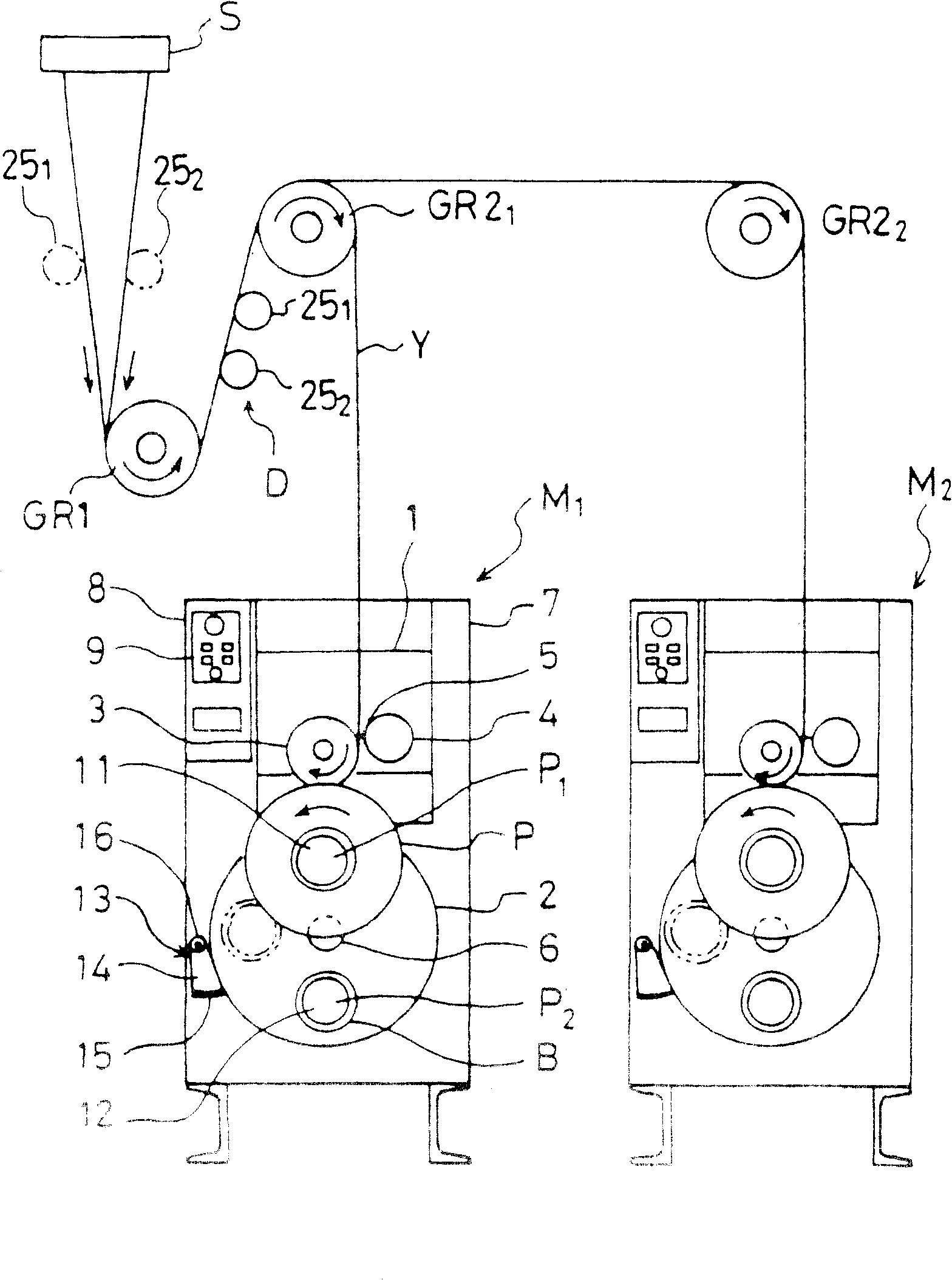

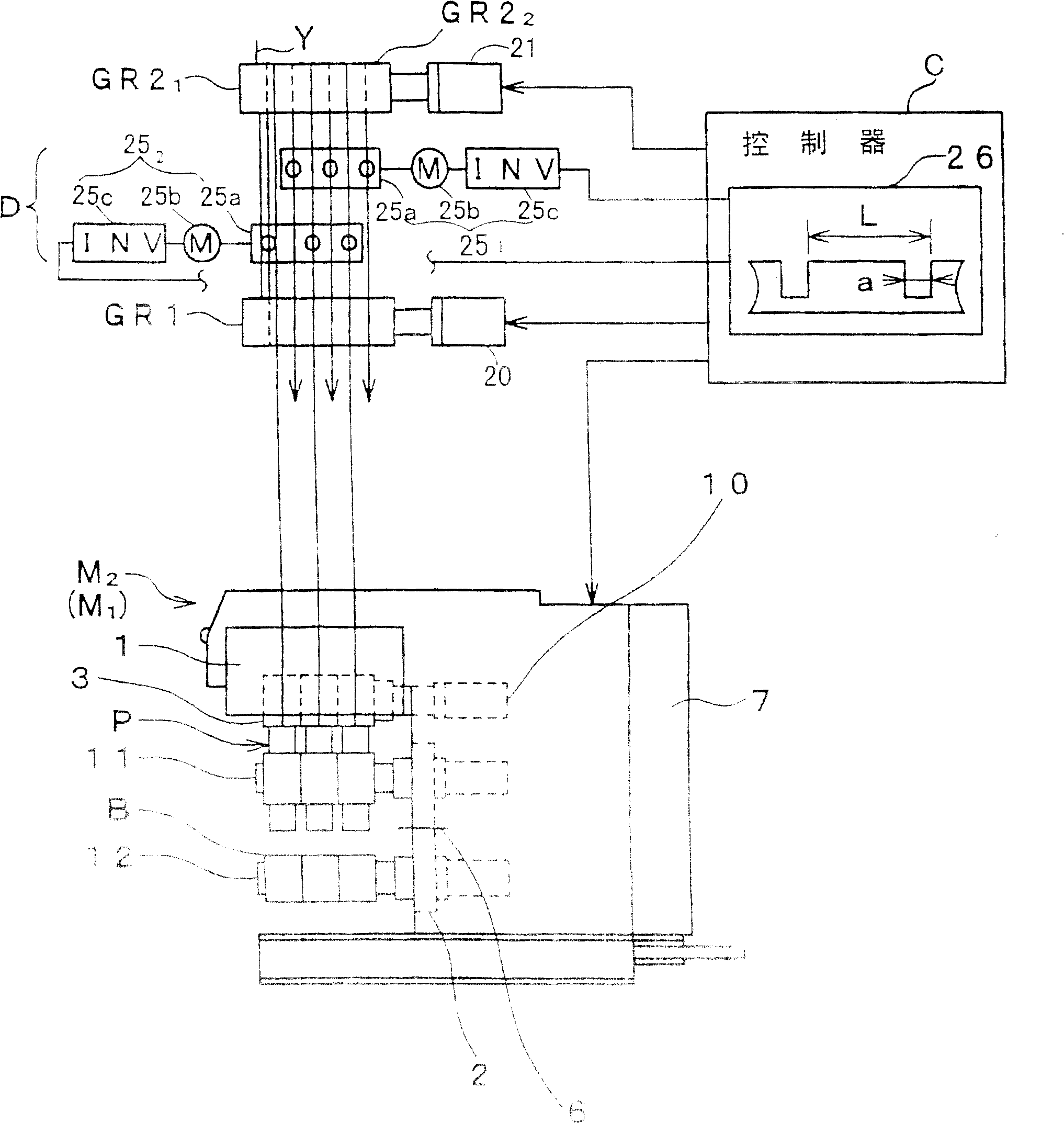

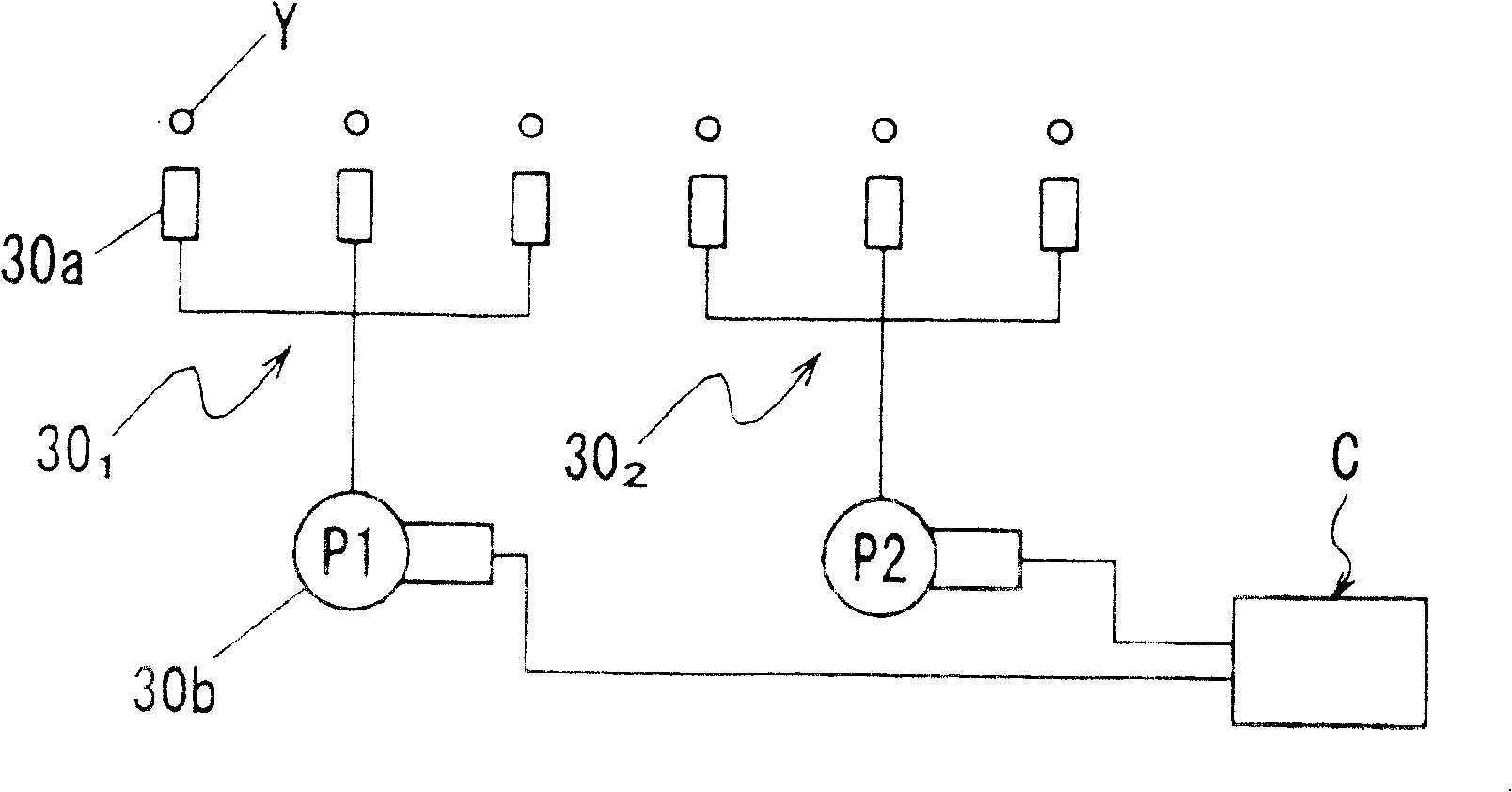

Dressing agent supply device for synthetic yarn winding device

The finishing agent supplying means 25<1>, 25<2>are divided per a spun yarn group to be led to the winders M<1>, M<2>, and a control means 26 is provided to separately control the finishing agent supply quantity to be supplied by each of the divided finishing agent supplying means 25<1>, 25<2>per the divided finishing agent supplying means.

Owner:MURATA MASCH LTD

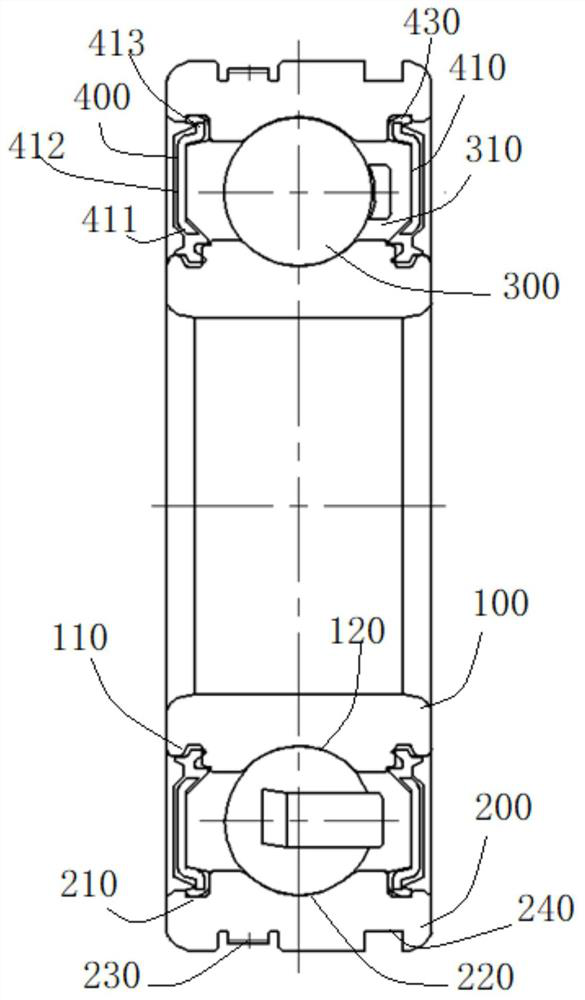

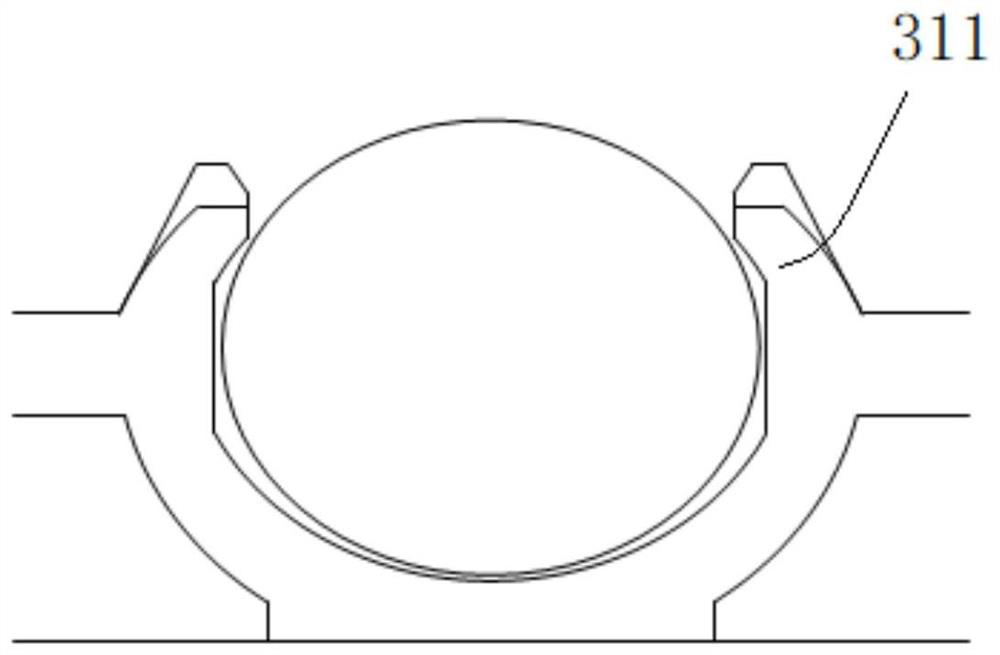

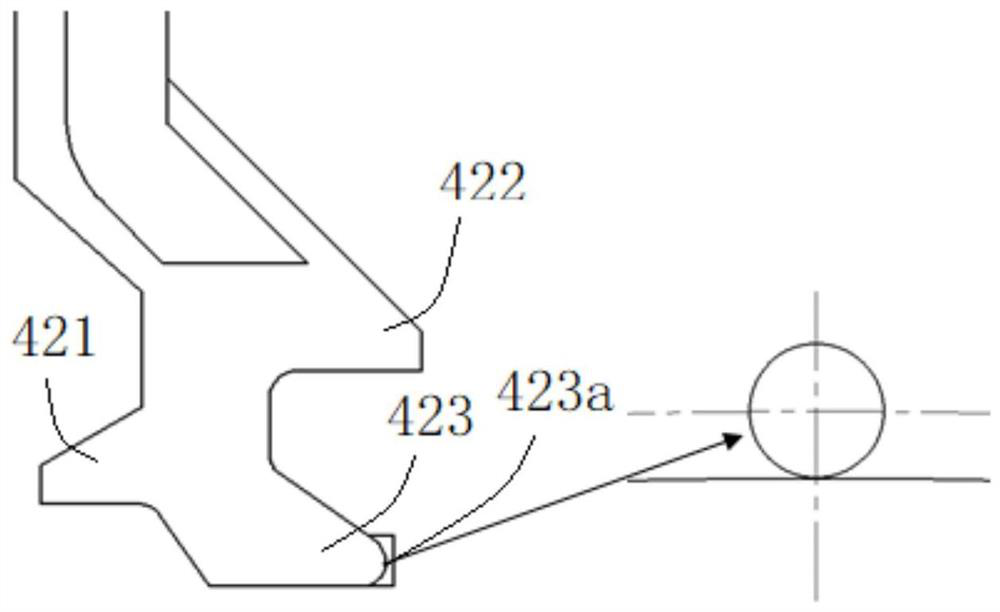

Bearing for belt pulley of high-speed low-torque tensioner

PendingCN113389813AImprove adsorption capacityReduce torqueEngine sealsRolling contact bearingsEngineeringSteel ball

The invention discloses a bearing for the belt pulley of a high-speed low-torque tensioner. The bearing comprises a bearing body, the bearing body is axially provided with a bearing inner ring and a bearing outer ring, and the bearing inner ring is provided with a first sealing ring mounting groove and a first steel ball mounting groove; a second sealing ring mounting groove and a second steel ball mounting groove are sequentially formed in the bearing outer ring; a sealing ring is arranged in a sealing cavity formed among the bearing inner ring, the bearing outer ring and a retainer; a framework is arranged in the sealing ring, the shape of the framework is matched with that of the retainer, the sealing ring is provided with a first sealing inner lip, a second sealing inner lip and a third sealing inner lip, and a bulge is arranged at the contact end of the third sealing inner lip; the sealing outer lip is in contact sealing with the second sealing ring mounting groove; and the outer wall of the bearing outer ring is provided with a knurling-shaped protruding part and an N-shaped groove. Torque and temperature rise can be reduced, and the phenomena of sliding of the sealing ring and falling of the sealing ring and outer ring accessories are improved.

Owner:广德中隆轴承有限公司

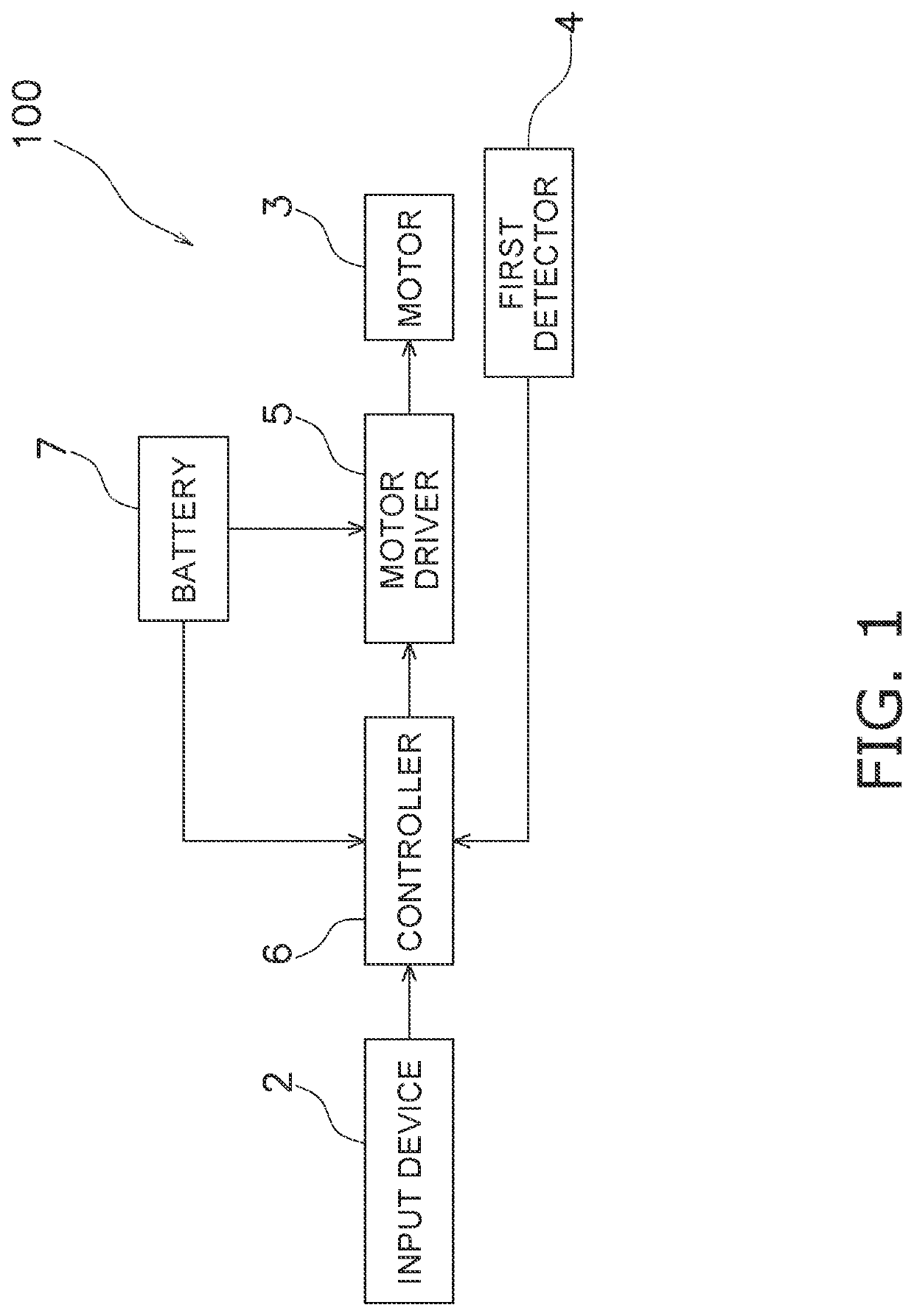

Drive unit

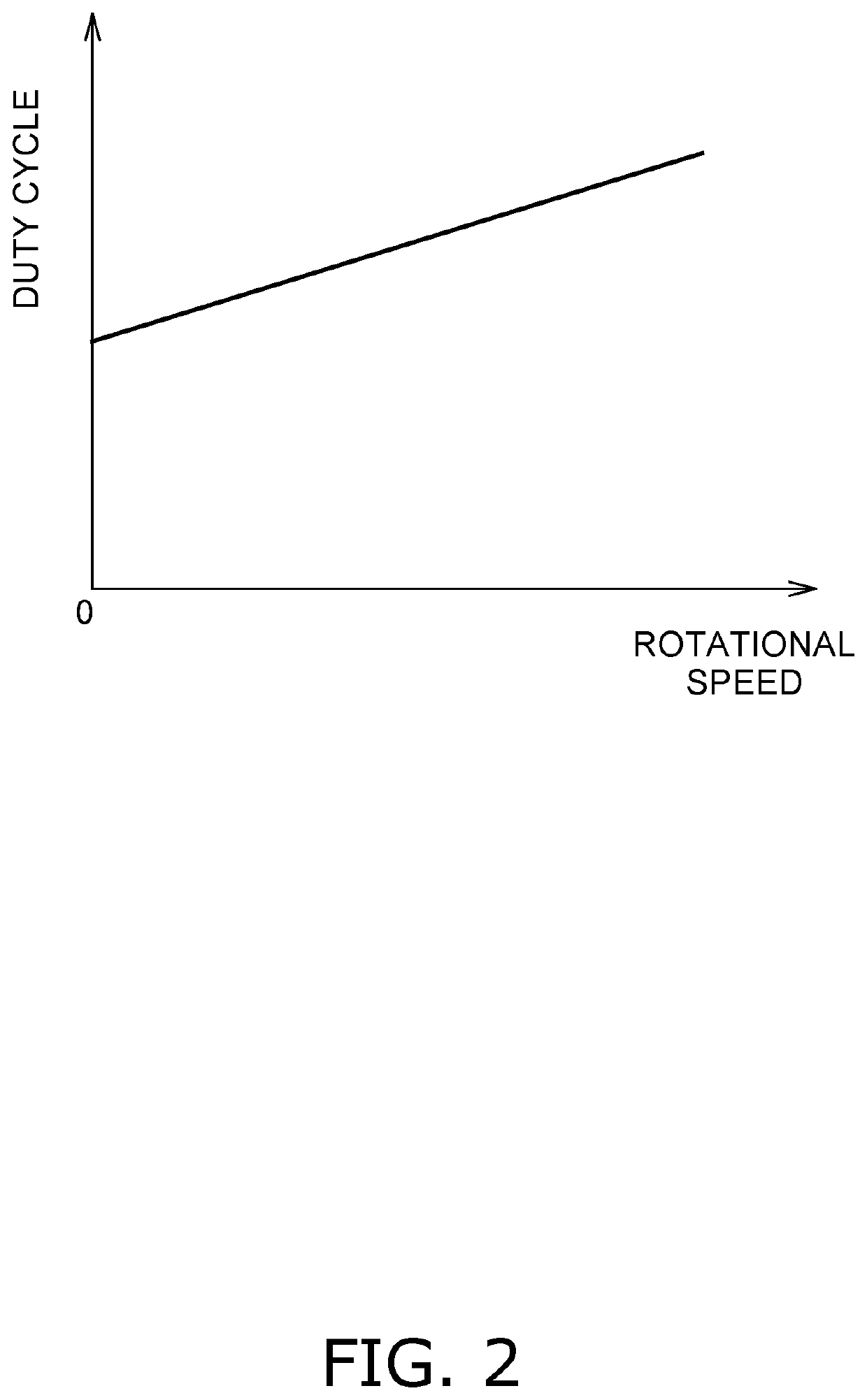

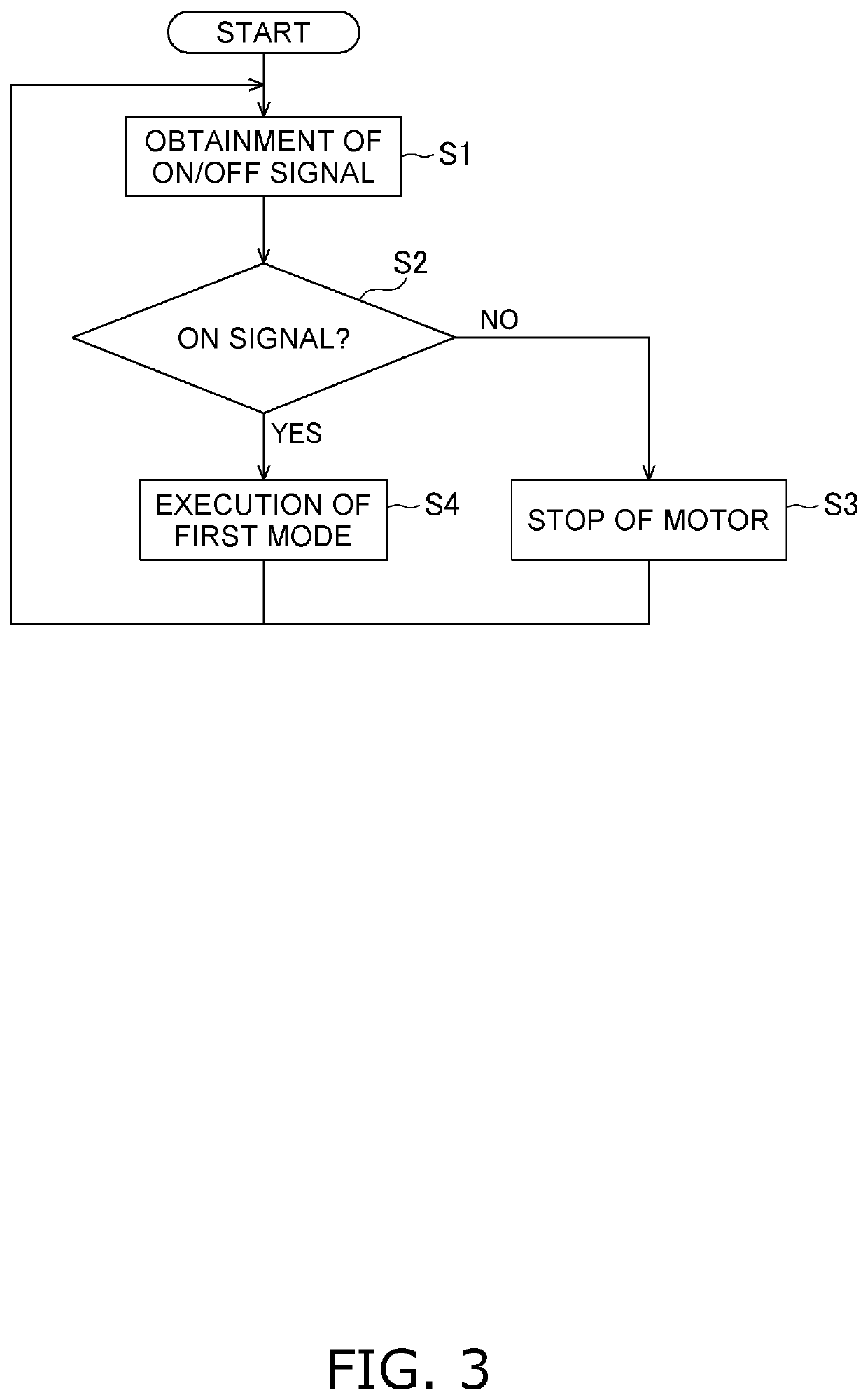

ActiveUS20220006402A1Improve slippagePrevent reduction in maximum rotational speed of motorSpeed controllerAC motor controlInformation controlMobile entity

A drive unit attached to a mobile entity is disclosed. The drive unit includes a motor, a first detector, and a controller. The first detector detects vehicle speed information regarding a vehicle speed of the mobile entity. The controller performs PWM control for the motor. The controller controls a duty cycle of a PWM signal in accordance with the vehicle speed information detected by the first detector.

Owner:EXEDY CORP

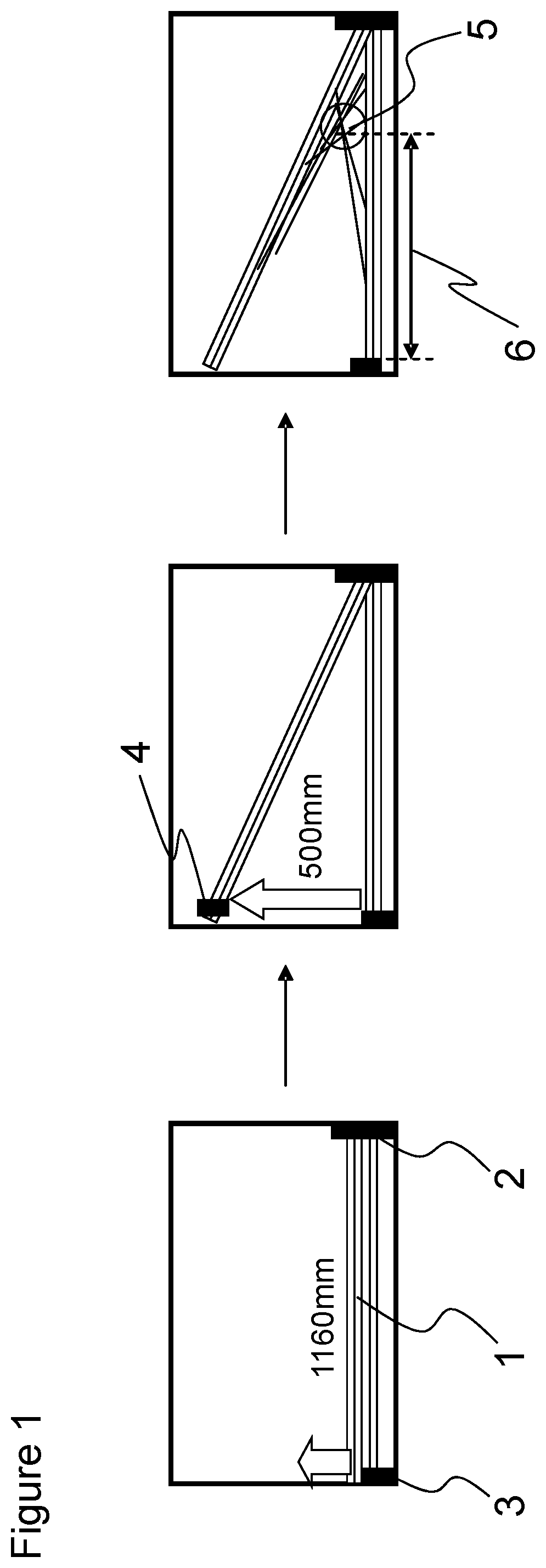

Door slider with V-shaped transmission structure

ActiveCN106522730AIncrease contact areaIncrease the maximum powerPower-operated mechanismReciprocating motionEngineering

The invention discloses a door slider. The door slider comprises a rotating wheel arranged on a drive device and a moving bar arranged on a door, wherein the drive device is used for driving the rotating wheel to rotate; and the rotating wheel and the moving bar realize connection through the matching between a groove and a bulge and then realize reciprocating motion of the moving bar. A transmission structure carries out power transmission through the groove and a structure matched with the groove, thus a transmission surface between the groove and the structure is expanded, then the maximum transmission force is increased, and finally the maximum transmission force between the groove and the structure is increased. Therefore, the transmission structure is capable of transmitting a heavier door without a slip phenomenon.

Owner:SHANGHAI YANGYANG DADUOLI HARDWARE PROD CO LTD

Torque vector control method for distributed drive electric vehicles based on double-layer control

ActiveCN109606133BImprove driving stabilityEasy rideSpeed controllerElectric energy managementVehicle dynamicsDrive wheel

The invention discloses a distributed driving electric automobile torque vector control method based on double-layer control. The control method comprises the following steps: establishing a vehicle dynamic model, and calculating a tire slip rate by utilizing a Dugoff tire model; establishing a torque distribution controller based on the vehicle dynamic model and the Dugoff tire model, wherein thetorque distribution controller comprises an upper controller and a lower controller; calculating the current drive torque of each driving wheel of the vehicle by the upper controller according to body yawing angular velocity; calculating a compensating torque needed for remaining an ideal slip rate of each driving wheel by the lower controller according to the ideal slip rate of each driving wheel serving as a control objective, and further performing compensation distribution on the driving torque, so that an actual torque is output to the driving wheel, and torque vector control is completed. According to the control method disclosed by the invention, the automobile torque can be effectively subjected to vector distribution, the vehicle driving stability and smoothness are improved, theoperating burden of the driver is obviously decreased, and the driving safety is improved.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

light rail bogie

The invention discloses a light rail bogie, which comprises a wheel frame, a wheel mounted on the wheel frame, a power assembly for driving the wheel to rotate, and a climbing auxiliary assembly connected to the front end and / or rear end of the wheel frame. The assembly includes a climbing auxiliary bracket mounted on the wheel frame in a vertically swingable manner, and a climbing auxiliary wheel rotationally fitted on the climbing auxiliary bracket. The climbing auxiliary bracket of the present invention can be driven to swing vertically, and when the light rail is climbing or descending, the climbing auxiliary bracket can be swung downward, so that the climbing auxiliary wheels are pressed above the rail to increase the distance between the rail and the rail. Friction, improve the wheel slipping phenomenon, improve the stability of light rail operation, and prevent safety accidents caused by skidding. When the light rail is running horizontally, the climbing auxiliary bracket swings upwards to make the climbing auxiliary wheel overhead above the track. At this time, the climbing auxiliary wheel Separated from the track to reduce running resistance.

Owner:李富盈

Fluorescent clothes drying pole

InactiveCN108625125ASimple structureEasy to dryLighting elementsOther drying apparatusEngineeringSlip and fall

The invention provides a fluorescent clothes drying pole. The pole comprises a pole body and groove openings distributed on the pole body, and the groove openings are coated with fluorescent paint. Hanging object positions are limited by utilizing the groove openings on the pole body, the groove openings are coated with the fluorescent paint, the problems that hanging objects on an original clothes drying pole can easily slip and fall, when faced with breeze, the hanging objects can gather together, so that the hanging objects are dried inconveniently, and the dried objects are inconvenientlyhung are solved. The drying pole has the advantages that the structure is simple, drying is convenient, the hanging objects cannot easily slip and fall, the visual effect is good, and to-be-dried objects can be hung accurately.

Owner:熊家双

A V-shaped transmission structure door shifter

ActiveCN106522730BIncrease contact areaIncrease the maximum powerPower-operated mechanismElectric power transmissionReciprocating motion

Owner:SHANGHAI YANGYANG DADUOLI HARDWARE PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com