Thin wall embedded self-lubricating bearing and manufacturing method thereof

A self-lubricating bearing, thin-walled technology, applied in the direction of bearing components, shafts and bearings, lubricating compositions, etc., can solve the problems of complex manufacturing process, complex production process and high product cost, achieve small size, reduce cost, and simplify production. The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

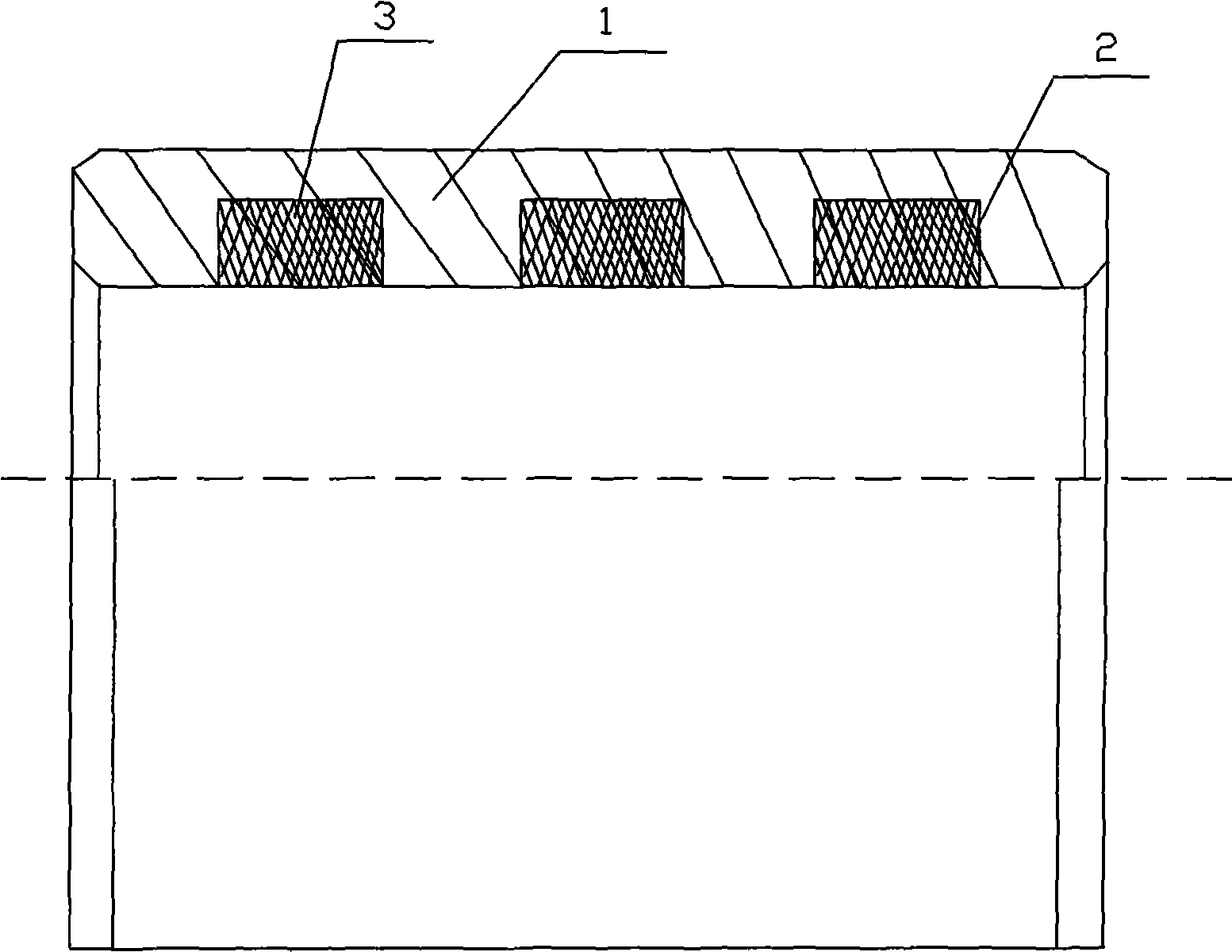

[0021] Such as figure 1 As shown, a thin-wall embedded self-lubricating bearing includes a plate 1, blind holes 2 are evenly distributed on the working surface of the plate 1, and solid lubricant 3 is embedded in the blind holes 2.

[0022] When the service temperature of the bearing is below 250°C, the parts by weight of the components of the solid lubricant 3 are:

[0023] PTFE 92 Lead powder 6 Molybdenum disulfide 2

[0024] Mix powdered polytetrafluoroethylene, lead powder and molybdenum disulfide according to the above weight ratio, extrude and sinter at a temperature of 460°C to make a solid lubricant used when the temperature is below 250°C Agent 3.

[0025] When the service temperature of the bearing is between 250°C and 400°C, the parts by weight of the components of the solid lubricant 3 are:

[0026] Flake graphite 98 Molybdenum disulfide 2

[0027] Mix powder flake graphite and molybdenum disulfide according to the above weight ratio, extrude and sinter at a te...

Embodiment 2

[0033] Such as figure 1 As shown, a thin-wall embedded self-lubricating bearing includes a plate 1, blind holes 2 are evenly distributed on the working surface of the plate 1, and solid lubricant 3 is embedded in the blind holes 2.

[0034] When the service temperature of the bearing is below 250°C, the parts by weight of the components of the solid lubricant 3 are:

[0035] PTFE 90 Lead powder 8 Molybdenum disulfide 2

[0036] Mix powdered polytetrafluoroethylene, lead powder and molybdenum disulfide according to the above weight ratio, extrude and sinter at a temperature of 460°C to make a solid lubricant used when the temperature is below 250°C Agent 3.

[0037] When the service temperature of the bearing is between 250°C and 400°C, the parts by weight of the components of the solid lubricant 3 are:

[0038] Flake graphite 97 Molybdenum disulfide 3

[0039] Mix powder flake graphite and molybdenum disulfide according to the above weight ratio, extrude and sinter at a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com