A clamping device for valve body end surface processing

An end face processing and clamping device technology, applied in positioning devices, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of inconvenient processing work, inconvenient clamping, poor clamping effect, etc., and achieve good popularization. , easy to operate, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

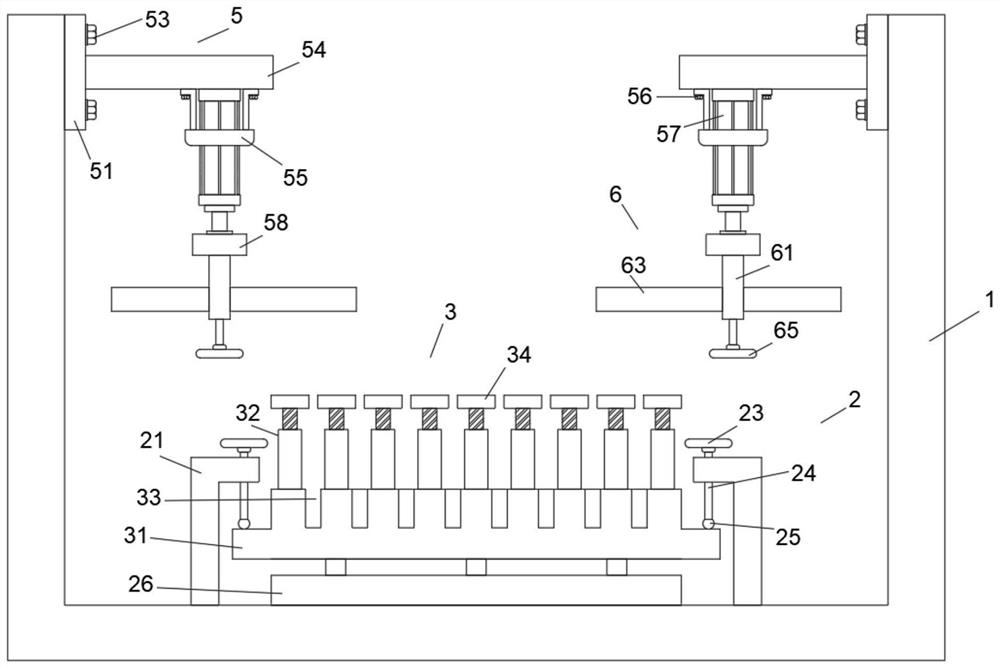

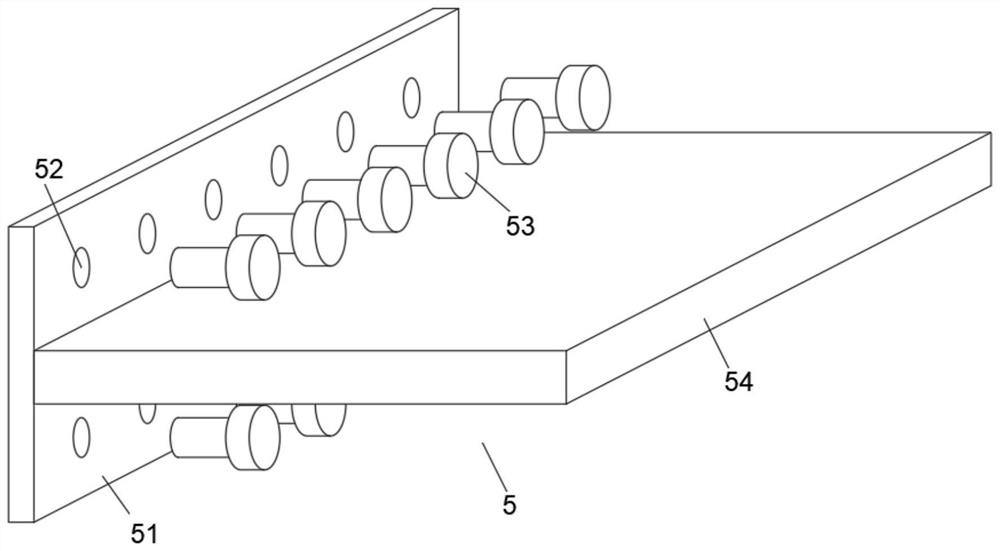

[0026] Embodiment 1: as Figure 1-6 As shown, this specific embodiment adopts the following technical solutions: a clamping device for valve body end surface processing, including a support frame 1, a rotation limiting mechanism 2 connected to the bottom of the support frame 1, and a fixing mechanism connected to the top of the rotation limiting mechanism 2 3. Two rows of connecting grooves 4 are dug through the top of the inner wall on both sides of the supporting frame 1, and the supporting frame 1 is respectively connected with supporting mechanisms 5 through the two rows of connecting grooves 4 on both sides, and the bottoms of the two supporting mechanisms 5 are connected with adjusting Agency 6;

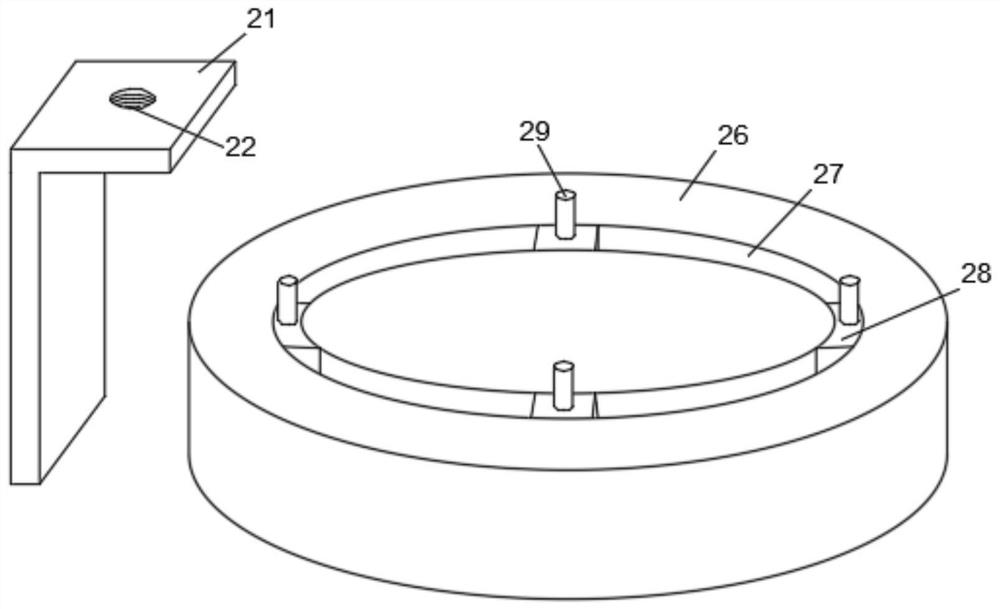

[0027] The rotation limiting mechanism 2 comprises two L plates 21, No. 1 thread groove 22, handle 23, threaded rod 24, No. 1 anti-slip block 25, base 26, chute 27, slide block 28 and support column 29, two L plates One end close to the top of 21 is drilled through a No. 1 thr...

Embodiment 2

[0038] Embodiment 2: In the present invention, the L plate 21, the No. 1 threaded groove 22, the handle 23, the threaded rod 24 and the No. 1 anti-skid block 25 can be replaced with two side plates, one end of the two side plates is connected to the supporting frame 1 through a torsion spring. The inner bottom end is connected, and the side walls of the other end of the two side plates are fixedly connected with anti-skid rubber pads. When rotating, the side plates are pulled open, and the side plates are rotated by the torsion spring. After turning the T-shaped seat 31, the side plates are released. The two side plates are reset by torsion springs, and the T-shaped seat 31 is limited by anti-skid pads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com