Fuel tank cover module

A fuel tank cap and module technology, which is applied in the application of connecting components, vehicle parts, locks, etc., can solve the problems of large space and large workload, and achieve the effect of saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

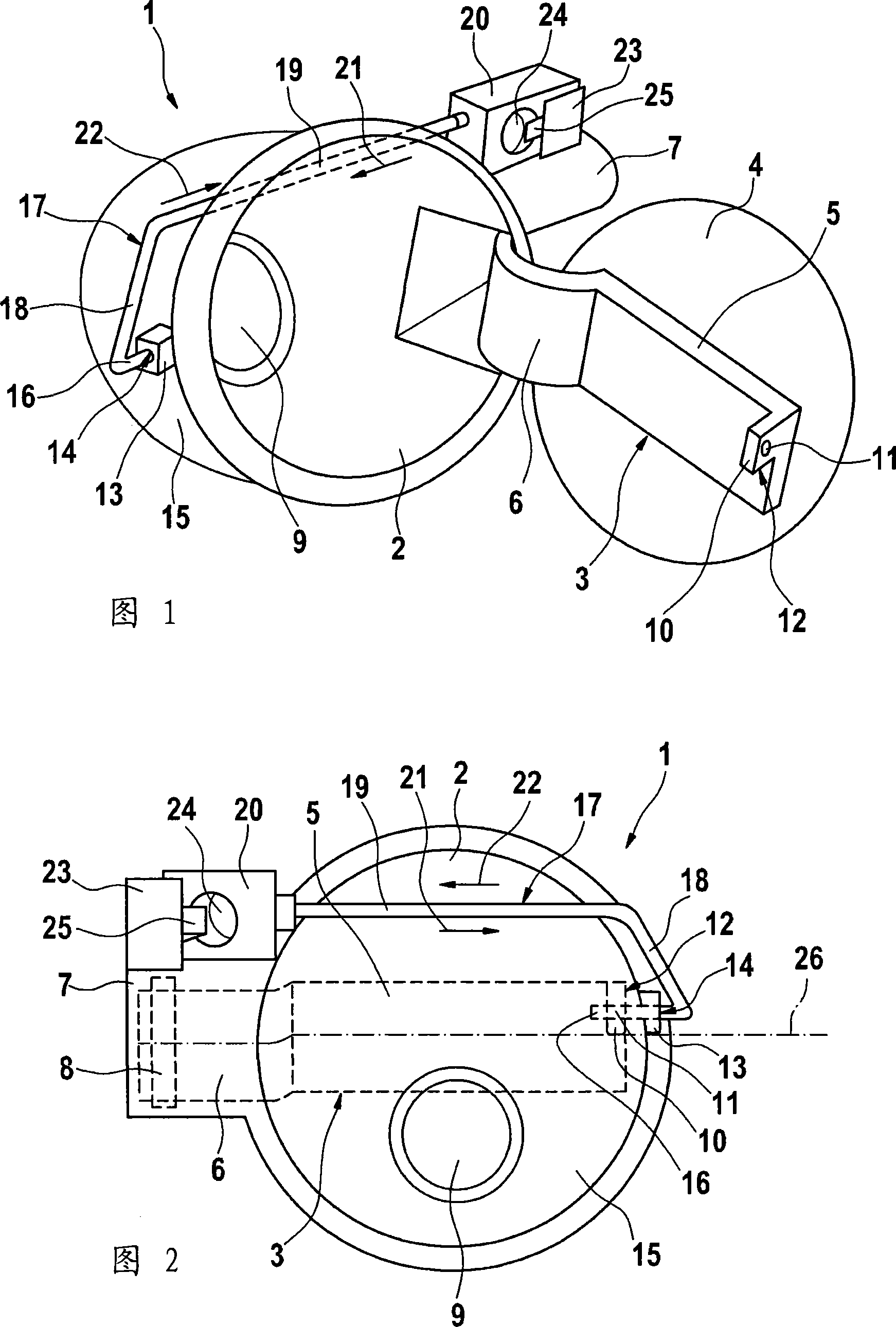

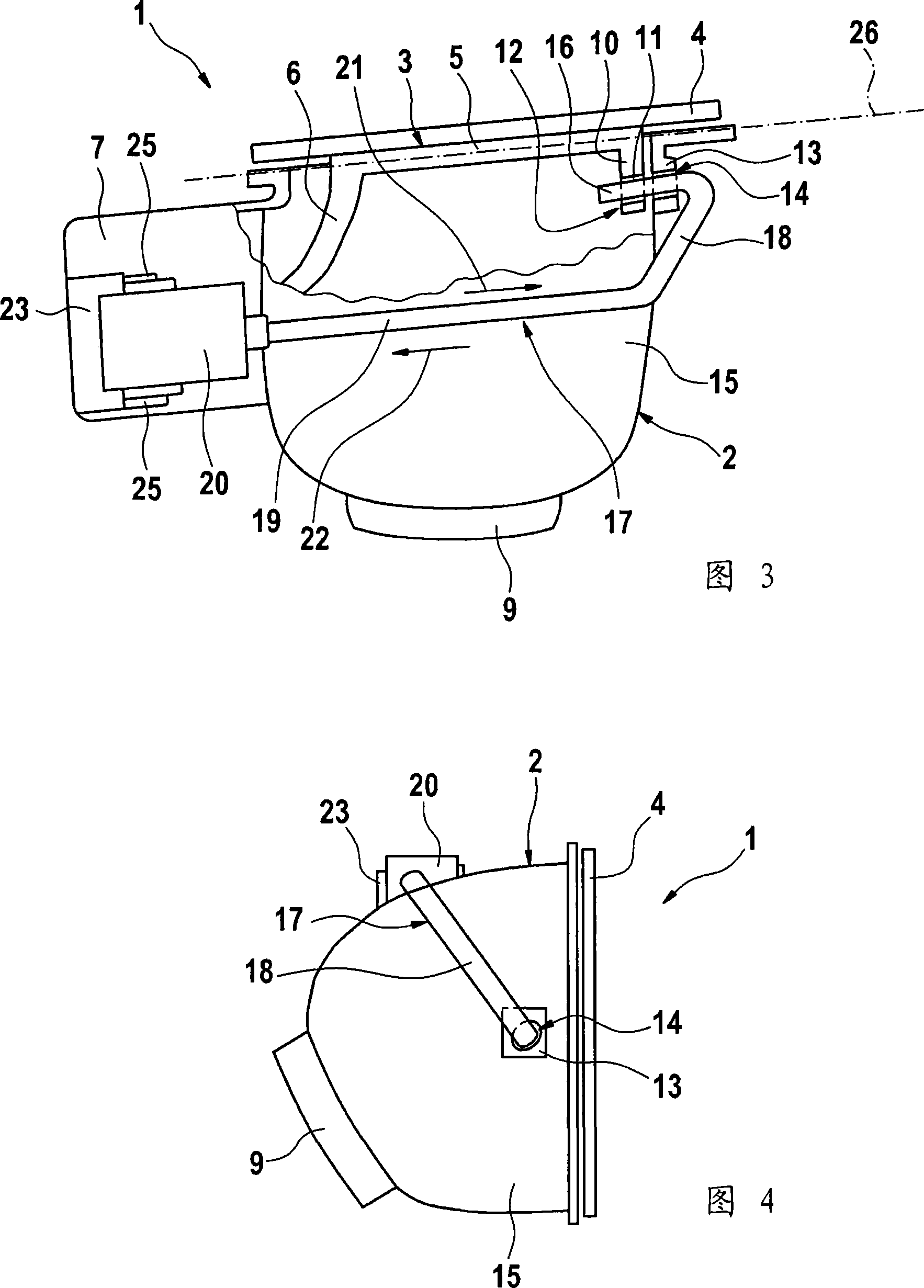

[0021] FIG. 1 shows a tank cover module 1, which comprises a module body 2 and a hinged arm 3 pivotally mounted on the module body 2, on which a fuel tank cover 4 is fastened.

[0022] The articulated arm 3 includes a longitudinal section 5 designed to install the fuel tank cover 4 and an arc section 6 connected thereto. The arc section 6 extends into the expansion shell 7 formed on the side of the module body 2 and can rotate around the axis of rotation. 8 (FIG. 2) is rotatably supported in the expansion housing.

[0023] Hole 9 is formed in the rear area of module body 2, and it is used for installing the oil tank filler connection that is not shown in the figure.

[0024] In the region of the free end of the articulated arm 3 is formed a projection 10 with a hole 11 which together forms a locking piece 12 .

[0025] A guide 13 with a guide hole 14 is arranged on the module body 2 substantially opposite the extension housing 7, the guide hole 14 passing through the wall 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com