Polyninylalcohol degradative enzyme high productive bacteria and method of its seed selection and uses said bacteria to produce polyving/alcoho/ degradation enzyme by fermentation method

A polyvinyl alcohol and enzyme-degrading technology, applied in biochemical equipment and methods, enzymes, enzymes, etc., can solve the problem of no Penicillium fungus degrading PVA and producing enzymes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

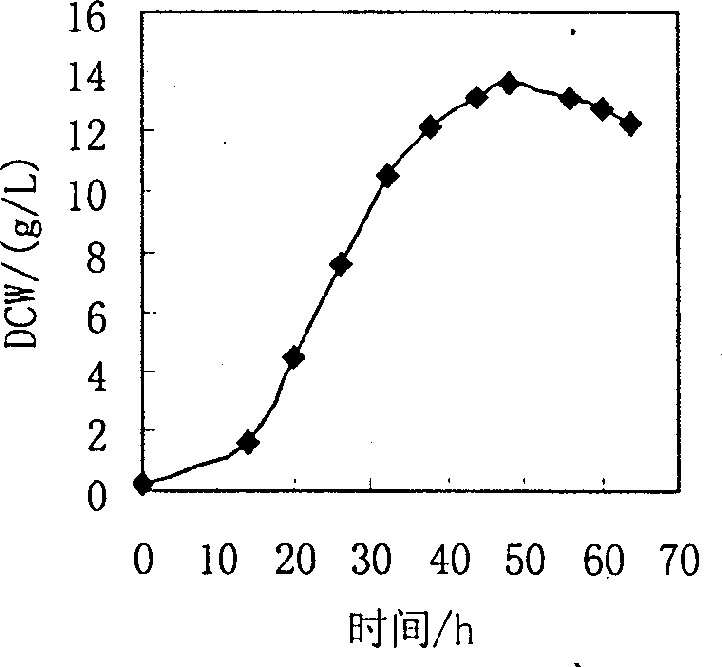

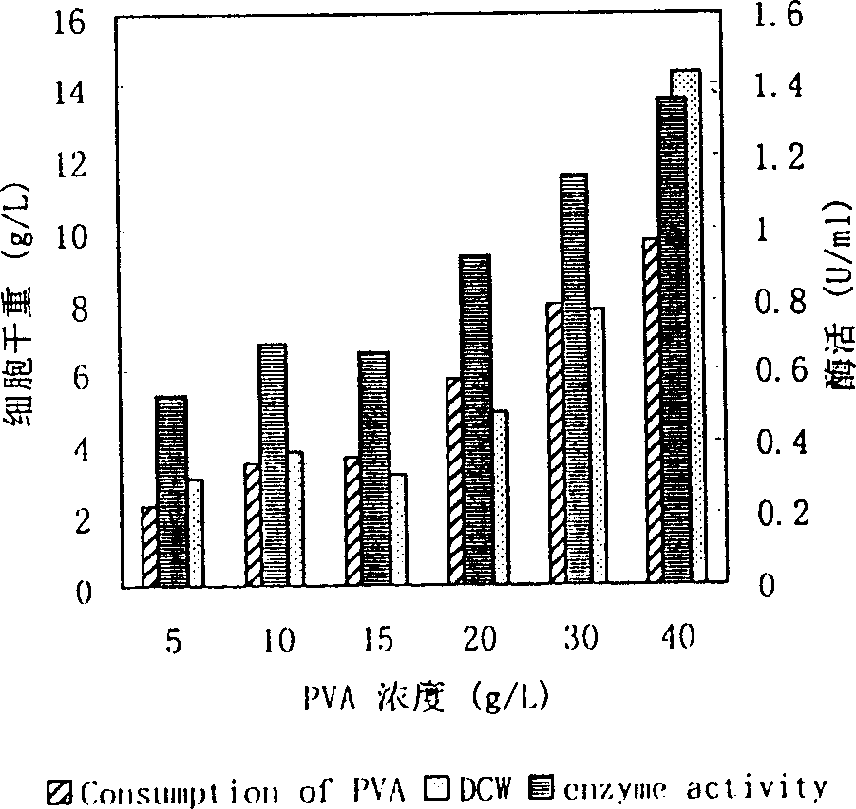

[0084] Use Penicillium CCTCC NO: M 203035 to prepare PVA degrading enzyme.

[0085] Fermentation medium (g / L): Glucose 5, PVA 40, NH 4 Cl8, KH 2 PO 4 3, yeast paste 1, MgSO 4 0.05, CaCl 2 0.05, FeSO 4 ·7H 2 O 0.02, NaCl 0.02, dilute to 1L with deionized water, pH6.0;

[0086] Fermentation conditions: shake flask culture on a rotary shaker, the rotation speed is 200r / min, and the culture temperature is 30°C. Get the slant strains and make spore suspension into a 500ml Erlenmeyer flask equipped with 150ml seed culture medium, and cultivate for 40 hours. The cultured 5ml seed solution was inserted into a 250ml Erlenmeyer flask containing 30ml of fermentation medium, fermented to produce enzymes for 72 hours, and the initial pH was controlled at 6.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com