Facade anti-skid waterproof coating composition and application thereof, coating and preparation method and application thereof

A technology of waterproof coatings and compositions, applied in the direction of asphalt coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor sag resistance, poor composite effect of coils and coatings, etc., and achieve improved slippage Phenomenon, high peel strength and shear strength, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Exemplarily, the present invention provides a method for preparing self-made SBS elastomer modified anionic emulsified asphalt comprising: mixing base asphalt, rubber oil, SBS elastomer, and anionic emulsifier to obtain an asphalt mixture; mixing a stabilizer, a pH regulator Dissolve in water, heat to obtain an aqueous solution containing a stabilizer, then emulsify the asphalt mixture and the aqueous solution containing a stabilizer through a colloid mill, and cool the discharge to obtain SBS elastomer modified anionic emulsified asphalt; It is prepared by mixing commercially available SBS latex with commercially available emulsified asphalt. The present invention has no special restrictions on the types and amounts of raw materials involved in the aforementioned self-made methods, and those skilled in the art can obtain them using the types and amounts known in the art. Some specific types of raw materials are exemplarily provided later in the present invention And th...

Embodiment 1

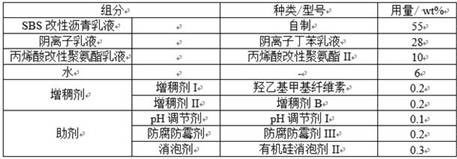

[0110] The formulation of this example is shown in Table 1.

[0111] Table 1

[0112]

[0113] Preparation method of coating:

[0114] S1: Mix the anionic emulsion and the acrylic modified polyurethane emulsion for the first time to obtain mixture I; wherein,

[0115] The conditions for the first mixing are: the temperature is 25°C, the stirring speed is 300rpm, and the time is 10min;

[0116] S2: In the presence of water, the thickener I is mixed with the mixture I for the second time to obtain the mixture II; wherein,

[0117]The second mixing conditions are as follows: the temperature is 25°C, the stirring speed is 700rpm, and the time is 10min;

[0118] S3: Mix the auxiliary agent with the mixture II for the third time to obtain the mixture III; wherein,

[0119] The third mixing condition is: the temperature is 25°C, the stirring speed is 700rpm, and the time is 5min;

[0120] S4: The thickener II is mixed with the mixture III for the fourth time to obtain the mix...

Embodiment 2

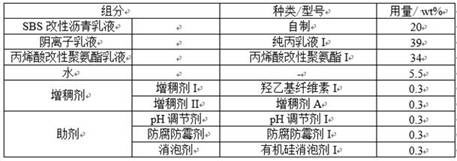

[0125] The formulation of this example is shown in Table 2.

[0126] Table 2

[0127]

[0128] Preparation method of coating:

[0129] S1: Mix the anionic emulsion and the acrylic modified polyurethane emulsion for the first time to obtain mixture I; wherein,

[0130] The conditions for the first mixing are: the temperature is 10°C, the stirring speed is 400rpm, and the time is 15min;

[0131] S2: In the presence of water, the thickener I is mixed with the mixture I for the second time to obtain the mixture II; wherein,

[0132] The second mixing conditions are as follows: the temperature is 35°C, the stirring speed is 600rpm, and the time is 10min;

[0133] S3: Mix the auxiliary agent with the mixture II for the third time to obtain the mixture III; wherein,

[0134] The third mixing condition is: the temperature is 10°C, the stirring speed is 600rpm, and the time is 10min;

[0135] S4: The thickener II is mixed with the mixture III for the fourth time to obtain the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com