Novel dyeing and finishing processing technology of micro polyester fabric

A processing technology, the technology of ultra-fine polyester, applied in the direction of fabric elongation, fabric surface trimming, heating/cooling fabric, etc., can solve the problems of affecting the dyeing quality, the surface is not smooth enough, the fiber radius is small, etc., to achieve low energy consumption, bright The effect of gloss, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0045] Fabric fabric: the material is polyester, 300T polyester taffeta, the specification is 50D / 72F, the warp and weft density is 58×52, and the door width is 164cm.

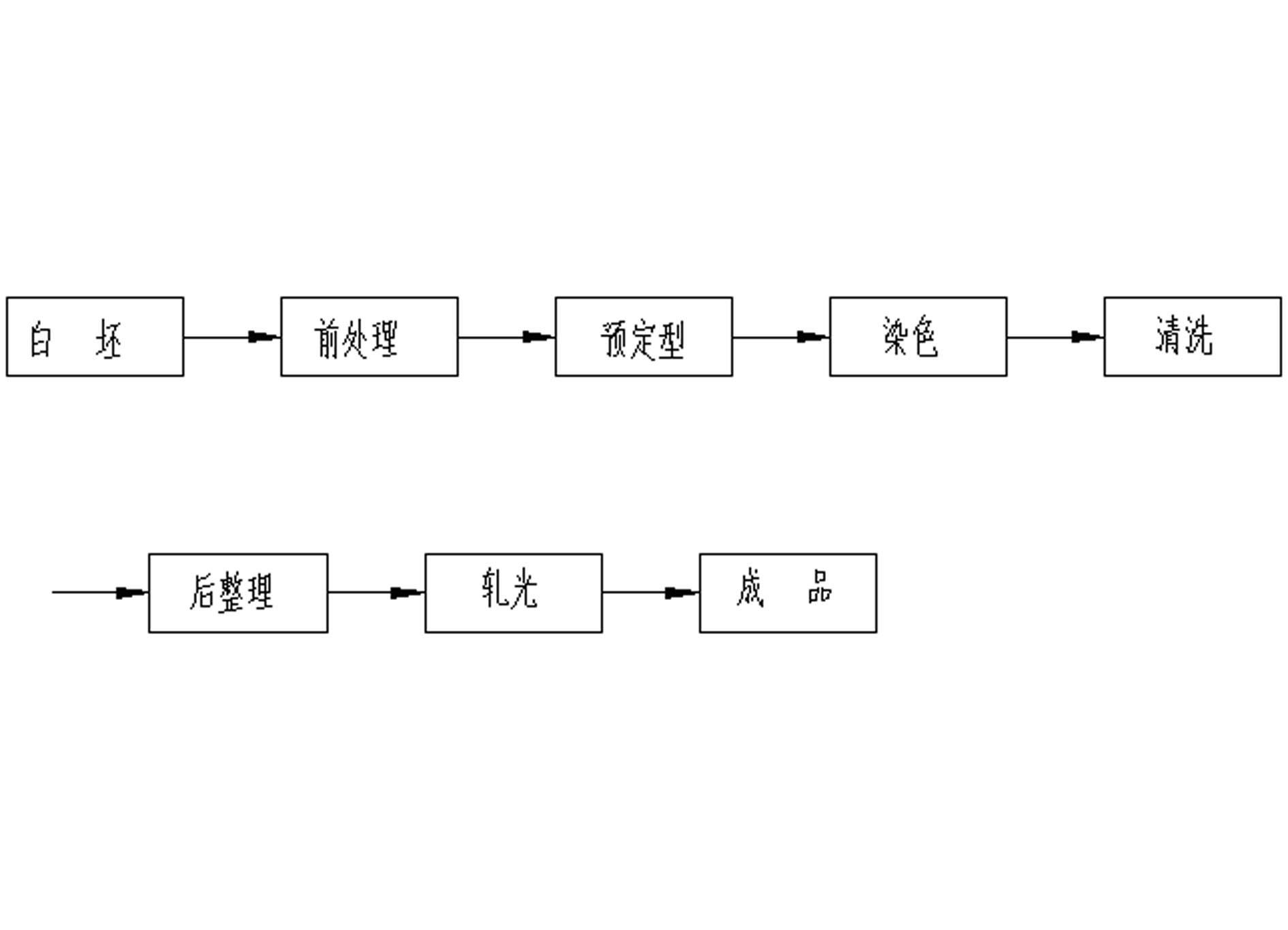

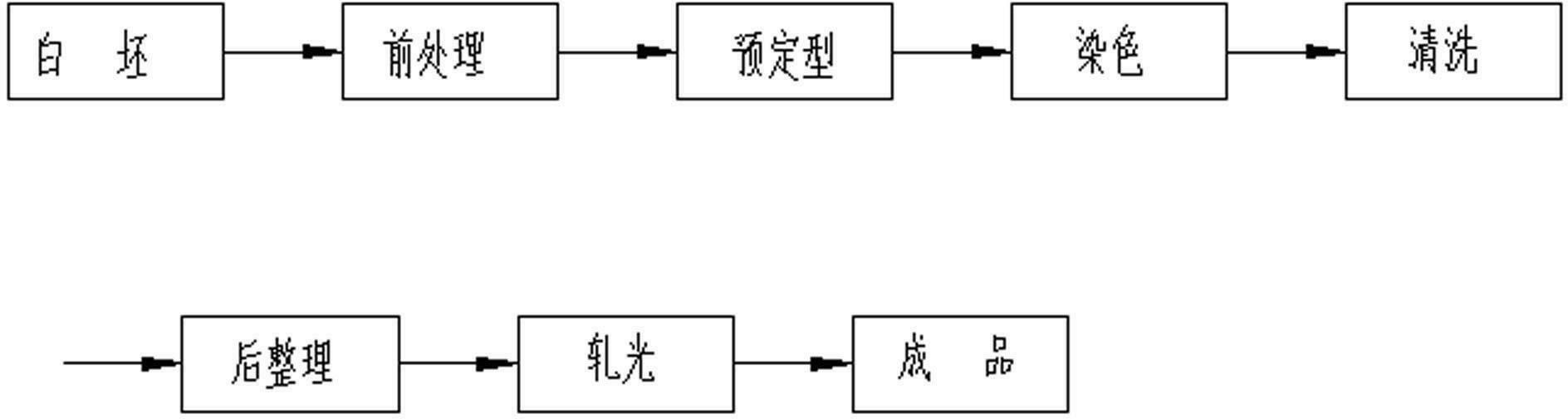

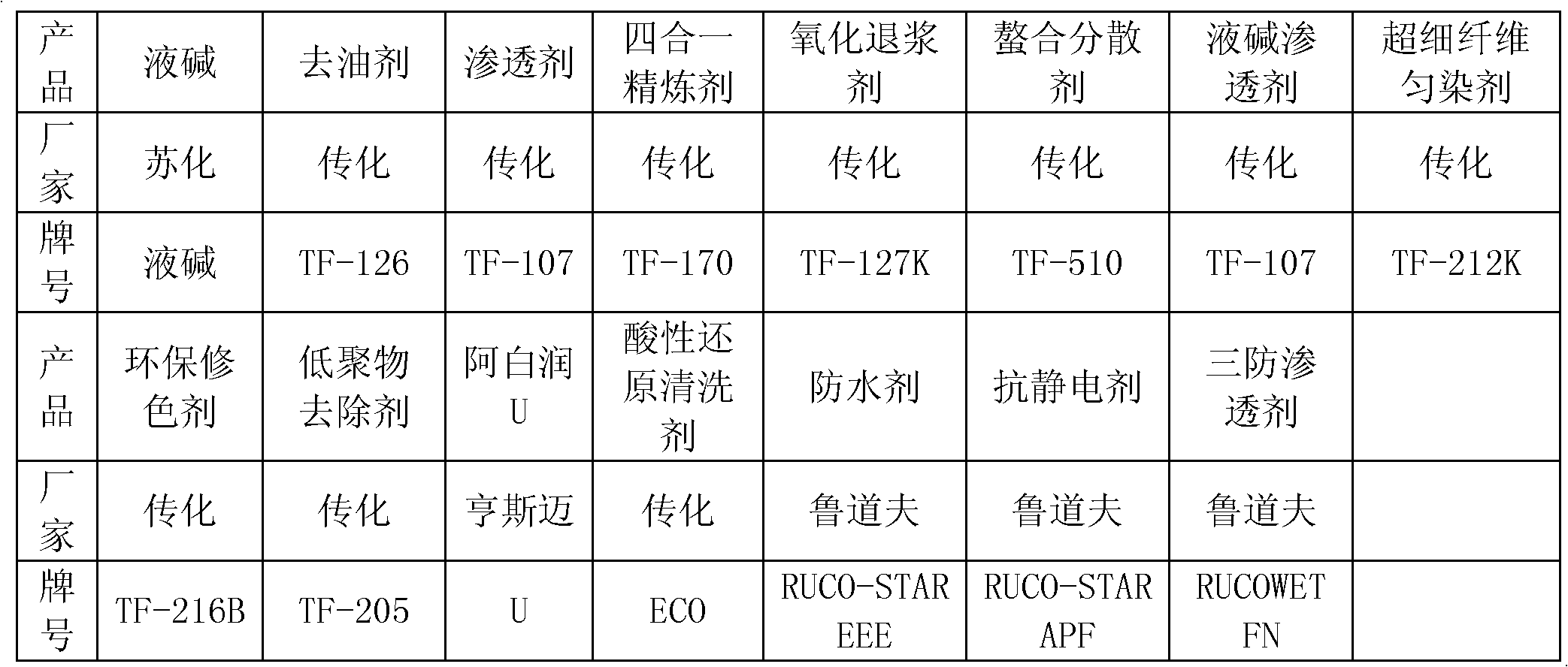

[0046] The novel dyeing and finishing process of superfine polyester fabric of the present invention comprises the following processing steps:

[0047] (1) Pretreatment: The polyester gray fabric is processed by a cold pad batch process including three stages of cold batching, hot alkali treatment and high-efficiency water washing. The three stages of the cold pad batch process are interpenetrated and intersected. The cold stacking process includes oxidizing and bleaching the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com