Prefabricated reinforced concrete beam-column edge joints

A technology of reinforced concrete beams and reinforced concrete columns, which is applied in the field of prefabricated building components, can solve the problems of not giving full play to the advantages of prefabricated structures, small joint construction operation space, performance and quality limitations, etc., to improve construction speed and production efficiency , Convenience in construction and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

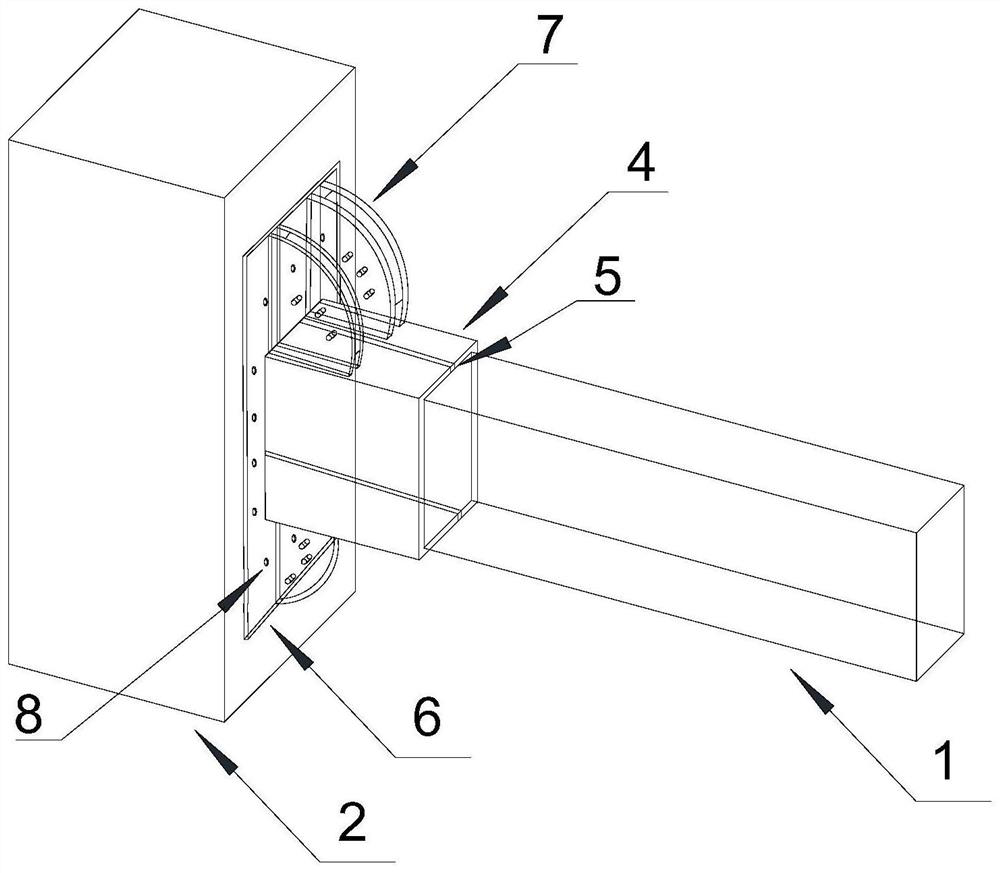

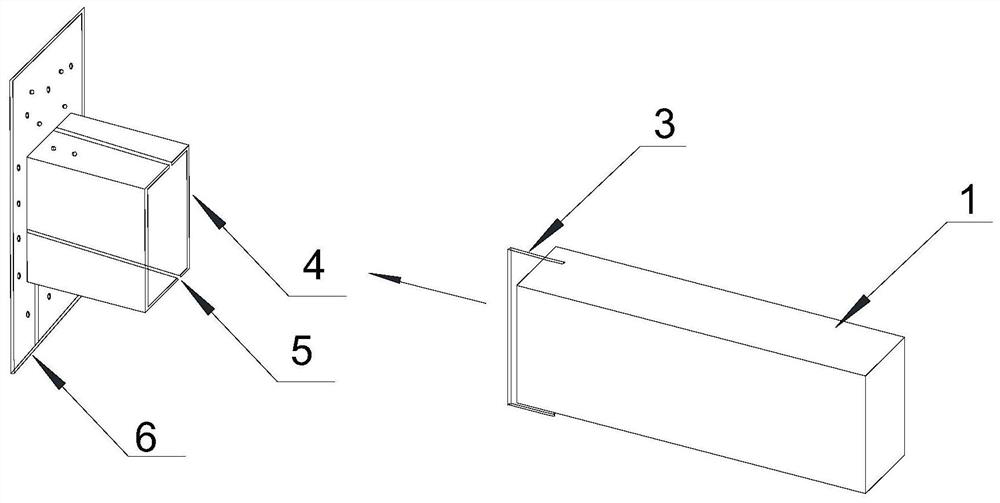

[0023] Such as figure 1 , 2 As shown, the prefabricated reinforced concrete beam-column edge node of the present invention is used to connect the prefabricated reinforced concrete beam 1 and the reinforced concrete column 2 .

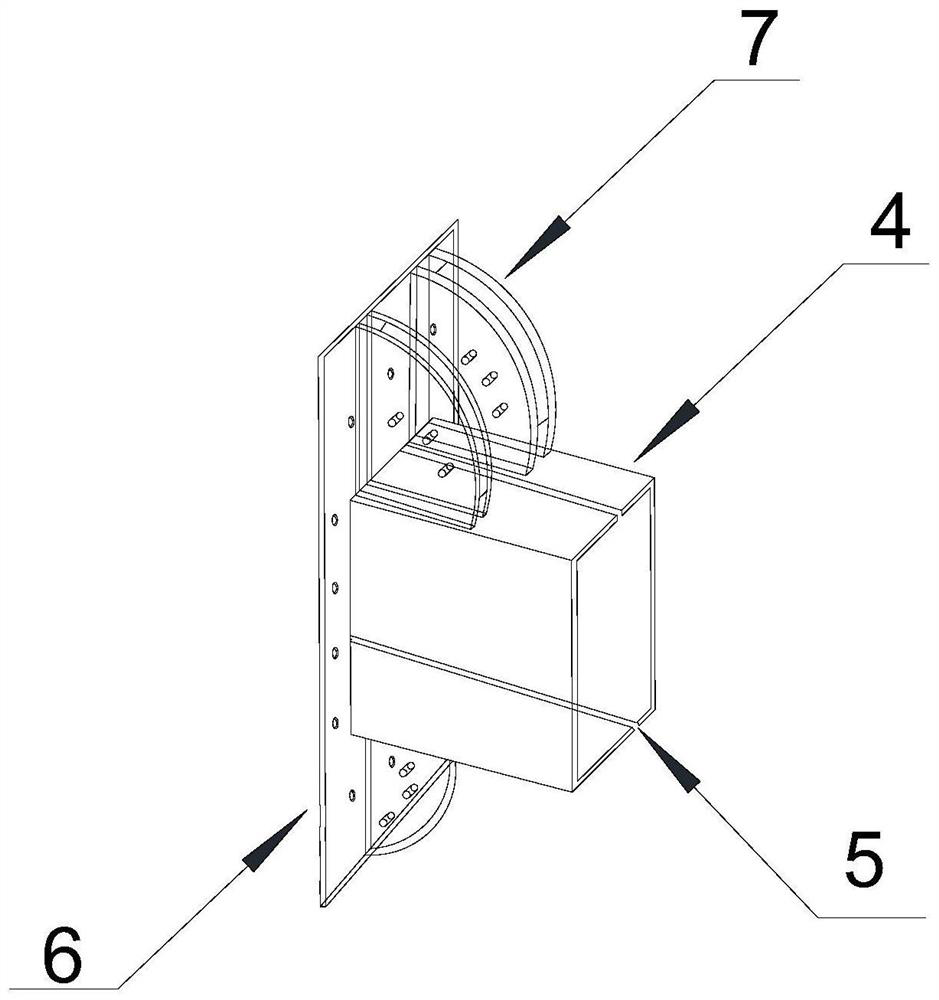

[0024] The prefabricated assembled reinforced concrete beam-column side joint of the present invention includes a column wall steel plate 6 that is detachably fixedly connected to the side of the reinforced concrete column 2 and a steel sleeve 4 that is fixedly connected to the front of the column wall steel plate 6 at one end;

[0025] The inner diameter of the steel sleeve 4 matches the outer diameter of the prefabricated reinforced concrete beam 1;

[0026] At least one side wall of the steel sleeve 4 is provided with a longitudinal notch 5, and the prefabricated reinforced concrete beam 1 is provided with a pre-embedded steel plate 3 near the end, and the pre-embedded steel plate 3 protrudes from the side wall of the prefabricated reinforced concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com