Novel radian-controllable carrier roller

A controllable, idler technology, applied in the direction of rollers, conveyors, conveyor objects, etc., can solve the problems of large diameter of conveyor idlers, reduced belt service life, uneven force, etc., to solve idler rollers Reduced service life or belt life, saving manufacturing costs, and facilitating assembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

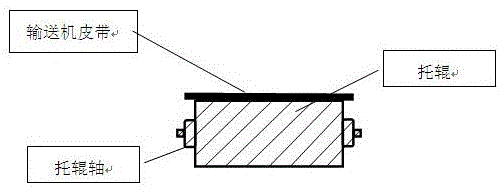

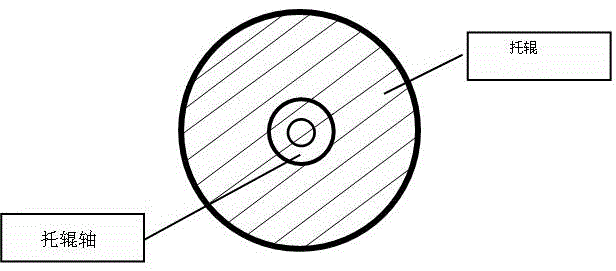

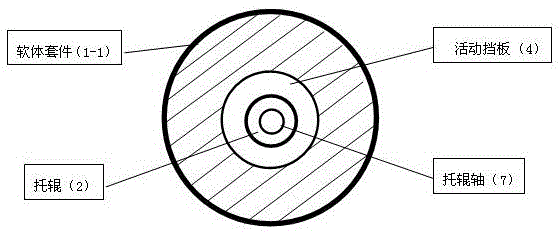

[0016] Now, preferred embodiments of the present invention will be described in detail by referring to the accompanying drawings so that those embodiments can be easily realized by those having ordinary skill in the art to which the present invention pertains. However, the present invention can also be realized in various forms, so the present invention is not limited to the embodiments described hereinafter.

[0017] as reference image 3 As shown, when using the belt conveyor, first put a movable baffle (4) on one end of the idler shaft (4) and fix it with a fastening clip (5) to prevent the movable baffle (4) from falling off. Fixing nails (5) can be directly wedged or screw fastened; then compare the two ends of the idler roller (2) with multiple soft wear-resistant sets (1-1), and the two ends are large and the middle is small. Sequentially put them on the idler roller (2), because the surface of the idler roller (2) is embossed, and the middle hollow diameter of the sof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com