Automatic bucket holding device based on automatic positioning

An automatic positioning and displacement technology, applied in the field of trash can cleaning, can solve problems such as slippage, slippage of the outer wall of the trash can, slipping of the trash can, etc., and achieve the effect of meeting large batches, facilitating standardization, and locking stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

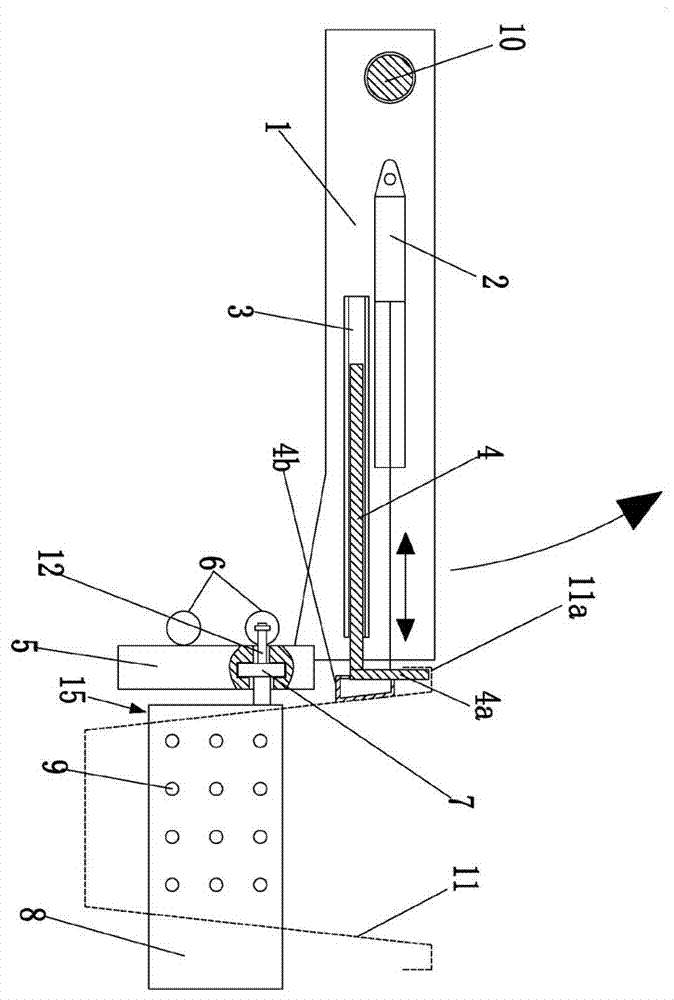

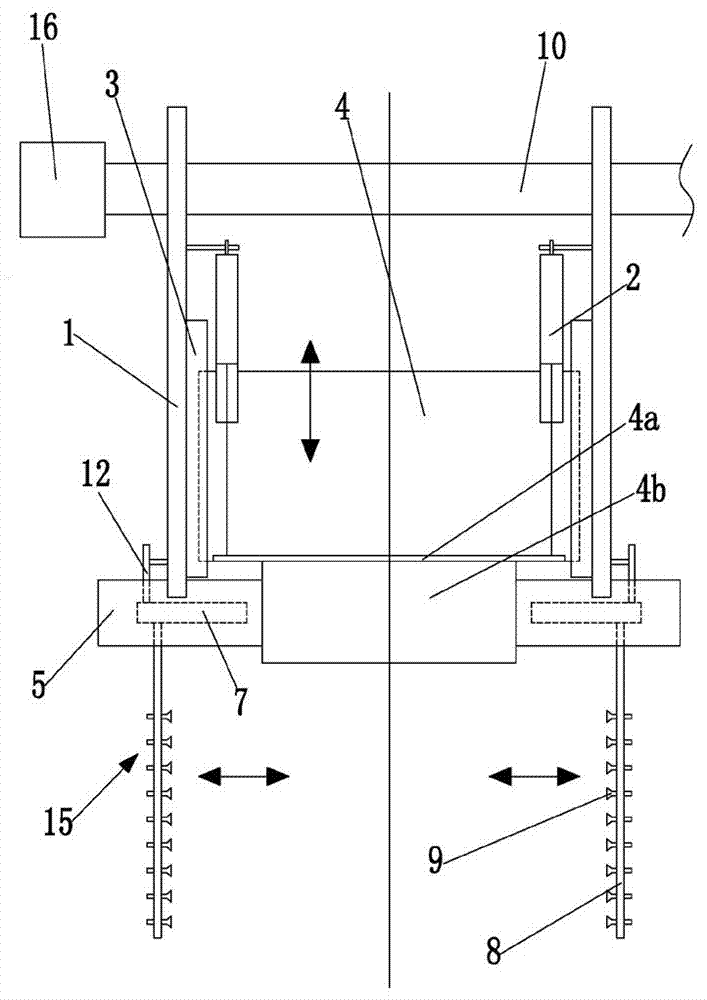

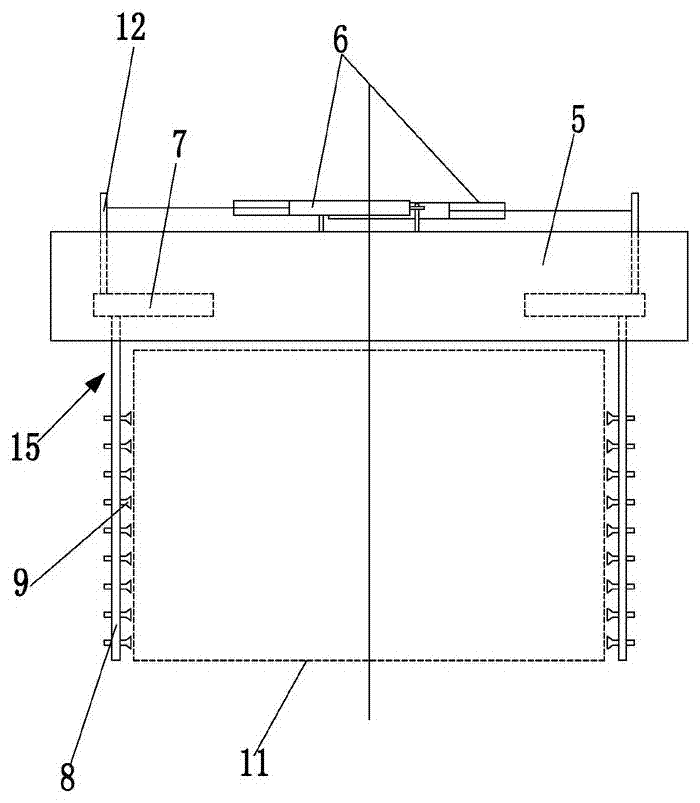

[0022] to combine figure 1 , 2 As shown, an automatic barrel holding device based on automatic positioning includes a rotary drive mechanism 16, an overturning main shaft 10 controlled by the rotary drive mechanism 16, an overturning frame 1 mounted on the overturning main shaft 10, and a The clamping unit of the trash can 11 arranged on the flip frame 1 also includes a negative pressure adsorption unit, a vacuum generator 14 connected with the negative pressure adsorption unit, and an automatic positioning mechanism for limiting the position of the trash can 11 .

[0023] The above-mentioned clamping unit includes a clamping seat 5 fixed on the flip frame 1, and also includes a pair of clamping seats 5 that are oppositely arranged on the clamping seat 5 and are used to hug the outer wall of the trash can 11 and are movable on the clamping seat 5. The movable clamping part 15 and the negative pressure adsorption unit are installed on the two movable clamping parts 15 cooperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com