Preparing method of chamois-imitation fabric

A technology for imitating suede and fabrics, applied in the field of fabrics, can solve the problems of incomparable moisture absorption and perspiration effect of natural fibers, poor dyeing fastness can not meet the requirements of clothing, inability to overcome the shortcomings of polyester fibers, etc., to increase aesthetics, improve color Fastness, the effect of increasing lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

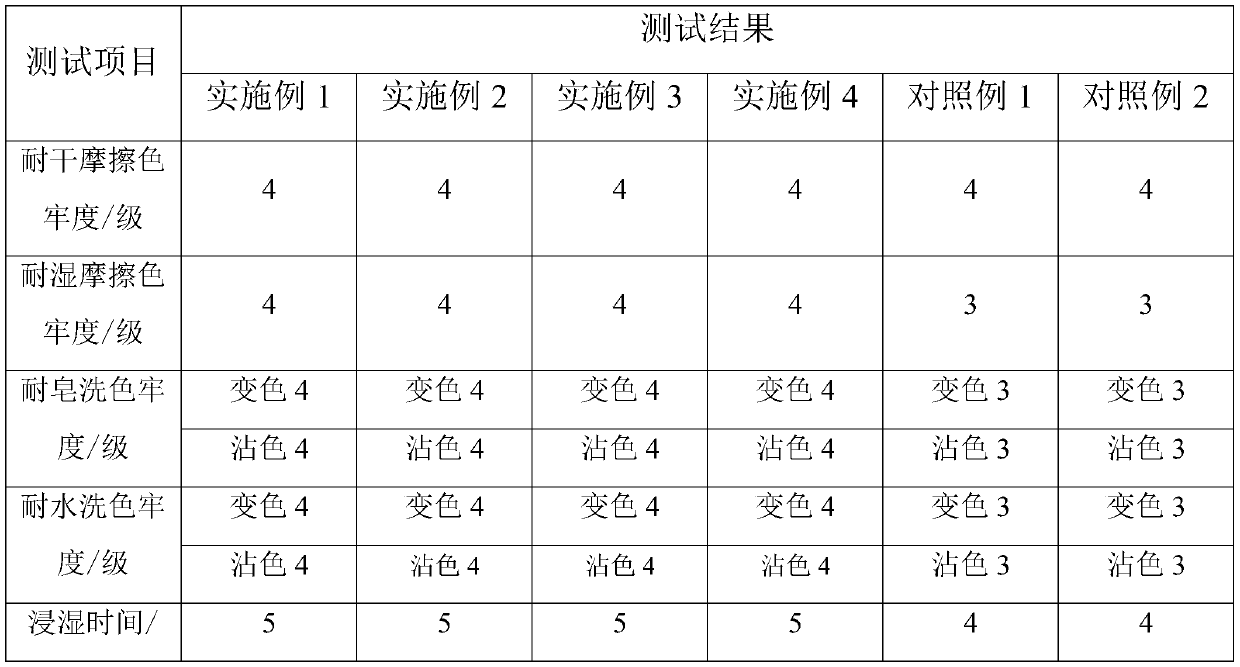

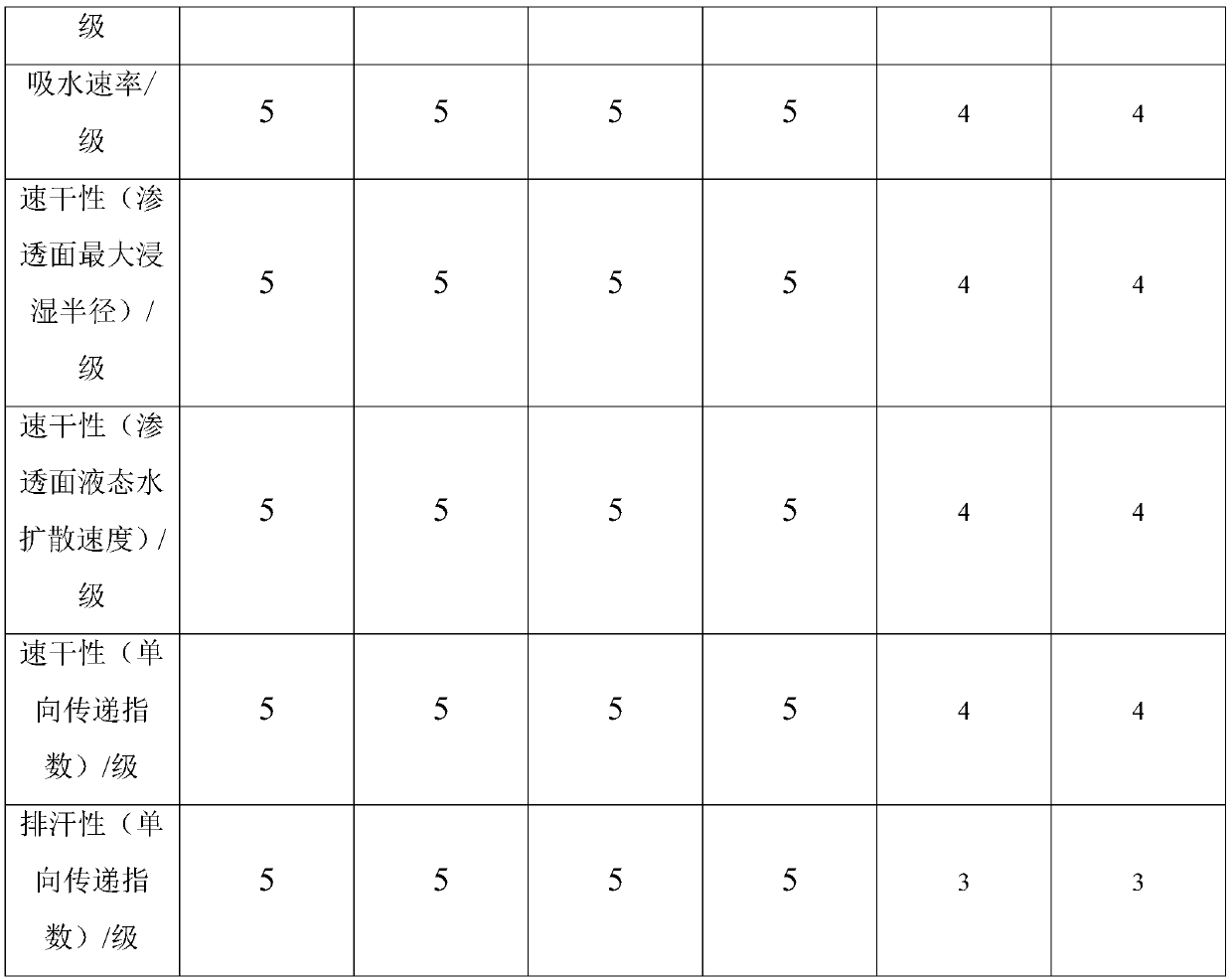

Examples

Embodiment 1

[0047] The preparation method of imitation suede fabric comprises the steps:

[0048] Step one, desizing:

[0049] The obtained polyester sea-island yarn is placed in a desizing agent for desizing to obtain a desizing gray cloth; the desizing agent includes the following components in terms of water volume: 0.5 g / L of NaOH, 0.3 g / L of benzyl alcohol, and 5 g of triethanolamine / L.

[0050] Step 2. Alkali weight reduction and fiber opening:

[0051] The desized gray cloth obtained in step 2 is opened by an overflow dyeing machine to obtain the opened fiber gray cloth; the auxiliary agent during the alkali weight reduction and fiber opening is NaOH 5g / L according to the water volume, the temperature is 110 ° C, and the time is 30 ~90min.

[0052] Step 3. Pre-ordering:

[0053] The pre-formed gray cloth obtained in step 2 is subjected to pre-setting treatment to obtain pre-shaped gray cloth; the temperature during pre-setting is 180° C., and the vehicle speed is 40 yards / min....

Embodiment 2

[0063] The preparation method of imitation suede fabric comprises the steps:

[0064] Step one, desizing:

[0065] The obtained polyester sea-island yarn is placed in a desizing agent for desizing to obtain a desizing gray cloth; the desizing agent includes the following components in terms of water volume: 0.6 g / L of NaOH, 0.4 g / L of benzyl alcohol, and 6 g of triethanolamine / L.

[0066] Step 2. Alkali weight reduction and fiber opening:

[0067] The desized gray cloth obtained in step 2 is opened by an overflow dyeing machine to obtain the opened fiber gray cloth; the auxiliary agent for alkali weight reduction and fiber opening is NaOH 6g / L based on water volume, the temperature is 112°C, and the time is 40min .

[0068] Step 3. Pre-ordering:

[0069] The pre-formed gray cloth obtained in step 2 was subjected to pre-setting treatment to obtain pre-shaped gray cloth; the temperature during pre-setting was 182° C., and the vehicle speed was 42 yards / min.

[0070] Step f...

Embodiment 3

[0079] The preparation method of imitation suede fabric comprises the steps:

[0080] Step one, desizing:

[0081] The obtained polyester sea-island yarn is placed in a desizing agent for desizing to obtain a desizing gray cloth; the desizing agent includes the following components in terms of water volume: 0.9 g / L of NaOH, 0.6 g / L of benzyl alcohol, and 8 g of triethanolamine / L.

[0082] Step 2. Alkali weight reduction and fiber opening:

[0083] The desized gray cloth obtained in step 2 is opened by an overflow dyeing machine to obtain the opened fiber gray cloth; the auxiliary agent for the alkali weight reduction and fiber opening is NaOH 12g / L based on the water volume, the temperature is 118°C, and the time is 80min .

[0084] Step 3. Pre-ordering:

[0085] The pre-formed gray cloth obtained in step 2 was subjected to pre-setting treatment to obtain pre-shaped gray cloth; the temperature during pre-setting was 188° C., and the vehicle speed was 48 yards / min.

[008...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com