Road grader front wheel auxiliary driving electro-hydraulic control system and road grader

An electro-hydraulic control system and auxiliary drive technology, applied in mechanically driven excavators/dredgers, earthmovers/shovels, construction, etc., can solve problems affecting construction efficiency, wheel slippage, etc., and improve construction efficiency , strong practicability, flexible control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

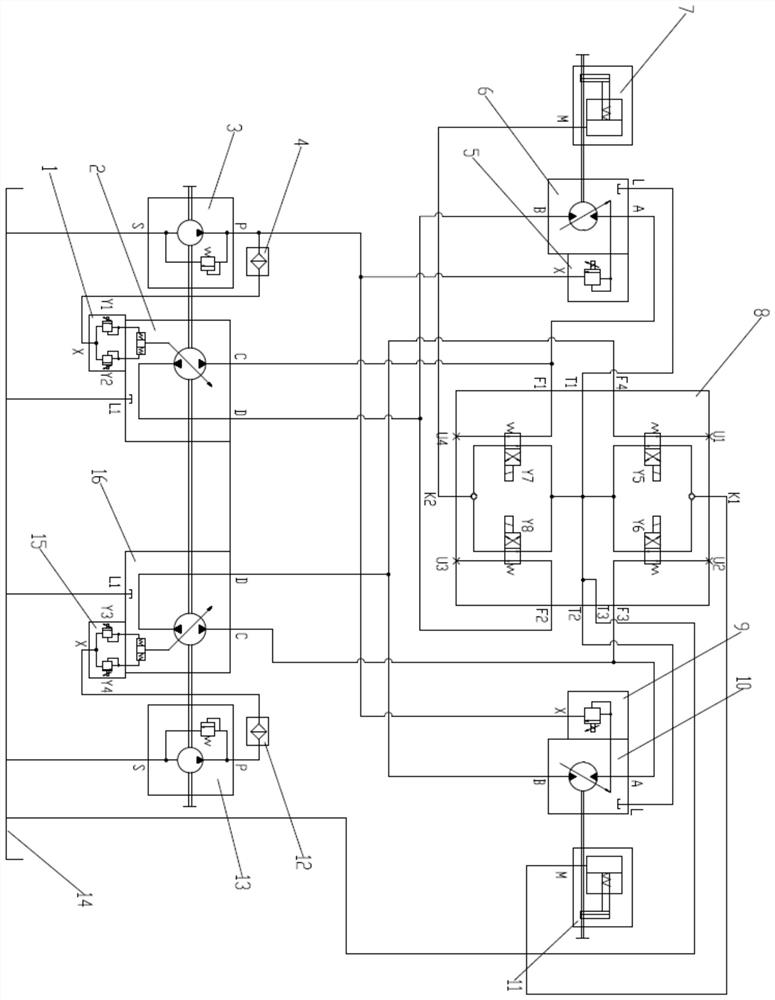

[0017] like figure 1 As shown, an electro-hydraulic control system for front wheel auxiliary drive of a motor grader, including a left front plunger pump control valve 1, a left front plunger pump 2, a left front charge oil pump 3, a left front filter 4, a left front motor control valve 5, and a left front motor 6 , left front reducer 7, front drive control valve 8, right front motor control valve 9, right front motor 10, right front reducer 11, right front filter 12, right front charge oil pump 13, hydraulic oil tank 14, right front plunger pump control valve 15 and right front column Plug pump 16 etc. parts. Through the connection of various components, the front wheel auxiliary drive hydraulic circuit is finally formed to provide driving force for the front wheels of the vehicle.

[0018] The S port of the left front charge pump 3 is connected to the hydraulic oil tank 14, and the P port is respectively connected to one end of the left front filter 4, the X port of the lef...

Embodiment 2

[0025] A motor grader. The front wheels of the motor grader described in this embodiment are equipped with the electro-hydraulic control system for the auxiliary drive of the motor grader front wheels described in Embodiment 1. The output shaft of the left front reducer 7 is connected to the left front wheel of the motor grader, and the right front The output shaft of speed reducer 11 connects the right front wheel of motor grader.

[0026]In the first working mode, the left front motor 6 drives the left front wheel of the grader through the left front reducer 7; the right front motor 10 drives the right front wheel of the grader through the right front reducer 11; the rear wheel of the grader is in neutral state; The machine as a whole is driven by two front wheels to achieve a two-wheel drive state. In the second working mode, the left front motor 6 drives the left front wheel of the grader through the left front reducer 7; the right front motor 10 drives the right front whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com