Vehicle frame welding device and welding method thereof

A frame welding and equipment technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of improving clamping comprehensiveness, improving welding efficiency and welding quality, and facilitating welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

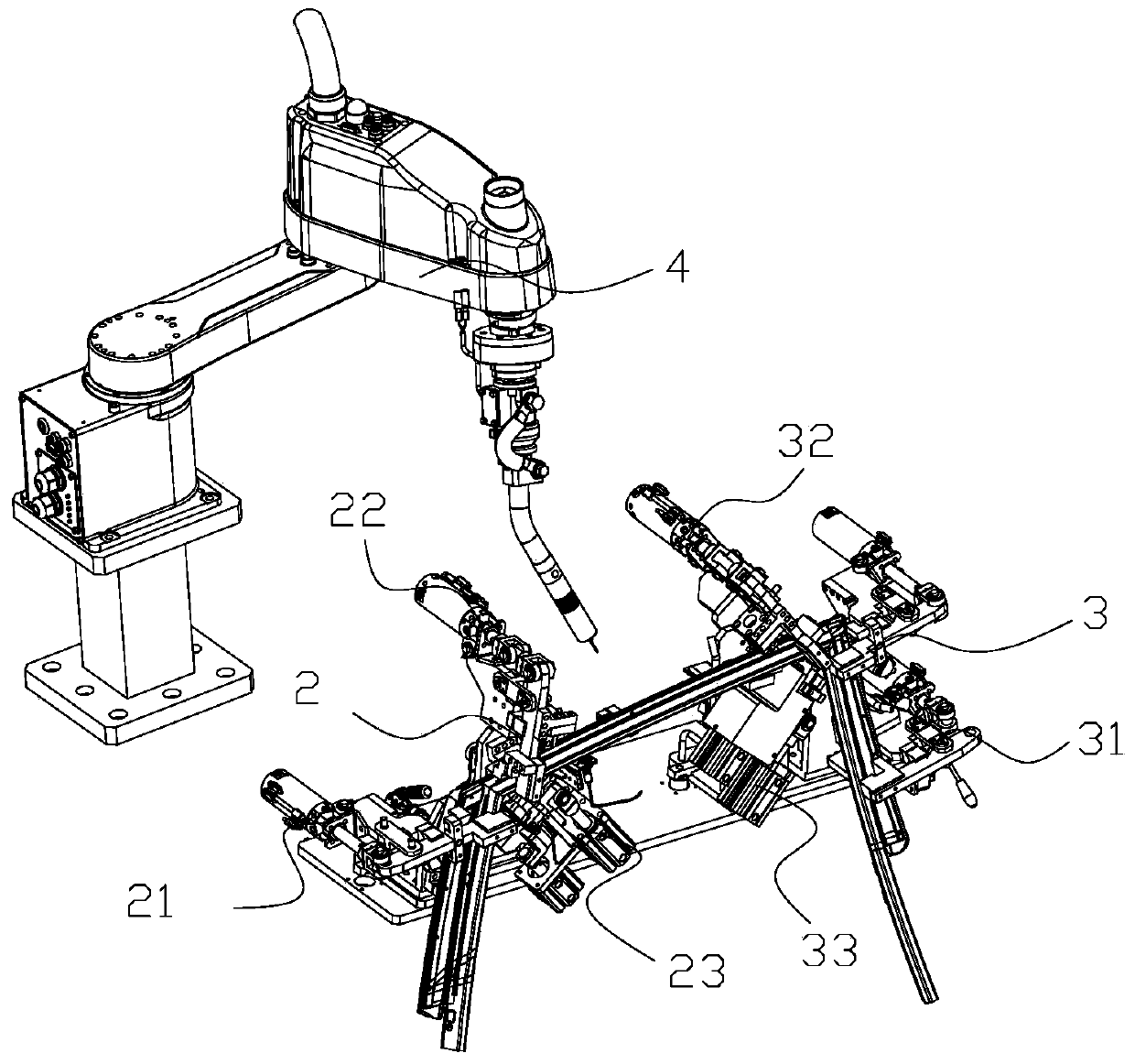

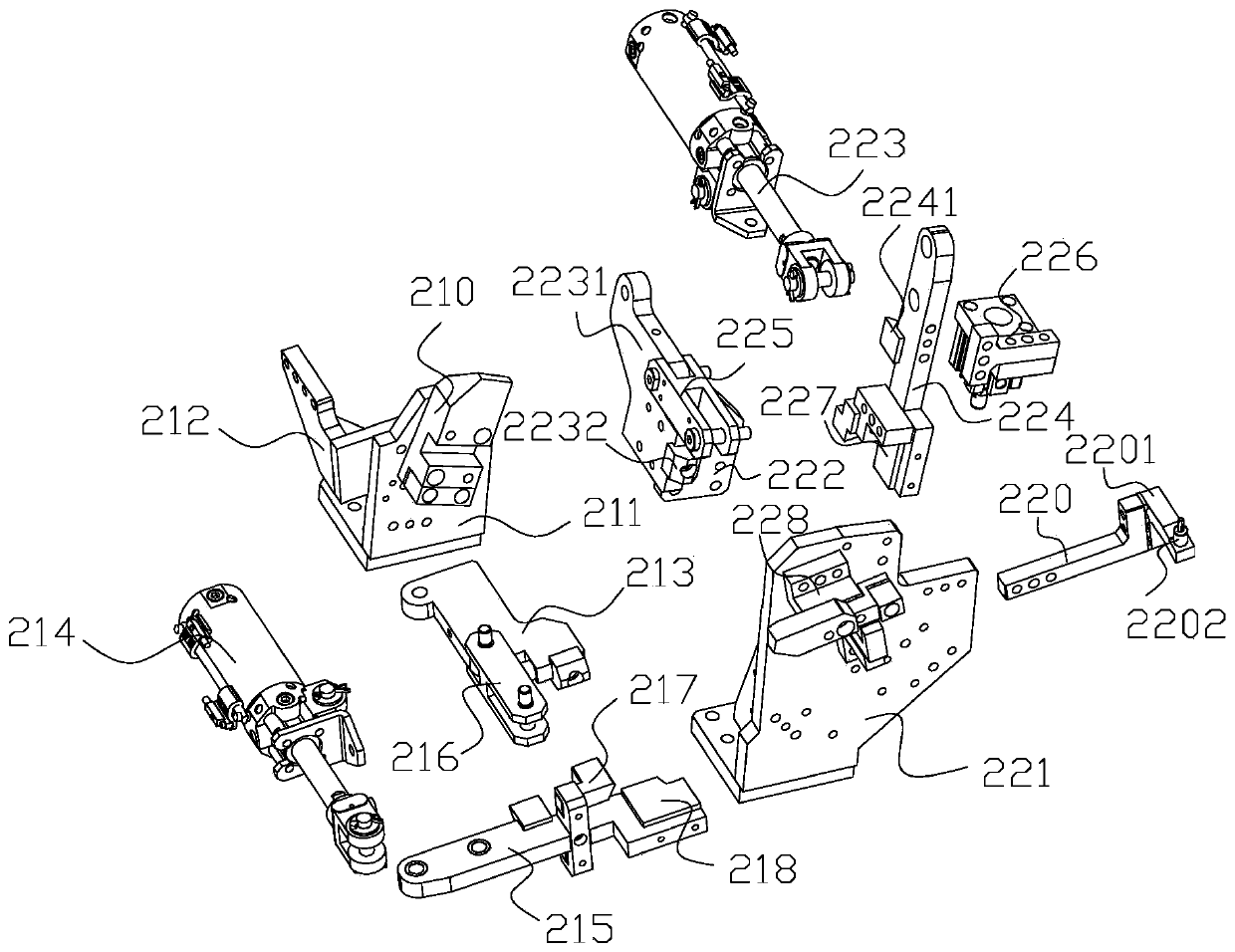

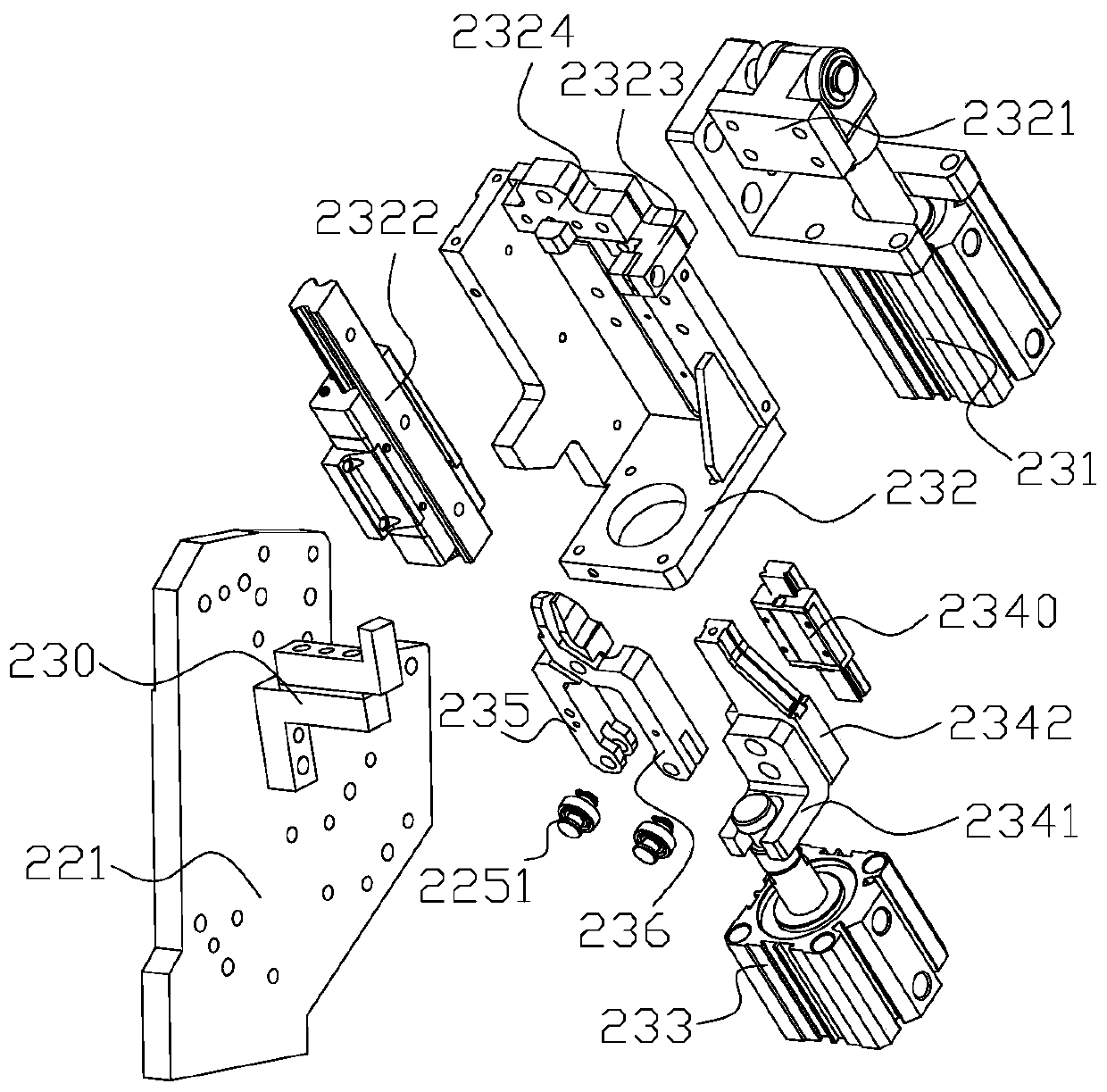

[0021] Such as figure 1 Shown, a kind of vehicle frame welding equipment, this equipment comprises frame 1, first fixing device 2, second fixing device 3, welding robot 4 and control system; First fixing device 2 comprises first fixing assembly 21, second Fixed assembly 22 and first support assembly 23; The first fixed assembly 21 and the second fixed assembly 22 are arranged on the left part of frame 1 respectively, and the second fixed assembly 22 is positioned at the right side of first fixed assembly 21; The first fixed assembly Assembly 21 is used for clamping the upper end of vehicle frame left bar; Second fixed assembly 22 is used for clamping the left end of vehicle frame cross bar; Used to support the connection between the left bar and the cross bar on the frame; the second fixing device 3 includes a third fixing assembly 31 , a fourth fixing assembly 32 and a second support assembly 33 ; the third fixing assembly 31 and the fourth fixing assembly 32 They are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com