Enzyme oxygen-bath-low-temperature bleach process for fibre pretreatment

A low temperature, fiber technology, applied in fiber treatment, biochemical fiber treatment, bleaching products, etc., can solve the problems of difficulty in factory acceptance, and achieve good desizing effect, soft hand feeling and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Dissolve the penetrant at 2g / L in the treatment bath at 30°C, put the textiles into it, and keep the treatment bath flowing evenly. Then raise the temperature to 55°C, add 1g / L biorefining enzyme and 3g / L hydrogen peroxide into the treatment bath, adjust the pH to 9, and treat for 40 minutes; then raise the temperature to 80°C, add 3g / L low-temperature bleaching agent, Under treatment for 20 minutes, then washed with water, enter the next process.

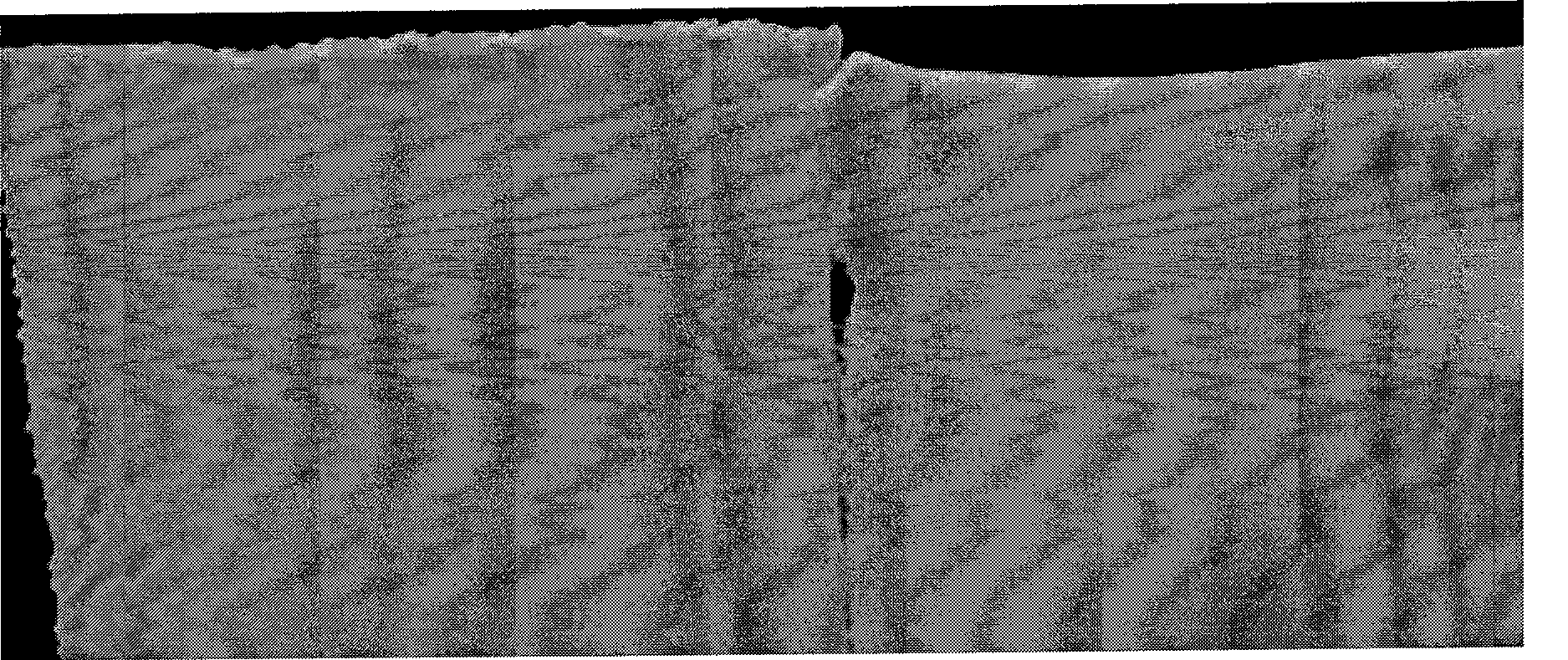

[0020] The whiteness of the textiles treated in the above way is 81.2, which is greater than the whiteness of 79.3 in the traditional alkali refining bleaching method. Such as figure 2 shown.

Embodiment 2

[0022] Dissolve the penetrating agent at 1g / L in the treatment bath at 30°C, put the fiber into it, and keep the treatment bath to circulate evenly. Then raise the temperature to 55°C, add 1g / L biorefining enzyme and 3g / L hydrogen peroxide into the treatment bath, adjust the pH to 7, and treat for 40 minutes; then raise the temperature to 80°C, add 3g / L low-temperature bleach, at this temperature Under treatment for 20 minutes, then washed with water, enter the next process.

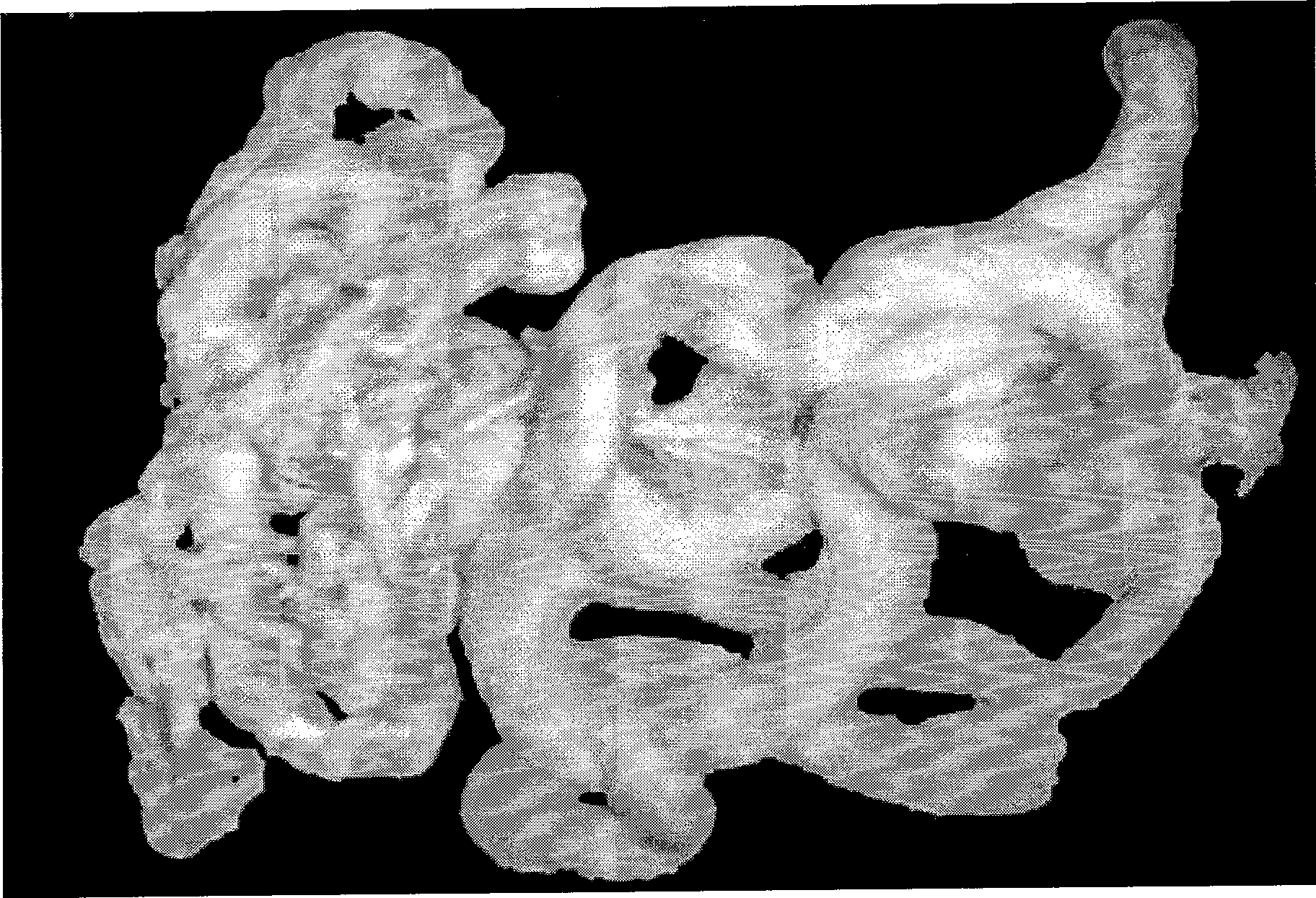

[0023] The whiteness of the fiber treated in the above way is 81.3, which is greater than the whiteness of 80.5 in the traditional alkali refining bleaching method. Such as figure 1 shown.

[0024] The technique of the present invention is through the productive test in the factory, and aspects such as its semi-finished product index and the uniformity of dyeing all reach or exceed the treatment effect of traditional technique, be worth popularizing vigorously.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com