Torque vector control method for distributed drive electric vehicles based on double-layer control

A technology for torque vectoring and electric vehicles, which is used in the control of drives, electric vehicles, control devices, etc., can solve the problems of complex operation of torque control algorithms, inability to distribute torque vector control, and increase the driver's burden on vehicle manipulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

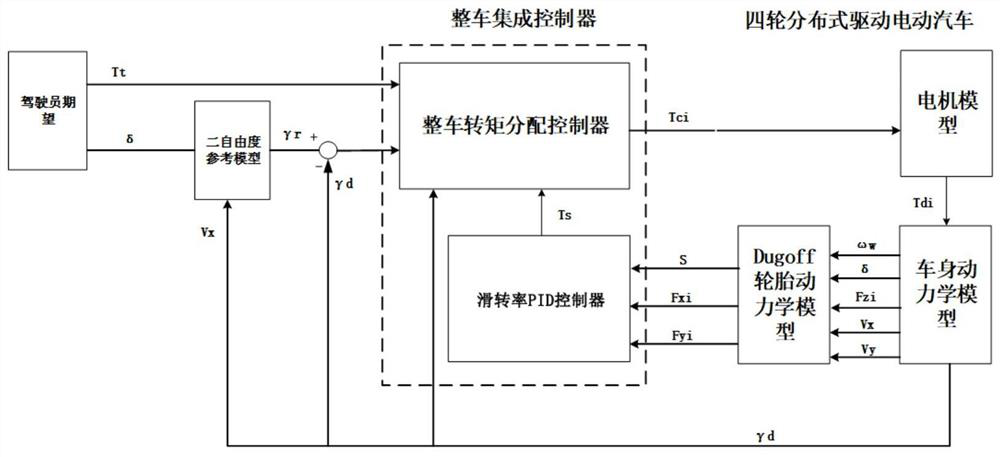

[0067] Embodiment: Torque vector control method for distributed drive electric vehicles based on double-layer control, as attached figure 1 shown, and follow the steps below:

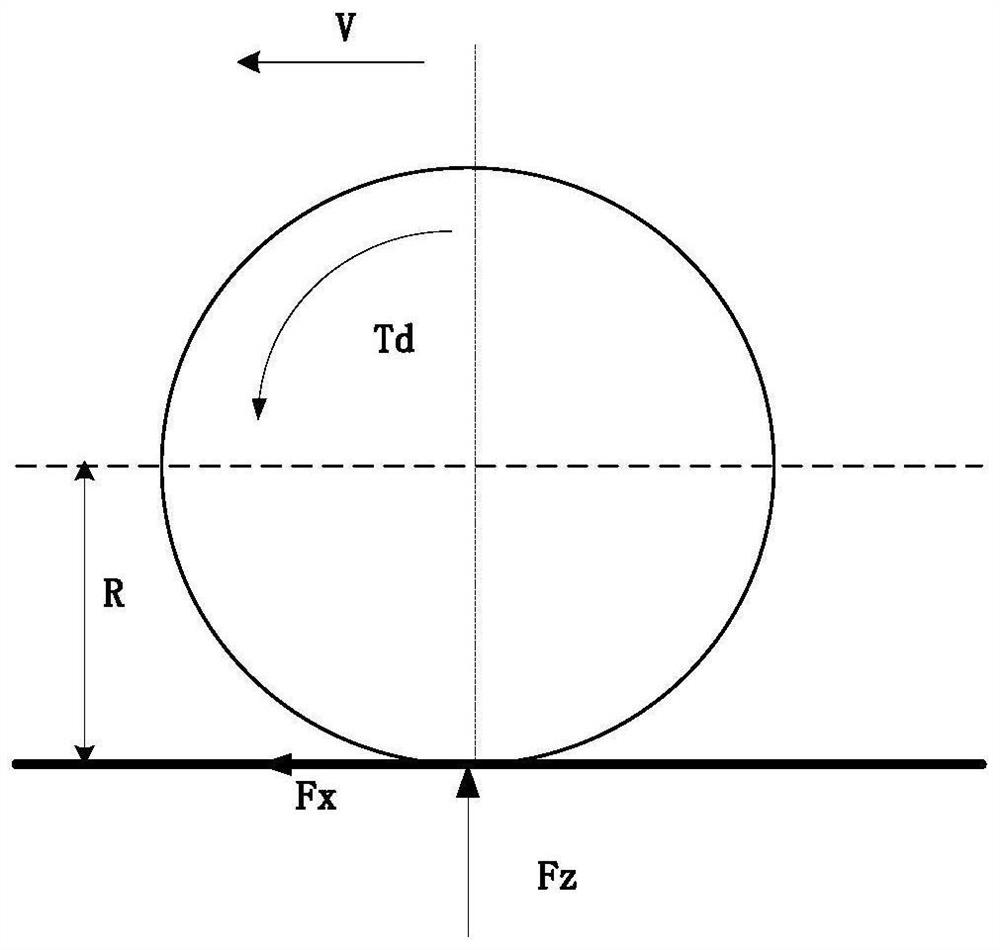

[0068] a. Establish a vehicle dynamics model to represent the stability of the vehicle's driving state, and use the Dugoff tire model to calculate the tire slip rate;

[0069] The vehicle dynamics model includes a two-degree-of-freedom vehicle dynamics model; the mathematical model of the two-degree-of-freedom vehicle dynamics model is:

[0070]

[0071] in: h β =C F +C R ;H δ =-C F ;

[0072] G β = a C F -b C R ;G δ =-C F ;

[0073] Where: ω r is the desired yaw rate, δ is the front wheel rotation angle, C F is the front wheel cornering stiffness, C R is the cornering stiffness of the rear wheel, a and b are the distances from the center of mass to the front and rear axles, respectively.

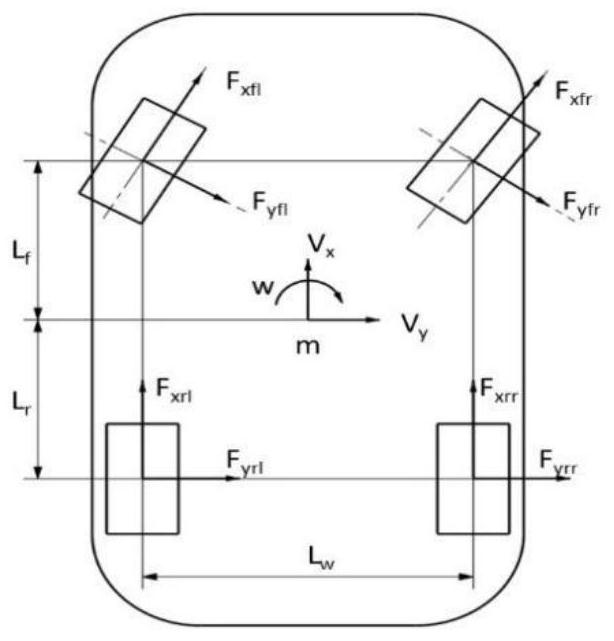

[0074] as attached figure 2 As shown, the vehicle dynamics model also includes a seven-de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com