Anti-skid method of milling machine and milling machine

A milling machine and anti-slip technology, which is applied in the field of milling machine control, can solve the problems of increasing the allowable difference between the instant speed of the track wheel and the reference value, the inability to accurately judge the anti-skid phenomenon, and the instability of the adjustment process, and achieve improvement. Slip phenomenon, enhance the anti-skid effect, avoid the effect of slip phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

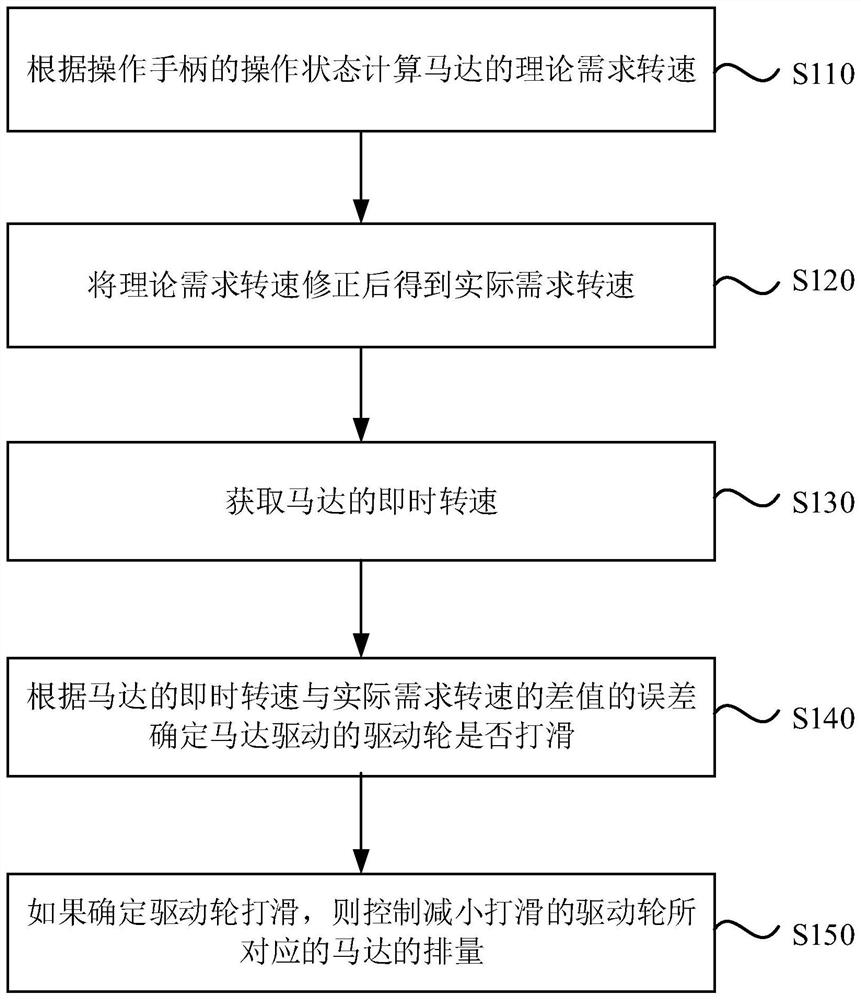

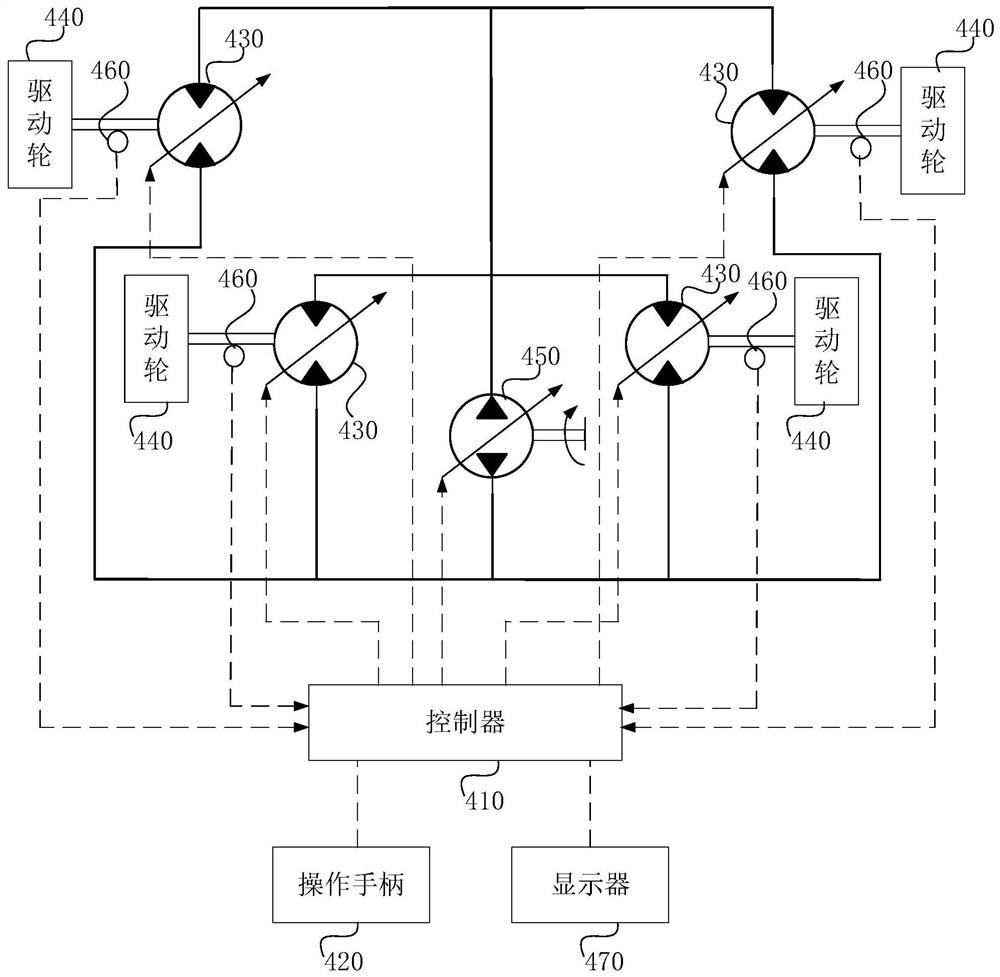

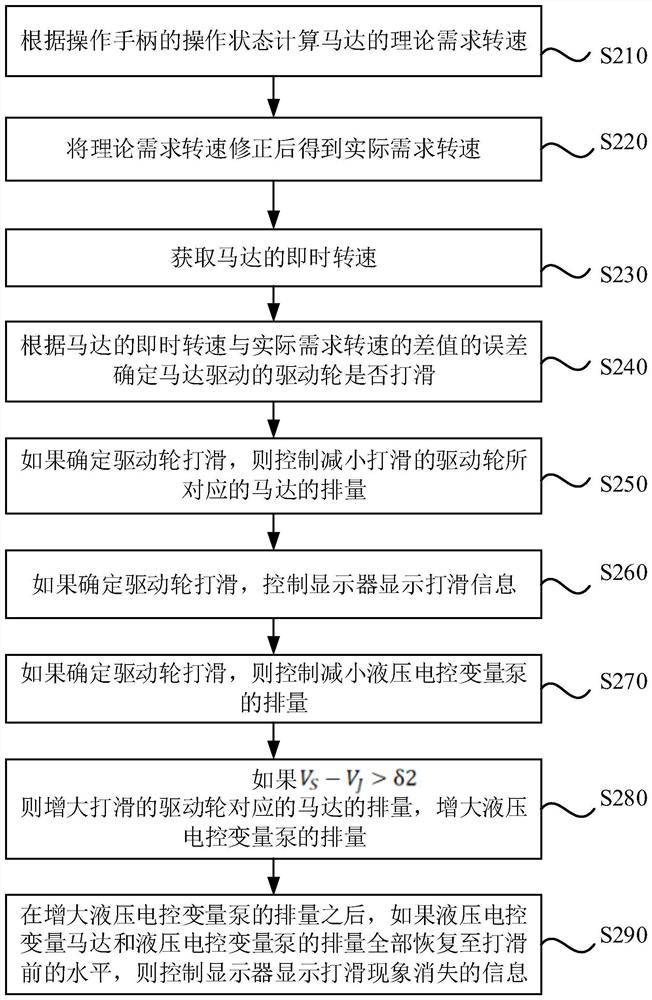

[0043] figure 1 It is a flow chart of a milling machine anti-skid method provided by an embodiment of the present invention, figure 2 It is a schematic structural diagram of a milling machine provided by the embodiment of the present invention. This embodiment is applicable to the situation of anti-skid of the milling machine. See figure 2 , The milling machine includes: a controller 410 , an operating handle 420 , a motor 430 , a driving wheel 440 , a hydraulic and electronically controlled variable pump 450 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com