Textile size for PVA-free sizing of medium-and-high-count pure cotton fabric warps

A technology for pure cotton fabrics and textile sizing, applied in textiles and papermaking, plant fibers, wear-resistant fibers, etc., can solve the problems of difficult desizing wastewater, difficult biodegradation, poor desizing performance, etc., and achieve improved durability Abrasiveness and hairiness conformity, less slumping and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: the performance of slurry

[0032] Prepare the slurry of three different formulations (all are mass percent, starch is wheat starch):

[0033] Formula ①: 50% starch, 25% gum arabic, 10% pectin, 10% polyacrylic acid-acrylamide copolymer slurry and 5% vegetable oil;

[0034] Formula ②: 40% starch, 30% gum arabic, 15% pectin, 10% polyacrylic acid-acrylamide copolymer slurry and 5% vegetable oil;

[0035] Formula ③: 30% starch, 37% gum arabic, 20% pectin, 10% polyacrylic acid-acrylamide copolymer slurry and 3% vegetable oil.

[0036] Its performance is as follows:

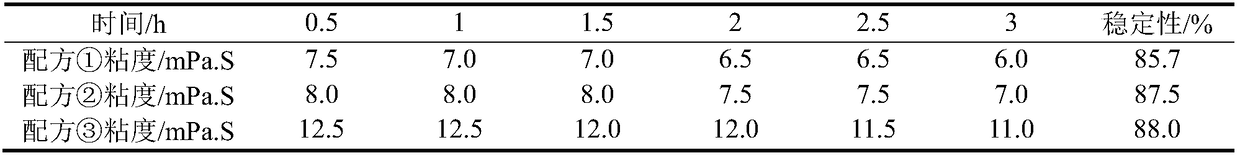

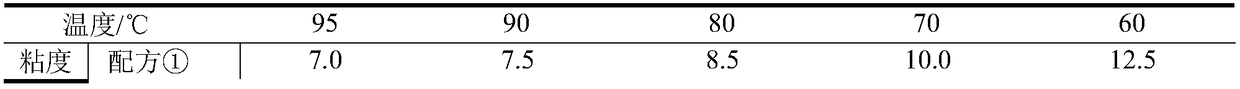

[0037] (1) Viscosity characteristics of slurry

[0038] ① thermal stability of viscosity

[0039] The viscosity stability of the three formulations was tested at 95°C after complete gelatinization / dissolution, and the results are shown in Table 1. It can be seen from the data in the table that the slurry viscosity of the three formula slurries decreases with the increase of the holding time at...

Embodiment 2

[0067] Three representative and difficult pure cotton fine-gauge high-density fabrics were selected for production and application, and a satisfactory sizing effect was achieved.

[0068] (1) Serum formula

[0069] Table 7 is the slurry formula of the production process. It can be seen that PVA is not used in the new formula, but 25-32.5kg of PVA will be used in the original formula.

[0070] Table 7 Serum formulation

[0071]

[0072] (2) Sizing process

[0073] The sizing is carried out on the Karl Mayer double sizing machine, and Table 8 shows the sizing process.

[0074] Table 8 Sizing process

[0075]

[0076] In the sizing process, the sizing with the new formula has good fluidity, stable viscosity, no foaming, brisk skeining, less sizing and cotton falling, smooth and soft hand feeling, good hairiness and no fuzziness during the sizing process. The sizing roller and the sizing roller are wound around the yarn.

[0077] (3) Sizing performance

[0078] Table 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com